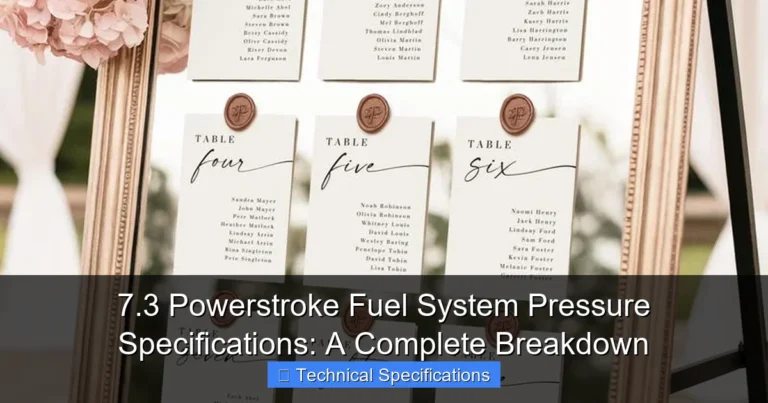

6.0 Powerstroke Fuel System Specifications: A Detailed Overview

Featured image for this comprehensive guide about 6.0 Powerstroke fuel system specifications

Image source: 3.bp.blogspot.com

Ah, the 6.0 Powerstroke. A legendary engine, revered by many for its raw power and performance, yet often misunderstood due to its intricate engineering. If you own one, you know the satisfaction it delivers when running optimally. But you also know that keeping this beast purring requires a deep understanding of its vital systems, none more critical than the 6.0 Powerstroke fuel system specifications.

Far from a simple fuel delivery mechanism, the 6.0 Powerstroke's fuel system is a sophisticated ballet of pressure, precision, and timing. It's the lifeblood that feeds those thirsty cylinders, turning diesel into dependable power. Understanding its intricacies – from the low-pressure pump to the high-pressure oil pump (HPOP) and the injectors themselves – isn't just for mechanics; it's essential for every owner looking to prevent common issues, enhance reliability, and squeeze every ounce of performance from their truck. Let’s dive deep into the specific components, pressures, and operational characteristics that define this fascinating system.

Quick Answers to Common Questions

What's the optimal fuel pressure for a 6.0 Powerstroke fuel system?

The 6.0 Powerstroke fuel system specifications ideally require a consistent fuel pressure of 45-55 PSI at the filter housing to ensure your injectors get the fuel they need and last longer. Monitoring this spec is key for engine health!

Where is the fuel pump located in the 6.0 Powerstroke fuel system?

Your 6.0 Powerstroke fuel system includes an electric fuel pump conveniently mounted on the frame rail, delivering fuel from the tank to the engine. It's a critical component for proper fuel delivery.

What are some common failure points in the 6.0 Powerstroke fuel system?

Common weak points in the 6.0 Powerstroke fuel system specifications often include the fuel pressure regulator, clogged fuel filters, and issues with the FICM or fuel injectors themselves. Keeping up with maintenance can prevent many of these headaches.

Can I upgrade the 6.0 Powerstroke fuel system for better performance?

Absolutely! Many owners choose to upgrade their 6.0 Powerstroke fuel system specifications with aftermarket pumps, filters, and fuel pressure regulators to enhance fuel delivery, prolong injector life, and gain more reliable performance. It's a popular modification.

How often should I change the fuel filters on my 6.0 Powerstroke fuel system?

For optimal performance and longevity, the 6.0 Powerstroke fuel system specifications recommend changing both fuel filters every 10,000 to 15,000 miles, or more frequently if you tow heavily. Clean fuel is the lifeblood of your injectors!

📋 Table of Contents

- Understanding the 6.0 Powerstroke Fuel System Architecture: A Holistic View

- The Low-Pressure Fuel System (LPFS): Foundation of Fuel Delivery

- The High-Pressure Oil Pump (HPOP) and High-Pressure Fuel System (HPFS): The Heart of Injection

