7.3 Powerstroke Turbocharger Specifications: How to Optimize Performance

Featured image for this comprehensive guide about 7.3 Powerstroke turbocharger specs

Image source: junglewood.xyz

The roar of a 7.3 Powerstroke engine is more than just sound; it’s a symphony of raw power, legendary reliability, and a mechanical heart that has captured the devotion of countless truck enthusiasts. At the core of this revered diesel engine’s performance lies its turbocharger – a critical component responsible for forcing more air into the engine, thus generating the immense torque and horsepower that these trucks are famous for. But like any high-performance component, understanding its intricacies is key to unlocking its full potential and ensuring its longevity.

Whether you’re a seasoned 7.3 Powerstroke owner looking to squeeze every ounce of performance from your rig, or a new enthusiast eager to learn the foundational mechanics of your powerful diesel, delving into 7.3 Powerstroke turbocharger specs is an essential journey. This isn’t just about numbers; it’s about understanding how your turbo breathes, what its limits are, and how you can optimize its operation to achieve outstanding results, whether that’s for heavy towing, spirited daily driving, or even competitive applications. Get ready to dive deep into the world of forced induction, where we’ll demystify the components, discuss common issues, and uncover the secrets to superior turbo performance.

In this comprehensive guide, we’ll peel back the layers of the 7.3 Powerstroke turbo, exploring its design, key specifications, and the impact these have on your truck’s overall power and efficiency. From the stock Garrett TP38 to popular upgrades like the GT38R, we’ll equip you with the knowledge to make informed decisions about maintenance, troubleshooting, and performance enhancements. Let’s fire up that diesel and explore how to truly optimize your 7.3 Powerstroke turbocharger specifications for peak performance.

Quick Answers to Common Questions

How big is the stock 7.3 Powerstroke turbocharger?

The original 7.3 Powerstroke turbocharger is a Garrett TP38, designed for reliable performance right off the assembly line. Its factory 7.3 Powerstroke turbocharger specs provide a good balance of power and efficiency for stock applications.

What are some common problems with the 7.3 Powerstroke turbocharger?

Typical issues include exhaust leaks from the up-pipes, a worn out wastegate actuator, or compressor surge, which can all negatively impact your 7.3 Powerstroke turbocharger’s performance. Addressing these early can prevent bigger headaches down the road.

What’s a popular first upgrade for the 7.3 Powerstroke turbocharger?

Many owners opt for an upgraded compressor wheel like the “Wicked Wheel 2” or even a complete Garrett GTP38R turbo, as these significantly improve airflow and reduce surge compared to the original 7.3 Powerstroke turbocharger specs. It’s a fantastic way to boost performance with a noticeable difference.

How can I tell if my 7.3 Powerstroke turbocharger is going bad?

Look out for tell-tale signs such as excessive black or blue smoke, a noticeable loss of power, a high-pitched whine, or increased oil consumption. These are strong indicators that your 7.3 Powerstroke turbocharger specs might be compromised and it needs attention.

What kind of boost pressure should I expect from my 7.3 Powerstroke turbocharger?

A healthy stock 7.3 Powerstroke turbocharger typically produces around 18-22 PSI of boost under load. Knowing these 7.3 Powerstroke turbocharger specs helps you monitor your engine’s performance and overall health.

📋 Table of Contents

- The Heart of the Beast: Understanding the Stock 7.3 Powerstroke Turbocharger

- Diving Deep into 7.3 Powerstroke Turbocharger Specifications

- Common Issues and What to Look For

- Optimizing Your 7.3 Powerstroke Turbo Performance: Upgrades and Modifications

- Essential Maintenance for Longevity

- Choosing the Right Turbo Upgrade for Your Needs

- Conclusion: Unleash Your 7.3 Powerstroke’s Full Potential

The Heart of the Beast: Understanding the Stock 7.3 Powerstroke Turbocharger

For nearly a decade, from 1994.5 to 2003, the 7.3 Powerstroke ruled the heavy-duty truck segment, and a significant part of its success was thanks to its robust turbocharger. The stock unit found in these trucks is the Garrett TP38, a fixed-geometry, journal-bearing turbo designed to provide reliable boost for a wide range of applications. While its design might seem rudimentary by today’s Variable Geometry Turbo (VGT) standards, the TP38 is a workhorse, known for its simplicity, durability, and a characteristic exhaust note that diesel enthusiasts adore.

