Ford 6.0 Powerstroke Engine Weight: Key Specifications for Your Build

Featured image for this comprehensive guide about Ford 6.0 Powerstroke engine weight

Image source: static.danhgiaxe.com

In the world of heavy-duty trucks and diesel enthusiasts, few engines spark as much discussion and passion as the Ford 6.0 Powerstroke. Launched in 2003, this V8 turbocharged beast quickly became known for its impressive power output, but also for its… shall we say, “character.” Beyond its infamous reliability challenges and the subsequent “bulletproofing” solutions, there’s a fundamental characteristic that plays a crucial role in vehicle dynamics, performance, and even modification planning: its weight.

Whether you’re a seasoned mechanic, an aspiring engine swapper, a truck owner looking to optimize performance, or just a curious enthusiast, understanding the Ford 6.0 Powerstroke engine weight is paramount. This isn’t just a number; it’s a critical factor that influences everything from your truck’s suspension setup and handling characteristics to its payload capacity and even fuel economy. It’s the silent partner in every turn, every acceleration, and every braking maneuver.

This comprehensive guide will delve deep into the specifics of the Ford 6.0 Powerstroke engine weight. We’ll explore what exactly contributes to its mass, why this weight matters so much for your truck’s performance and longevity, how it compares to other popular diesel engines, and what you need to consider when planning modifications or even a full engine swap. Prepare to gain a holistic understanding that goes beyond the raw numbers, empowering you with the knowledge to make informed decisions for your Powerstroke-powered machine.

Quick Answers to Common Questions

What’s the typical Ford 6.0 Powerstroke engine weight?

The dry weight for a complete Ford 6.0 Powerstroke engine is generally around 850-900 pounds, making it a substantial component for any heavy-duty truck build.

Does “wet” versus “dry” weight make a big difference for the 6.0?

Absolutely! When filled with fluids like oil and coolant, the Ford 6.0 Powerstroke engine weight can easily increase by another 50-70 pounds, pushing it closer to 900-950 pounds on the scale.

Why is knowing the Ford 6.0 Powerstroke engine weight important for my build?

Understanding the engine’s weight is crucial for selecting appropriate engine hoists, stand capacities, and ensuring your truck’s front suspension can properly handle the load, especially if you’re making other modifications.

Is the 6.0 Powerstroke engine considered heavy compared to other diesels?

While certainly hefty, the Ford 6.0 Powerstroke engine weight is fairly typical for a V8 diesel of its displacement, often comparable to or slightly lighter than its larger 7.3L Powerstroke predecessor.

What components are usually included in the stated Ford 6.0 Powerstroke engine weight?

The typical stated weight usually refers to a “long block” or complete engine, including the turbo, manifolds, and common bolt-on accessories, but generally without the transmission or transfer case attached.

📋 Table of Contents

- The Core Question: What is the Ford 6.0 Powerstroke Engine Weight?

- Why Does Engine Weight Matter for Your Ford 6.0 Powerstroke?

- Dissecting the Weight: Components of the 6.0 Powerstroke

- Comparing the 6.0 Powerstroke’s Weight to its Peers

- Optimizing for Weight: Performance and Durability Upgrades

- Essential Data: Ford 6.0 Powerstroke Engine Specifications Table

- Conclusion: The Enduring Significance of the 6.0 Powerstroke’s Mass

The Core Question: What is the Ford 6.0 Powerstroke Engine Weight?

Let’s cut straight to the chase and answer the most pressing question: what is the Ford 6.0 Powerstroke engine weight? While exact figures can vary slightly based on specific accessories and configurations, a generally accepted range for the dry weight of the 6.0 Powerstroke engine is between 860 to 900 pounds (approximately 390 to 408 kilograms). This figure represents the engine without fluids like oil, coolant, or fuel.

When we talk about the wet weight – meaning the engine fully dressed with all its necessary fluids – the figure naturally increases. A fully wet Ford 6.0 Powerstroke engine weight, including oil, coolant, and typical accessories (alternator, power steering pump, A/C compressor, exhaust manifolds, turbocharger, etc.), can easily push the total mass closer to 950 to 1,000 pounds (approximately 430 to 450 kilograms). This distinction between dry and wet weight is crucial for accurate planning, especially for shipping, installation, or evaluating front axle loading.

