7.3 Powerstroke Turbocharger Specifications: How to Optimize Performance

Featured image for this comprehensive guide about 7.3 Powerstroke turbocharger specs

Image source: 1.bp.blogspot.com

The iconic 7.3 Powerstroke diesel engine holds a legendary status among truck enthusiasts and heavy-duty workers alike. Renowned for its unparalleled durability, simplicity, and workhorse capabilities, this engine powered Ford Super Duty trucks from 1999 to early 2003, leaving an indelible mark on automotive history. While the engine itself is a marvel of engineering, a significant portion of its power and distinctive rumble comes from one crucial component: its turbocharger. Understanding the intricacies of your 7.3 Powerstroke turbocharger specs isn’t just for mechanics; it’s essential for any owner looking to maintain, troubleshoot, or, most excitingly, enhance their truck’s performance.

For many, the 7.3 Powerstroke isn’t just a truck; it’s a way of life, a reliable companion for hauling heavy loads, navigating tough terrain, or simply cruising with confidence. The turbocharger is the heart of its forced induction system, compressing air into the engine to create more power and improve fuel efficiency. Neglect it, and you risk a significant drop in performance and potentially costly repairs. Optimize it, and you unlock the true potential of your diesel beast. This comprehensive guide will dive deep into the factory 7.3 Powerstroke turbocharger specifications, discuss common issues, explore popular upgrades, and provide actionable tips to keep your turbo spinning strong for years to come.

Whether you’re a seasoned diesel mechanic, a new owner eager to learn, or a veteran enthusiast planning your next power upgrade, mastering the knowledge surrounding your 7.3 Powerstroke turbo is key. We’ll strip back the layers to reveal what makes this component tick, what to look out for, and how to make informed decisions that will directly impact your truck’s longevity and on-road prowess. Get ready to supercharge your understanding of one of the most vital parts of your beloved 7.3 Powerstroke.

Quick Answers to Common Questions

What are the basic 7.3 Powerstroke turbocharger specs for a stock engine?

The factory 7.3 Powerstroke turbocharger specs typically feature a Garrett TP38 or GTP38, which is a dependable journal-bearing turbo. It provides solid performance and quick spool-up for everyday driving.

Why do owners often look to upgrade their 7.3 Powerstroke turbocharger?

Many owners modify their 7.3 Powerstroke turbocharger specs to gain more horsepower and torque, lower exhaust gas temperatures (EGTs), and improve overall engine efficiency, especially when towing or running custom tunes.

What’s a popular initial upgrade if I’m happy with my 7.3 Powerstroke turbocharger specs but want more?

A common first step to enhance your existing 7.3 Powerstroke turbocharger specs is to replace the stock compressor wheel with an aftermarket “wicked wheel” or a 38R style wheel. This can improve airflow and reduce surge without replacing the entire unit.

How can I tell if my current 7.3 Powerstroke turbocharger specs might be showing signs of wear?

Listen for unusual whining or whistling noises, look for excessive blue or black smoke, and check for oil leaks around the turbo housing. These are tell-tale signs that your 7.3 Powerstroke turbocharger specs might need attention.

Will upgrading my 7.3 Powerstroke turbocharger specs require other engine modifications?

For significant upgrades to your 7.3 Powerstroke turbocharger specs, you’ll often need supporting mods like custom tuning, bigger injectors, and an upgraded fuel system to fully realize the power gains safely and efficiently.

📋 Table of Contents

- Understanding the Heart of Your Beast: The Stock 7.3 Powerstroke Turbocharger

- Unpacking the Factory 7.3 Powerstroke Turbocharger Specs

- Common Issues and Wear Points of the Stock 7.3L Turbo

- Upgrading Your 7.3 Powerstroke Turbo: Enhancing Performance and Reliability

- Beyond the Turbo: Supporting Modifications for Optimal 7.3 Powerstroke Performance

- Maintenance Essentials for Your 7.3 Powerstroke Turbocharger

- Conclusion: Mastering Your 7.3 Powerstroke Turbo for Peak Performance

Understanding the Heart of Your Beast: The Stock 7.3 Powerstroke Turbocharger

Before diving into the specifics of performance optimization, it’s crucial to understand the foundation: the factory 7.3 Powerstroke turbocharger. From 1999 to 2003 (with minor variations), Ford equipped the 7.3L Powerstroke with a Garrett TP38 turbocharger. This robust, wastegated unit was designed to provide a balance of power, fuel economy, and reliability for heavy-duty applications. Its design was relatively simple, yet highly effective, contributing significantly to the engine’s legendary reputation.