Learn more about 7.3 Powerstroke turbocharger specs – 7.3 Powerstroke Turbocharger Specifications: How to Optimize Performance

Image source: img.freepik.com

The primary function of any turbocharger is to increase the density of air entering the engine’s combustion chambers. It does this by utilizing exhaust gases – which would otherwise be wasted – to spin a turbine wheel. This turbine, in turn, spins a compressor wheel, drawing in fresh air and compressing it before sending it into the intake manifold. More air means more oxygen, which allows for more fuel to be burned, resulting in a significant increase in power and torque compared to a naturally aspirated engine.

| Specification | OEM Garrett GTP38 (1999.5-2003) | Garrett GTP38R (Common Upgrade) |

|---|---|---|

| Turbocharger Model | Garrett GTP38 | Garrett GTP38R |

| Compressor Wheel Inducer (mm) | 60 mm | 66 mm (Billet) |

| Turbine Wheel Exducer (mm) | 68 mm | 68 mm |

| Compressor Housing A/R | 0.84 A/R | 0.84 A/R |

| Bearing Type | Journal Bearing | Dual Ball Bearing |

| Typical Max Boost (psi) | ~20-22 psi | ~30-35+ psi |

Understanding the components of the stock TP38 is crucial for anyone looking to maintain or upgrade their 7.3 Powerstroke turbocharger. These include:

- Compressor Housing: The snail-shaped casing on the intake side that directs compressed air to the engine.

- Compressor Wheel: The finned wheel that draws in and compresses ambient air.

- Center Housing Rotating Assembly (CHRA): The core of the turbo, containing the shaft, bearings, and oil passages.

- Turbine Wheel: The finned wheel spun by exhaust gases.

- Turbine Housing (Exhaust Housing): The casing on the exhaust side that directs exhaust gases to spin the turbine.

- Wastegate: A valve that bypasses some exhaust gases around the turbine to prevent overboosting and control boost pressure.

- Exhaust Back Pressure Valve (EBPV): Unique to the 7.3 Powerstroke turbo, this valve restricts exhaust flow during warm-up to help the engine reach operating temperature faster and also acts as an exhaust brake in some applications.

While the TP38 is incredibly reliable, its fixed-geometry design means it’s a compromise between quick spool-up at low RPMs and maximum airflow at high RPMs. This is why many owners eventually look into 7.3 Powerstroke turbo upgrades to improve responsiveness and power across the entire RPM range.

