Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Featured image for this comprehensive guide about Torque specs for 6.0 Powerstroke cylinder head bolts

Image source: dieselplace.com

The 6.0 Powerstroke engine. For many Ford truck owners, those words evoke a mix of powerful performance and, let’s be honest, a touch of trepidation. This V8 turbodiesel, produced from 2003 to 2007, is renowned for its impressive torque and hauling capabilities. However, it’s also infamous for a few key Achilles’ heels, none more prominent than its cylinder head gasket and bolt design. If you’re tackling a head gasket replacement or an engine rebuild on your 6.0 Powerstroke, understanding and correctly applying the torque specs for 6.0 Powerstroke cylinder head bolts is not just important – it’s absolutely critical for the long-term health and reliability of your engine.

Getting the 6.0 Powerstroke head bolt torque wrong can lead to catastrophic consequences: blown head gaskets, warped cylinder heads, and costly repairs that could have been avoided. Whether you’re a seasoned DIY mechanic or entrusting your truck to a professional, having a clear grasp of the correct procedures and specifications is paramount. This comprehensive guide will delve deep into the world of 6.0 Powerstroke cylinder head bolts, covering everything from the original OEM specifications to the highly recommended aftermarket solutions like ARP head studs, ensuring your Powerstroke runs strong for years to come.

We’ll cut through the noise, provide actionable advice, and give you the precise torque specs for 6.0 Powerstroke cylinder head bolts you need to follow. Our aim is to equip you with the knowledge to make informed decisions and execute the job flawlessly. So, let’s dive into the specifics and demystify the process of securing those vital components.

Quick Answers to Common Questions

What are the actual torque specs for 6.0 Powerstroke cylinder head bolts?

The most commonly recommended torque specs for 6.0 Powerstroke cylinder head bolts involve a multi-stage process, typically starting with 65 ft-lbs, then 75 ft-lbs, and finally 85 ft-lbs for OEM bolts. However, aftermarket studs will have different values, so always double-check with the specific manufacturer’s instructions.

Is there a specific tightening sequence I should follow?

Absolutely! Following the correct tightening sequence for 6.0 Powerstroke cylinder head bolts is just as critical as the torque values themselves. This sequence ensures even pressure distribution across the head, preventing warping and promoting a proper seal.

Do I need to replace my cylinder head bolts when doing this job?

For 6.0 Powerstroke cylinder head bolts, it’s highly recommended to replace them with new, quality bolts or studs. The original OEM bolts are Torque-to-Yield (TTY), meaning they stretch during the initial tightening and aren’t designed for reuse.

What happens if I don’t use the correct torque specs?

Failing to use the precise torque specs for 6.0 Powerstroke cylinder head bolts can lead to catastrophic issues like head gasket failure, coolant leaks, or even a warped cylinder head. It’s a critical step that directly impacts the engine’s reliability and longevity.

Are aftermarket head studs torqued differently than OEM bolts?

Yes, absolutely! Aftermarket head studs, like those from ARP, generally have different and often higher torque specs for 6.0 Powerstroke cylinder head bolts compared to OEM bolts. Always refer to the specific instructions provided by the stud manufacturer for accurate values and a proper installation.

📋 Table of Contents

- Understanding the 6.0 Powerstroke’s Achilles’ Heel: The Head Gasket & Bolt Saga

- The Original Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts

- Upgrading for Durability: ARP Head Studs and Their Torque Requirements

- Beyond Torque: Essential Best Practices for 6.0 Head Gasket & Bolt Replacement

- Common Mistakes and How to Avoid Them During Head Bolt Installation

- Final Thoughts on Maintaining Your 6.0 Powerstroke’s Cylinder Heads

Understanding the 6.0 Powerstroke’s Achilles’ Heel: The Head Gasket & Bolt Saga

Before we discuss the precise torque specs for 6.0 Powerstroke cylinder head bolts, it’s essential to understand why this topic is so critical for the 6.0L Powerstroke. The engine’s cylinder head gasket and bolt design were, frankly, a significant weak point from the factory. This inherent flaw often led to premature head gasket failure, which became one of the most common and expensive repairs for this engine.