Learn more about 7.3 Powerstroke turbocharger specs – 7.3 Powerstroke Turbocharger Specifications: How to Optimize Performance

Image source: junglewood.xyz

The Garrett TP38 is an oil-lubricated, journal-bearing turbocharger. It operates by harnessing the energy from the engine’s exhaust gases to spin a turbine wheel. This turbine, in turn, is connected by a shaft to a compressor wheel on the intake side. As the compressor wheel spins, it draws in ambient air, compresses it, and forces it into the engine’s cylinders. This increased volume of air allows for more fuel to be burned efficiently, resulting in a substantial increase in power and torque compared to a naturally aspirated engine.

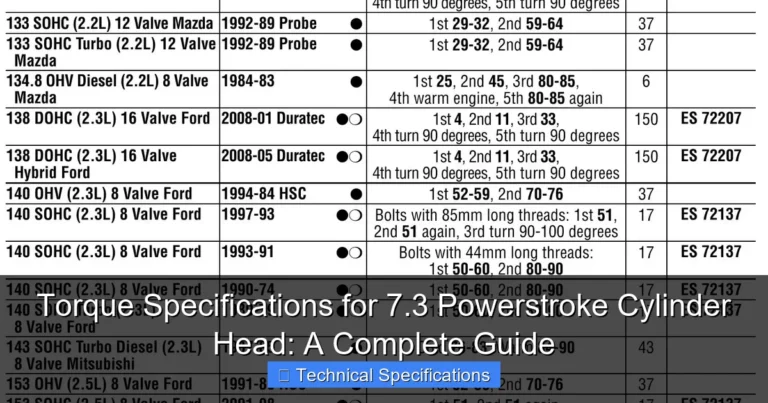

| Turbocharger Type / Model | Application / Year Range | Compressor Wheel Inducer (mm) | Turbine Wheel Exducer (mm) |

|---|---|---|---|

| Garrett TP38 (Stock) | 1994.5-1997 F-Series (OBS) | 58 mm | 70 mm |

| Garrett GTP38 (Stock) | 1999-2003 F-Series/Excursion (Super Duty) | 60 mm | 76 mm |

| GTP38 with Billet Compressor Upgrade | 1999-2003 F-Series/Excursion (Common Upgrade) | 63 mm | 76 mm |

| Aftermarket Performance (e.g., KC Turbos 63/68) | All 7.3L Powerstroke (Performance Upgrade) | 63-66 mm | 68-71 mm |

A key feature of the stock 7.3 Powerstroke turbocharger is its Exhaust Back Pressure Valve (EBPV). Located within the turbine housing, the EBPV serves two primary functions:

- Engine Braking: When activated, typically during cold starts or heavy deceleration, the EBPV closes partially to create backpressure, helping to warm up the engine faster and provide a degree of engine braking.

- Quick Spool-up: In certain conditions, it can help the turbo spool up quicker by restricting exhaust flow slightly.

While the EBPV has its benefits, it’s also a common source of issues, which we’ll discuss later. For its time, the Garrett TP38 was an excellent piece of engineering, perfectly matched to the capabilities of the 7.3 Powerstroke engine, delivering an impressive blend of durability and performance for millions of miles.

Unpacking the Factory 7.3 Powerstroke Turbocharger Specs

To truly understand how to optimize your 7.3 Powerstroke turbocharger, it’s essential to get into the nitty-gritty of its factory specifications. Knowing these numbers provides a baseline for evaluating performance, diagnosing issues, and planning upgrades. The Garrett TP38, while robust, has specific design parameters that define its operational characteristics.

Learn more about 7.3 Powerstroke turbocharger specs – 7.3 Powerstroke Turbocharger Specifications: How to Optimize Performance

Image source: img.freepik.com

Compressor and Turbine Wheel Dimensions

The heart of any turbocharger lies in its compressor and turbine wheels. These components dictate the air volume and pressure the turbo can generate.