Diving Deep into 7.3 Powerstroke Turbocharger Specifications

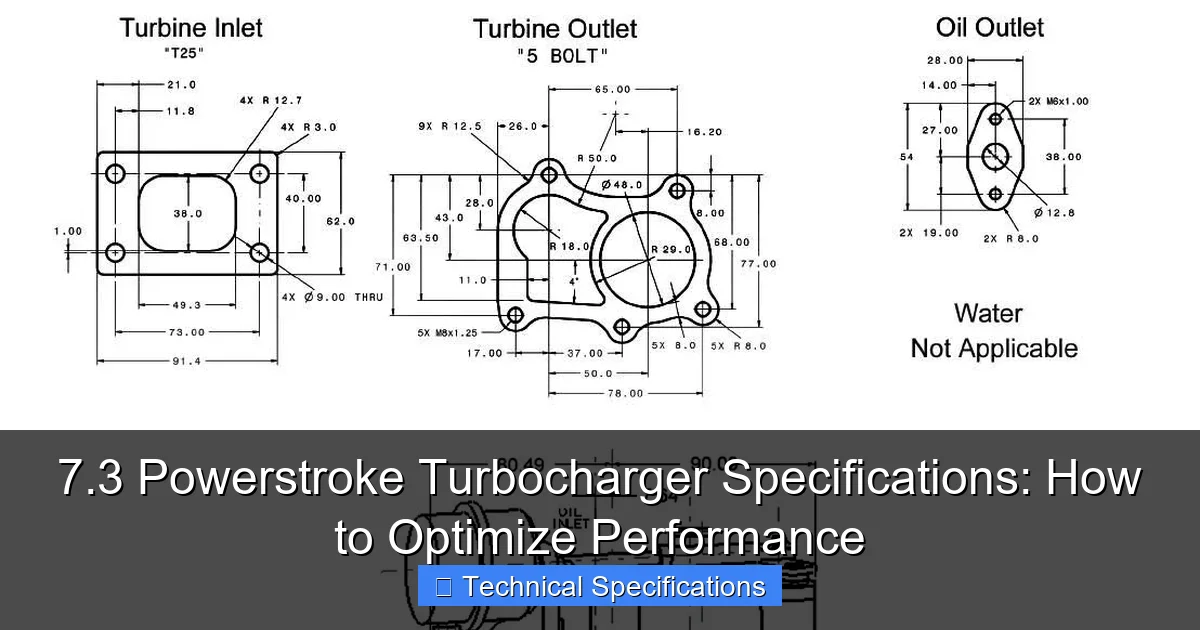

When we talk about 7.3 Powerstroke turbocharger specs, we’re referring to a series of measurements and design elements that dictate how the turbo performs. These numbers provide a blueprint of its capabilities and limitations. Let’s break down the key specifications for the stock Garrett TP38 and a popular upgrade, the Garrett GT38R, which is essentially a ball-bearing version of the TP38 with a few enhancements.

Learn more about 7.3 Powerstroke turbocharger specs – 7.3 Powerstroke Turbocharger Specifications: How to Optimize Performance

Image source: 1.bp.blogspot.com

Compressor Side Specifications

The compressor side is where the magic of forced air induction begins. Key specs include:

- Compressor Wheel Inducer Diameter: The diameter where the air first enters the compressor wheel. For the stock TP38, this is typically around 59.9mm.

- Compressor Wheel Exducer Diameter: The diameter where the air exits the compressor wheel after compression. Stock TP38 is usually around 80mm.

- Compressor Trim: A ratio derived from the inducer and exducer diameters (Inducer² / Exducer² * 100). This value gives an indication of the wheel’s design for flow versus pressure ratio.

Larger inducer and exducer diameters generally mean more airflow potential, but can also lead to increased turbo lag, as more mass needs to be spun up. The aftermarket GT38R often features a slightly larger compressor wheel for increased airflow.

Turbine Side Specifications

The turbine side is where exhaust gas energy is harnessed to spin the compressor. Critical dimensions here are:

- Turbine Wheel Inducer Diameter: Where exhaust gases first enter the turbine wheel. Stock TP38 is typically around 76mm.

- Turbine Wheel Exducer Diameter: Where exhaust gases exit the turbine wheel. Stock TP38 is usually around 69mm.

- Turbine Trim: Similar to compressor trim, indicating flow characteristics.

- Turbine Housing A/R Ratio (Area/Radius): This is a critical spec for the turbine housing. It represents the ratio of the inlet area to the radius from the turbine wheel’s center to the centroid of that area. For the stock 7.3 Powerstroke turbo, the A/R ratio is typically 1.15. A smaller A/R will spool faster but choke at higher RPMs, while a larger A/R will have more top-end flow but slower spool-up.

Bearing System

The stock TP38 utilizes a journal bearing system, which is robust and cost-effective. However, the aftermarket GT38R upgrades to a ball-bearing system. Ball bearings significantly reduce friction, leading to:

- Faster Spool-up: Less rotational resistance means the turbo builds boost quicker.

- Improved Transient Response: Quicker reaction to throttle input changes.

- Better Durability: Often handle higher shaft speeds and temperatures more efficiently.

Exhaust Back Pressure Valve (EBPV)

The EBPV, located within the turbine housing, is a distinctive feature of the 7.3 Powerstroke turbo. While beneficial for quick warm-ups and acting as a mild exhaust brake, it can also be a source of problems. Common issues include:

- Sticking Open or Closed: Can lead to excessive exhaust back pressure (if closed) or no warm-up assist (if open).

