Jet Fuel in a Powerstroke Engine: What You Need to Know

Featured image for this comprehensive guide about jet fuel in a powerstroke engine

Image source: i.ytimg.com

The roar of a Powerstroke engine is music to many ears – a testament to raw power, reliability, and robust performance. Ford’s iconic diesel workhorse is known for tackling tough jobs and hauling heavy loads, making it a beloved choice for truckers, farmers, and enthusiasts alike. But in the world of diesel engines, questions often arise about fuel choices, especially when it comes to unconventional alternatives. One such query that frequently surfaces in forums and garage discussions is: what happens if you put jet fuel in a Powerstroke engine?

It’s a tempting thought for some. Jet fuel, designed for high-performance aviation turbines, might seem like a natural fit for another powerful engine. Perhaps it’s a misconception that it’s “cleaner,” more efficient, or even cheaper in some niche circumstances. However, the reality is far more complex, and the consequences of using jet fuel in a Powerstroke engine can range from inconvenient performance issues to catastrophic, expensive engine damage. This comprehensive guide will dissect the differences between these two fuel types, explore the specific risks to your Powerstroke’s intricate systems, and equip you with the knowledge to protect your investment.

So, buckle up as we navigate the crucial distinctions, debunk common myths, and arm you with the actionable insights you need to ensure your Powerstroke runs optimally on the fuel it was designed for. Understanding why standard diesel fuel is king for your truck is not just about performance; it’s about preserving the longevity and health of your prized diesel engine.

Quick Answers to Common Questions

Can I put jet fuel in my Powerstroke engine?

Short answer: No, you really shouldn’t. While your Powerstroke might technically *run* on jet fuel for a very brief period, it is not designed for it and can cause serious, expensive damage.

What happens if I accidentally put jet fuel in a Powerstroke engine?

You might notice rough running, power loss, and increased smoke. More critically, jet fuel lacks the necessary lubricity and cetane for your Powerstroke, leading to rapid wear on vital fuel system components like the injectors and fuel pump.

Is jet fuel better for Powerstroke performance?

Absolutely not. Despite some myths, jet fuel will not improve your Powerstroke’s performance; in fact, its lower cetane rating and different composition will likely cause a significant *decrease* in power and efficiency.

Will using jet fuel in a Powerstroke engine damage it permanently?

Potentially, yes. The lack of proper lubrication in jet fuel can quickly wear out expensive components, leading to costly repairs or even complete engine failure over time if not addressed promptly.

What should I do if I’ve already put jet fuel in my Powerstroke?

Do not start or run the engine if possible. If you’ve already driven it, stop immediately and have the fuel tank drained and the entire fuel system inspected by a qualified mechanic to prevent further damage.

📋 Table of Contents

- The Allure and the Myth: Why Some Consider Jet Fuel for a Powerstroke

- Key Differences: Jet Fuel vs. Diesel Fuel

- The Immediate and Long-Term Dangers to Your Powerstroke

- Specific Powerstroke Components at Risk

- What Happens If You Accidentally Use Jet Fuel? Action Steps

- Safer Alternatives and Best Practices for Your Powerstroke

- Conclusion

The Allure and the Myth: Why Some Consider Jet Fuel for a Powerstroke

The idea of fueling a diesel truck with jet fuel often stems from a combination of curiosity, misinformation, and sometimes, a perceived opportunity for cost savings or performance gains. Let’s explore some of the common misconceptions that might lead someone to consider putting jet fuel in a Powerstroke engine.

Learn more about jet fuel in a powerstroke engine – Jet Fuel in a Powerstroke Engine: What You Need to Know

Image source: i.ytimg.com

Myth 1: Jet Fuel is Just “Cleaner” or “Higher Octane” Diesel

- The Reality: This is perhaps the most widespread misunderstanding. Jet fuel (typically Jet A or Jet A-1) and diesel fuel (Diesel #2) are both refined from crude oil, but they are engineered for entirely different applications and engine types. While jet fuel is indeed highly refined, its “cleanliness” refers to its purity for aviation turbine engines, which operate differently than internal combustion diesel engines. The concept of “octane” is relevant for gasoline engines (which use spark plugs for ignition) but not for diesel engines, which rely on compression ignition. For diesel, the equivalent measure is the cetane rating, and here, jet fuel falls significantly short.