-

Compressor Wheel: The stock TP38 typically features a cast compressor wheel.

- Inducer Diameter: Approximately 59.87 mm

- Exducer Diameter: Approximately 80.00 mm

The compressor wheel’s job is to pull in ambient air and compress it before sending it to the engine. The dimensions affect how much air can be moved and at what efficiency.

-

Turbine Wheel: The turbine wheel is driven by the hot exhaust gases.

- Inducer Diameter: Approximately 76.50 mm

- Exducer Diameter: Approximately 67.56 mm

The turbine’s design influences how effectively exhaust energy is converted into rotational force, directly impacting turbo spool-up and backpressure.

Housing Specifications

The housings that encase the compressor and turbine wheels are equally important, as they guide the airflow and exhaust gases.

- Compressor Housing: Designed to channel the compressed air efficiently into the intercooler (if equipped) or directly to the engine’s intake manifold. The stock housing is optimized for the factory compressor wheel.

- Turbine Housing (Exhaust Housing): The ‘A/R’ (Area/Radius) ratio of the turbine housing is a critical spec. The stock 7.3 Powerstroke turbocharger typically features a 1.15 A/R turbine housing. This ratio affects the velocity of exhaust gases hitting the turbine wheel, directly influencing spool-up time and peak power. A larger A/R (e.g., 1.15) generally means slower spool but better top-end flow, while a smaller A/R would spool faster but restrict high-RPM flow.

Boost Pressure and Flow Characteristics

Out of the factory, the 7.3 Powerstroke turbo was designed to deliver conservative but effective boost pressures.

- Peak Boost: A healthy stock 7.3 Powerstroke turbocharger typically generates between 18-22 PSI of boost.

- Flow Rate: While not a published spec like compressor/turbine dimensions, the TP38’s flow capabilities are sufficient for the stock engine’s roughly 235-275 horsepower range (depending on year and calibration). It provides excellent low-end torque for towing and everyday driving.

EBPV (Exhaust Back Pressure Valve)

As mentioned, the EBPV is an integral part of the stock TP38. It’s a butterfly valve controlled by an oil-pressure-activated actuator, often visible at the front of the turbine housing. Its operation is managed by the Powertrain Control Module (PCM).

Data Table: Stock 7.3 Powerstroke Turbocharger Specifications (Garrett TP38)

Below is a quick reference table summarizing the key 7.3 Powerstroke turbocharger specs for the factory Garrett TP38 unit.

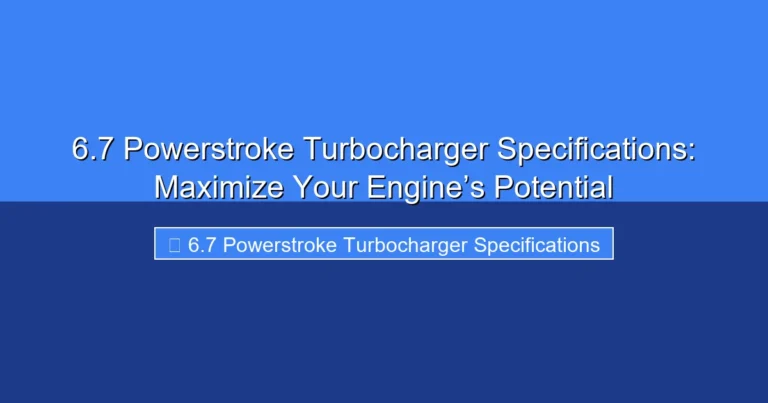

| Specification | Value (Approximate) | Notes |

|---|---|---|

| Turbocharger Model | Garrett TP38 | Factory installed turbocharger |

| Bearing Type | Journal Bearing | Oil-lubricated for robust operation |

| Compressor Wheel Inducer | ~59.87 mm | Air intake side |

| Compressor Wheel Exducer | ~80.00 mm | Air outlet side |

| Turbine Wheel Inducer | ~76.50 mm | Exhaust gas intake side |

| Turbine Wheel Exducer | ~67.56 mm | Exhaust gas outlet side |

| Turbine Housing A/R Ratio | 1.15 A/R | Affects spool-up and exhaust flow |

| Wastegate | Internal | Regulates peak boost pressure |

| Peak Boost (Stock) | 18-22 PSI | Typical operating range for a healthy unit |

| Exhaust Back Pressure Valve (EBPV) | Yes | For engine braking and faster warm-up |

Common Issues and Wear Points of the Stock 7.3L Turbo

Even with its legendary durability, the stock 7.3 Powerstroke turbocharger is not immune to wear and tear, especially given the age of these trucks. Recognizing common failure points and symptoms is crucial for preventative maintenance and timely repairs.

