6.0 Powerstroke Engine Problems : Troubleshooting Guide

When it comes to diesel engines, the 6.0 Powerstroke has gained notoriety for its recurring issues. Owners of vehicles equipped with this engine often encounter a range of problems that can be frustrating and costly to repair. In this article, we will explore some of the most prevalent 6.0 Powerstroke engine problems and how they can impact the performance and reliability of your vehicle.

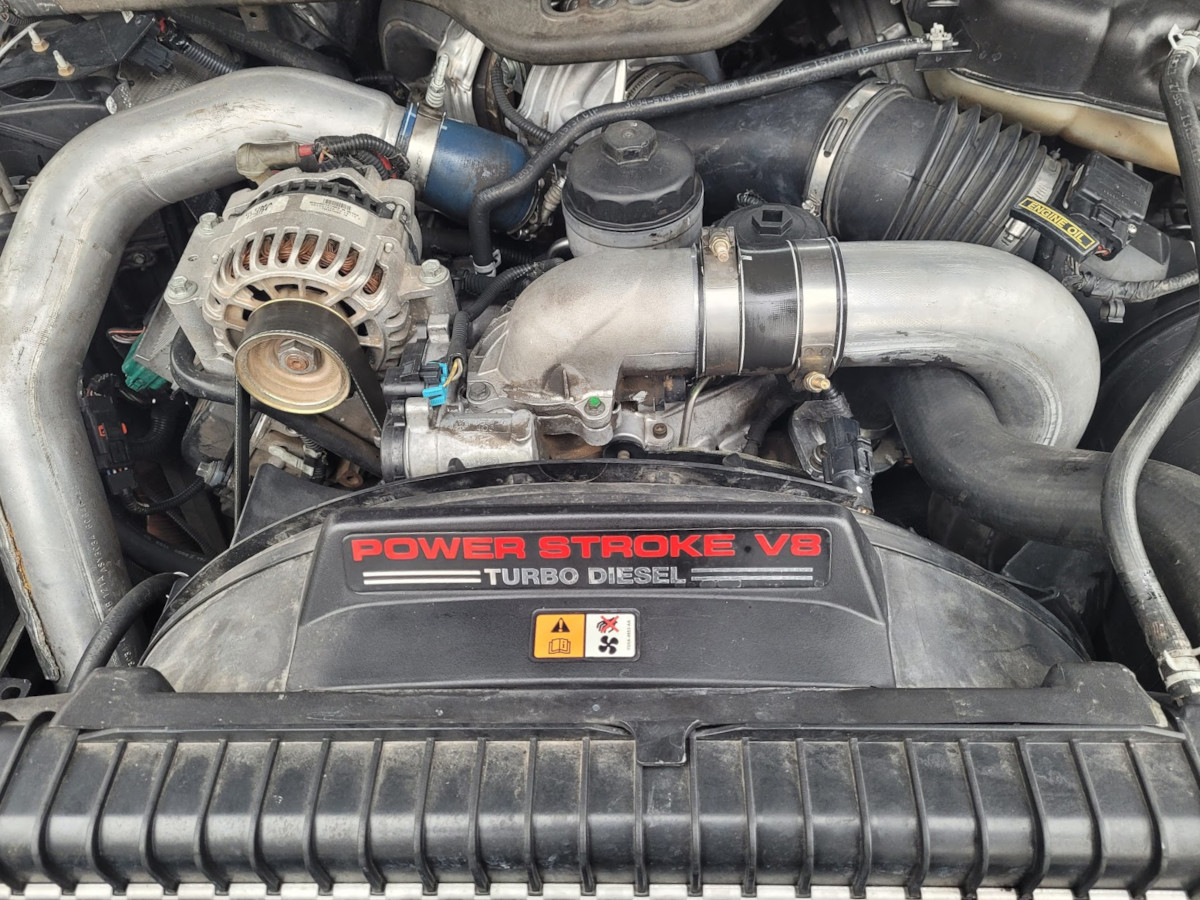

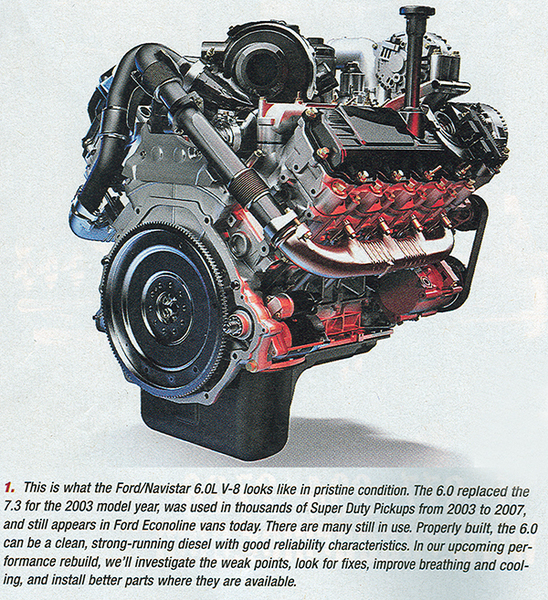

The 6.0L Powerstroke engine, a powerhouse found in Ford trucks from 2003 to 2010, is a legend amongst diesel enthusiasts. Renowned for its impressive towing capability and tire-shredding torque, it’s a dream engine for hauling heavy loads and conquering tough terrains. However, this mighty engine also has a reputation for encountering certain problems along the way.

Here’s the key: While the 6.0 Powerstroke can be an incredibly dependable workhorse, being proactive about potential issues is crucial. Early identification and repair of problems can save you significant headaches – and prevent them from snowballing into expensive breakdowns that leave you stranded on the side of the road. This guide will equip you with the knowledge to recognize common 6.0 Powerstroke problems, understand their causes, and ensure your truck keeps running strong for years to come.

Common 6.0 Powerstroke Engine Problems

The 6.0L Powerstroke engine, a formidable force found in Ford trucks from 2003 to 2010, is a legend for its towing prowess and raw power. But even legends have their weaknesses. This engine, while undoubtedly capable, is known for encountering certain problems along the way. The key to keeping your 6.0 Powerstroke reliable is early identification and repair of these potential issues.

Here’s a breakdown of the common foes you might encounter with your 6.0 Powerstroke:

1. Head Gasket Failure:

- Symptoms: Keep an eye out for these warning signs:

- Coolant Leaks: Puddles of coolant under your truck or a disappearing coolant reservoir might indicate a failing head gasket allowing coolant to leak.

- White Smoke: Billowing white smoke from the exhaust pipe suggests coolant burning in the engine combustion chamber, often due to a compromised head gasket.

- Overheating: A failing head gasket can disrupt proper coolant circulation, leading to excessive engine temperatures.

- Causes:

- Excessive Heat: Running the engine at extreme temperatures for extended periods puts stress on the head gasket and hastens its failure.

