6.7 Powerstroke Engine Specifications: Detailed Insights into Performance

Featured image for this comprehensive guide about 6.7 Powerstroke engine specifications

The roar of a diesel engine, the undeniable pulling power, and the sheer capability of a heavy-duty truck are sensations intimately familiar to anyone who’s ever depended on a Ford F-Series Super Duty. At the heart of these workhorses since 2011 lies a marvel of modern engineering: the 6.7 Powerstroke diesel engine. This engine isn’t just a component; it’s a testament to Ford’s commitment to power, efficiency, and reliability in the demanding world of commercial and heavy-duty personal use.

For truck enthusiasts, fleet managers, and anyone considering a Super Duty, understanding the intricacies of its powerhouse is crucial. It’s more than just horsepower and torque numbers; it’s about the underlying design, the advanced technologies, and the careful balance of performance and emissions compliance that makes this engine stand out. From its innovative turbocharger placement to its robust block construction, every detail plays a role in its legendary performance.

This comprehensive guide delves deep into the fascinating world of the 6.7 Powerstroke engine specifications. We’ll explore its history, dissect its core mechanical components, analyze its evolving performance metrics, and highlight the advanced engineering that defines it. Whether you’re a seasoned diesel mechanic or simply curious about what makes your Super Duty tick, prepare for an insightful journey into the heart of one of the most respected diesel engines on the market.

Quick Answers to Common Questions

Kicking things off, how much horsepower and torque does a 6.7 Powerstroke engine typically crank out?

Depending on the year, the 6.7 Powerstroke engine can deliver impressive figures, often ranging from 400-500 horsepower and 800-1200+ lb-ft of torque, making it a towing powerhouse!

What’s the actual displacement of the 6.7 Powerstroke?

The “6.7” in its name refers to its 6.7-liter displacement. This V8 engine configuration is designed for heavy-duty performance and efficiency.

Many wonder about durability; how reliable is the 6.7 Powerstroke engine generally considered to be?

While early models had some known issues, Ford has continuously refined the 6.7 Powerstroke, and later generations are widely regarded as very reliable, especially with proper maintenance.

What kind of turbocharger system does the 6.7 Powerstroke utilize to achieve its robust power?

The 6.7 Powerstroke uses a Garrett variable geometry turbocharger (VGT), allowing for excellent boost response across the RPM range and contributing to its impressive towing capabilities.

Let’s talk fuel: what type of fuel injection system is found in the 6.7 Powerstroke?

The 6.7 Powerstroke employs a high-pressure common rail (HPCR) fuel injection system. This sophisticated system uses precise electronic control for optimal fuel delivery, performance, and emissions.

📋 Table of Contents

- The Evolution of Power: A Brief History of the 6.7 Powerstroke

- Core Mechanics: Unveiling Key 6.7 Powerstroke Engine Specifications

- Performance Metrics: Horsepower, Torque, and Towing Capabilities

- Advanced Engineering: Design Innovations and Component Breakdown

- Maintaining the Beast: Tips for Longevity and Reliability

- The 6.7 Powerstroke Legacy: A Concluding Perspective

The Evolution of Power: A Brief History of the 6.7 Powerstroke

The journey of the 6.7 Powerstroke began not with a quiet hum, but with a thunderous declaration of independence. Prior to 2011, Ford had relied on external partners for its Powerstroke diesel engines. However, facing increasing pressure from stringent emissions regulations and a desire for greater control over engine development, Ford made a pivotal decision: they would design and build their next heavy-duty diesel engine entirely in-house. This marked the birth of the “Scorpion” engine, which we now universally know as the 6.7 Powerstroke diesel engine.

Introduced in the 2011 model year F-Series Super Duty trucks, the 6.7 Powerstroke was a fresh start. It replaced the previous 6.4-liter Powerstroke, bringing with it a host of new technologies and a significant leap in power, all while meeting the challenging new emissions standards. This first iteration delivered an impressive 400 horsepower and 800 lb-ft of torque, immediately setting a new benchmark in the heavy-duty truck segment.