1. EBPV Malfunction and Leaks

The Exhaust Back Pressure Valve (EBPV) is arguably the most common culprit for issues with the stock 7.3 Powerstroke turbo.

- Sticking EBPV: The valve can become caked with soot and carbon, leading to it sticking in either the open or closed position. A stuck-closed valve causes excessive backpressure, higher EGTs (Exhaust Gas Temperatures), and restricted exhaust flow, severely impacting performance. A stuck-open valve can reduce engine braking effectiveness and potentially lead to slower warm-ups in cold weather.

- Actuator Leaks: The EBPV actuator, which uses engine oil pressure to operate the valve, can develop leaks. This is often indicated by oil dripping from the turbo pedestal area. An internal leak can also lead to a loss of oil pressure, affecting other engine components.

Many owners choose to perform an EBPV delete, which involves removing the valve and sometimes replacing the pedestal. This simplifies the system, eliminates a potential failure point, and can improve exhaust flow, though it sacrifices some engine braking.

2. Oil Leaks from Pedestal and Seals

The 7.3 Powerstroke turbocharger sits on a pedestal, and oil is routed through this pedestal to lubricate the turbo’s journal bearings.

- O-Ring Failure: Over time, the O-rings that seal the turbo to the pedestal, and the pedestal to the engine block, can harden and crack, leading to oil leaks. This is a very common source of oil drips under the truck.

- Internal Seal Leaks: While less common, the internal oil seals within the turbo itself can fail, leading to oil entering either the exhaust or intake side. Oil in the exhaust can cause excessive smoke, while oil in the intake can coat the intercooler and intake manifold, reducing efficiency.

3. Compressor Wheel and Bearing Wear

The journal bearings within the TP38 are robust but eventually wear out, especially if oil change intervals are neglected or low-quality oil is used.

- Shaft Play: Excessive radial (side-to-side) or axial (in-and-out) play in the turbo shaft indicates worn bearings. This can cause the compressor or turbine wheels to rub against their respective housings, leading to damage.

- Compressor Wheel Damage: Debris entering the intake system (e.g., from a failing air filter, or even small rocks) can nick or bend the delicate blades of the compressor wheel. This damage significantly reduces efficiency and can create an imbalance, accelerating bearing wear.

- “Dusting”: If the air filter isn’t sealing properly or is of poor quality, fine dust can enter the compressor housing. This acts like sandpaper, slowly eroding the compressor wheel and housing, a condition known as “dusting.” It’s irreversible and severely compromises turbo performance.

4. Turbine Housing Cracks

The turbine housing is subjected to extreme heat from the exhaust gases. Over time, especially with high EGTs (from heavy towing, aggressive tuning, or prolonged hard use), the cast iron can develop cracks. These cracks allow exhaust gas to escape before hitting the turbine wheel, reducing turbo efficiency and boost.

Regular inspection of these areas, listening for unusual noises (like a “siren” or “whistling” sound, often indicating bearing wear), and monitoring engine performance are key to catching these issues early. Addressing them promptly not only saves money in the long run but also keeps your 7.3 Powerstroke turbocharger performing optimally.

Upgrading Your 7.3 Powerstroke Turbo: Enhancing Performance and Reliability

While the stock 7.3 Powerstroke turbocharger is a workhorse, many owners seek to unlock more power, reduce EGTs, and improve overall driveability. The aftermarket offers a wide range of turbo upgrade options, from mild enhancements to complete overhauls. Choosing the right upgrade depends on your specific goals, budget, and supporting modifications.

Why Upgrade Your 7.3L Turbo?