Myth 2: It Will Boost Performance or Power

- The Reality: Some believe that because jet engines are powerful, their fuel must impart superior performance to a Powerstroke. This couldn’t be further from the truth. Powerstroke engines are finely tuned to burn diesel fuel efficiently. Introducing jet fuel, with its different burning characteristics and lower energy density per unit volume (despite common belief, we’ll dive deeper into BTU later), will almost certainly lead to a decrease in power, rough running, and poor fuel economy, not an increase.

Myth 3: Jet Fuel is Cheaper or More Accessible

- The Reality: In some very specific, niche scenarios (e.g., military surplus, certain agricultural operations where large quantities are stored), jet fuel might appear cheaper at first glance. However, for the average consumer, acquiring jet fuel legally and conveniently is difficult and often more expensive than standard diesel. Furthermore, the potential cost savings are utterly dwarfed by the massive repair bills that would inevitably follow from using it in your Powerstroke.

These myths, while persistent, fail to account for the fundamental chemical and physical differences between these fuels and the precise engineering of a Powerstroke engine designed to operate exclusively on diesel fuel. Understanding these distinctions is the first critical step in appreciating why using jet fuel in a Powerstroke engine is a perilous endeavor.

| Fuel Property | #2 Diesel Fuel (Typical) | Jet A Fuel (Typical) | Impact on Powerstroke Engine (if using Jet Fuel) |

|---|---|---|---|

| **Cetane Number** | 40-55 | 35-50 (often lower end) | Poor ignition, hard starting, rough running, potential engine damage due to misfires. |

| **Lubricity** | Good (required for pump/injector life) | Poor | Accelerated wear on high-pressure fuel pump and injectors, leading to premature failure. |

| **Energy Content (BTU/gallon)** | ~138,700 | ~135,000 | Slight reduction in power output and fuel efficiency due to lower energy density. |

| **Flash Point** | ~125°F (~52°C) | ~100°F (~38°C) | Increased fire hazard, especially during handling, refueling, and in warmer operating conditions. |

Key Differences: Jet Fuel vs. Diesel Fuel

To truly grasp why jet fuel in a Powerstroke engine is a recipe for disaster, we must delve into the fundamental differences between these two petroleum products. While both are distillates from crude oil, their distinct properties are tailored for their specific applications.

Learn more about jet fuel in a powerstroke engine – Jet Fuel in a Powerstroke Engine: What You Need to Know

Image source: blogger.googleusercontent.com

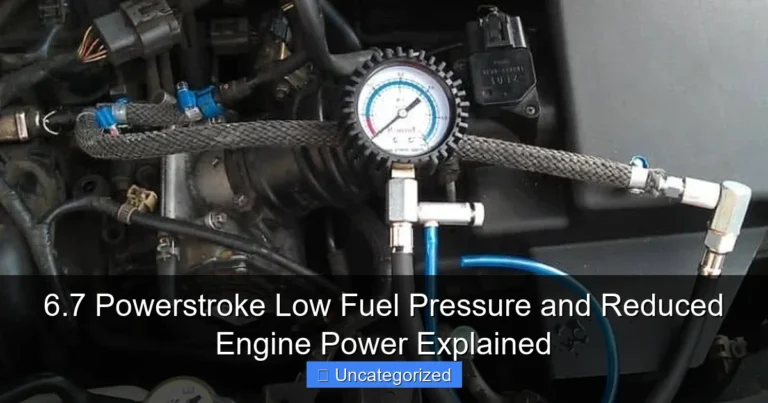

Cetane Rating: The Ignition Quality

- Diesel Fuel: Standard #2 diesel typically has a cetane rating of 40-55. Cetane is a measure of how quickly and completely diesel fuel ignites under compression. A higher cetane number indicates a shorter ignition delay, leading to smoother combustion, less engine noise, and easier cold starts.

- Jet Fuel: Jet A and Jet A-1 have significantly lower cetane ratings, often in the range of 35-45. This lower cetane means a longer ignition delay in a diesel engine. In a Powerstroke, this translates to rougher operation, increased engine knock (diesel “clatter”), incomplete combustion, and potentially higher exhaust temperatures, all detrimental to engine health and longevity.

Lubricity: Protecting Vital Components

- Diesel Fuel: Modern ultra-low sulfur diesel (ULSD) has naturally reduced lubricity compared to older diesel fuels. However, diesel fuel is specifically formulated with lubricating additives to protect the precision components of a diesel fuel system, such as fuel injectors and high-pressure fuel pumps (like the HPOP in older Powerstrokes or the CP4 in newer ones). These components rely on the fuel itself for lubrication.