- 6.0 Powerstroke Fuel Injector Specifications: Precision and Power

- Critical 6.0 Powerstroke Fuel System Specifications: A Data Overview

- Maintaining and Optimizing Your 6.0 Powerstroke Fuel System: Best Practices

- Conclusion: Mastering Your 6.0 Powerstroke's Fuel System

Understanding the 6.0 Powerstroke Fuel System Architecture: A Holistic View

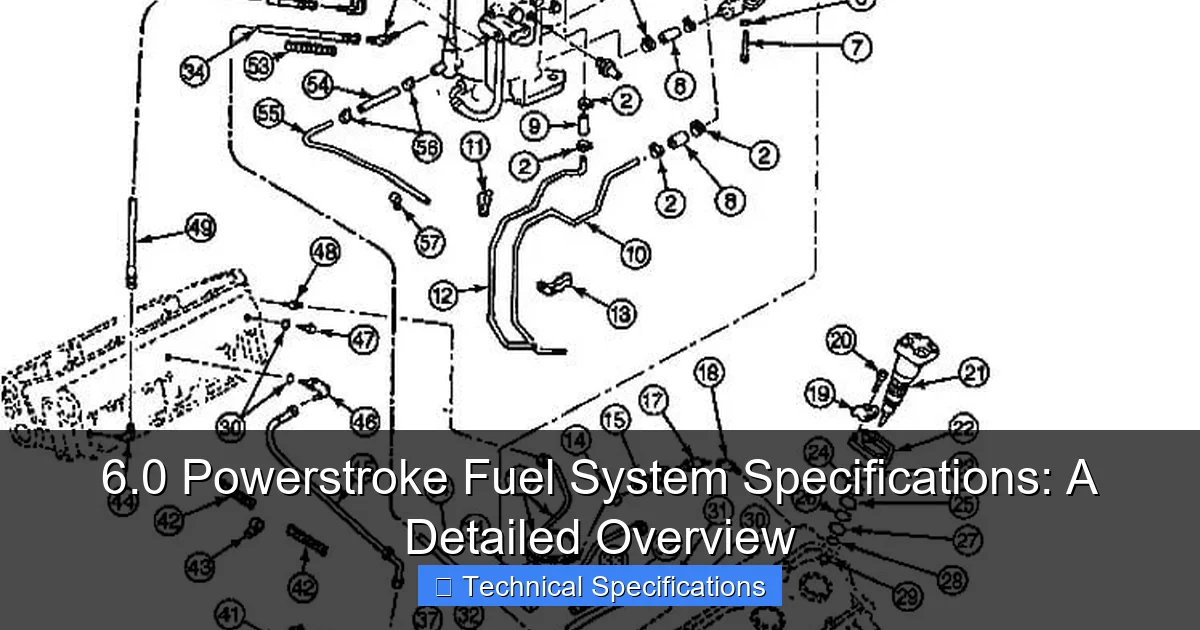

The 6.0 Powerstroke utilizes a unique hydraulically actuated electronically controlled unit injector (HEUI) system. Unlike common rail systems, the HEUI design uses engine oil, pressurized by the HPOP, to actuate the fuel injectors. This design provides incredible control over injection timing and pressure, contributing to both power and emissions control. However, it also introduces additional complexity and potential points of failure if not properly maintained. Before we delve into specific components, let's grasp the overall flow:

Learn more about 6.0 Powerstroke fuel system specifications - 6.0 Powerstroke Fuel System Specifications: A Detailed Overview

Image source: avatars.miarroba.st

- Fuel Supply: Diesel from the tank is drawn and filtered by the low-pressure fuel system.

- High-Pressure Oil: Engine oil is pressurized by the HPOP and sent to the fuel injectors via internal passages in the cylinder heads.

- Fuel Injection: The high-pressure oil then acts as a hydraulic intensifier inside each injector, compressing the fuel to extremely high pressures for atomization and injection into the cylinders.

- Return Fuel/Oil: Excess fuel and oil are returned to their respective systems.

This intricate dance requires precise coordination and adherence to strict 6.0 Powerstroke fuel system specifications. Any deviation in pressure, flow, or filtration can lead to significant operational problems, from reduced power and rough idling to catastrophic engine damage.

| Specification | OEM Value | Unit / Type | Notes / Importance |

|---|---|---|---|

| Target Regulated Fuel Pressure | 45-50 | PSI | Crucial for injector longevity; low pressure causes damage. |

| OEM Low Pressure Fuel Pump | Frame-mounted electric | Gerotor/Turbine | Supplies fuel to the High Pressure Fuel Pump (HPFP). |

| Primary Fuel Filter (Chassis) | 10-20 | Micron | Removes larger contaminants before the HPFP. |

| Secondary Fuel Filter (Engine) | 2-5 | Micron | Fine filtration, protects injectors from minute particles. |

| FICM Output Voltage | 48.0-48.5 | Volts | Powers the fuel injectors; low voltage causes performance issues. |

The Dual-System Approach: Fuel and Oil Integration

The 6.0 Powerstroke's reliance on engine oil to drive fuel injection is a defining characteristic. This means that issues with your oil system (e.g., low oil pressure, contaminated oil) can directly impact fuel delivery. For instance, if your engine oil is too thin or too thick, or if there's an internal leak in the high-pressure oil system, the injectors won't fire correctly, leading to performance degradation. This interdependency underscores the importance of not just fuel system maintenance, but also diligent engine oil management.

