6.0 Powerstroke Turbo Specifications: Complete Performance Details

Featured image for this comprehensive guide about 6.0 Powerstroke turbo specifications

6.0 Powerstroke Turbo Specifications: Complete Performance Details

Ah, the 6.0 Powerstroke turbo. For many Ford truck enthusiasts, this phrase conjures a mix of respect, curiosity, and perhaps a touch of trepidation. Introduced in 2003, the 6.0L Powerstroke engine quickly became a powerhouse, known for its impressive torque and horsepower capabilities. At the heart of its performance lies a sophisticated and sometimes misunderstood component: its variable geometry turbocharger (VGT). This turbo isn’t just a simple air pump; it’s a marvel of engineering designed to deliver optimal boost across a wide RPM range, making your heavy-duty truck feel surprisingly nimble.

However, the complexity that grants the 6.0 Powerstroke turbo its performance edge also makes it a focal point for discussion, maintenance, and potential issues. Understanding its intricate design, precise 6.0 Powerstroke turbo specifications, and operational nuances is crucial for any owner looking to maximize their truck’s longevity and performance. Whether you’re a seasoned diesel mechanic, a DIY enthusiast, or simply someone who relies on their Ford Super Duty for work or play, delving into the specifics of this turbocharger will empower you with the knowledge to troubleshoot, maintain, and even upgrade your diesel beast effectively.

In this comprehensive guide, we’re going to pull back the curtain on the 6.0 Powerstroke turbo. We’ll explore its fundamental components, dive deep into its critical specifications, discuss common failure points, and provide actionable tips for maintenance and performance upgrades. Get ready to gain a profound understanding of what makes your 6.0L Powerstroke roar!

Quick Answers to Common Questions

What is 6.0 Powerstroke turbo specifications?

6.0 Powerstroke turbo specifications refers to essential knowledge and techniques that can significantly improve your understanding and results.

Why is 6.0 Powerstroke turbo specifications important?

Mastering 6.0 Powerstroke turbo specifications provides practical benefits and helps you achieve better outcomes in various situations.

How does 6.0 Powerstroke turbo specifications work?

6.0 Powerstroke turbo specifications involves specific methods and approaches that deliver effective results when applied correctly.

When should I use 6.0 Powerstroke turbo specifications?

You can apply 6.0 Powerstroke turbo specifications techniques whenever you need to improve your approach or achieve better results.

What are the benefits of 6.0 Powerstroke turbo specifications?

Learning 6.0 Powerstroke turbo specifications offers numerous advantages including improved efficiency, better results, and practical applications.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Variable Geometry Turbo (VGT)

- Key Components of the 6.0 Powerstroke Turbo

- Detailed 6.0 Powerstroke Turbo Specifications

- Common Issues and Failure Points of the 6.0 Powerstroke Turbo

- Maintenance and Longevity Tips for Your 6.0 Powerstroke Turbo

- Upgrading Your 6.0 Powerstroke Turbo for Enhanced Performance

- Conclusion: Mastering Your 6.0 Powerstroke Turbo

Understanding the 6.0 Powerstroke Variable Geometry Turbo (VGT)

The 6.0 Powerstroke turbo is not your conventional fixed-geometry turbocharger. It employs a sophisticated Variable Geometry Turbocharger (VGT) design, which is key to the engine’s impressive power delivery and emissions control. Unlike older turbos that had a fixed turbine housing, the VGT system on the 6.0L Powerstroke allows for dynamic adjustment of exhaust gas flow into the turbine wheel.

This adjustment is achieved through a movable nozzle ring or vanes located within the turbine housing. At low engine speeds, these vanes close down, effectively narrowing the exhaust gas path. This increases the velocity of the exhaust gas impacting the turbine wheel, causing the turbocharger to spool up much faster and produce boost earlier. This significantly reduces turbo lag, providing a more responsive feel off the line.