- Jet Fuel: Jet fuel has very poor lubricity. Turbine engines don’t require the same level of fuel lubrication as a diesel engine’s intricate fuel injection system. Running jet fuel in a Powerstroke engine will rapidly strip away the vital lubrication, leading to premature wear and catastrophic failure of expensive fuel system components.

Energy Content (BTU per Gallon)

- Diesel Fuel: Diesel #2 generally has a higher energy content (measured in British Thermal Units or BTU) per gallon than jet fuel. This higher energy density contributes to the greater torque and efficiency expected from a diesel engine.

- Jet Fuel: While often perceived as having higher energy, jet fuel typically has slightly lower BTU per gallon than diesel. This means you’ll get less power and worse fuel economy if you use it in your Powerstroke. Its energy density is optimized for thrust in a turbine, not for the rotational force in a piston engine.

Flash Point and Volatility

- Diesel Fuel: Diesel has a relatively high flash point (above 125°F or 52°C), meaning it requires a higher temperature to ignite. This makes it safer to store and handle. It is also less volatile.

- Jet Fuel: Jet fuel has a lower flash point and is more volatile than diesel. While this isn’t directly damaging to the engine in terms of combustion, it poses increased safety risks in terms of flammability and handling, especially in a non-aviation context.

Additives

- Diesel Fuel: Formulated with a specific blend of additives for road vehicles, including lubricity enhancers, cetane improvers, detergents, and anti-foaming agents.

- Jet Fuel: Contains additives tailored for aviation, such as anti-icing agents, static dissipaters, and corrosion inhibitors. These additives are not beneficial for a Powerstroke and may even contribute to problems.

Comparative Fuel Properties: Jet A vs. Diesel #2

Understanding these quantitative differences is crucial. Here’s a simplified comparison:

| Property | Diesel #2 (Typical) | Jet A (Typical) |

|---|---|---|

| Cetane Number | 40-55 | 35-45 |

| Lubricity (HFRR Wear Scar Diameter) | < 520 microns | > 600 microns (poor) |

| Energy Content (BTU/gallon) | ~138,700 | ~135,000 |

| Flash Point | > 125°F (52°C) | > 100°F (38°C) |

| Specific Gravity | 0.83 – 0.87 | 0.775 – 0.840 |

Note: Values are approximate and can vary slightly based on source, blend, and region. HFRR (High-Frequency Reciprocating Rig) wear scar diameter measures lubricity; a smaller number indicates better lubricity.

As the table clearly illustrates, jet fuel in a Powerstroke engine is an incompatible blend, differing significantly in critical performance metrics that directly impact engine health and operation.

The Immediate and Long-Term Dangers to Your Powerstroke

The consequences of using jet fuel in a Powerstroke engine are not theoretical; they are real, severe, and expensive. From immediate drivability issues to long-term component degradation, your truck will suffer.

Immediate Performance Degradation

- Rough Idling and Stalling: Due to the lower cetane rating, the fuel will not ignite as efficiently, leading to rough engine operation, misfires, and potentially stalling, especially when cold.

- Loss of Power: The lower energy content and inefficient combustion will result in a noticeable drop in horsepower and torque, making your Powerstroke feel sluggish and unresponsive.

- Increased Engine Noise (Knock): The longer ignition delay will cause a harsher, louder combustion event, often described as a distinct “knock” or “clatter” that is abnormal for a properly running diesel engine.

- Poor Fuel Economy: Less efficient combustion means you’ll burn more fuel to do the same work, negating any perceived cost savings of jet fuel.

Catastrophic Fuel System Failure

- Injector Damage: Modern Powerstroke injectors operate at extremely high pressures and rely heavily on the lubricating properties of diesel fuel. Jet fuel’s poor lubricity will cause rapid wear on the delicate internal components of the injectors, leading to sticking, scoring, and eventual failure. This can manifest as poor spray patterns, resulting in incomplete combustion, increased emissions, and potential engine damage.

- High-Pressure Fuel Pump (HPFP) Failure: The HPFP (or HPOP in older 7.3L/6.0L Powerstrokes) is the heart of your fuel system, creating immense pressure to deliver fuel to the injectors. It is highly susceptible to wear without proper lubrication. Jet fuel will quickly degrade the internal components, leading to metal-on-metal contact, generating metal shavings that contaminate the entire fuel system, and causing pump failure.