The Low-Pressure Fuel System (LPFS): Foundation of Fuel Delivery

The journey of diesel fuel in your 6.0 Powerstroke begins in the low-pressure fuel system. This often-overlooked segment is crucial because it ensures a consistent, clean supply of fuel at the correct pressure to the high-pressure side. Think of it as the foundation upon which the rest of the system operates.

Learn more about 6.0 Powerstroke fuel system specifications - 6.0 Powerstroke Fuel System Specifications: A Detailed Overview

Image source: ww2.justanswer.com

Key LPFS Components and Specifications:

- Fuel Tank and Pickup: The reservoir for your diesel. The pickup tube inside the tank can sometimes clog or develop issues, restricting flow.

- Primary Fuel Pump (Lift Pump): This electric pump, typically frame-mounted, draws fuel from the tank and pushes it through the filtration system.

- Original Equipment (OE) Specification: Approximately 45-70 PSI (pounds per square inch) at idle, though sustained pressure above 45 PSI under load is ideal. Flow rate is typically around 160-180 liters per hour (LPH).

- Criticality: Maintaining adequate 6.0 Powerstroke fuel pump pressure is paramount. Low pressure here can lead to issues like "stiction" in the injectors due to insufficient fuel volume, causing premature wear and failure.

- Fuel Filters: The 6.0 Powerstroke employs a two-stage fuel filtration system.

- Primary Filter (Frame-mounted or integrated with pump): Coarse filtration, typically 10-20 microns.

- Secondary Filter (Engine-mounted, under the oil filter housing): Fine filtration, typically 2 microns. This is crucial for protecting the injectors from minuscule contaminants.

- Fuel Pressure Regulator (FPR): Located in the secondary fuel filter housing, this mechanical valve ensures that the fuel entering the cylinder heads is at a consistent pressure, usually around 45-60 PSI.

- Fuel Lines: Connect all these components, ensuring a leak-free path for fuel.

LPFS Common Issues and Actionable Tips:

- Low Fuel Pressure: Often caused by a failing lift pump, clogged fuel filters, or a faulty FPR.

- Tip: Regularly monitor your fuel pressure, especially under load. An aftermarket fuel pressure gauge is a wise investment for any 6.0 owner. Replace fuel filters every 10,000-15,000 miles, or as recommended by your owner's manual/filter manufacturer.

- Air Intrusion: Leaky fuel lines or a cracked fuel pickup can introduce air, leading to rough running and hard starts.

- Tip: Inspect fuel lines periodically for cracks or chafing. Address any fuel leaks immediately.

- Fuel Contamination: Water or particulate matter in the fuel can wreak havoc.

- Tip: Always buy fuel from reputable sources. Consider adding a high-quality fuel additive that helps emulsify water and provides lubrication.

The High-Pressure Oil Pump (HPOP) and High-Pressure Fuel System (HPFS): The Heart of Injection

This is where the magic (and sometimes the mayhem) happens. The HPOP is a critical component that builds the immense oil pressure needed to actuate the injectors. Coupled with the HPFS, it’s responsible for delivering fuel under extreme pressure for optimal atomization.

Key HPFS Components and Specifications:

- High-Pressure Oil Pump (HPOP): Gear-driven, located at the back of the engine, under the turbo. It takes engine oil and pressurizes it to incredible levels.

- OE Specification: Capable of producing up to 3,600 PSI (or even higher on some late models, up to 4,000 PSI) of oil pressure. The actual operating pressure varies with engine RPM and load, but a minimum of 500-700 PSI is needed to start, and up to 3,600-4,000 PSI under full load.

- ICPR (Injector Control Pressure Regulator): This valve, located on the HPOP or on the passenger side valve cover, controls the high-pressure oil output to the injectors. It's crucial for precisely regulating 6.0 Powerstroke HPOP pressure.