Learn more about Torque specs for 6.0 Powerstroke cylinder head bolts – Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Image source: 2carpros.com

The OEM Design Flaw: Why Head Gaskets Failed

At the heart of the 6.0 Powerstroke’s head gasket woes was a combination of factors. The engine generates immense combustion pressures, especially when tuned or under heavy load. The original equipment manufacturer (OEM) head gaskets were designed to seal these pressures, but they often weren’t robust enough to withstand the sustained abuse. Compounding this issue was the design of the factory head bolts.

| Step | Torque Specification | Notes/Action |

|---|---|---|

| 1 | 65 ft-lbs | Initial Pass – Tighten all bolts in the specified sequence (center out). |

| 2 | 85 ft-lbs | Second Pass – Tighten all bolts in sequence. |

| 3 | 100 ft-lbs | Third Pass – Tighten all bolts in sequence. |

| 4 | Additional 90 degrees | Final Pass – Turn all bolts an additional 1/4 turn (90°) in sequence. |

| Important Note | N/A | Always use new Torque-to-Yield (TTY) bolts when following these specifications. Aftermarket studs (e.g., ARP) require different torque values. |

The Role of TTY Bolts and Their Limitations

The 6.0 Powerstroke utilized Torque-to-Yield (TTY) bolts from the factory. TTY bolts are designed to be torqued to a specific value and then tightened an additional number of degrees (e.g., 90 degrees, 45 degrees, etc.). This process stretches the bolt into its plastic deformation range, meaning it’s permanently stretched to achieve the desired clamping force. While TTY bolts offer a very consistent clamping force when new and properly installed, they have a critical limitation: they are single-use items. Once stretched, they lose their elasticity and cannot be reused. More importantly for the 6.0, the factory TTY bolts were simply not strong enough to maintain the necessary clamping force on the head gaskets under the engine’s high operating temperatures and pressures, especially when combined with a less-than-ideal head gasket design. This often led to the head lifting slightly, allowing combustion gases to escape, thereby “blowing” the head gasket. Addressing the 6.0 Powerstroke cylinder head bolts with a stronger solution became a necessity, not just an upgrade.

The Original Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts

Understanding the original torque specs for 6.0 Powerstroke cylinder head bolts provides a foundation, even if most owners eventually opt for an upgrade. From the factory, the 6.0 Powerstroke utilized TTY (Torque-to-Yield) bolts, which involve a specific multi-step tightening sequence rather than a single foot-pound specification. It’s crucial to remember that these specifications are for new OEM TTY bolts only. Reusing TTY bolts is a critical mistake that will almost certainly lead to head gasket failure.

Learn more about Torque specs for 6.0 Powerstroke cylinder head bolts – Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Image source: ls1tech.com