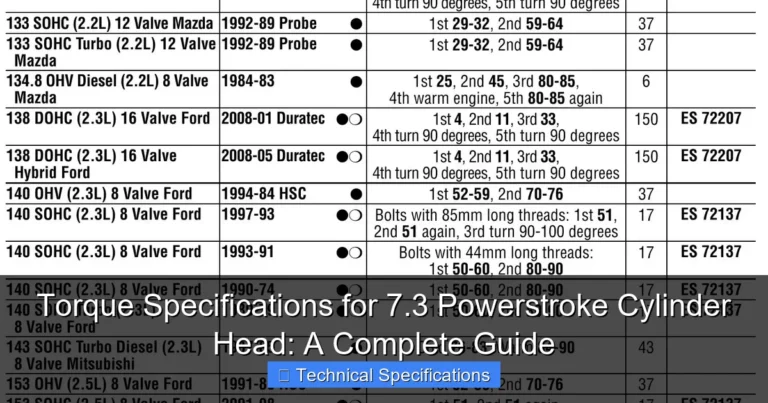

| Specification | Value/Detail | Notes/Characteristics |

|---|---|---|

| **Turbocharger Type** | Variable Geometry Turbo (VGT) | Allows for rapid boost response and enhanced engine braking. |

| **OEM Manufacturer/Model** | Garrett GT3782VA | Often referred to simply as the GT37V or GT37. |

| **Compressor Wheel Size** | ~63.5 mm Inducer / ~82 mm Exducer | Typically features a 10-blade design. |

| **Turbine Wheel Size** | ~72.5 mm Inducer / ~66 mm Exducer | Features a unique 13-blade design. |

| **Typical Boost Pressure** | 18-28 psi (stock range) | Can peak slightly higher under specific conditions (~30 psi). |

| **VGT Actuation Method** | Electronic Servo Motor | Common failure point due to heat and carbon buildup affecting solenoid. |

As engine RPMs increase and more exhaust gas is produced, the VGT vanes open up. This widens the exhaust path, preventing over-boosting and allowing for maximum airflow at higher engine loads. This intelligent control ensures that the engine receives the precise amount of boost it needs at any given moment, optimizing both performance and fuel efficiency. Furthermore, the VGT plays a critical role in the engine’s Exhaust Gas Recirculation (EGR) system, using backpressure to drive exhaust gases back into the intake for emissions reduction. Understanding this fundamental principle is the first step to truly grasping the complexities of the 6.0 Powerstroke turbo.

How the VGT System Works

- Low RPM: Vanes close, increasing exhaust gas velocity and accelerating the turbine wheel. Result: Quicker spool-up, reduced turbo lag.

- High RPM: Vanes open, allowing maximum exhaust flow, preventing over-boosting, and maintaining optimal pressure ratios. Result: Sustained power, efficient operation.

- EGR Integration: The VGT can create backpressure to force exhaust gases into the intake manifold, aiding in the EGR process for emissions control.

Key Components of the 6.0 Powerstroke Turbo

To fully appreciate the 6.0 Powerstroke turbo specifications, it’s essential to understand its main components and their functions. Each part plays a critical role in the overall performance and reliability of this complex system.

Compressor Wheel and Housing

Located on the “cold” side of the turbocharger, the compressor wheel is responsible for drawing in ambient air, compressing it, and forcing it into the engine’s intake manifold. The compressed air is denser, allowing more oxygen to enter the cylinders, which in turn permits more fuel to be injected and burned, producing more power. The compressor housing channels this air efficiently. The design and size of the compressor wheel are crucial for determining the turbo’s maximum airflow and boost capabilities.

Turbine Wheel and Housing

On the “hot” side, the turbine wheel is driven by the hot exhaust gases expelled from the engine. These gases spin the turbine wheel, which is connected by a shaft to the compressor wheel. The turbine housing encapsulates the turbine wheel and, in the case of the 6.0 Powerstroke VGT turbo, houses the variable geometry mechanism. The efficiency of the turbine in converting exhaust gas energy into rotational energy is vital for the turbo’s overall performance.