- ICP Sensor (Injector Control Pressure Sensor): Monitors the actual oil pressure in the high-pressure oil rails. This sensor provides feedback to the PCM (Powertrain Control Module).

- High-Pressure Oil Rails: Integrated into the cylinder heads, these rails distribute the high-pressure oil to each injector.

- Standpipes and Dummy Plugs: These internal components within the high-pressure oil system on the 2004.5+ engines are notorious for failure.

- Function: Standpipes connect the HPOP output to the oil rails, while dummy plugs seal off unused oil rail passages. Their O-rings are a common failure point, leading to high-pressure oil leaks.

- STC Fitting (Snap To Connect Fitting): Found on 2005+ HPOPs, this connects the HPOP discharge tube to the passenger side standpipe. Its design is prone to failure, causing catastrophic oil leaks and no-start conditions.

- Actionable Tip: Many owners proactively upgrade to a one-piece STC fitting to prevent future issues.

HPFS Common Issues and Actionable Tips:

- HPOP Failure: Can be mechanical or due to ICPR failure. Symptoms include hard starts, no-starts (especially when hot), and loss of power.

- Tip: Regular, high-quality oil changes are vital. Use only engine oil that meets Ford's specifications (Ford WSS-M2C171-F1). Monitor ICP and IPR (Injector Pressure Regulator) duty cycle with a diagnostic tool.

- Leaking Standpipes/Dummy Plugs/STC Fitting: Leads to loss of high-pressure oil, resulting in extended cranking or no-start conditions.

- Tip: If you're experiencing hard starts, especially when hot, these are prime suspects. Consider upgrading to the revised parts or an aftermarket one-piece STC fitting if you haven't already.

- ICP Sensor Failure: Can cause erratic idle, stalling, and hard starts.

- Tip: If diagnostic codes point to the ICP sensor, replace it with a genuine Ford or high-quality aftermarket part.

6.0 Powerstroke Fuel Injector Specifications: Precision and Power

The fuel injectors are arguably the most complex and critical components in the 6.0 Powerstroke fuel system. They are responsible for taking the high-pressure fuel from the rails and atomizing it into the combustion chamber with precise timing and quantity. Each injector is a marvel of electro-hydraulic engineering.

How HEUI Injectors Work:

- Low-pressure fuel enters the injector body.

- High-pressure oil from the HPOP enters the injector, pushing on an intensifier piston.

- The intensifier piston multiplies the fuel pressure (typically by a 7:1 ratio), pushing fuel into the nozzle chamber at extremely high pressures.

- An electronic solenoid, commanded by the PCM, opens the poppet valve, allowing the highly pressurized fuel to spray into the cylinder.

Key Injector Specifications:

- Fuel Pressure at Nozzle: Due to the intensifier, fuel pressure at the injector nozzle can reach an astonishing 20,000-26,000 PSI, ensuring ultra-fine atomization for efficient combustion.

- Injector Types: The 6.0 Powerstroke uses different injector designs depending on the model year.

- Early 2003: "Split-shot" design (some early 2003 models used a slightly different design than later ones).

- Late 2003 - 2004: These are generally considered the "best" factory injectors by many, known for their robustness.

- 2005 - 2007 (Updated Design): These injectors, while performing well, are sometimes linked to issues with the internal solenoid and spool valve if not properly maintained. They have an updated "spool valve" design.

- Flow Rate (Stock): Typically measured in cubic millimeters per stroke (mm³). Stock injectors are rated for sufficient flow for factory power levels. Aftermarket injectors offer higher flow rates for performance applications.

- Internal Components: Each injector contains numerous precision parts, including the spool valve, intensifier piston, nozzle, and solenoid. Wear on any of these can lead to injector failure.

Injector Common Issues and Actionable Tips:

- Injector Stiction (Sticky Injectors): This is perhaps the most famous 6.0 Powerstroke injector problem. It occurs when deposits build up on the spool valve, preventing it from moving freely.

- Symptoms: Hard starts, rough idle, misfires, especially when cold.

- Tip: Use a high-quality fuel additive regularly that specifically addresses stiction, such as Archoil AR9100 or Hot Shot's Secret Stiction Eliminator. Ensure your oil change intervals are strict, and use the correct specification oil.

- Internal Leaks: Wear in the internal seals can cause fuel to leak into the oil, or vice versa, leading to diluted oil, lower rail pressure, or even hydro-locking.