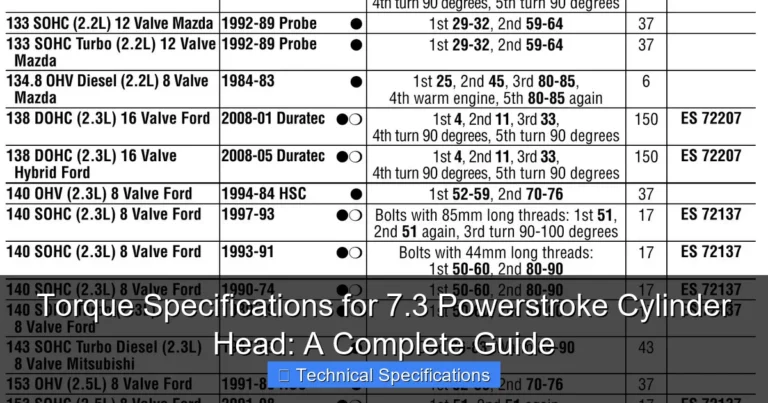

| Engine Configuration | Weight (lbs) | Weight (kg) | Notes |

|---|---|---|---|

| 6.0L Powerstroke Long Block | 740 | 335 | Engine block with cylinder heads, dry |

| 6.0L Powerstroke Complete Engine | 920 | 417 | Dry weight, including turbo, injectors, etc. |

| 6.0L Powerstroke Complete Engine (Wet) | ~1030 | ~467 | Approximate, with fluids (oil, coolant) |

| 7.3L Powerstroke Complete Engine | 970 | 440 | For comparison (predecessor), dry weight |

| 6.7L Powerstroke Complete Engine | 1040 | 472 | For comparison (successor), dry weight |

Dry vs. Wet Weight: Understanding the Distinction

The terms “dry weight” and “wet weight” are frequently used in automotive specifications, but their meanings are distinct and vital for clarity:

- Dry Weight: This refers to the engine’s mass without any fluids. It includes the block, heads, rotating assembly, turbocharger, manifolds, and most bolt-on accessories that are integral to the engine’s operation but excludes oil, coolant, and sometimes even the flywheel/flexplate or certain accessory drive components. This is often the figure used for initial engine design and comparison.

- Wet Weight: This is the more practical figure for real-world applications. It encompasses the dry engine weight plus the weight of all operational fluids (engine oil, coolant in the block/heads/radiator, fuel in the rails) and any auxiliary components typically mounted directly to the engine and necessary for its function in the vehicle (e.g., alternator, starter motor, power steering pump, A/C compressor, complete turbo system). When you install an engine into a vehicle, it’s the wet weight that dictates much of the front-end load.

For the 6.0 Powerstroke, considering its substantial oil capacity (around 15 quarts) and intricate cooling system, the difference between dry and wet weight is significant, adding well over 50 pounds to the total mass.

Key Components Contributing to Weight

The Ford 6.0 Powerstroke engine weight isn’t just one big chunk; it’s the sum of many heavy-duty components designed for immense pressures and temperatures. The primary contributors to its substantial mass include:

- Cast Iron Block: The foundation of the engine, the robust cast iron block is engineered to withstand the extreme forces of diesel combustion. This single component is arguably the heaviest.

- Cast Iron Cylinder Heads: Similarly, the two large cast iron cylinder heads, each housing four valves per cylinder and complex oil galleys for the HEUI system, add significant bulk.

- Crankshaft, Connecting Rods, and Pistons: The internal rotating assembly, built to handle high torque, is made from forged steel (crankshaft) and heavy-duty alloys.

- Turbocharger System: The variable geometry turbocharger (VGT), along with its heavy cast iron manifolds and up-pipes, is a substantial contributor.

- Oil Cooler and EGR Cooler: These heat exchangers, particularly the stock steel/iron units, are dense and add to the overall mass.

- HEUI Pump and High-Pressure Oil System: The heavy-duty high-pressure oil pump and associated components contribute to the system’s weight.

Why Does Engine Weight Matter for Your Ford 6.0 Powerstroke?

Understanding the Ford 6.0 Powerstroke engine weight isn’t merely an academic exercise; it has profound implications for every aspect of your truck’s life. From how it drives to what it can carry, the mass of this engine is a fundamental parameter to consider.

Vehicle Performance and Handling

The laws of physics dictate that a heavier object requires more force to accelerate, decelerate, and change direction. The substantial front-end Ford 6.0 Powerstroke engine weight directly impacts:

- Acceleration: While the 6.0 Powerstroke produces ample torque, its weight requires more power to get moving, subtly affecting acceleration times compared to lighter gasoline counterparts.