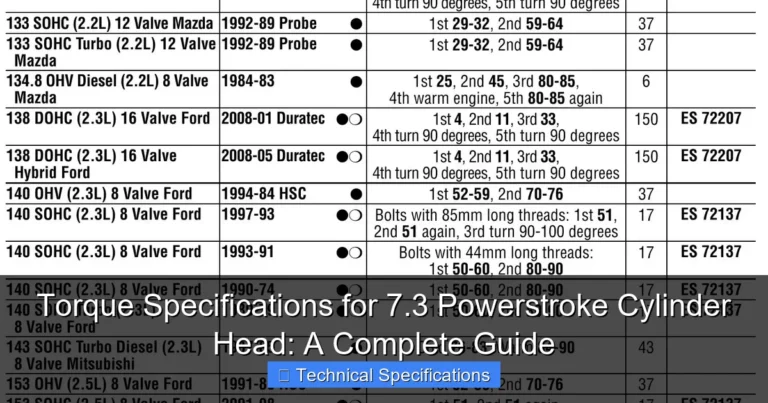

| Specification | Value | Details / Notes |

|---|---|---|

| Engine Configuration | V8, 32-Valve Diesel | Overhead Valve (OHV) |

| Displacement | 6.7 Liters (406 cu. in.) | |

| Max Horsepower | 500 hp | (e.g., 2023+ models) at 2,600 rpm |

| Max Torque | 1,200 lb-ft | (e.g., 2023+ models) at 1,600 rpm |

| Induction System | Single Variable Geometry Turbocharger | Often referred to as “GT37” or “GT3788R” |

| Fuel System | High-Pressure Common Rail | Piezoelectric Direct Injection |

What truly defines the 6.7 Powerstroke‘s history is its continuous evolution. Ford hasn’t rested on its laurels, consistently pushing the boundaries of what this engine can achieve. Each subsequent generation of the Super Duty brought with it refinements and upgrades to the 6.7 Powerstroke engine specifications, resulting in increased power, improved fuel efficiency, and enhanced reliability. From upgraded turbochargers and fuel systems to revised cylinder heads and internal components, the engine has been a dynamic platform for innovation. This commitment to improvement has solidified its reputation as a reliable and powerful choice for demanding truck owners.

Core Mechanics: Unveiling Key 6.7 Powerstroke Engine Specifications

To truly appreciate the 6.7 Powerstroke, we must look beyond the glossy marketing materials and delve into its fundamental mechanical architecture. This engine is a carefully engineered symphony of components designed for extreme durability and efficiency. Understanding these core 6.7 Powerstroke engine specifications provides insight into why it performs the way it does.

Engine Block and Internal Components

- Displacement: At its heart, the 6.7 Powerstroke displaces 6.7 liters, or approximately 406 cubic inches. This generous displacement is key to its substantial torque output.

- Cylinder Block Material: Unlike many diesel engines that use cast iron, Ford opted for Compacted Graphite Iron (CGI) for the 6.7 Powerstroke‘s block. CGI is significantly stronger and lighter than traditional gray iron, offering superior fatigue strength and stiffness, which is crucial for handling the immense pressures of a modern diesel engine.

- Bore & Stroke: The engine features an oversquare design with a bore of 3.90 inches (99 mm) and a stroke of 4.29 inches (109 mm). This configuration generally favors higher RPM capabilities and contributes to its robust power delivery.

- Compression Ratio: Depending on the year and specific tuning, the compression ratio typically ranges from 16.2:1 to 16.7:1. A high compression ratio is inherent to diesel engines, promoting efficient combustion without spark plugs.

- Connecting Rods: Forged steel connecting rods are employed, designed to withstand the high cylinder pressures and provide long-term durability.

- Pistons: The pistons are typically aluminum, designed for strength and heat dissipation, often featuring unique bowl designs to optimize combustion efficiency and reduce emissions.

Cylinder Heads and Valvetrain

- Cylinder Head Material: The heads are constructed from aluminum, contributing to weight savings and improved heat dissipation.