- Oil Leaks: The EBPV actuator can leak oil over time.

- Reduced Flow: Even when fully open, the EBPV flapper and rod slightly restrict exhaust flow, potentially hindering performance. Many owners opt for an EBPV delete for this reason.

Here’s a simplified comparison table of key 7.3 Powerstroke turbocharger specs:

| Specification | Stock Garrett TP38 (Typical) | Garrett GT38R (Typical) |

|---|---|---|

| Compressor Inducer | 59.9 mm | 60 mm |

| Compressor Exducer | 80 mm | 88 mm |

| Turbine Inducer | 76 mm | 76 mm |

| Turbine Exducer | 69 mm | 69 mm |

| Turbine Housing A/R | 1.15 | 1.00 or 1.15 (depending on model) |

| Bearing Type | Journal Bearing | Ball Bearing |

| Wastegate | External / Internal (depending on year) | Internal |

| EBPV | Yes | Yes (can be deleted) |

It’s important to note that specific measurements can vary slightly depending on the exact year and revision of the stock TP38, and different aftermarket GT38R variants may exist. Always verify with the manufacturer or supplier for precise figures.

Common Issues and What to Look For

Even with the legendary reliability of the 7.3 Powerstroke, its turbocharger isn’t immune to wear and tear. Recognizing common issues early can save you significant repair costs and prevent further engine damage. Here are some of the most frequent problems associated with the 7.3 Powerstroke turbo:

1. EBPV Malfunctions

As mentioned, the Exhaust Back Pressure Valve is a common culprit. Symptoms of a failing EBPV include:

- Stuck Closed: Can cause excessive exhaust back pressure, leading to high exhaust gas temperatures (EGTs), reduced power, black smoke, and a whistling noise.

- Stuck Open: Prevents proper engine warm-up in cold weather, potentially leading to longer warm-up times and reduced efficiency.

- Oil Leaks: The actuator for the EBPV is oil-driven. Leaks can manifest as oil stains around the turbo pedestal or a gradual loss of engine oil.

Many owners opt for an EBPV delete kit, replacing the EBPV components with a solid pedestal or an exhaust housing that lacks the valve altogether. This simplifies the system, improves exhaust flow slightly, and eliminates a potential failure point.

2. Oil Leaks (Non-EBPV Related)

Turbochargers rely on engine oil for lubrication and cooling. Leaks can occur at various points:

- Oil Feed/Drain Lines: Inspect the banjo bolts, seals, and hose connections for any signs of seepage.

- CHRA Seals: Internal seals can wear out, allowing oil to pass into the compressor or turbine housing. Symptoms include blue smoke from the exhaust (oil burning), oil in the intercooler pipes, or oil dripping from the exhaust outlet.

Always address oil leaks promptly, as low oil levels can quickly lead to catastrophic turbo failure.

3. Excessive Shaft Play

The turbocharger shaft spins at incredibly high RPMs. Over time, the journal bearings (on a TP38) can wear, leading to excessive play. You can often check for this by carefully removing the intake boot and attempting to move the compressor wheel:

- Side-to-Side Play: A small amount of radial play (side-to-side) is normal for journal bearings, but if the wheel can touch the housing, it’s excessive.

- In-and-Out Play (Axial Play): There should be minimal to no axial play (in-and-out). Any significant movement here indicates severe bearing wear and impending failure.

Symptoms of excessive shaft play include a loud whining or scraping noise from the turbo, reduced boost, and potential damage from the wheel contacting the housing.

4. Boost Leaks

While not strictly a turbo failure, boost leaks can significantly impact turbo performance. Leaks in the intercooler pipes, boots, or clamps mean that pressurized air is escaping before it reaches the engine. This results in:

- Reduced Power: Less air means less fuel can be burned effectively.

- Increased EGTs: The engine runs richer, leading to higher exhaust gas temperatures.

- Black Smoke: Incomplete combustion due to insufficient air.

- Turbo Over-speeding: The turbo works harder to try and reach the desired boost level, putting stress on the bearings.

Regularly inspect all intake and intercooler boots for cracks, tears, or loose clamps. A simple boost leak test can help pinpoint elusive leaks.

