7.3 Powerstroke EGR Cooler Specifications: How to Keep Your Engine Clean

Featured image for this comprehensive guide about 7.3 Powerstroke EGR cooler specifications

Image source: i.ytimg.com

7.3 Powerstroke EGR Cooler Specifications: How to Keep Your Engine Clean

Ah, the 7.3 Powerstroke – a legendary engine revered for its reliability, power, and often, its surprisingly simple mechanical design compared to its younger siblings. If you’re a proud owner of one of these workhorses, you’re likely passionate about keeping it running in peak condition. As part of your research into maintaining this iconic diesel, you might have stumbled upon discussions about EGR coolers and found yourself wondering about 7.3 Powerstroke EGR cooler specifications. It’s a natural line of inquiry, especially given the complexities of modern diesel emissions systems.

However, here’s where we need to clarify a crucial point right from the start: the factory 7.3 Powerstroke engine, produced between 1994.5 and 2003, did not come equipped with an Exhaust Gas Recirculation (EGR) system, and therefore, no EGR cooler. That’s right – your beloved 7.3, in its original configuration, operates without this component. This distinction is vital for understanding its unique maintenance needs and why information regarding 7.3 Powerstroke EGR cooler specifications might seem elusive or confusing.

So, why the persistent search for 7.3 Powerstroke EGR cooler specifications? Often, it stems from confusion with later Powerstroke generations (like the 6.0L, 6.4L, and 6.7L) that heavily rely on EGR systems to meet increasingly stringent emissions standards. While your 7.3 may not have an EGR cooler, the principles of keeping your engine clean, efficient, and long-lasting are paramount. In this comprehensive guide, we’ll dive deep into this common misconception, explain why the 7.3 stands apart, and provide you with actionable insights and specifications for the components that truly matter to your engine’s health and longevity. Let’s unravel the mysteries and ensure your 7.3 continues to roar for years to come!

Quick Answers to Common Questions

Does my 7.3 Powerstroke actually have an EGR cooler?

No, the 7.3 Powerstroke engine was designed without an EGR cooler or an EGR system from the factory, unlike its later Powerstroke counterparts. This means you won’t find 7.3 Powerstroke EGR cooler specifications in your owner’s manual!

If there’s no stock 7.3 Powerstroke EGR cooler, why am I hearing about them?

This is a common confusion! Many owners mistake the 7.3 with newer Powerstroke models (like the 6.0L or 6.4L) that do incorporate EGR coolers for emissions control. Don’t worry, your 7.3 is just built differently.

Does the absence of a 7.3 Powerstroke EGR cooler affect engine cleanliness or performance?

Actually, not having an EGR system means less soot and carbon buildup within your intake, which helps keep your 7.3 Powerstroke engine inherently cleaner than those with EGR. This often translates to robust, long-lasting performance!

Are there aftermarket 7.3 Powerstroke EGR cooler options available for my truck?

Generally, no. Since the 7.3 Powerstroke wasn’t designed with an EGR system, aftermarket solutions for an EGR cooler are virtually non-existent. People often look for EGR delete kits for newer models, not additions for a 7.3.

What does this mean for maintaining my 7.3 Powerstroke without an EGR cooler?

It means you don’t have to worry about EGR cooler-related issues like clogs or failures! Focus on regular oil changes, fuel filter replacements, and keeping your air filter clean to ensure your 7.3 Powerstroke runs strong and spotless.