- Valvetrain: The 6.7 Powerstroke utilizes an overhead valve (OHV) design with 4 valves per cylinder (32 valves total). This configuration, combined with hydraulic roller lifters, provides excellent airflow for combustion and exhaust, which is critical for both power and emissions control.

- Reverse-Flow Cylinder Heads: A unique and innovative feature of the 6.7 Powerstroke is its reverse-flow cylinder head design. The exhaust manifolds are located in the engine’s valley (between the cylinder banks), while the intake ports are on the outside. This design allows for a more compact engine package, quicker turbocharger spool-up due to shorter exhaust gas travel, and improved heat management, contributing to lower exhaust gas temperatures (EGTs).

Fuel System

- Common Rail Injection: The engine employs a high-pressure common rail (HPCR) fuel injection system, a standard in modern diesels for precise fuel delivery.

- Fuel Pump: Early models utilized a Bosch CP4.2 high-pressure fuel pump, which some later models upgraded or modified for enhanced reliability. Later engines often feature more robust pumps, such as the Bosch CP4.2 or a proprietary design, capable of delivering extremely high fuel pressures (up to 29,000 psi or more).

- Injectors: Piezoelectric fuel injectors are used, known for their rapid response times and the ability to perform multiple injection events per combustion cycle. This precision allows for finer control over combustion, leading to improved efficiency, reduced noise, and lower emissions.

These foundational 6.7 Powerstroke engine specifications lay the groundwork for its incredible performance and reliability. Every component is chosen and designed with the demanding tasks of a Super Duty in mind.

Performance Metrics: Horsepower, Torque, and Towing Capabilities

The true measure of a heavy-duty truck engine often boils down to its ability to haul and tow heavy loads with authority. The 6.7 Powerstroke diesel engine has consistently delivered, evolving significantly in its horsepower and torque outputs over the years, directly translating into ever-increasing towing capabilities for the Ford Super Duty lineup.

The Ascent of Power

From its inception, the 6.7 Powerstroke has been on a relentless upward trajectory in terms of power output. This continuous improvement is a testament to Ford’s ongoing engineering advancements and a response to the ever-demanding market for more capable trucks:

- 2011-2014 Models: The first generation set a high bar with 400 horsepower and 800 lb-ft of torque. These numbers were class-leading at the time and immediately showcased the engine’s potential.

- 2015-2016 Models: Ford introduced a significant power bump, pushing the output to an impressive 440 horsepower and 860 lb-ft of torque. This was achieved through various refinements, including a larger turbocharger and updated fuel calibration.

- 2017-2019 Models: Another leap forward saw the 6.7 Powerstroke reach 450 horsepower and 925 lb-ft of torque. This update focused on improvements to the turbocharger, fuel system, and cylinder heads, further enhancing both power and efficiency.

- 2020-2022 Models: With the introduction of the 10-speed TorqShift automatic transmission, the engine received substantial upgrades, culminating in an astounding 475 horsepower and 1,050 lb-ft of torque. This marked the first time a heavy-duty diesel engine surpassed the 1,000 lb-ft torque barrier in a production truck.

- 2023+ Models (Standard Output): The latest iteration of the 6.7 Powerstroke continues to impress, offering a standard output of 475 horsepower and 1,050 lb-ft of torque.

- 2023+ Models (High-Output): For those demanding the absolute maximum, Ford introduced a High-Output version of the 6.7 Powerstroke, pushing the boundaries to an incredible 500 horsepower and an industry-leading 1,200 lb-ft of torque. This truly showcases the immense capabilities engineered into the Powerstroke platform.

Towing and Hauling Prowess

These escalating power figures directly translate into unparalleled towing and hauling capabilities for Ford Super Duty trucks. While specific towing capacities vary significantly based on truck configuration (2WD/4WD, cab style, bed length, axle ratio, single/dual rear wheels), the 6.7 Powerstroke consistently enables best-in-class performance.

- Conventional Towing: Depending on the year and configuration, 6.7 Powerstroke-equipped Super Duty trucks can conventionally tow anywhere from 18,000 lbs to over 22,000 lbs.