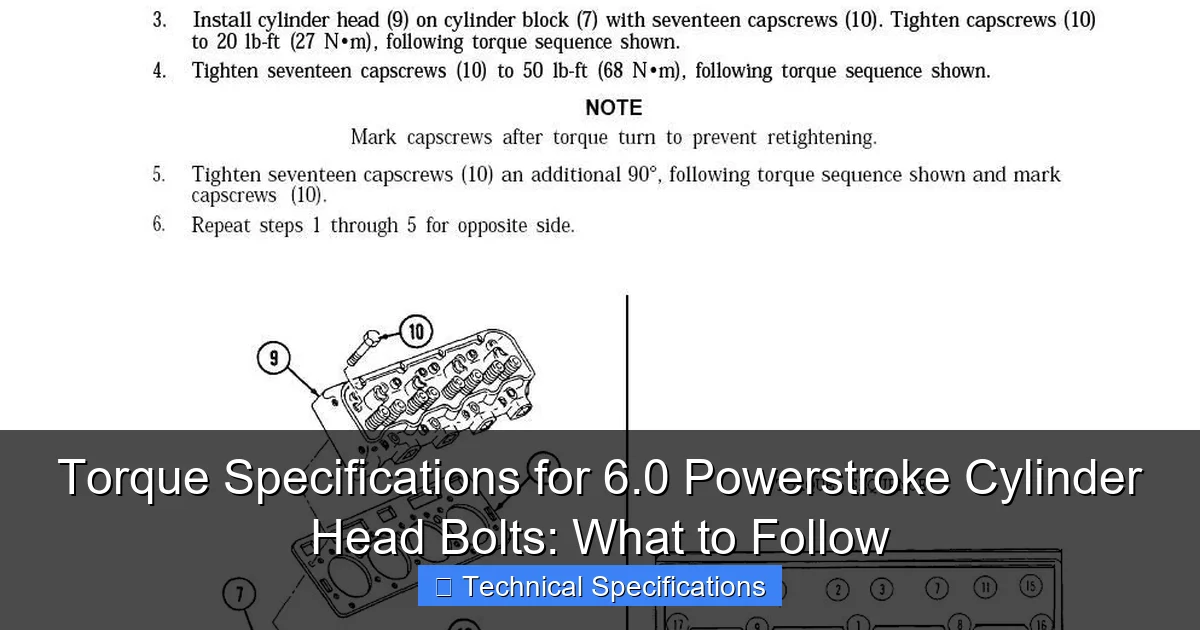

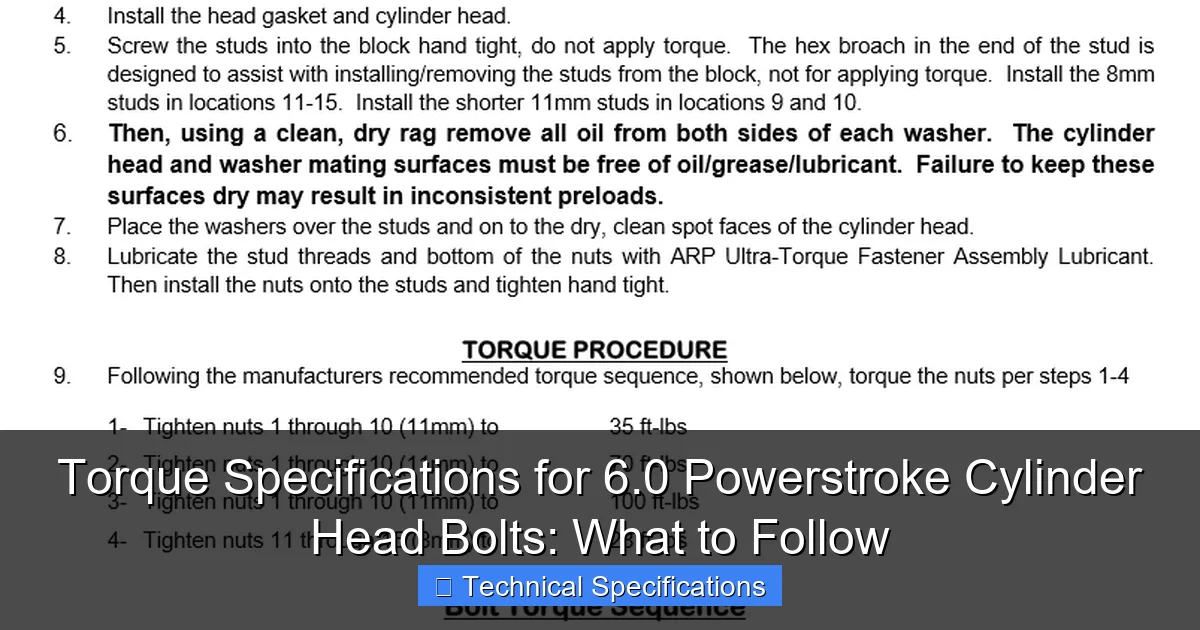

Step-by-Step OEM Torque Procedure

The original OEM procedure for tightening the 6.0 Powerstroke head bolts was a meticulous process designed to evenly distribute clamping force across the cylinder head. While we strongly recommend against reusing these bolts, here’s a general outline of the OEM procedure for new TTY bolts:

- Apply a small amount of engine oil to the threads of the head bolts and under the head of the bolt.

- Install all head bolts finger tight in the specified sequence (always work from the center outwards in a spiral pattern).

- First Pass: Torque all head bolts to 20-25 ft-lbs (27-34 Nm) in the specified sequence. This is a preliminary seating torque.

- Second Pass: Torque all head bolts to 40-45 ft-lbs (54-61 Nm) in the specified sequence.

- Third Pass: Tighten all head bolts an additional 90 degrees (1/4 turn) in the specified sequence.

- Fourth Pass: Tighten all head bolts another 90 degrees (1/4 turn) in the specified sequence.

This multi-stage process was intended to stretch the TTY bolts into their plastic range, providing a consistent clamping force. However, as noted, this force often proved insufficient for the demands of the 6.0 Powerstroke.

Why OEM Specs Often Weren’t Enough

Despite the precise procedure, the factory 6.0 Powerstroke torque specs, when applied to the TTY bolts, often didn’t provide enough consistent clamping force to prevent head lift. The TTY bolts themselves, while effective in other applications, were found to be marginal for the high cylinder pressures and thermal cycling inherent in the 6.0L Powerstroke. This, combined with the original head gasket material, created a recipe for failure. Many experienced mechanics and enthusiasts quickly learned that a more robust solution was needed to truly bulletproof the engine and prevent recurring head gasket issues. This led to the widespread adoption of aftermarket solutions, primarily ARP head studs.