📋 Table of Contents

- The 7.3 Powerstroke and the EGR Cooler: Clarifying a Common Misconception

- Why the 7.3 Powerstroke Doesn’t Have a Factory EGR System

- Understanding EGR Systems (A General Overview for Diesel Engines)

- Maintaining Your 7.3 Powerstroke for Optimal Cleanliness and Longevity

- Powerstroke Emissions System Comparison: EGR Presence Across Generations

- EGR Cooler Delete Kits: A Discussion (Mostly for Later Powerstrokes)

- Conclusion: Embracing the 7.3 Powerstroke’s Unique Cleanliness

The 7.3 Powerstroke and the EGR Cooler: Clarifying a Common Misconception

The quest for 7.3 Powerstroke EGR cooler specifications is a well-trodden path for many owners, but it’s built on a foundation of misunderstanding. Let’s set the record straight: the 7.3 Powerstroke, known for its robustness and mechanical simplicity, was designed and produced before the era of widespread and mandatory Exhaust Gas Recirculation systems for light-duty diesel trucks in the U.S. This means that from the factory, your 1994.5-2003 7.3L Powerstroke simply does not have an EGR valve or an EGR cooler.

This isn’t a design flaw or an oversight; it’s a testament to the emissions standards of its time. The 7.3L primarily met federal emissions requirements through its combustion efficiency and, in later years, through a catalytic converter. It predates the introduction of more complex exhaust aftertreatment systems seen in subsequent diesel engines, which include the EGR system, Diesel Particulate Filters (DPF), and Selective Catalytic Reduction (SCR).

| Specification/Component | 7.3L Powerstroke (1994-2003) | Notes/Context |

|---|---|---|

| EGR System Presence | Not equipped from the factory. | The 7.3L Powerstroke predates the widespread mandate for EGR systems in US diesel engines. |

| EGR Cooler Presence | Not applicable (no factory EGR cooler). | As there is no EGR system, there is no need for an EGR cooler to reduce exhaust gas temperatures. |

| Primary NOx Reduction Method | Engine design, optimized combustion, and fuel injection strategy. | NOx emissions were managed without the use of exhaust gas recirculation. |

| Applicable Emission Standards | Pre-2004 US EPA diesel emissions standards (e.g., Tier 0/1 for light-duty vehicles). | Stricter standards (e.g., EPA 2007, 2010) mandated advanced EGR and DPF systems for later Powerstroke engines. |

| Aftermarket “EGR Delete” Relevance | Not relevant for the 7.3L Powerstroke. | An EGR delete is only applicable to engines originally equipped with an EGR system (e.g., 6.0L, 6.4L, 6.7L Powerstroke). |

So, when you search for “7.3 Powerstroke EGR cooler specifications,” you won’t find genuine OEM parts or technical data because they don’t exist for this engine. Any aftermarket “EGR cooler” advertised for a 7.3 Powerstroke is either mislabeled, designed for a different application (perhaps a heavy-duty variant or an experimental setup), or potentially part of a very niche, custom emissions-compliant modification that is not standard or widely recognized. For the vast majority of 7.3 Powerstroke owners, the absence of an EGR cooler means one less complex component to worry about, maintain, or replace.

Why the Confusion? The Evolution of Powerstroke Engines

The confusion largely arises when 7.3 Powerstroke owners encounter discussions about EGR systems in the broader Powerstroke community. Later iterations, specifically the 6.0L Powerstroke (2003-2007), the 6.4L Powerstroke (2008-2010), and the 6.7L Powerstroke (2011-present), were all equipped with sophisticated EGR systems, including EGR coolers, right from the factory. These engines were designed under much stricter emissions regulations, necessitating the recirculation of a portion of exhaust gases back into the engine’s combustion chambers to reduce nitrogen oxide (NOx) emissions.

This generational leap in emissions technology meant a significant increase in complexity and new failure points, such as EGR cooler failures. It’s these later engines that commonly require attention to EGR cooler maintenance, EGR cooler replacement, or even EGR cooler delete modifications (where legal and applicable for off-road use only). Therefore, when searching for solutions related to engine cleanliness or emissions, it’s easy for 7.3 owners to mistakenly apply information relevant to 6.0L or 6.4L engines to their own.

Why the 7.3 Powerstroke Doesn’t Have a Factory EGR System

Understanding why the 7.3 Powerstroke eschews the EGR system is crucial for appreciating its design philosophy and operational characteristics. It boils down to the historical context of emissions regulations and engineering priorities during its production run.