- 5th-Wheel/Gooseneck Towing: This is where the 6.7 Powerstroke truly shines, allowing for massive towing capacities often exceeding 30,000 lbs, with the latest High-Output models pushing past an astounding 40,000 lbs.

- Payload Capacity: The robust chassis and powerful engine also contribute to impressive payload capacities, allowing Super Duty trucks to carry thousands of pounds in their beds.

The integration of the TorqShift automatic transmission, initially a 6-speed and later a 10-speed, has been pivotal. These transmissions are meticulously calibrated to harness the immense torque of the 6.7 Powerstroke, providing smooth shifts, optimal gear ratios for various loads, and enhanced fuel efficiency.

In essence, the performance metrics of the 6.7 Powerstroke engine specifications are not just numbers on a spec sheet; they represent the raw power and capability that empower owners to tackle the toughest jobs with confidence and ease.

Advanced Engineering: Design Innovations and Component Breakdown

The 6.7 Powerstroke is more than just raw power; it’s a showcase of sophisticated engineering designed to deliver that power reliably and efficiently while meeting stringent environmental standards. Several key design innovations set this engine apart, making it a benchmark in the heavy-duty diesel segment.

Turbocharging Excellence

One of the most defining characteristics of the 6.7 Powerstroke engine specifications is its turbocharger system. Unlike many diesel engines that place the turbocharger on the outside of the engine, the 6.7 Powerstroke features a unique ‘hot V’ or ‘scorpion’ design:

- Valley-Mounted Turbocharger: The single variable geometry turbocharger (VGT) is positioned in the valley between the cylinder banks, directly above the exhaust manifold. This central location offers several advantages:

- Shorter Exhaust Paths: The exhaust manifolds are integrated into the cylinder heads and exit directly into the turbocharger, significantly reducing the distance exhaust gases travel. This design minimizes turbo lag, resulting in quicker boost response and improved throttle linearity.

- Compact Packaging: Placing the turbo in the valley contributes to a more compact engine package, which can aid in vehicle packaging and serviceability.

- Improved Heat Management: While concentrated, the heat is managed effectively, aiding in quicker warm-up for emissions control.

- Garrett GT32 SST / Honeywell VGT: Early models used a unique Garrett GT32 SST (Sequential Series Turbo) which, despite its name, was a single turbo with a dual-sided compressor wheel. Later versions (especially from 2015 onwards) adopted advanced Honeywell VGT turbos, which allow for precise control of exhaust gas flow to the turbine, optimizing boost across a wide RPM range. The latest models continue to refine these VGT units for even quicker response and higher boost pressures.

Sophisticated Cooling Systems

Managing the significant heat generated by a powerful diesel engine is critical for longevity and performance. The 6.7 Powerstroke employs a robust and innovative cooling strategy:

- Dual Cooling System: The engine features two separate cooling circuits:

- High-Temperature Circuit: Dedicated to cooling the engine block and cylinder heads, ensuring optimal engine operating temperatures.

- Low-Temperature Circuit: This circuit manages the temperatures of critical components like the charge air cooler (intercooler), EGR cooler, and fuel cooler. Keeping these components cool helps improve power, reduce emissions, and enhance overall efficiency.

- Large Capacity: Both circuits are generously sized to provide ample cooling capacity, crucial for sustained towing and hauling in extreme conditions.

Emissions Control Technology

Meeting ever-stricter emissions regulations without sacrificing power is a monumental task. The 6.7 Powerstroke incorporates a suite of advanced emissions control technologies:

- Diesel Particulate Filter (DPF): Captures soot from the exhaust gases, preventing it from being released into the atmosphere. The DPF undergoes periodic regeneration cycles, where heat is used to burn off the collected soot.

- Selective Catalytic Reduction (SCR) with DEF: Diesel Exhaust Fluid (DEF) is injected into the exhaust stream, where it reacts with nitrogen oxides (NOx) in the SCR catalyst, converting them into harmless nitrogen and water vapor. This system significantly reduces NOx emissions.