- Poor Maintenance: Neglecting regular maintenance, like coolant changes and leak checks, can contribute to head gasket issues.

- Solutions: Replacing a blown head gasket is a serious repair best handled by a qualified mechanic. It’s crucial to address the problem promptly to prevent further engine damage.

- Preventative Measures: Maintain a proper coolant mixture, avoid overheating, and follow the recommended maintenance schedule for your specific 6.0L Powerstroke model year.

2. EGR Cooler and Valve Issues:

- The EGR System: The Exhaust Gas Recirculation (EGR) system reduces emissions by recirculating a portion of exhaust gases back into the engine. The EGR cooler helps cool these recirculated gases before they re-enter the engine.

- Common Problems:

- Clogged EGR Cooler: Over time, the EGR cooler can become clogged with soot and debris, hindering its ability to cool exhaust gases. This can lead to reduced engine performance and potential overheating.

- Faulty EGR Valve: A malfunctioning EGR valve might not open or close properly, causing issues with engine performance and potentially allowing uncooled exhaust gases back into the engine.

- Symptoms: Reduced power, rough idling, and an illuminated check engine light are common signs of EGR system problems.

- Solutions: Cleaning or replacing the EGR cooler and/or valve might be necessary depending on the severity of the issue. A qualified mechanic can diagnose the problem and recommend the appropriate course of action.

- Preventative Maintenance: Regular cleaning of the EGR system components can help prevent clogging and extend their lifespan. Consult your owner’s manual or a trusted mechanic for recommended cleaning intervals.

3. FICM (Fuel Injection Control Module) Failure:

- Function: The FICM acts as the brain of the fuel injection system. It receives signals from the engine computer and regulates the voltage delivered to the fuel injectors, ensuring proper fuel delivery and engine performance.

- Symptoms: A failing FICM can manifest in various ways, including rough idling, lack of power, and difficulty starting the engine.

- Solutions: In most cases, a malfunctioning FICM requires replacement. A qualified mechanic can diagnose the problem and perform the replacement.

- Preventative Measures: While FICM failures can occur due to internal wear, maintaining a clean electrical connection and avoiding voltage spikes can help prolong its lifespan.

4. Injector Stiction:

- The Issue: Injector stiction occurs when the internal spool valve within a fuel injector gets stuck due to friction. This prevents the injector from properly opening and closing, leading to a variety of problems.