When the 7.3 Powerstroke was introduced in late 1994, federal emissions standards for light-duty diesel trucks were significantly less stringent than they are today. The primary focus was on particulate matter (soot) and overall engine efficiency. The 7.3L, with its robust direct-injection design and large displacement, was capable of meeting these standards through relatively simple means: precise fuel injection timing, efficient combustion, and in later models, an oxidation catalytic converter.

Emissions Standards and Engine Design

- Pre-2003 Landscape: The early-to-mid 2000s marked a turning point in diesel emissions regulations. Prior to this, NOx reduction was not as high a priority for light-duty diesels as it became in later years. The 7.3L was designed to comply with standards that did not mandate the significant NOx reductions that an EGR system provides.

- Focus on Simplicity and Durability: Ford and Navistar (the original manufacturer of the International T444E, on which the 7.3 Powerstroke is based) prioritized simplicity, reliability, and sheer pulling power. Adding a complex EGR system would have increased manufacturing costs, added potential failure points, and complicated maintenance, without a compelling regulatory need at the time.

- The Rise of EGR: The 6.0L Powerstroke, introduced in 2003, was the first Ford diesel truck engine to feature a factory EGR system. This was a direct response to the Environmental Protection Agency’s (EPA) Tier 2 and Tier 3 emissions regulations, which set much lower limits for NOx. The 6.0L’s EGR cooler and associated components became a necessary, albeit often problematic, part of its emissions strategy.

In essence, the 7.3 Powerstroke‘s lack of an EGR cooler is a feature, not a bug, reflecting an era when diesel engines were engineered with a different set of regulatory and performance priorities. This contributes significantly to its reputation for uncomplicated maintenance and long-term durability, as owners don’t have to contend with the common EGR cooler issues that plague later models.

Understanding EGR Systems (A General Overview for Diesel Engines)

While the 7.3 Powerstroke doesn’t have an EGR system, understanding how these systems work is beneficial, especially if you also own newer diesels or are simply curious about modern diesel technology. The primary function of an Exhaust Gas Recirculation (EGR) system is to reduce nitrogen oxide (NOx) emissions, which are harmful pollutants produced during high-temperature combustion.

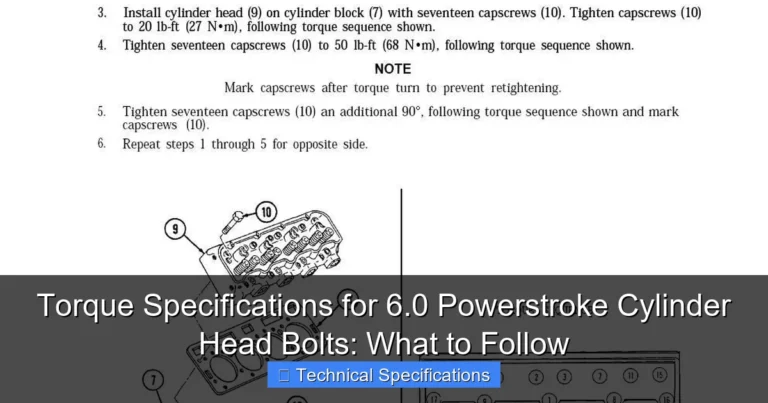

Here’s how a typical diesel EGR system functions:

- Exhaust Gas Diversion: A portion of the exhaust gas, after exiting the engine, is diverted before reaching the exhaust pipe.

- Cooling (EGR Cooler): This hot exhaust gas then passes through an EGR cooler. The cooler, typically a heat exchanger, uses engine coolant to significantly lower the temperature of the exhaust gas. Cooling the gas increases its density, allowing more gas to be recirculated, and also reduces the overall temperature within the combustion chamber when it’s reintroduced.

- Metering (EGR Valve): After cooling, the exhaust gas is regulated by an EGR valve. This valve precisely controls the amount of exhaust gas that is allowed back into the intake manifold.

- Reintroduction into Intake: The cooled and metered exhaust gas mixes with fresh incoming air and is drawn back into the engine’s cylinders.