5. Wastegate Malfunctions

The wastegate controls maximum boost pressure. If it’s sticking open, you’ll experience low boost. If it’s sticking closed, you’ll likely overboost, potentially causing engine damage. A common issue with the stock TP38’s internal wastegate is the actuator failing or the arm becoming seized.

Optimizing Your 7.3 Powerstroke Turbo Performance: Upgrades and Modifications

The stock 7.3 Powerstroke turbocharger is a great foundation, but there’s significant room for improvement, especially if you’re chasing more power, better responsiveness, or enhanced efficiency. Upgrading your 7.3 Powerstroke turbo can transform your truck’s driving experience. Here are some of the most popular and effective modifications:

1. Turbocharger Upgrades (Full Turbo Replacement)

The most direct way to boost performance is to replace the entire turbo assembly.

- Garrett GT38R: This is arguably the most popular and well-regarded direct drop-in upgrade for the 7.3 Powerstroke turbo. It shares many dimensions with the stock TP38 but incorporates a ball-bearing CHRA and often a slightly larger, more efficient compressor wheel. The ball bearings mean significantly faster spool-up and better transient response, while the improved compressor wheel can support more airflow and higher boost pressures.

- Larger & Hybrid Turbos: For those seeking even more power, options like the “Big Head” Garrett turbos, or various hybrid setups (e.g., combining components from different turbos) are available. These often feature significantly larger compressor wheels (e.g., 66mm or 68mm) and sometimes different turbine housings for increased flow. Be aware that larger turbos typically require supporting modifications like upgraded injectors, custom tuning, and a higher-flow air intake and exhaust system.

- Non-VGT Aftermarket Turbos: Companies like KC Turbos, Industrial Injection, and Banks offer a range of fixed-geometry turbos specifically designed for the 7.3 Powerstroke, often with billet compressor wheels for improved strength and efficiency.

2. Compressor Wheel Upgrades (While Retaining Stock Housing)

If a full turbo replacement isn’t in the budget, upgrading just the compressor wheel can offer a noticeable improvement, especially when moving from a cast wheel to a billet one.

- Billet Compressor Wheels: These wheels are CNC-machined from a solid block of aluminum, making them stronger, lighter, and often designed with more aggressive blade profiles. This can lead to increased airflow, a broader powerband, and sometimes faster spool-up within the limits of the stock turbine.

3. Supporting Modifications

A turbo is only as good as the system it operates within. To truly optimize your 7.3 Powerstroke turbo performance, consider these supporting mods:

- High-Flow Air Intake System: A restrictive stock air filter and intake tract choke the turbo. An aftermarket cold air intake (CAI) with a larger filter and smoother piping allows the turbo to breathe easier, improving efficiency and power.

- Larger Exhaust System: The stock exhaust on a 7.3 Powerstroke is restrictive. Upgrading to a 3.5-inch or 4-inch turbo-back exhaust system significantly reduces exhaust back pressure, allowing the turbo to spool faster and lowering EGTs.

- Performance Injectors: More air from an upgraded turbo means the engine can burn more fuel. Matching your turbo upgrade with larger injectors (e.g., 160/80, 200/30) is crucial for maximizing power gains.

- Custom Tuning: This is non-negotiable for any significant turbo or injector upgrade. Custom tunes (Flashed to your PCM or via a chip) adjust fuel delivery, timing, and boost parameters to safely and efficiently utilize your new hardware. Without proper tuning, you risk engine damage or poor performance.

- Intercooler Upgrades: A more efficient intercooler can significantly drop intake air temperatures (IATs), leading to denser air, more power, and reduced EGTs.

Essential Maintenance for Longevity

To ensure your 7.3 Powerstroke turbocharger continues to deliver reliable performance for hundreds of thousands of miles, diligent maintenance is key. Proactive care can prevent costly repairs down the line and keep your beast roaring strong.

1. Regular Oil Changes with Quality Oil

This is arguably the single most important maintenance item for your turbo. The turbocharger’s bearings are lubricated and cooled by engine oil, and it experiences extreme temperatures and rotational speeds.