The motivations for upgrading a 7.3 Powerstroke turbo are diverse:

- Increased Horsepower & Torque: The primary reason for most. A larger or more efficient turbo can push significantly more air, allowing for more fuel and thus more power.

- Lower EGTs: A more efficient turbo can reduce exhaust gas temperatures, especially when towing or under heavy load, prolonging engine life.

- Faster Spool-up: Some upgrades can improve throttle response by getting the turbo to build boost quicker.

- Improved Reliability: Modern turbo designs often incorporate better bearing systems (like ball bearings) and more robust materials.

- Support for Other Mods: If you’re upgrading injectors or tuning, a stock turbo will quickly become a bottleneck.

Popular Turbo Upgrade Options for Your 7.3 Powerstroke

1. Wicked Wheel 2 (WW2) Compressor Wheel Upgrade

This is often the first and most cost-effective upgrade for a stock 7.3 Powerstroke turbocharger. The WW2 is an aftermarket billet compressor wheel designed to replace the cast stock wheel.

- Benefits: Faster spool-up, reduced turbo “surge” (a fluttering sound under certain conditions), and slightly increased airflow. It’s a relatively easy install and a great value.

- Limitations: While it improves the stock turbo’s characteristics, it’s still limited by the overall design and turbine housing of the TP38. It won’t deliver massive power gains on its own but is an excellent foundational mod.

2. Garrett GTP38R Ball Bearing Turbocharger

The GTP38R is a direct bolt-on replacement for the stock TP38, but with significant internal upgrades. It’s considered one of the best “mild” upgrades for the 7.3 Powerstroke.

- Key Feature: Ball bearing cartridge system. This drastically reduces rotational friction compared to journal bearings, leading to much faster spool-up and better throttle response.

- Other Enhancements: Features a larger, billet compressor wheel and often a higher-flow turbine section compared to the stock TP38. It also has a more robust wastegate actuator.

- Benefits: Excellent balance of quick spool, improved power (typically supporting up to ~400 HP with supporting mods), and enhanced reliability. It’s a very popular choice for daily drivers and towing rigs.

3. KC Turbos and Other Hybrid/Custom Solutions

Companies like KC Turbos specialize in rebuilding and upgrading stock TP38 turbos or offering entirely new designs tailored for the 7.3 Powerstroke.

- Hybrid Turbos: These often involve fitting larger compressor and/or turbine wheels into modified stock housings. For example, a “38R-style” compressor with a larger exhaust wheel and housing.

- Common Offerings: Turbos like KC38R, KC S300 variants, etc. These can range from mild upgrades similar to the GTP38R to setups capable of supporting 500+ horsepower.

- Benefits: Tailored performance, often good value, and can be designed for specific power goals (e.g., better towing, competition).

- Considerations: May require more supporting modifications (injectors, fuel system, tuning) as power levels increase.

4. Larger Frame Aftermarket Turbos (e.g., S300 and S400 Based)

For serious power goals (500+ HP), stepping up to a larger frame turbocharger based on BorgWarner S300 or S400 platforms is often necessary.

- Characteristics: These are physically larger turbos with much higher airflow capabilities. They often require custom piping, different pedestals, and external wastegates.

- Benefits: Massive power potential, excellent for competition or extreme towing with proper setup.

- Drawbacks: Much more expensive, significantly more complex installation, often slower spool-up at lower RPMs (though modern designs have mitigated this), and absolutely require extensive supporting modifications (injectors, fuel, tuning, transmission upgrades, head studs). Not typically for casual use.

Considerations When Choosing an Upgrade

When selecting an upgrade for your 7.3 Powerstroke turbocharger, consider these factors:

- Your Goals: Daily driver, towing rig, street performance, or competition?

- Budget: Upgrades range from a few hundred dollars for a WW2 to several thousands for a complete turbo system.

- Supporting Modifications: Your turbo won’t perform optimally without adequate fuel delivery (injectors, fuel pump), sufficient airflow (intake, exhaust), and proper tuning.

- Installation Difficulty: Some are bolt-on; others require significant fabrication.

- EGR/Emissions Compliance: Check local regulations if you’re replacing emissions-related components. (Note: 7.3L Powerstrokes do not have EGR or DPF systems, simplifying matters for now).