- NOx Reduction: By introducing inert exhaust gas into the combustion chamber, the peak combustion temperatures are lowered. Lower combustion temperatures directly translate to reduced formation of NOx.

Types of EGR Coolers and Common Issues

EGR coolers come in various designs, but the most common for light-duty diesels are tube-and-fin or plate-style heat exchangers. They are critical for the efficient operation of the EGR system. However, they are also prone to specific problems:

- Clogging: Soot and carbon deposits from the exhaust gas can accumulate inside the cooler, restricting exhaust flow and reducing its cooling efficiency. This is a common EGR cooler issue.

- Cracking/Leaking: The extreme thermal cycles (hot exhaust, cold coolant) and corrosive nature of exhaust gases can cause the cooler’s internal passages to crack. A leaking EGR cooler can allow coolant to enter the exhaust system or combustion chamber, leading to white smoke, coolant loss, hydrostatic lock, and severe engine damage.

- Reduced Performance: A failing or clogged EGR cooler can lead to inefficient EGR operation, which in turn can cause increased NOx emissions, reduced fuel economy, and a decrease in engine performance.

These are the types of challenges that owners of later Powerstroke engines (6.0L, 6.4L, 6.7L) frequently face, but which are thankfully absent from the maintenance routine of a 7.3 Powerstroke.

Maintaining Your 7.3 Powerstroke for Optimal Cleanliness and Longevity

Since your 7.3 Powerstroke doesn’t have an EGR cooler, your focus shifts to other critical areas to ensure its legendary reliability and keep your engine running clean and strong. The principles of proper maintenance for a 7.3 are about ensuring optimal combustion, protecting vital components, and preventing carbon buildup where it can occur. Ignoring these can lead to decreased engine performance, reduced fuel economy, and costly repairs.

Key Maintenance Areas for a Healthy 7.3

To keep your 7.3 Powerstroke in top shape, pay close attention to these components and systems:

- Fuel System Health:

- Fuel Filter Replacement: Crucial for preventing contaminants from reaching your 7.3 Powerstroke injectors. Replace at recommended intervals (typically every 10,000-15,000 miles, or more frequently if using lower quality fuel).

- Fuel Quality: Use high-quality diesel fuel. Consider adding a reputable diesel fuel additive for lubrication, cetane boost, and to keep the fuel system clean.

- Injector Maintenance: While not a maintenance item in the traditional sense, healthy injectors are vital for clean combustion. Poor spray patterns can lead to carbon buildup and reduced efficiency.

- Oil System Integrity:

- Oil and Filter Changes: Regular oil changes with high-quality, correct-specification diesel engine oil are paramount. The 7.3 Powerstroke uses its engine oil not just for lubrication but also to actuate the injectors (HEUI system). Dirty or degraded oil can severely impact 7.3 Powerstroke engine performance and longevity. Adhere to 5,000-7,500 mile intervals.

- Oil Cooler: While not an EGR cooler, the 7.3 does have an engine oil cooler. Ensure your cooling system is properly maintained to prevent oil temperatures from rising too high, which can degrade oil quickly.

- Air Intake System:

- Air Filter: A clean air filter is essential for proper combustion. A restricted air filter can cause the engine to run rich, leading to more soot and reduced power. Check and replace as needed, often every 15,000-30,000 miles, depending on driving conditions.

- Boost Leaks: Inspect turbocharger intercooler (CAC) boots and piping for cracks or loose clamps. Boost leaks can significantly impact 7.3 Powerstroke performance and fuel economy.

- Cooling System:

- Coolant Flushes and Quality: Maintain your cooling system with regular flushes and proper diesel-specific coolant (e.g., Extended Life Coolant or fully formulated coolants with SCA additives). A well-functioning cooling system is critical for overall diesel engine longevity.

- Thermostat and Water Pump: Ensure these components are functioning correctly to maintain optimal engine operating temperatures.