- Braking: A heavier front end means more inertia to overcome during braking, potentially leading to longer stopping distances or increased wear on front brake components.

- Cornering and Handling: The distribution of weight, particularly the heavy front end of a diesel truck, influences the vehicle’s balance and responsiveness. A heavy engine can contribute to understeer, where the front tires lose grip before the rear.

- Tire Wear: Increased load on the front axle due to the heavy engine translates to accelerated wear on the front tires.

Suspension and Chassis Considerations

Perhaps the most immediate and critical impact of the Ford 6.0 Powerstroke engine weight is on the suspension system. Ford’s F-Series trucks equipped with the 6.0 Powerstroke were designed with this heavy engine in mind, featuring:

- Stiffer Front Springs: To support the considerable weight, trucks with the 6.0 Powerstroke typically have heavier-duty front coil springs or leaf springs compared to gasoline versions.

- Robust Shock Absorbers: Shocks are tuned to dampen the motion of the heavy front end, providing stability and ride comfort.

- Stronger Front Axle Components: The axle, steering components, and ball joints must be capable of enduring the constant stress of the engine’s mass, especially over rough terrain or during hard braking.

- Frame and Chassis Design: The overall chassis and frame rails are engineered to manage the stresses and loads imposed by the heavy diesel engine.

When upgrading suspension components, always account for the specific Powerstroke engine weight to ensure proper ride height, load capacity, and handling characteristics. Incorrectly matched components can lead to a “nose-diving” appearance, poor ride quality, or premature component failure.

Fuel Economy Impact

While the 6.0 Powerstroke is known for its torque and towing prowess, the inherent Powerstroke engine weight does play a role in fuel efficiency. More mass requires more energy (fuel) to move and stop. Although diesel engines are inherently more fuel-efficient than gasoline engines in similar applications, a lighter truck would theoretically achieve better mileage. This factor becomes more pronounced during stop-and-go driving or when carrying additional payload.

Payload and Towing Capacity

The gross vehicle weight rating (GVWR) and gross combined weight rating (GCWR) of a truck are finite. The substantial Ford 6.0 Powerstroke engine weight consumes a significant portion of the truck’s available payload capacity. For example, if two identical trucks have the same GVWR, but one has a heavier engine, the truck with the heavier engine will have less remaining capacity for cargo and passengers. This is a crucial consideration for those who frequently haul heavy loads or tow large trailers, as every pound counts.

Engine Swaps and Conversions

For enthusiasts contemplating an engine swap, knowing the Ford 6.0 Powerstroke engine weight is non-negotiable. Swapping this engine into a vehicle not originally designed for its mass requires extensive modifications to the suspension, frame, and possibly the entire drivetrain. The added weight will dramatically alter the vehicle’s balance and center of gravity, necessitating careful engineering to ensure safety and drivability.

Dissecting the Weight: Components of the 6.0 Powerstroke

To truly appreciate the Ford 6.0 Powerstroke engine weight, it’s helpful to understand which primary components contribute most to its overall mass. Each part is engineered for durability and performance, often at the expense of lightness.

The Cast Iron Block and Cylinder Heads

Unsurprisingly, the vast majority of the 6.0 Powerstroke weight comes from its foundational components. The engine block, made of robust cast iron, is designed to withstand immense internal pressures and temperatures. It’s a dense, solid piece of engineering. Similarly, the two large cast iron cylinder heads, which bolt to the block, are heavy due to their intricate design, multiple valve seats, and the internal oil galleys required for the HEUI (Hydraulically-actuated, Electronically-controlled, Unit Injector) system. These two components alone easily account for more than half of the engine’s dry weight.

Turbocharger System

The 6.0 Powerstroke utilizes a Garrett GT3782VA Variable Geometry Turbocharger (VGT). This turbo, while efficient, is a substantial piece of equipment. Combined with its heavy cast iron exhaust manifolds and the robust up-pipes that channel exhaust gases to the turbo, the entire turbocharger system adds a considerable amount to the overall Powerstroke engine weight. Its placement high on the engine further influences the center of gravity.

Cooling System Components

Diesel engines generate significant heat, requiring robust cooling systems. The 6.0 Powerstroke includes several heavy components dedicated to heat management:

- Oil Cooler: A thick, heavy heat exchanger typically located within the valley of the engine.

- EGR Cooler: Another substantial heat exchanger, often made of stainless steel or other heavy alloys, designed to cool exhaust gases before recirculation. (The upgraded ‘bulletproof’ versions can sometimes be even heavier due to more robust construction.)