Center Housing Rotating Assembly (CHRA)

The CHRA is the core of the 6.0 Powerstroke turbo, containing the shaft that connects the compressor and turbine wheels, along with the bearings that allow for high-speed rotation. These bearings are typically hydro-dynamic (oil-fed) and require a constant supply of clean engine oil for lubrication and cooling. Any disruption to this oil supply or contamination can lead to catastrophic failure.

VGT Actuator and Nozzle Ring

The VGT actuator is arguably one of the most critical and, at times, problematic components. On the 6.0L, this is an electronic solenoid-driven mechanism that precisely controls the position of the nozzle ring (also known as the unison ring) within the turbine housing. The nozzle ring, in turn, adjusts the angle of the vanes, thereby controlling exhaust gas flow to the turbine. A malfunctioning actuator or a sticking nozzle ring due to soot and carbon buildup can severely impair 6.0 Powerstroke turbo performance, leading to codes, reduced power, and excessive “turbo whistle.”

Detailed 6.0 Powerstroke Turbo Specifications

Understanding the actual numbers and measurements of the 6.0 Powerstroke turbo provides insight into its engineering and performance potential. The turbocharger used in the 6.0L Powerstroke is a Garrett GT3782VA, a highly capable unit for its time.

| Specification Aspect | Details / Values |

|---|---|

| Turbocharger Model | Garrett GT3782VA (Variable Geometry Turbocharger) |

| Compressor Wheel Inducer Diameter | Approx. 63.5 mm (2.5 inches) |

| Compressor Wheel Exducer Diameter | Approx. 82.0 mm (3.23 inches) |

| Turbine Wheel Inducer Diameter | Approx. 72.5 mm (2.85 inches) |

| Turbine Wheel Exducer Diameter | Approx. 66.0 mm (2.6 inches) |

| Compressor A/R (Area/Radius) | Fixed, generally optimized for engine characteristics |

| Turbine A/R (Area/Radius) | Effectively variable, due to VGT mechanism (simulates wide range) |

| Max Rated Boost Pressure | Typically 28-32 psi (pounds per square inch) stock |

| Maximum RPM | Can exceed 150,000 RPM at peak operation |

| Bearing Type | Journal Bearing (oil-lubricated) |

| Actuator Type | Electronic Solenoid-Controlled |

These 6.0 Powerstroke turbo specifications highlight the robust design. The wheel sizes are well-matched to the 6.0L engine’s displacement and flow requirements, allowing for excellent low-end response and decent top-end power. The ability to vary the effective A/R (Area/Radius) of the turbine housing is the core advantage of the VGT system, making it adaptable to different engine speeds and loads. The journal bearings, while reliable, underscore the importance of clean, consistent oil pressure.

Common Issues and Failure Points of the 6.0 Powerstroke Turbo

While the 6.0 Powerstroke turbo is a capable component, it’s not without its Achilles’ heel. Owners often encounter specific problems that can lead to reduced performance, diagnostic trouble codes (DTCs), and eventually, failure. Being aware of these common issues is the first step in proactive maintenance and timely repairs.

Sticking VGT Actuator and Nozzle Ring

This is arguably the most notorious issue. Over time, soot and carbon from the exhaust gases, combined with oil residue, can build up around the VGT nozzle ring and vanes within the turbine housing. This buildup causes the vanes to stick, preventing the VGT actuator from moving them freely. The result is often inconsistent boost, excessive turbo lag, or continuous over-boosting. Symptoms can include:

- Lack of power, especially at lower RPMs.

- “Limiting speed” mode (engine defueling).

- Illumination of the Check Engine Light with codes like P0238 (Boost Sensor A Circuit High) or P0299 (Turbo/Super Charger Underboost).

- A noticeably louder or different “turbo whistle” sound.