- Nozzle Wear/Damage: Poor fuel quality or excessive mileage can wear down the nozzle, leading to poor spray patterns and reduced performance.

- Tip: Maintain impeccable fuel filtration and avoid running your tank extremely low, which can stir up sediment.

- Electrical Failure: The solenoid can fail, preventing the injector from firing.

- Tip: Diagnose with an Ohm meter or a diagnostic scan tool.

Critical 6.0 Powerstroke Fuel System Specifications: A Data Overview

To help visualize the vital numbers, here’s a summary of key 6.0 Powerstroke fuel system specifications you should be aware of. These are general guidelines; specific values can vary slightly based on model year, engine condition, and modifications.

| Component/Parameter | Specification/Value | Notes/Tolerance |

|---|---|---|

| Low-Pressure Fuel Pump (Lift Pump) Pressure (Key-On Engine-Off) | 45-70 PSI | Should not drop below 40 PSI under load. |

| Low-Pressure Fuel Pump (Lift Pump) Flow Rate | ~160-180 LPH (42-48 GPH) | Sufficient flow is critical, not just pressure. |

| Fuel Pressure Regulator (FPR) Output Pressure | 45-60 PSI | Maintained to the injectors. |

| Primary Fuel Filter Micron Rating | 10-20 Micron | Coarse filtration. |

| Secondary Fuel Filter Micron Rating | 2 Micron | Fine filtration, critical for injector longevity. |

| High-Pressure Oil Pump (HPOP) Max Pressure | 3,600 - 4,000 PSI | Actual operating pressure varies with RPM/load. |

| Minimum Injector Control Pressure (ICP) for Start | ~500 PSI | Below this, the engine will not start. |

| Injector Control Pressure (ICP) at Idle | ~700-800 PSI | Should be stable. |

| Fuel Injector Nozzle Pressure | 20,000 - 26,000 PSI | Achieved via oil pressure intensification. |

| Injector Pressure Regulator (IPR) Duty Cycle (Idle) | ~20-30% | Higher duty cycles (e.g., >40% at idle, >75% under load) can indicate high-pressure oil leaks. |

| Oil Temperature for HPOP Operation | >50°F (10°C) | Engine oil must be warm enough for proper HPOP function. |

Monitoring these specifications, especially with a diagnostic scanner or an aftermarket gauge cluster, is one of the most proactive steps you can take in maintaining your 6.0 Powerstroke.

Maintaining and Optimizing Your 6.0 Powerstroke Fuel System: Best Practices

Understanding the 6.0 Powerstroke fuel system specifications is only half the battle; the other half is implementing proactive maintenance and wise upgrades. The 6.0 Powerstroke is a robust engine when properly cared for, and its fuel system is no exception.

Essential Maintenance Tips:

- Rigorous Fuel Filtration: This cannot be overstated. Always use high-quality, OEM-spec or better fuel filters. Change them religiously, typically every 10,000-15,000 miles. Clogged filters starve the lift pump, overwork it, and allow contaminants to reach the injectors.

- Quality Diesel Fuel: Source your fuel from reputable stations to minimize water and sediment. If you live in an area with questionable fuel quality, consider a reputable lift pump system with additional filtration.

- Fuel Additives: Incorporate a quality diesel fuel additive that offers several benefits:

- Lubricity: Modern ultra-low sulfur diesel (ULSD) has reduced lubricity, which is hard on pumps and injectors.

- Cetane Boost: Improves combustion efficiency, leading to smoother running and potentially better fuel economy.

- Detergents: Cleans injectors and prevents deposit buildup (e.g., for stiction prevention).

- Water Demulsifier: Helps separate water from fuel, protecting components from corrosion and freezing.

- Oil Changes with OE-Spec Oil: Since your engine oil actuates the injectors, its quality is paramount. Use only oil that meets Ford's WSS-M2C171-F1 specification and adhere to recommended oil change intervals (e.g., 5,000-7,500 miles, or sooner under heavy-duty conditions). Dirty or incorrect oil can lead to injector stiction and HPOP wear.

- Monitor Pressures: Install an aftermarket fuel pressure gauge and regularly monitor ICP and IPR duty cycle via a diagnostic tool (like Forscan or a dedicated monitor). Deviations are early warning signs.