- Turbocharger Health:

- Regular Inspection: While the 7.3 turbo is generally robust, inspect for shaft play, oil leaks, and exhaust leaks. A healthy turbo ensures efficient airflow and power delivery, preventing excessive soot.

By focusing on these areas, you ensure your 7.3 Powerstroke operates at its cleanest and most efficient, bypassing the specific EGR cooler issues that later engines encounter. This proactive approach is the real secret to the 7.3 Powerstroke‘s legendary diesel engine longevity.

Powerstroke Emissions System Comparison: EGR Presence Across Generations

To further clarify the context around EGR systems and the 7.3 Powerstroke, let’s look at a comparative table outlining the presence of key emissions components across different Powerstroke generations. This table highlights why discussions about EGR coolers are primarily relevant to post-2003 engines and why 7.3 Powerstroke EGR cooler specifications simply don’t exist.

| Powerstroke Engine | Production Years | EGR System (Valve & Cooler) | Diesel Particulate Filter (DPF) | Selective Catalytic Reduction (SCR) / DEF | Primary NOx Reduction Strategy |

|---|---|---|---|---|---|

| 7.3L Powerstroke | 1994.5 – 2003 | NO (Not Present) | NO | NO | Combustion Efficiency, Catalytic Converter (later models) |

| 6.0L Powerstroke | 2003 – 2007 | YES | NO | NO | EGR System |

| 6.4L Powerstroke | 2008 – 2010 | YES | YES | NO | EGR System, DPF |

| 6.7L Powerstroke | 2011 – Present | YES | YES | YES | EGR System, DPF, SCR (DEF) |

As you can clearly see from the table, the 7.3 Powerstroke stands apart as the only engine generation that did not incorporate a factory EGR system. This is a significant factor in its reputation for simpler maintenance and fewer emissions-related failures compared to its successors. The evolution of diesel engine longevity has been increasingly intertwined with the complexity of emissions controls, making the 7.3 a unique anomaly in the modern diesel landscape.

EGR Cooler Delete Kits: A Discussion (Mostly for Later Powerstrokes)

The term “EGR cooler delete” frequently comes up in discussions about diesel emissions systems, particularly concerning the 6.0L and 6.4L Powerstrokes. While it’s a common search term that might lead 7.3 Powerstroke owners to wonder about its relevance, it’s important to understand that an EGR cooler delete kit is almost exclusively applicable to engines that actually have an EGR system from the factory.

What is an EGR Cooler Delete?

An EGR cooler delete typically involves removing the existing EGR cooler and often the EGR valve, and replacing them with block-off plates and a new standpipe. This modification prevents exhaust gases from being recirculated back into the engine. The primary reasons owners of later Powerstrokes consider an EGR cooler delete include:

- Preventing Failures: EGR cooler failures (leaks, clogs) are a known weak point in some later Powerstroke engines. Deleting the system eliminates this potential failure point.

- Improving Reliability: By removing complex components and reducing carbon buildup in the intake, owners aim to improve overall engine reliability.

- Enhanced Performance: Some argue that an EGR delete can lead to slightly improved engine performance and fuel economy by allowing the engine to run on cooler, cleaner air exclusively.

- Maintenance Reduction: It simplifies the engine bay and reduces the number of components requiring maintenance related to the EGR system.

Legality and Your 7.3 Powerstroke

It’s crucial to state that performing an EGR cooler delete on any road-going vehicle is illegal in the U.S. and many other regions for emissions-controlled vehicles. These modifications are intended for off-road, competition, or export use only. Altering emissions equipment on a vehicle used on public roads can result in significant fines and the inability to pass emissions inspections.

For your 7.3 Powerstroke, the concept of an EGR cooler delete is largely moot. Since the engine was never equipped with an EGR cooler to begin with, there’s nothing to delete in that regard. Any “delete kit” advertised for a 7.3 is likely a generic product that targets other non-EGR related emissions devices (if any were present) or is simply miscategorized. The closest equivalent modifications for a 7.3 might involve upgrading the exhaust system (e.g., removing the catalytic converter in off-road applications) or optimizing the turbocharger and fuel system for better airflow and combustion, but these are distinct from an EGR cooler delete.