Oil Contamination and Supply Issues

As mentioned, the CHRA’s journal bearings rely heavily on clean engine oil for lubrication and cooling. Sludge, dirty oil, or infrequent oil changes can lead to premature wear of these bearings. Additionally, issues with oil supply pressure to the turbocharger (e.g., restricted oil lines, failing oil pump) can starve the bearings, causing rapid damage and failure. The 6.0L Powerstroke is known to be sensitive to oil quality; using the correct specification oil and adhering to strict change intervals is paramount.

EGR System Related Issues

The 6.0 Powerstroke turbo and the EGR system are intricately linked. A faulty EGR valve, cooler, or clogged EGR passages can lead to excessive soot buildup within the exhaust system, which then contributes to the sticking VGT issue. Leaking EGR coolers can also introduce coolant into the exhaust, which exacerbates carbon buildup and can even damage the turbo.

Bearing Failure / Shaft Play

Beyond oil-related issues, the bearings themselves can simply wear out over time, especially if the turbo is frequently pushed to its limits or if the engine experiences unbalanced conditions. Excessive shaft play (movement of the compressor/turbine shaft) can lead to the wheels rubbing against their respective housings, causing severe damage, noise, and ultimately, turbo failure. This often manifests as a grinding noise or metal shavings in the intercooler pipes.

Maintenance and Longevity Tips for Your 6.0 Powerstroke Turbo

Keeping your 6.0 Powerstroke turbo healthy is essential for the overall well-being of your truck. Proactive maintenance can significantly extend its lifespan and prevent costly repairs. Here are actionable tips to ensure your turbo continues to spool strong:

- Strict Oil Change Intervals and Quality: This cannot be stressed enough. Use only high-quality, synthetic-blend or full-synthetic diesel engine oil that meets Ford’s specifications (e.g., CJ-4 or CK-4 for newer oils). Adhere strictly to the recommended oil change intervals, typically 5,000 to 7,500 miles, especially if you tow heavy loads or idle frequently. Clean oil is the lifeblood of your journal-bearing turbo.

- Monitor Exhaust Gas Temperatures (EGTs): Installing an EGT gauge is a wise investment, especially if you tow or have performance tunes. High EGTs can stress the turbine components and lead to premature wear. Aim to keep EGTs below 1250°F (677°C) for sustained periods.

- Allow for Proper Cool Down: After heavy towing or high-speed driving, allow your engine to idle for a few minutes before shutting it off. This allows engine oil to circulate and cool the hot turbocharger components, preventing oil from coking (burning and solidifying) in the bearings.

- Check for Boost Leaks: Periodically inspect all intercooler pipes and connections for cracks, loose clamps, or leaks. Boost leaks force the turbocharger to work harder to achieve target boost, increasing wear and reducing efficiency.

- Regularly Inspect and Clean the VGT Actuator and Nozzle Ring: While a full removal and cleaning might be a bigger job, many owners perform a “VGT cycling” routine using diagnostic tools to keep the actuator moving. For early signs of sticking, professional cleaning of the nozzle ring or even turbo removal for a thorough clean can prevent a full replacement.

- Maintain the EGR System: A healthy EGR system reduces soot going through the turbo. Ensure your EGR valve is clean and functioning correctly, and consider checking the EGR cooler for leaks or blockages.

- Use Quality Fuel Filters: Clean fuel helps the engine run efficiently, which in turn benefits the turbo. Replace fuel filters at recommended intervals using OEM or high-quality aftermarket filters.

- Listen for Unusual Noises: A healthy 6.0 Powerstroke turbo produces a distinct “whistle” that changes with engine load. Any new grinding, scraping, or excessively loud whining noises should prompt immediate investigation.

Upgrading Your 6.0 Powerstroke Turbo for Enhanced Performance

For those looking to extract even more power from their 6.0L Powerstroke, upgrading the factory 6.0 Powerstroke turbo is a popular modification. Whether you’re aiming for higher horsepower for racing, improved towing capability, or simply better reliability, the aftermarket offers a range of solutions. However, it’s crucial to understand the implications of such upgrades.