- Radiator and Intercooler: While technically not part of the ‘engine weight’ itself, these components are critical for engine function and contribute significantly to the total front-end vehicle weight.

Fuel Injection System

The high-pressure common rail fuel injection system of the 6.0 Powerstroke includes the robust HEUI pump, which is a significant, complex hydraulic component. The eight unit injectors themselves are also substantial in size and mass, contributing to the overall 6.0 Powerstroke engine weight. The fuel rails and lines, while not excessively heavy individually, add to the cumulative total.

Flywheel and Flexplate

Depending on whether the engine is mated to a manual or automatic transmission, either a heavy flywheel (manual) or a flexplate with a torque converter (automatic) will be bolted to the rear of the crankshaft. These components, especially the flywheel, are designed for mass and inertia, adding dozens of pounds to the total assembly, though they are often considered part of the drivetrain rather than strictly the engine.

Accessory Drive

While often considered external, the components of the accessory drive system – such as the alternator, power steering pump, air conditioning compressor, and their respective brackets – are typically installed directly onto the engine. These accessories, while not the primary focus when discussing bare engine weight, add substantially to the ‘wet’ or ‘dressed’ Ford 6.0 Powerstroke engine weight that a vehicle’s front suspension must support.

Comparing the 6.0 Powerstroke’s Weight to its Peers

To fully contextualize the Ford 6.0 Powerstroke engine weight, it’s valuable to compare it to other popular diesel engines, both within the Powerstroke family and from competing manufacturers. This comparison highlights design differences and technological advancements that influence weight.

6.0 vs. 7.3 Powerstroke Weight

The 7.3L Powerstroke, the predecessor to the 6.0L, is renowned for its durability and mechanical simplicity. It is also a very heavy engine. The 7.3 Powerstroke dry weight typically falls in the range of 920-970 pounds (417-440 kg). This makes the 7.3L slightly heavier than the 6.0L, primarily due to its larger displacement and generally more robust, older-generation cast iron block and heads, as well as its gear-driven high-pressure oil pump (HPOP).

- Ford 6.0 Powerstroke Dry Weight: ~860-900 lbs

- Ford 7.3 Powerstroke Dry Weight: ~920-970 lbs

Despite being smaller in displacement, the 6.0L manages to be a bit lighter, largely due to advancements in casting technology and a slightly more compact design.

6.0 vs. 6.4 & 6.7 Powerstroke Weight

When comparing the 6.0L to its successors, the 6.4L and especially the 6.7L, we see a trend towards increased weight, even with advancements in materials:

- Ford 6.4 Powerstroke Dry Weight: Approximately 980-1,000 pounds (445-454 kg). The 6.4L, while sharing some architecture with the 6.0L, introduced heavier components like a larger turbocharger system and a more complex exhaust aftertreatment system (though some of that is external). Its block is also a bit beefier.

- Ford 6.7 Powerstroke Dry Weight: Approximately 1,050-1,100 pounds (476-499 kg). The 6.7L – a completely new, “Scorpion” engine – is the heaviest of the Powerstroke family. This is primarily due to its compacted graphite iron (CGI) block (which is incredibly strong but also dense), single sequential turbocharger (which is large), and advanced emissions equipment.

This shows that while the 6.0L is heavy, it sits in the middle of the Powerstroke lineage regarding weight, being lighter than both its predecessor (7.3L) and its immediate successors (6.4L, 6.7L).

Comparisons with Competitors (Cummins/Duramax)

A brief look at competing diesel engines further places the Ford 6.0 Powerstroke engine weight in perspective:

- Cummins 5.9L/6.7L I6: Cummins engines, particularly the 6BT (5.9L) and later 6.7L, are known for their inline-six configuration, which is inherently long but often results in a relatively lower weight per liter compared to V8 diesels. A Cummins 5.9L dry weight is around 1,100 pounds (500 kg), and the 6.7L Cummins dry weight is closer to 1,150 pounds (520 kg). Despite being I6s, their robust cast iron construction makes them quite heavy. Interestingly, the 6.0 Powerstroke is lighter than a Cummins.

- Duramax (e.g., LB7/LLY/LBZ/LML): GM’s Duramax V8 diesel engines are often lauded for their relatively lighter weight thanks to their aluminum cylinder heads. A typical Duramax engine dry weight (e.g., LB7) is around 835-850 pounds (379-386 kg). This makes the Duramax generally lighter than the 6.0 Powerstroke, a notable difference that contributes to slightly better weight distribution in GM trucks.