Therefore, if you’re a 7.3 Powerstroke owner, you can cross “EGR cooler delete” off your list of potential modifications or maintenance concerns, as it simply doesn’t apply to your factory setup. Focus instead on the core maintenance practices that truly enhance your engine’s natural strengths.

Conclusion: Embracing the 7.3 Powerstroke’s Unique Cleanliness

The journey to understand 7.3 Powerstroke EGR cooler specifications ultimately leads to a liberating realization: your iconic 7.3 simply doesn’t have one! This fundamental difference from later Powerstroke generations is a key factor in its renowned durability and simpler maintenance profile. While the absence of an EGR cooler might initially cause confusion, it also eliminates a common source of headaches and costly repairs that plague many modern diesel engines.

Instead of searching for EGR cooler replacement parts or contemplating an EGR cooler delete, 7.3 Powerstroke owners can redirect their focus to the core elements that truly dictate their engine’s health and diesel engine longevity. Diligent attention to the fuel, oil, air, and cooling systems—ensuring quality inputs and timely changes—is the real secret to keeping your engine clean, powerful, and ready for countless more miles.

Embrace the mechanical honesty of your 7.3 Powerstroke. Its design, free from the complexities of an EGR system, means less to go wrong and a more straightforward path to maintenance. By adhering to a rigorous maintenance schedule and understanding the unique needs of your engine, you’re not just preserving a vehicle; you’re safeguarding a legacy of engine performance and reliability. Drive on with confidence, knowing that your 7.3 is a testament to an era of robust diesel engineering, unburdened by the emissions hardware of its successors.

Frequently Asked Questions

Did the 7.3 Powerstroke originally come equipped with an EGR cooler?

No, the 7.3 Powerstroke engine, produced from 1994.5 to 2003, did not come from the factory with an Exhaust Gas Recirculation (EGR) system or an EGR cooler. This emissions control technology was introduced in later Powerstroke models to meet stricter environmental regulations.

Why might I be seeing “7.3 Powerstroke EGR cooler specifications” if it wasn’t factory installed?

You might encounter this topic due to common confusion with later Powerstroke engines (like the 6.0L or 6.4L) which did feature EGR coolers. Occasionally, aftermarket discussions or mislabeled information online could also lead to searches about a non-existent factory 7.3 Powerstroke EGR cooler.

What is the function of an EGR cooler in a diesel engine, and how does it relate to keeping the engine clean?

An EGR cooler’s primary function is to reduce the temperature of exhaust gases before they are recirculated back into the engine’s intake manifold. By lowering combustion temperatures, it helps to reduce the formation of nitrogen oxides (NOx) emissions, which contributes to overall engine cleanliness by managing exhaust gas composition.

Are there aftermarket EGR cooler options available for the 7.3 Powerstroke?

There are no readily available aftermarket “EGR cooler” kits specifically designed to add a complete EGR system to the 7.3 Powerstroke, as the engine was not designed for it. While custom fabrication or highly specialized modifications might be conceivable, they are not common or recommended for this engine platform.

What are common issues or maintenance concerns associated with EGR coolers in other Powerstroke engines?

In Powerstroke engines that do have them (e.g., 6.0L, 6.4L), common issues include clogging from carbon deposits, coolant leaks, and internal failure due to thermal stress. Regular maintenance, such as flushing the cooling system and monitoring for coolant loss, is crucial to prevent these problems and ensure the EGR cooler functions correctly.

How can I keep my 7.3 Powerstroke engine clean and ensure longevity without an EGR cooler?

To maintain a clean and healthy 7.3 Powerstroke, focus on consistent preventative maintenance like regular oil and filter changes, using high-quality fuel, and ensuring the air intake system is clean. Monitoring exhaust gas temperatures (EGTs) and considering a quality fuel additive can also help keep internal components clean and extend engine life.