- Exhaust Gas Recirculation (EGR): A portion of the exhaust gas is cooled and recirculated back into the engine’s intake. This lowers combustion temperatures, which in turn reduces the formation of NOx. The 6.7 Powerstroke utilizes both high-pressure and low-pressure EGR systems for maximum effectiveness.

These advanced engineering solutions are integral to the 6.7 Powerstroke engine specifications, allowing it to deliver powerful performance while being a relatively clean-burning diesel engine. The continuous refinement of these systems ensures that the Powerstroke remains at the forefront of diesel technology.

Maintaining the Beast: Tips for Longevity and Reliability

The 6.7 Powerstroke diesel engine is renowned for its durability and long-term reliability, but like any sophisticated piece of machinery, it thrives on proper care and maintenance. Understanding the common issues and implementing a proactive maintenance schedule is key to maximizing the lifespan and performance of your 6.7 Powerstroke-equipped Ford Super Duty.

Common Concerns (Primarily Early Models)

While later iterations of the 6.7 Powerstroke have addressed many initial concerns, it’s worth being aware of some issues that owners have historically encountered:

- CP4 High-Pressure Fuel Pump (Early Models): Some early CP4 pumps were susceptible to failure, potentially leading to costly widespread fuel system contamination. Ford has made revisions and provided extended warranties in certain cases. Many owners opt for aftermarket disaster prevention kits or upgraded fuel pumps.

- Exhaust Sensors and DPF Regeneration: As with any modern diesel, exhaust sensors (NOx, O2, EGT) can fail, and the DPF requires periodic regeneration. Frequent short trips can hinder proper DPF regeneration, leading to build-up and potential issues.

- EGR Cooler Leaks: Especially in early models, EGR coolers could be prone to leaking, leading to coolant loss or contamination. Revisions have been made to improve durability.

- Turbocharger Actuator Issues: While the turbo itself is robust, the electronic actuator controlling the variable geometry vanes can sometimes encounter issues, affecting boost control.

- Radiator Issues: Some early models experienced radiator failures or leaks, necessitating replacement.

It’s important to note that many of these issues are either less prevalent in newer models due to design improvements or are manageable with proper maintenance and vigilance. The overall reliability of the 6.7 Powerstroke remains excellent, particularly in its later generations.

Proactive Maintenance for Your 6.7 Powerstroke

Adhering to a strict maintenance schedule is paramount. Here are essential tips to ensure your 6.7 Powerstroke runs smoothly for hundreds of thousands of miles:

- Oil Changes:

- Use the manufacturer-recommended synthetic API CJ-4 or CK-4 heavy-duty motor oil (typically 15W-40 or 5W-40).

- Adhere to the prescribed oil change intervals, usually every 7,500 to 10,000 miles or sooner under severe service (heavy towing, extreme temperatures).

- Always use a high-quality, OEM-spec oil filter.

- Fuel Filter Replacement:

- This is arguably the most critical maintenance item for the 6.7 Powerstroke‘s fuel system. Replace both the frame-mounted and engine-mounted fuel filters according to Ford’s schedule (typically every 15,000-22,500 miles, or more frequently if fuel quality is questionable).

- Clean fuel is essential to protect the high-pressure fuel pump and injectors.

- Coolant System Maintenance:

- Monitor coolant levels regularly for both cooling circuits.

- Follow Ford’s recommendations for coolant flushes and replacement (typically every 100,000 miles or 5 years), using the specified Motorcraft Gold or Yellow Extended Life Coolant.

- Inspect hoses and connections for leaks or wear.

- DEF System Care:

- Always use fresh, high-quality Diesel Exhaust Fluid that meets ISO 22241 standards.

- Do not allow the DEF tank to run completely dry, as this can trigger engine derates or prevent starting.

- Store DEF properly to prevent contamination or freezing/thawing cycles.

- Air Filter Replacement:

- Replace the engine air filter as recommended or more frequently if operating in dusty conditions. A clean air filter is vital for proper combustion and turbocharger longevity.

- Transmission Service:

- While not strictly engine maintenance, the TorqShift transmission works in harmony with the engine. Follow Ford’s service intervals for fluid and filter changes (often around 150,000 miles or less for severe duty).