Always consult with reputable diesel performance shops or experts to ensure you choose the best 7.3 Powerstroke turbo upgrade for your specific needs and ensure proper installation and tuning.

Beyond the Turbo: Supporting Modifications for Optimal 7.3 Powerstroke Performance

A powerful 7.3 Powerstroke turbocharger is only as good as the components around it. Think of your engine as an orchestra; the turbo might be the lead violinist, but without the percussion, brass, and woodwinds, the music falls flat. To truly optimize your 7.3 Powerstroke performance, you must consider a holistic approach that addresses fuel delivery, air intake, exhaust flow, and engine management. Neglecting these areas will bottleneck your turbo’s potential and can even lead to reliability issues.

1. Fuel System Upgrades

More air from an upgraded turbo means the engine needs more fuel to make power.

- Larger Injectors: The stock injectors (known as “AD” or “AC” codes for most ’99-03 trucks) are sufficient for stock power levels. However, as soon as you upgrade your turbo or tune aggressively, larger injectors (e.g., 160/30, 238/80, etc. referring to flow rate and nozzle size) become essential. These deliver more fuel per injection event.

- Fuel Pump and HPOP (High-Pressure Oil Pump): The stock “frame-mounted” fuel pump is often replaced with a higher-flow electric pump (e.g., FASS, AirDog, Walbro) to ensure adequate fuel supply to the injectors, especially under high demand. The High-Pressure Oil Pump (HPOP) is crucial for the 7.3L’s hydraulically actuated injectors (HEUI system). As you increase injector size, the HPOP works harder; upgrading to a “T500” or similar larger HPOP can maintain the necessary oil pressure for efficient injection.

2. Air Intake System

The turbo needs a free-flowing and clean supply of air to work efficiently.

- Cold Air Intake (CAI): An aftermarket CAI system typically replaces the restrictive stock airbox with a larger filter and smoother intake tubing. This allows the turbo to pull in more air with less restriction, improving efficiency and slightly reducing turbo noise. Crucially, ensure the filter offers excellent filtration to prevent “dusting” of the compressor wheel.

- Intercooler: While most 7.3Ls come with an intercooler, ensuring it’s clean and free of obstructions is important. For extreme power, larger aftermarket intercoolers can be considered, though less common than on newer diesels.

3. Exhaust System

Just as crucial as getting air in is getting exhaust gases out efficiently.

- Larger Diameter Exhaust: A 4-inch or 5-inch aftermarket exhaust system (replacing the stock 3-inch or 3.5-inch) significantly reduces exhaust backpressure. This allows the turbine wheel to spin more freely, improving turbo spool-up, reducing EGTs, and contributing to overall horsepower and torque gains.

- Turbine Housing Porting: Some advanced users will port the turbo’s turbine housing to smooth out exhaust flow, further reducing backpressure.

4. Engine Tuning (Custom ECM Calibration)

This is perhaps the most critical supporting modification. Without proper tuning, none of the other upgrades will perform optimally, and you risk engine damage.

- Custom Tunes: A reputable tuner will create custom engine calibrations (tunes) for your specific combination of turbo, injectors, and other modifications. This involves adjusting fuel delivery, injection timing, boost targets, and transmission shift points.

- Benefits: Maximizes power and efficiency, ensures safe EGTs, and provides smooth driveability across the RPM range. Off-the-shelf “canned” tunes are rarely ideal for modified trucks.

5. Monitoring Gauges

To ensure your modified 7.3 Powerstroke runs safely and efficiently, monitoring key parameters is non-negotiable.

- EGT Gauge (Exhaust Gas Temperature): Absolutely essential. High EGTs can melt pistons, crack cylinder heads, and damage your turbo. Keep EGTs below 1250°F (sustained) or 1400°F (briefly).

- Boost Gauge: Monitors the pressure your turbo is generating. Helps you understand turbo performance and diagnose potential issues.

- Fuel Pressure Gauge: Ensures your fuel system is adequately supplying fuel to the injectors under load.

- Transmission Temperature Gauge: Crucial for automatics, especially with increased power and towing.

By addressing these supporting systems in conjunction with your 7.3 Powerstroke turbocharger specs, you create a cohesive and powerful package that not only performs exceptionally but also remains reliable for years to come.