Why Upgrade?

- Increased Horsepower and Torque: Larger or more efficient turbos can deliver significantly more air, allowing for more fuel and thus more power.

- Improved Towing Performance: Upgraded turbos can maintain boost more effectively under heavy loads, reducing EGTs and improving overall towing experience.

- Enhanced Reliability: Some aftermarket turbos address known weak points of the stock unit, offering more robust designs or improved bearing systems.

- Better “Turbo Whistle“: For some, the sound alone is a compelling reason!

Popular Upgrade Paths

- “Drop-in” Performance Turbos: These are designed to replace the stock GT3782VA without major modifications to the exhaust or intake. They often feature larger compressor wheels (e.g., 64mm or 66mm) and/or revised turbine designs for improved airflow and efficiency. Examples include various Street Stock or S300 series hybrid turbos. These often require custom tuning to fully utilize their potential.

- Non-VGT Conversions: Some owners opt to convert their 6.0 Powerstroke turbo to a fixed-geometry, non-VGT setup, often using turbos like the Garrett GT4088R or BorgWarner S300/S400 series. While these can offer immense power gains, they typically involve significant modifications (pedestal, exhaust piping, external wastegate) and require custom tuning. The VGT functionality for EGR is lost, so emissions considerations are key.

- Compound Turbo Systems: For extreme power, compound (twin) turbo setups are employed. This involves using two turbos of different sizes, with the smaller one feeding into the larger one, to provide excellent response and massive top-end power. This is a highly complex and expensive modification, generally reserved for dedicated competition vehicles.

Considerations Before Upgrading

- Supporting Modifications: A turbo upgrade is rarely a standalone modification. You’ll likely need:

- Custom engine tuning (mandatory for most upgrades).

- Upgraded fuel system (injectors, fuel pump) to supply enough fuel for the increased air.

- Improved exhaust system (larger diameter, less restrictive).

- Heavy-duty transmission to handle the increased power and torque.

- Stronger head studs to prevent head gasket issues.

- Reliability vs. Performance: Pushing your engine beyond its stock limits can reduce the lifespan of other components. Choose a turbo upgrade that matches your intended use and budget.

- Emissions Regulations: Be aware that some aftermarket turbo modifications, especially non-VGT conversions, may not be street legal in certain regions due to changes in emissions control systems.

Conclusion: Mastering Your 6.0 Powerstroke Turbo

The 6.0 Powerstroke turbo is an ingenious piece of engineering that delivers impressive power and efficiency to your Ford Super Duty. Its variable geometry design allows for excellent responsiveness across the RPM range, making it a crucial component in the engine’s performance. However, like any complex system, it requires understanding, respect, and diligent maintenance to perform optimally and last for years to come.

By delving into its detailed 6.0 Powerstroke turbo specifications, understanding its key components like the VGT actuator and nozzle ring, and recognizing common failure points, you are now better equipped to diagnose issues, perform preventive maintenance, and make informed decisions about potential upgrades. Remember, regular oil changes with the right oil, monitoring EGTs, and allowing proper cooldown are not just suggestions—they are vital practices for maximizing the longevity and reliability of your Powerstroke turbo.

Whether you choose to maintain your stock setup for reliable daily driving or embark on a journey of performance upgrades, the knowledge gained about your 6.0 Powerstroke turbo will empower you to keep your diesel running strong. Embrace the power, maintain with care, and enjoy the roar of your magnificent 6.0L Powerstroke for many miles ahead!

Frequently Asked Questions

What is 6.0 Powerstroke turbo specifications?

6.0 Powerstroke turbo specifications is an important topic with many practical applications and benefits.

How can 6.0 Powerstroke turbo specifications help me?

Understanding 6.0 Powerstroke turbo specifications can improve your knowledge and provide practical solutions.