- Use High-Quality Diesel-Specific Oil: Follow manufacturer recommendations for oil type and viscosity. Many 7.3 Powerstroke owners swear by Shell Rotella T4/T5/T6, Mobil Delvac, or Valvoline Premium Blue.

- Adhere to Shorter Intervals: While Ford recommended 5,000-mile intervals for the 7.3 Powerstroke, many diesel enthusiasts opt for 3,000-5,000-mile changes, especially with heavy use, towing, or if using a stock oil filter.

- Consider an Oil Bypass Filtration System: These systems can extend oil life and provide superior filtration, reducing wear on turbo bearings.

2. Air Filter Inspections and Replacements

A clean air filter is vital for turbo health. A clogged filter restricts airflow, forcing the turbo to work harder, which can lead to:

- Reduced Performance: Less air means less power.

- Increased EGTs: The engine struggles to breathe.

- Turbo Over-speeding: The turbo spins faster trying to draw in enough air, increasing wear.

- Compressor Wheel Damage: Extreme suction can pull dirt through the filter or cause the wheel to cavitate.

Inspect your air filter regularly and replace it according to your owner’s manual or more frequently if driving in dusty conditions. For aftermarket cold air intakes, follow the manufacturer’s cleaning/replacement schedule.

3. Inspecting Intercooler and Intake Boots

As mentioned in common issues, boost leaks are detrimental. Regularly inspect all rubber boots and clamps in your intake and intercooler system:

- Check for cracks, tears, or swelling in the boots.

- Ensure all clamps are tight and secure.

- Consider upgrading to silicone boots and T-bolt clamps, which are more durable and provide a tighter seal than stock rubber boots and worm-gear clamps.

4. Checking for Exhaust Leaks

Exhaust leaks before the turbo can reduce the energy available to spin the turbine, impacting boost. Common culprits are:

- Exhaust Manifold Gaskets: Listen for a ticking sound that gets louder under load.

- Up-Pipes: The exhaust pipes leading from the manifolds to the turbo are prone to cracking or leaking at their donut gaskets. Upgrading to bellowed up-pipes is a popular and effective solution for preventing future leaks.

5. EBPV Maintenance (If Not Deleted)

If you’ve retained your EBPV, periodically check its function. You can often hear it cycle during cold starts. If it’s sticking, cleaning it with a suitable solvent (while disassembled) or replacing the actuator can help. Many find the benefits outweigh the hassle of dealing with potential issues.

Choosing the Right Turbo Upgrade for Your Needs

Deciding on a 7.3 Powerstroke turbo upgrade isn’t a one-size-fits-all decision. Your choice should align with your specific goals and how you use your truck. Consider these factors:

1. Daily Driver / Light Towing (100-150 HP Increase)

If you’re looking for improved throttle response, lower EGTs, and a modest power bump without sacrificing drivability, a Garrett GT38R is an excellent choice. Its ball-bearing design significantly reduces turbo lag, making the truck feel much more responsive. Combine this with a good intake, exhaust, and custom tuning for a truly enjoyable experience.

- Recommended Turbos: Garrett GT38R, KC Turbos Stage 1, Powerstroke Products PP1.

- Recommended Injectors: Stock AD (160cc/0%) or mild upgrades like 160/30s.

2. Heavy Towing / Work Truck (150-250 HP Increase)

For those who frequently haul heavy loads or use their 7.3 Powerstroke as a dedicated work truck, you need a turbo that can maintain boost under sustained load without generating excessive EGTs. A turbo with a slightly larger compressor wheel (e.g., 63mm-66mm) and an efficient turbine housing can provide the necessary airflow.

- Recommended Turbos: KC Turbos Stage 2 (63/68), Industrial Injection Super PhatShaft.

- Recommended Injectors: 180cc/30%, 205cc/30%.

Focus on turbos that offer good balance between spool-up and top-end flow, ensuring you have power when you need it for those demanding pulls. Upgraded intercoolers become more important here.

3. Performance / Racing (250+ HP Increase)

If your goal is maximum power, faster quarter-mile times, or competitive sled pulling, you’ll be looking at significantly larger turbos. These often involve more extensive modifications and careful calibration.