Upgrading for Durability: ARP Head Studs and Their Torque Requirements

When it comes to addressing the notorious head gasket issues of the 6.0 Powerstroke, one solution stands head and shoulders above the rest: ARP head studs. This aftermarket upgrade has become almost standard practice for anyone serious about improving the reliability and longevity of their engine. Understanding the ARP head studs 6.0 Powerstroke torque specifications and proper installation procedures is paramount for their effectiveness.

The Case for ARP Head Studs: A Permanent Solution

Unlike the factory TTY bolts, ARP (Automotive Racing Products) head studs are reusable, non-yield fasteners made from much stronger materials, typically a proprietary alloy called ARP2000 or Custom Age 625+. Instead of stretching into their plastic range, studs provide a much higher and more consistent clamping force on the cylinder heads without yielding. This superior strength significantly reduces the likelihood of cylinder head lift, which is the primary cause of head gasket failure. When installed correctly with the appropriate torque specs for 6.0 Powerstroke cylinder head bolts, ARP studs offer a virtually permanent solution to the head gasket problem, allowing the engine to withstand higher boost pressures and operate reliably.

ARP Torque Specifications: The New Standard

The torque specs for 6.0 Powerstroke cylinder head bolts when using ARP studs are distinctly different from the OEM TTY bolt procedure. ARP studs utilize a traditional torque-to-spec method, but the exact values depend critically on the lubricant used during installation. ARP provides specific lubricants (ARP Ultra-Torque Fastener Assembly Lube, often referred to as moly lube) that are designed to minimize friction and ensure accurate torque readings. Using the incorrect lubricant, or none at all, will result in an inaccurate clamping force, regardless of the wrench setting.

Here are the generally accepted and recommended ARP head studs 6.0 Powerstroke torque specifications:

- With ARP Ultra-Torque Fastener Assembly Lube (Moly Lube):

- First Pass: 70 ft-lbs (95 Nm)

- Second Pass: 135 ft-lbs (183 Nm)

- Third Pass: 210-230 ft-lbs (285-312 Nm)

Note: Many experienced builders often aim for the higher end of the range, around 220-230 ft-lbs, for maximum clamping force. Always verify the specific instructions that come with your ARP kit.

- With 30wt Engine Oil (if ARP lube is unavailable):

- First Pass: 90 ft-lbs (122 Nm)

- Second Pass: 170 ft-lbs (230 Nm)

- Third Pass: 250-260 ft-lbs (339-353 Nm)

It is highly recommended to use the specified ARP lubricant for the most accurate and consistent results. Engine oil creates more friction, requiring higher torque values to achieve the same clamping force.

The Critical ARP Torque Procedure: Oil vs. Moly Lube

The installation procedure for ARP studs is just as important as the torque values themselves. The studs should be threaded into the block finger tight, and then the cylinder head, washers, and nuts are installed. The ARP moly lube (or specified alternative) should be applied generously to the threads of the stud that the nut will engage, and also under the head of the nut where it contacts the washer. This reduces friction and ensures that the torque wrench reading accurately translates to stud stretch and clamping force. The tightening sequence is crucial: always work from the center of the cylinder head outwards in a spiral pattern, following the specified torque passes until the final value is reached. Consistency is key when applying the 6.0 Powerstroke torque specs for these studs.

Beyond Torque: Essential Best Practices for 6.0 Head Gasket & Bolt Replacement

While correct torque specs for 6.0 Powerstroke cylinder head bolts are undoubtedly critical, they are just one piece of a larger puzzle. A successful head gasket and bolt replacement on a 6.0 Powerstroke requires meticulous attention to several other best practices. Overlooking any of these steps can compromise even the best quality studs and gaskets, leading to premature failure and repeated frustration. Ensuring a holistic approach to the repair is what truly guarantees longevity for your Powerstroke.

Surface Preparation: The Foundation of Success

The sealing surfaces of both the cylinder block and the cylinder heads must be impeccably clean and perfectly flat. Any residual gasket material, corrosion, or foreign debris on these surfaces will create an uneven seal, regardless of how perfectly you apply the 6.0 Powerstroke head bolt torque. Use appropriate gasket scrapers, fine abrasives (like Scotch-Brite pads, carefully to avoid scratching), and plenty of solvent (like brake cleaner) to remove all traces of old gasket material and oil. Follow up with compressed air to clear away any particles. A clean, smooth surface is non-negotiable for a lasting head gasket seal.