Recommended Upgrades for Enhanced Reliability:

- Blue Spring Mod: This is an inexpensive, easy modification that replaces the spring in the factory fuel pressure regulator (FPR) housing. It increases fuel pressure by 10-15 PSI, often bringing it into a more optimal range (60-70 PSI) and reducing stress on the injectors and lift pump.

- Aftermarket Lift Pump System: For those seeking maximum reliability and performance, upgrading to an aftermarket FASS or AirDog fuel system can provide superior filtration, improved fuel pressure stability, and air/vapor removal. This is especially beneficial for modified engines.

- STC Fitting Upgrade: If your 2005+ 6.0 Powerstroke still has the factory two-piece STC fitting, proactively replacing it with a revised one-piece unit is highly recommended to prevent a common failure point.

- Updated Standpipes and Dummy Plugs: For 2004.5+ engines, if you haven't replaced these, consider doing so with the updated designs (or during any major engine work) to prevent high-pressure oil leaks.

By understanding these specifications and implementing these maintenance and upgrade strategies, you can significantly improve the longevity and performance of your 6.0 Powerstroke, transforming it from a potential headache into a reliable workhorse.

Conclusion: Mastering Your 6.0 Powerstroke's Fuel System

The 6.0 Powerstroke's fuel system is a complex, high-performance assembly that demands attention and respect. From the low-pressure lift pump delivering consistent fuel to the incredible pressures generated by the HPOP and the precise action of the HEUI injectors, every component plays a vital role. By thoroughly understanding the 6.0 Powerstroke fuel system specifications, you empower yourself to diagnose issues, perform proactive maintenance, and make informed decisions about upgrades.

Don't wait for a problem to arise. Arm yourself with knowledge, invest in quality parts, adhere to strict maintenance schedules, and consider beneficial upgrades. Your 6.0 Powerstroke is a powerful machine, and with a well-maintained fuel system, it will continue to deliver the robust performance you expect for many miles to come. Drive smart, maintain diligently, and enjoy the ride!

🎥 Related Video: How to test for Failed Injectors on 6.0 #powerstrokediesel #ford

📺 It’s Maynard

Frequently Asked Questions

What are the main components that define the 6.0 Powerstroke fuel system specifications?

The 6.0 Powerstroke fuel system consists of several key components, including the frame-mounted electric fuel pump, primary and secondary fuel filters, a fuel pressure regulator, high-pressure fuel lines, and the fuel rails that feed the HEUI (Hydraulically Electronic Unit Injector) injectors. These components work together to deliver clean, pressurized fuel to the engine for optimal combustion.

What is the ideal fuel pressure specification for a 6.0 Powerstroke, and why is it important?

The optimal fuel pressure specification for the 6.0 Powerstroke is typically between 45-70 PSI at idle and under load. Maintaining adequate fuel pressure is crucial for the proper operation and longevity of the HEUI injectors, as insufficient pressure can lead to injector stiction, poor performance, and eventually failure.

How many fuel filters are in the 6.0 Powerstroke fuel system, and what is their recommended service interval?

The 6.0 Powerstroke fuel system utilizes two fuel filters: a primary filter located on the frame rail (often integrated with the fuel pump module) and a secondary filter located in the engine valley. It’s generally recommended to replace both fuel filters every 15,000 miles or annually, whichever comes first, to ensure optimal fuel quality and protect the injectors.

What type of fuel pump does the 6.0 Powerstroke fuel system use, and where is it located?

The 6.0 Powerstroke fuel system employs a frame-mounted electric fuel pump, typically located along the driver’s side frame rail. This pump is responsible for drawing fuel from the tank and delivering it under pressure through the filtration system to the engine’s fuel rails.

What are common signs or symptoms of issues within the 6.0 Powerstroke fuel system specifications?

Common symptoms of problems in the 6.0 Powerstroke fuel system include hard starting (especially when warm), loss of power, rough idle, extended cranking, and misfires. Often, these issues can be traced back to low fuel pressure, clogged filters, or failing injectors, which fall under the overarching 6.0 Powerstroke fuel system specifications.

How do the HEUI injectors interact with the 6.0 Powerstroke fuel system?

The 6.0 Powerstroke uses HEUI (Hydraulically Electronic Unit Injector) injectors, which are unique in that they are actuated by high-pressure engine oil rather than solely fuel pressure. While oil provides the force to fire the injector, the fuel system is responsible for supplying clean, pressurized fuel to the injectors at the correct volume for atomization and combustion.