Maintenance Essentials for Your 7.3 Powerstroke Turbocharger

Even with robust factory 7.3 Powerstroke turbocharger specs, consistent maintenance is the bedrock of longevity and sustained performance. Neglecting your turbo can lead to premature wear, reduced efficiency, and costly repairs. Adhering to a diligent maintenance schedule will keep your 7.3 Powerstroke turbo spinning optimally and extend its lifespan.

1. Regular Oil Changes and Quality Oil

This is perhaps the single most critical maintenance item for any turbocharger, especially the journal-bearing Garrett TP38.

- Frequent Changes: Turbochargers rely on clean engine oil for lubrication and cooling. Contaminated or degraded oil quickly leads to premature bearing wear. Follow or exceed the manufacturer’s recommended oil change intervals, typically every 3,000-5,000 miles for a 7.3 Powerstroke under normal use. If you’re towing heavily, running high horsepower, or frequently driving in dusty conditions, consider even shorter intervals.

- Quality Oil: Use a high-quality, heavy-duty diesel engine oil (typically 15W-40) that meets Ford’s specifications (e.g., API CI-4 Plus or CJ-4, though newer CK-4 is also suitable). These oils contain additives that resist breakdown under high heat and pressure.

- Oil Filter: Always replace the oil filter with a new, high-quality filter at every oil change.

2. Air Filter Maintenance and Inspection

Clean, unrestricted airflow is vital for turbo health and efficiency.

- Regular Inspection: Visually inspect your air filter frequently, especially if you drive in dusty environments. A dirty filter restricts airflow, forcing the turbo to work harder, and can even compromise filtration.

- Replacement: Replace your air filter according to manufacturer recommendations or sooner if it appears clogged or dirty. Use a high-quality filter (e.g., Motorcraft, Baldwin, Donaldson, AFE, S&B) that ensures excellent filtration and airflow.

- Check for Leaks: Ensure all connections in the intake system, from the airbox to the turbo inlet, are tight and free of cracks or leaks. Even small leaks can allow unfiltered air into the turbo, leading to “dusting” of the compressor wheel, which is irreversible damage.

3. Exhaust System and EBPV Checks

Proper exhaust flow is crucial for the turbine side of the turbo.

- Exhaust Backpressure Valve (EBPV): If you still have the EBPV, periodically check its operation. Listen for unusual noises during cold starts or engine braking. If it starts to stick, consider cleaning it or performing an EBPV delete for simplicity and improved exhaust flow.

- Exhaust Leaks: Inspect the exhaust manifold, up-pipes, and downpipe for any leaks. Leaks before the turbine housing reduce the energy hitting the turbine, leading to less boost and slower spool-up.

4. Cool-Down Procedures

This is an often-overlooked but crucial practice for turbo longevity, particularly after heavy loads or high-speed driving.

- Idle Time: After hard driving, towing, or long highway stretches, allow the engine to idle for 2-5 minutes before shutting it off. This allows oil to continue flowing through the turbo’s bearings, dissipating residual heat.

- Prevent “Coking”: If you shut down a hot engine immediately, the oil supply to the turbo stops, but the extreme heat in the turbocharger can “coke” (burn) the stagnant oil in the bearings. This leaves hard carbon deposits that restrict oil flow and rapidly wear down the bearings.

5. Listen and Observe

Your 7.3 Powerstroke turbocharger often provides audible clues when something isn’t right.

- Unusual Sounds: Listen for excessive whistling (beyond normal turbo whine), a “siren” sound (often indicative of bearing failure), or metallic scraping (wheel contact with housing).

- Smoke: Blue or white smoke from the exhaust could indicate oil burning, possibly from a leaking turbo seal. Black smoke indicates too much fuel or not enough air.

- Performance Changes: A noticeable drop in power, slower spool-up, or reduced boost could signal turbo issues.

By integrating these maintenance practices into your routine, you’re not just preserving the integrity of your 7.3 Powerstroke turbocharger specs; you’re actively ensuring your beloved diesel continues to deliver the reliable power and performance it’s famous for. Proactive care is always more cost-effective than reactive repairs.