In summary, the Ford 6.0 Powerstroke engine weight is substantial, heavier than a Duramax but generally lighter than a Cummins or even its own 7.3L and 6.4L Powerstroke brethren.

Optimizing for Weight: Performance and Durability Upgrades

While you can’t magically shave hundreds of pounds off the core Ford 6.0 Powerstroke engine weight without compromising its integrity, smart modifications and upgrades can optimize its performance, compensate for its mass, and enhance overall vehicle dynamics. The goal isn’t always to reduce engine weight directly, but to manage its effects.

Aftermarket Parts and Their Weight Impact

When selecting aftermarket components, consider their weight. Some upgrades might offer slight weight advantages or maintain weight while providing significant performance benefits:

- Aluminum Intercoolers: Replacing a stock steel or copper intercooler with a high-performance aluminum unit can save a few pounds while improving cooling efficiency.

- Lightweight Flywheels/Flexplates: For manual transmission setups, an aftermarket lightweight flywheel can reduce rotational mass, improving engine responsiveness, though it won’t change the static engine weight. For automatics, specialized torque converters or flexplates might offer marginal savings.

- Tubular Exhaust Manifolds: While not a primary weight saver, some performance tubular manifolds might be slightly lighter than stock cast iron units while offering better flow.

- Coolant/Oil Filtration Systems: Adding external filters can introduce a small amount of weight, but the benefits in engine longevity often outweigh this minor increase.

Most “bulletproofing” components, such as upgraded EGR coolers (which are often thicker and more robust), head studs, and standpipes/dummy plugs, are generally similar in weight or negligibly heavier than their OEM counterparts. Their purpose is durability, not weight reduction.

Suspension Upgrades to Compensate for Front End Weight

Given the inherent Ford 6.0 Powerstroke engine weight, proper suspension tuning is critical for both performance and comfort. If you’re lifting your truck, adding heavy bumpers, or installing a snowplow, these modifications further increase front-end load and necessitate suspension adjustments:

- Heavy-Duty Coil Springs/Leaf Springs: Essential for maintaining proper ride height and preventing bottoming out. Select springs rated for the expected front axle weight.

- Performance Shock Absorbers: Upgraded shocks (e.g., Fox, Bilstein, King) can significantly improve ride quality, damping, and control, especially when dealing with a heavy front end.

- Adjustable Track Bars/Control Arms: These components help maintain proper axle alignment and steering geometry, crucial when the suspension is heavily loaded.

- Air Bags/Helper Springs: For those who frequently carry variable heavy loads or use snowplows, supplementary air bags or helper springs can provide adjustable load support.

Always consult with suspension experts and provide them with your truck’s estimated front axle weight (including the engine and any added accessories) to ensure you select the correct components.

Weight Reduction Strategies for the Vehicle (Beyond the Engine)

If overall vehicle weight reduction is a primary goal (e.g., for racing or extreme off-roading), focus on areas outside the core Powerstroke engine weight:

- Wheels and Tires: Lighter aftermarket wheels and tires can significantly reduce unsprung weight, improving handling and acceleration.

- Body Panels: For custom builds, replacing steel body panels with fiberglass or carbon fiber alternatives can shave considerable weight.

- Interior Stripping: Removing unnecessary interior components (rear seats, sound deadening, etc.) for dedicated work or race trucks.

- Aluminum Accessories: Where possible, opt for aluminum components over steel (e.g., custom bumpers, bed racks).

- Remove Unnecessary Items: Every tool, spare part, or piece of junk in the bed adds to the overall weight.

The “Bulletproofing” Effect on Weight

It’s worth noting that the popular “bulletproofing” modifications for the 6.0 Powerstroke – such as head studs, upgraded EGR coolers, and improved oil cooler systems – don’t significantly alter the core Ford 6.0 Powerstroke engine weight. In some cases, upgraded components might be slightly heavier due to more robust materials (e.g., thicker stainless steel EGR coolers), but the increase is usually negligible in the grand scheme of things. The value of these upgrades lies in dramatically enhancing reliability and longevity, allowing the engine to perform consistently without catastrophic failure, which is a different form of “optimization” than weight reduction.