Quality Gaskets Matter: OEM vs. Aftermarket

Just as important as the bolts themselves are the head gaskets. While the original OEM gaskets were a weak point, Ford has since revised and improved their gasket design. However, many aftermarket manufacturers also offer robust solutions. When selecting gaskets, look for multi-layer steel (MLS) gaskets, which are known for their durability and ability to handle high cylinder pressures. Ensure the gaskets are designed specifically for the 6.0 Powerstroke and consider reputable brands that have a proven track record. Skimping on gasket quality is a false economy that can quickly negate all your hard work on the 6.0 Powerstroke cylinder head bolts.

The Importance of Head Surfacing and Inspection

Before reinstalling the cylinder heads, it is absolutely essential to have them inspected and, if necessary, resurfaced by a reputable machine shop. The intense heat cycles and potential head lift that contributed to the original gasket failure can cause the cylinder heads to warp or become uneven. Even a slight warp can prevent a proper seal, leading to another blown gasket. A machine shop will check for flatness, cracks, and other damage. If resurfacing is required, they will shave a minimal amount of material to restore flatness. This step is critical for ensuring the torque specs for 6.0 Powerstroke cylinder head bolts can effectively seal the heads.

Coolant System Health: A Often Overlooked Factor

The health of your 6.0 Powerstroke’s cooling system directly impacts the longevity of your head gaskets and the effectiveness of your 6.0 Powerstroke torque specs. Overheating is a primary killer of head gaskets. Before completing the head gasket job, inspect and service your entire cooling system. This includes:

- Flushing the radiator and engine block.

- Replacing the thermostat.

- Inspecting or replacing the water pump.

- Checking all hoses for cracks or swelling.

- Ensuring the EGR cooler is either deleted or a robust aftermarket cooler is installed, as EGR cooler failures often lead to head gasket issues by introducing combustion gasses into the coolant.

- Refilling with the correct type and concentration of coolant.

A properly functioning cooling system maintains stable engine temperatures, reducing thermal stress on the head gaskets and allowing your expertly torqued 6.0 Powerstroke cylinder head bolts to do their job effectively.

Common Mistakes and How to Avoid Them During Head Bolt Installation

Even with the right components and the correct torque specs for 6.0 Powerstroke cylinder head bolts, mistakes during installation can undermine the entire repair. The complex nature of a 6.0 Powerstroke head gasket job leaves little room for error. Being aware of common pitfalls can save you significant time, money, and frustration. Precision and patience are your best allies when dealing with these critical engine components.

Reusing TTY Bolts: A Recipe for Disaster

This cannot be stressed enough: DO NOT reuse factory Torque-to-Yield (TTY) bolts. As discussed, these bolts are designed to stretch permanently upon initial tightening. Once removed, they lose their ability to provide consistent clamping force and will not adequately hold the cylinder heads in place. Reusing TTY bolts is a guarantee of future head gasket failure, typically sooner rather than later. If you’re not upgrading to studs, always use brand new OEM TTY bolts with the specified 6.0 Powerstroke torque specs.

Improper Lubrication: Impact on Torque Accuracy

The type and amount of lubricant used on the threads and under the head of the nuts (for studs) or bolts is paramount. Torque specifications are derived assuming a specific coefficient of friction. If you use no lubricant, or the wrong type, the actual clamping force achieved will deviate significantly from what the torque wrench reads. For ARP studs, always use their recommended ARP Ultra-Torque Fastener Assembly Lube. If unavailable, 30wt engine oil is a less ideal but acceptable alternative, but remember the torque values change dramatically. Insufficient lubrication can lead to under-torquing, while excessive or incorrect lubrication can lead to over-torquing, both of which can compromise the head gasket seal or damage the threads in the block. Consistency with lubrication is key to accurately applying the ARP head studs 6.0 Powerstroke torque values.

Skipping Torque Sequence or Steps

The tightening sequence for cylinder head bolts or studs is designed to evenly distribute stress across the head and gasket, preventing warpage and ensuring a uniform seal. Skipping steps, tightening bolts out of sequence, or failing to follow the multi-pass procedure can result in uneven clamping force. This unevenness creates high-stress points on the gasket and can lead to leaks or premature failure. Always follow the specified pattern (typically a spiral from the center outwards) and complete all torque passes for both OEM TTY bolts and aftermarket ARP studs to ensure proper 6.0 Powerstroke torque specs are met.