- Recommended Turbos: KC Turbos Stage 3 (66/73), FFD (Full Force Diesel) 66mm/74mm, T4 S300 or S400 kits (non-stock mount).

- Recommended Injectors: 238cc/80%, 250cc/100%, or larger.

These setups typically require:

- Larger Injectors: Crucial to supply enough fuel for the increased airflow.

- Dual High-Pressure Oil Pumps (HPOP): To maintain adequate oil pressure for larger injectors.

- Fuel System Upgrades: A regulated return fuel system and potentially larger fuel lines.

- Transmission Upgrades: The stock transmission will quickly become a weak link.

- Aggressive Custom Tuning: Absolutely essential for safety and performance.

Always consult with reputable diesel performance shops and tuners when planning high-horsepower builds to ensure compatibility and reliability of all components.

Conclusion: Unleash Your 7.3 Powerstroke’s Full Potential

The 7.3 Powerstroke turbocharger is a remarkable piece of engineering, an integral part of what makes these diesel trucks so beloved and legendary. By understanding its fundamental 7.3 Powerstroke turbocharger specifications, from the dimensions of its compressor and turbine wheels to the nuances of its bearing system and the sometimes-finicky EBPV, you gain the power to make informed decisions about your truck’s performance and longevity. We’ve explored the stock TP38, delved into common issues to watch out for, and highlighted the myriad ways you can upgrade and optimize your turbo for any application, from reliable daily driving to competitive performance.

Whether you’re performing routine maintenance, diagnosing an issue, or planning a significant power upgrade, remember that attention to detail, quality parts, and proper tuning are paramount. The journey to a perfectly optimized 7.3 Powerstroke turbo is an ongoing one, but with the right knowledge and a commitment to smart modifications and regular care, you can truly unleash the full potential of your iconic diesel beast. So, get out there, perform those checks, plan those upgrades, and enjoy the unparalleled power and reliability that only a well-maintained and smartly optimized 7.3 Powerstroke can offer. Your truck, and your driving experience, will thank you for it!

Frequently Asked Questions

What are the stock 7.3 Powerstroke turbocharger specifications?

The factory 7.3 Powerstroke came equipped with a Garrett GTP38 turbocharger. This unit typically featured a 60mm compressor wheel and a 76mm turbine wheel, designed to provide reliable boost for everyday driving and light-duty work.

What are common upgrade options for the 7.3 Powerstroke turbocharger to optimize performance?

Popular upgrade options include the Garrett GTP38R for improved airflow and lower EGTs, or various “wicked wheel” compressor upgrades for better spool. For significant power gains, larger aftermarket turbos from brands like KC Turbos or BorgWarner are favored, often requiring supporting engine modifications.

How can I tell if my 7.3 Powerstroke turbocharger is failing?

Common signs of a failing turbocharger include excessive black or blue smoke from the exhaust, a noticeable loss of power, a whining or grinding sound from the turbo itself, or increased oil consumption. Checking for excessive shaft play in the compressor wheel can also indicate an issue.

What 7.3 Powerstroke turbocharger setups are best for heavy towing?

For heavy towing, you’ll want a turbocharger that provides quick spool-up and helps maintain lower exhaust gas temperatures (EGTs) under load. Turbos with slightly larger turbine housings or those designed for quicker boost response, often featuring billet compressor wheels, are excellent choices for improved towing performance.

Do I need other modifications when upgrading my 7.3 Powerstroke turbocharger?

Yes, upgrading your 7.3 Powerstroke turbocharger often requires supporting modifications to truly optimize performance and ensure reliability. Injector upgrades, a custom engine tune, an improved fuel system, and better exhaust flow are highly recommended to fully utilize the potential of a new turbo.

What boost levels can I expect from a 7.3 Powerstroke turbocharger, both stock and upgraded?

A stock 7.3 Powerstroke turbocharger typically produces around 18-22 PSI of boost under normal driving conditions. With aftermarket turbos and proper tuning, you can often achieve boost levels ranging from 28-40+ PSI, depending on the turbo’s size and your engine’s specific setup.