Conclusion: Mastering Your 7.3 Powerstroke Turbo for Peak Performance

The 7.3 Powerstroke turbocharger is an engineering marvel that defines the character and capability of one of the most beloved diesel engines ever produced. From its humble yet robust beginnings as the Garrett TP38, designed to provide reliable power for the working man, to the myriad of aftermarket upgrades available today, understanding its inner workings and requirements is paramount for any dedicated owner. We’ve delved deep into the factory 7.3 Powerstroke turbocharger specs, identifying the core components, their functions, and the common pitfalls that can arise over years of dedicated service.

Whether your goal is to simply maintain the legendary durability of your stock setup or to unlock significantly more horsepower and torque, the journey begins with knowledge. We’ve highlighted how crucial proactive maintenance, such as diligent oil changes and air filter inspections, is for preserving the health of your turbo. Furthermore, we’ve explored the exciting world of turbo upgrades, from the quick-spooling Garrett GTP38R to more aggressive hybrid and large-frame solutions, each promising a unique enhancement to your truck’s performance.

Remember, the turbo doesn’t work in isolation. Achieving optimal 7.3 Powerstroke performance requires a holistic approach, where supporting modifications like fuel system upgrades, enhanced air intake, free-flowing exhaust, and precise custom tuning work in harmony. Without these, even the most advanced turbo upgrade will struggle to deliver its full potential, and reliability can be compromised.

Your 7.3 Powerstroke is more than just a truck; it’s a legacy. By understanding its turbocharger specifications and committing to smart maintenance and informed upgrades, you’re not just ensuring its longevity, but also maximizing its legendary power and efficiency. So go forth, embrace the rumble, and keep that turbo spinning strong for countless miles to come! Your beast deserves nothing less.

🎥 Related Video: How to choose the right turbocharger || EXPLAINED

📺 MZopyrus

In this video I explain how to choose the correct turbo size for your car! All the formulas and calculations are in the video. Let me …

Frequently Asked Questions

What are the stock 7.3 Powerstroke turbocharger specs?

The factory 7.3 Powerstroke came equipped with a Garrett GTP38 turbocharger, featuring a 66mm compressor wheel and a 76mm turbine wheel. This setup also includes an Exhaust Back Pressure Valve (EBPV) housing on the turbine side, which can restrict exhaust flow, especially with performance modifications.

What are the most common upgrades to improve 7.3 Powerstroke turbocharger performance?

Popular upgrades include installing a “Wicked Wheel” compressor wheel for better spool and reduced surge, or upgrading to a 1.0 A/R exhaust housing to lower exhaust back pressure. For more significant gains, a larger compressor and turbine wheel upgrade or a full ball-bearing turbo conversion can be pursued.

How can I tell if my 7.3 Powerstroke turbocharger is failing or needs service?

Common signs of a failing turbo include excessive black or blue smoke from the exhaust, a noticeable loss of power or increased turbo lag, and a distinct whining or whistling sound. You might also observe oil leaks around the turbo housing or shaft play when inspecting the compressor wheel.

Can I improve my 7.3 Powerstroke turbocharger specs without replacing the entire turbo?

Absolutely! Many owners opt for cost-effective internal upgrades like a high-flow compressor wheel (e.g., Wicked Wheel) to enhance spool-up and reduce surge. Replacing the restrictive EBPV housing with a non-EBPV 1.0 A/R housing is another excellent way to improve exhaust flow and lower EGTs.

What are the benefits of upgrading to an aftermarket turbo for a 7.3 Powerstroke?

Upgrading to an aftermarket turbo typically provides significantly increased airflow, allowing for more power potential and better efficiency across the RPM range. You can expect quicker spool-up, reduced exhaust gas temperatures (EGTs), and a broader powerband, especially when paired with appropriate fuel system and tuning modifications.

How much boost should my 7.3 Powerstroke turbocharger make, and what’s considered too much?

A stock 7.3 Powerstroke turbocharger typically produces around 18-22 PSI of boost under full load. With performance tuning and minor modifications, boost levels can safely range from 25-30 PSI. Exceeding 35-40 PSI on a stock or mildly upgraded turbo can lead to premature wear, compressor surge, and potentially damage internal engine components if not properly managed.