Essential Data: Ford 6.0 Powerstroke Engine Specifications Table

For those who appreciate hard numbers, here’s a concise table summarizing the key specifications of the Ford 6.0 Powerstroke engine, including its approximate weight, to provide a quick reference for your projects and understanding.

| Specification | Value |

|---|---|

| Engine Type | V8, OHV (Overhead Valve) |

| Displacement | 6.0 Liters (365 cu in) |

| Bore x Stroke | 3.74 in x 4.13 in (95 mm x 105 mm) |

| Compression Ratio | 18.0:1 |

| Valvetrain | 32-Valve (4 valves per cylinder) |

| Fuel System | HEUI (Hydraulically-actuated, Electronically-controlled, Unit Injector) |

| Aspiration | Variable Geometry Turbocharger (VGT) |

| Horsepower (Stock) | 325 hp @ 3,300 rpm |

| Torque (Stock) | 560-570 lb-ft @ 2,000 rpm |

| Engine Oil Capacity | 15 quarts (approx. 14.2 liters) |

| Cooling System Capacity | Approx. 28-30 quarts (approx. 26.5-28.4 liters) |

| Block Material | Cast Iron |

| Cylinder Head Material | Cast Iron |

| Approx. Dry Weight | 860-900 lbs (390-408 kg) |

| Approx. Wet Weight (Dressed) | 950-1,000 lbs (430-450 kg) |

This table serves as a quick reference for critical specifications, highlighting the considerable Ford 6.0 Powerstroke engine weight in both its dry and wet configurations. These numbers are vital for anyone working with or planning modifications for this robust engine.

Conclusion: The Enduring Significance of the 6.0 Powerstroke’s Mass

The Ford 6.0 Powerstroke engine weight is far more than just a number on a spec sheet; it’s a fundamental characteristic that profoundly shapes the identity and capabilities of any truck it powers. From its substantial cast iron components to its intricate turbocharger system, every pound is a testament to its heavy-duty design and the immense power it’s built to deliver.

Understanding this weight is key to making informed decisions, whether you’re planning a suspension upgrade, evaluating payload capacity, or simply trying to comprehend why your diesel truck handles differently than its gasoline counterpart. The 6.0 Powerstroke, for all its storied history, remains a formidable engine, and its mass is an intrinsic part of its enduring legacy. By appreciating the engineering behind its weight, you’re better equipped to maintain, modify, and master your Powerstroke-powered vehicle, ensuring it continues to perform reliably for years to come.

🎥 Related Video: Runaway Diesel Engine Stopped with a Leap of Faith 🚛🔥

📺 Trucking Talent

When a runaway diesel engine strikes, it’s do-or-die for the driver. In this heart-stopping moment, a trucker faces a critical decision …

Frequently Asked Questions

What is the typical Ford 6.0 Powerstroke engine weight?

The “dry” weight of a Ford 6.0 Powerstroke engine, meaning without fluids like oil or coolant, generally falls between 880 to 900 pounds (approximately 400-408 kg). When fully dressed with all accessories and filled with fluids, this weight can increase further, often approaching 950-1000 pounds.

How does the Ford 6.0 Powerstroke engine’s weight compare to other diesel engines in its class?

The 6.0 Powerstroke’s weight is fairly typical for heavy-duty diesel truck engines of its era, aligning with competitors like the Duramax or Cummins B-series. Its robust construction contributes to this weight, necessary for the high torque and demanding towing capabilities it offers.

What factors influence the Ford 6.0 Powerstroke engine weight, and does it vary by year?

The core weight of the 6.0 Powerstroke engine remains largely consistent across its production years (2003-2007) due to its standardized block and head design. Minor variations in accessory components or slight updates to parts like the turbocharger or intake manifold usually have a negligible impact on the overall engine weight.

Why is knowing the Ford 6.0 Powerstroke engine weight important for a vehicle project or swap?

Understanding the engine weight is crucial for proper vehicle engineering, including selecting appropriate suspension components, ensuring frame integrity, and optimizing weight distribution. This knowledge helps maintain safe handling characteristics and structural soundness for any build or engine swap project.

What components are typically included in the Ford 6.0 Powerstroke engine weight measurement?

A “dry” engine weight usually encompasses the block, cylinder heads, crankshaft, pistons, camshaft, turbocharger, and main engine accessories like intake and exhaust manifolds. Additional external components such as alternators, power steering pumps, and AC compressors will add to the total “dressed” weight.

What is the estimated shipping weight for a Ford 6.0 Powerstroke engine?

When preparing for shipment, a Ford 6.0 Powerstroke engine is typically crated and secured on a pallet, adding significant bulk and weight. The total shipping weight, including the crate and packaging materials, can easily exceed 1000-1100 pounds (450-500 kg), which is an important factor for calculating freight costs.