Over-Torquing or Under-Torquing

Both over-torquing and under-torquing can lead to problems. Under-torquing means insufficient clamping force, allowing the cylinder head to lift and the gasket to blow. Over-torquing, especially with TTY bolts, can prematurely stretch or even break the bolt. With ARP studs, while they are much stronger, excessive over-torquing can still damage the threads in the engine block or the studs themselves. Always use a high-quality, recently calibrated torque wrench. Digital torque wrenches offer superior accuracy. Double-check your torque specs for 6.0 Powerstroke cylinder head bolts and your wrench settings before starting.

Final Thoughts on Maintaining Your 6.0 Powerstroke’s Cylinder Heads

The 6.0 Powerstroke is a formidable engine, capable of incredible power and longevity, but only when its known weaknesses are properly addressed. The issue of head gaskets and head bolts has plagued this engine since its inception, making a thorough and correct repair absolutely non-negotiable for anyone looking to keep their truck running strong. Understanding and meticulously applying the correct torque specs for 6.0 Powerstroke cylinder head bolts is the linchpin of this crucial repair.

Whether you’re sticking with new OEM TTY bolts (and understanding their limitations) or, as is highly recommended, upgrading to ARP head studs, the details matter. The shift from a multi-angle TTY procedure to a specific foot-pound torque for ARP studs, coupled with the critical role of proper lubrication, highlights the need for precision. This isn’t a job where “good enough” will suffice. Every step, from surface preparation and gasket selection to the final torque pass, contributes to the overall success and durability of your engine.

Investing the time and effort into a proper head gasket and bolt replacement, following all best practices and adhering to the precise 6.0 Powerstroke head bolt torque specifications, will pay dividends in the long run. It transforms a notorious weakness into a robust strength, allowing your 6.0 Powerstroke to deliver the powerful performance it was designed for, without the constant worry of catastrophic failure. Drive confidently, knowing your engine’s heart is secured with the utmost care and precision.

🎥 Related Video: Torque ARP studs on 6.0

📺 JamesRRossII

What you need to do before tightening studs.

Frequently Asked Questions

What are the specific torque specifications for 6.0 Powerstroke cylinder head bolts?

The torque procedure for 6.0 Powerstroke cylinder head bolts is a multi-stage process involving specific torque values and final angle turns. Typically, you will follow stages like initial snug, a specific torque value, and then one or two additional angle turns, such as 90 degrees or 65 degrees, depending on the specific Ford factory service manual revision. Always consult the latest Ford service manual for the most accurate and up-to-date figures.

Is there a required torque sequence for 6.0 Powerstroke cylinder head bolts?

Yes, following a precise torque sequence is absolutely critical for 6.0 Powerstroke cylinder head bolts to ensure even clamping force across the head gasket. This sequence usually starts from the center bolts and works its way outwards in a criss-cross pattern. Adhering to the correct pattern prevents warpage of the cylinder head and promotes a proper seal.

Should I reuse my old 6.0 Powerstroke cylinder head bolts, or are new ones necessary?

You should *never* reuse old 6.0 Powerstroke cylinder head bolts; new bolts are absolutely essential for a successful repair. The original Ford bolts are “Torque-to-Yield” (TTY) fasteners, which are designed to stretch permanently when first torqued. Reusing them will result in insufficient clamping force and almost guaranteed head gasket failure.

Do the torque specifications differ when using ARP head studs on a 6.0 Powerstroke?

Yes, if you are installing ARP head studs on your 6.0 Powerstroke, their torque specifications will be different from the OEM bolt procedures. ARP studs are designed to stretch elastically and provide superior clamping force, and their recommended torque values are typically higher and may involve a different lubricant and tightening process. Always refer to the specific instructions provided by ARP for their head stud kits.

What are the consequences of not properly torquing 6.0 Powerstroke cylinder head bolts?

Improperly torquing 6.0 Powerstroke cylinder head bolts can lead to severe and costly engine damage, primarily resulting in premature head gasket failure. This can manifest as coolant leaks, oil leaks, combustion gases entering the cooling system, or even engine overheating. Correct torque ensures a robust seal and prevents these critical issues.

Is a retorque procedure required for 6.0 Powerstroke cylinder head bolts after initial installation?

For factory 6.0 Powerstroke cylinder head bolts, a retorque procedure after initial installation is generally not required or recommended once the multi-stage torque-to-yield process is completed. However, some aftermarket head stud manufacturers, like ARP, might have specific break-in and retorque recommendations, so always consult their instructions. For OEM bolts, once the final angle turn is achieved, the job is done.