- Causes: The primary culprit behind injector stiction is often poor fuel quality. Low-quality diesel fuel can lack proper lubrication and contain contaminants that can cause the spool valve to stick.

- Symptoms: Rough idle, decreased engine power, and increased emissions are common signs of injector stiction. You might also experience black smoke coming from the exhaust due to improper fuel combustion.

- Solutions: There are two main approaches: cleaning or replacement. In some cases, cleaning the injectors with specialized tools and solutions might be sufficient. However, in severe cases, injector replacement might be necessary.

- Preventative Measures: Using high-quality diesel fuel that meets Ford’s specifications is the best defense against injector stiction. Regularly adding injector cleaner to your fuel tank, following the manufacturer’s recommendations, can also help prevent problems.

5. The HPOP (High-Pressure Oil Pump) :

The HPOP System:* The HPOP system is the lifeblood of the 6.0L Powerstroke’s fuel injection. It’s responsible for delivering high-pressure oil to the fuel injectors, enabling them to precisely atomize fuel for optimal combustion.

Common Problems:* Two of the most frequent issues with the HPOP system are low oil pressure and leaks.

Low Oil Pressure:* Insufficient oil pressure can significantly impact engine performance and injector function. It can be caused by: * Failing HPOP: A worn-out HPOP pump can struggle to generate the necessary oil pressure. * Worn Internal Components: Internal wear and tear on components within the HPOP system can also lead to pressure loss. * Leaks: Leaks within the HPOP system allow oil to escape, reducing overall pressure.

Leaks:* Leaks within the HPOP system can lead to a loss of oil pressure and potential engine damage if left unaddressed. Leaks can occur at various points, including: * HPOP Seals: Seals within the HPOP pump itself can deteriorate over time, causing leaks. * High-Pressure Oil Lines: The high-pressure oil lines that carry oil from the HPOP to the injectors can develop cracks or leaks. * IPR (Injection Pressure Regulator) Valve: The IPR valve regulates oil pressure, and a malfunctioning valve can lead to internal leaks.

Symptoms:* Reduced engine power, rough idle, and an illuminated check engine light are common signs of HPOP system problems. In severe cases, you might experience engine stalling or difficulty starting.

Solutions:* Depending on the severity of the problem, solutions for HPOP system issues can range from: * Replacing Worn Components: Replacing worn seals, sensors, or the IPR valve might be sufficient. * HPOP Replacement: In some cases, a complete HPOP replacement might be necessary.

Preventative Measures:* Maintaining a regular oil change schedule with high-quality oil that meets Ford’s recommendations is vital for the HPOP system’s health. This ensures proper lubrication and reduces wear and tear on internal components.

Beyond the Engine: Additional Considerations for 6.0 Powerstroke Maintenance

- Importance of Regular Maintenance: Following the recommended maintenance schedule for your specific 6.0L Powerstroke model year is crucial. This includes routine oil changes, fuel filter replacements, coolant flushes, and inspections of critical components like belts and hoses. A well-maintained engine is less likely to encounter problems associated with the common foes we’ve discussed.

- Overheating: Overheating is a serious threat to any engine, and the 6.0L Powerstroke is no exception. Several factors can contribute to overheating, including:

- Failing Thermostat: A malfunctioning thermostat can prevent the engine from reaching its proper operating temperature or trap excessive heat.

- Clogged Radiator: A clogged radiator can impede proper coolant circulation and heat dissipation.

- Low Coolant Level: Insufficient coolant can lead to overheating.

It’s important to address the root cause of any overheating issue promptly to prevent potential engine damage.

Frequently Asked Questions

What Year Of 6.0 Power Stroke To Avoid?

The 6. 0 Power Stroke engine years to avoid are the ones produced between 2003 and 2007 due to frequent issues with head gasket failure, FICM failure, oil cooler problems, EGR cooler failure, EGR valve failure, and other design issues.

What Is The Biggest Problem With The 6.0 Power Stroke?

The biggest problem with the 6. 0 Power Stroke is head gasket failure due to torque-to-yield head studs.

Is The Ford 6.0 Diesel Engine Any Good?

Yes, the Ford 6. 0 diesel engine is known for its power and performance, but it also has a history of reliability issues such as EGR and head gasket failures.

What Year Did The Ford 6.0 Diesel Have Problems?

The Ford 6. 0 diesel had problems in the year it was introduced, 2003.

Conclusion

While the 6.0 Powerstroke engine has garnered a reputation for its problems, proactive maintenance and timely repairs can help mitigate these issues and ensure the longevity of your vehicle. By staying informed about these common problems and addressing them promptly, you can enjoy a more reliable and efficient driving experience with your 6.0 Powerstroke-equipped vehicle.