- Listen and Observe: Pay attention to any unusual noises, smells, or warning lights. Addressing minor issues promptly can prevent them from escalating into major, costly repairs.

By investing time and resources into diligent maintenance, owners can expect their 6.7 Powerstroke diesel engine to provide reliable, powerful service for many years and countless miles, truly living up to its robust 6.7 Powerstroke engine specifications.

The 6.7 Powerstroke Legacy: A Concluding Perspective

From its inception as Ford’s in-house diesel project, the 6.7 Powerstroke diesel engine has carved out an indelible legacy in the heavy-duty truck market. It represented a bold new direction for Ford, moving away from external diesel engine suppliers to fully embrace proprietary engineering. This decision has paid off handsomely, delivering an engine that consistently redefines the standards for power, efficiency, and capability in the Super Duty lineup.

We’ve journeyed through the intricate 6.7 Powerstroke engine specifications, from its robust Compacted Graphite Iron block and innovative reverse-flow cylinder heads to its escalating horsepower and torque figures that now push beyond the 1,200 lb-ft mark. We’ve explored the advanced engineering behind its valley-mounted turbocharger, dual cooling systems, and sophisticated emissions controls, all of which contribute to its formidable performance and environmental compliance.

The continuous evolution of the 6.7 Powerstroke showcases Ford’s unwavering commitment to improvement. Each model year brings refinements that enhance its reliability, further increase its power, and optimize its fuel efficiency. While early models had their learning curves, Ford’s dedication to addressing issues and continuously innovating has ensured that the Powerstroke remains a top contender, winning the trust of countless truck owners who demand nothing but the best.

For anyone who relies on a Ford Super Duty for work or recreation, understanding the detailed 6.7 Powerstroke engine specifications is more than just technical knowledge; it’s an appreciation for the engineering prowess that underpins their vehicle’s exceptional capabilities. With proper maintenance and care, the 6.7 Powerstroke is designed to be a long-lasting, powerful partner, ready to tackle any challenge thrown its way. It stands as a true testament to American ingenuity and a cornerstone of the modern heavy-duty truck segment.

Frequently Asked Questions

What are the horsepower and torque ratings for the 6.7 Powerstroke engine?

The 6.7 Powerstroke engine has seen various power output upgrades throughout its lifespan. Initially, it produced around 400 horsepower and 800 lb-ft of torque, but newer iterations often exceed 475 horsepower and 1050 lb-ft of torque in stock form.

What is the displacement and cylinder configuration of the 6.7 Powerstroke engine?

The 6.7 Powerstroke engine features a displacement of 6.7 liters, which is equivalent to 406 cubic inches. It is configured as a V8 engine, with all cylinders arranged in a “V” shape.

Can you detail the turbocharger system used in the 6.7 Powerstroke engine?

The 6.7 Powerstroke utilizes a single sequential turbocharger (SST) system, which is a unique variable geometry turbo design mounted in the valley of the engine. This “reverse flow” setup helps to improve throttle response, reduce turbo lag, and enhance overall efficiency by optimizing exhaust gas flow.

What type of fuel injection system does the 6.7 Powerstroke utilize?

The 6.7 Powerstroke engine employs a high-pressure common rail (HPCR) fuel injection system. This system allows for extremely precise control over fuel delivery, operating at very high pressures to enable multiple injection events per combustion cycle for improved efficiency and performance.

Have there been significant specification changes or updates to the 6.7 Powerstroke over its production years?

Yes, the 6.7 Powerstroke has undergone several key updates and refinements since its introduction in 2011, focusing on increasing horsepower and torque, improving reliability, and meeting evolving emissions standards. Notable updates include revised turbocharger designs, improved fuel system components, and enhanced engine internals, contributing to its continuous evolution.

What is the compression ratio and bore/stroke of the 6.7 Powerstroke engine?

The 6.7 Powerstroke engine typically features a compression ratio of 16.2:1, which is optimized for diesel combustion. Its bore measures approximately 3.90 inches (99 mm), and its stroke is 4.29 inches (109 mm), contributing to its impressive torque output and efficient combustion characteristics.