- Seal and O-Ring Degradation: Diesel fuel is formulated to be compatible with the rubber and plastic seals and O-rings throughout your fuel system. Jet fuel’s different chemical composition and additives can cause these seals to swell, shrink, or harden, leading to leaks, loss of fuel pressure, and compromised system integrity.

Engine Internal Damage

- Piston and Cylinder Wear: Incomplete combustion due to low cetane fuel can lead to excessive carbon buildup on piston crowns, cylinder walls, and valves. This carbon can cause abrasive wear, leading to reduced compression and eventual engine overhaul.

- Turbocharger Issues: The exhaust gases produced by inefficient combustion can be hotter and contain more particulate matter, potentially leading to increased stress and wear on your turbocharger.

- DPF and SCR System Damage: For newer Powerstrokes with advanced emissions systems (Diesel Particulate Filter, Selective Catalytic Reduction), incomplete combustion and unusual exhaust gas components from jet fuel can quickly clog the DPF and damage the SCR catalyst, leading to expensive repairs and compliance issues.

In essence, using jet fuel in a Powerstroke engine is akin to running a marathon without water: it might work for a short distance, but the damage will be severe and enduring.

Specific Powerstroke Components at Risk

While we’ve broadly covered fuel system components, it’s worth highlighting how critical and expensive specific Powerstroke parts are, making the risk of using jet fuel in a Powerstroke engine even more daunting.

Fuel Injectors

Whether you have a 7.3L Powerstroke with its HEUI (Hydraulically Actuated Electronic Unit Injector) system, a 6.0L with its complex injectors and high-pressure oil pump (HPOP), or a modern 6.7L with its common-rail, piezo-electric injectors, these components are precision instruments. They are designed with incredibly tight tolerances, some parts moving at fractions of a millimeter. Jet fuel’s lack of lubricity will quickly score the injector pintles, nozzles, and internal plungers, leading to:

- Stuck open or closed injectors.

- Poor fuel atomization (fuel spray pattern).

- Reduced fuel delivery, leading to misfires.

- Increased soot production and DPF clogging.

- Potential for fuel dilution of engine oil.

Replacing a single Powerstroke injector can cost hundreds of dollars, and a full set can easily run into the thousands, not including labor.

High-Pressure Fuel Pumps (HPOP, CP3, CP4)

Different generations of Powerstroke engines use different high-pressure fuel pumps, but all are equally vulnerable to poor lubricity:

- 7.3L/6.0L Powerstroke (HPOP): The High-Pressure Oil Pump on these engines pressurizes engine oil, which then acts as a hydraulic fluid to actuate the fuel injectors. While the HPOP itself doesn’t directly pump diesel fuel, if jet fuel somehow contaminates the engine oil, or if low-lubricity fuel degrades other parts of the fuel system that rely on oil, it could indirectly affect the HPOP’s lifespan. More importantly, the fuel pump that delivers fuel to the injectors is still at risk.

- 6.4L Powerstroke (Siemens K16): These high-pressure pumps are known for being sensitive and expensive.

- 6.7L Powerstroke (Bosch CP4): The CP4 pump, in particular, is notorious for its intolerance to poor fuel quality and lack of lubricity. Metal-on-metal contact within a CP4 pump, caused by jet fuel, can lead to catastrophic failure, spewing fine metal particles throughout the entire fuel system. This often requires replacing not just the pump, but also all injectors, fuel lines, fuel rails, and sometimes even the fuel tank – an astronomically expensive repair that can easily exceed $10,000, sometimes even $15,000.

Fuel Lines, Fuel Rails, and Return Lines

As mentioned, metal shavings from a failing HPFP will travel throughout the entire fuel system. These abrasive particles will damage everything in their path, including:

- The delicate surfaces inside fuel lines.

- Pressure regulators.

- Sensors.

- The fuel tank itself (requiring removal and thorough cleaning or replacement).

The cleanup and replacement required after a major fuel system failure due to jet fuel in a Powerstroke engine is exhaustive and financially draining.

What Happens If You Accidentally Use Jet Fuel? Action Steps

Mistakes happen. Whether it’s a moment of distraction at a rural pump or an honest misunderstanding, accidentally putting jet fuel in a Powerstroke engine is a frightening scenario. If you suspect or confirm that you’ve used the wrong fuel, immediate action is crucial to minimize damage.

- DO NOT START THE ENGINE (If Not Already Started): This is the most critical step. If you realize your mistake before turning the key, you’ve significantly improved your chances of avoiding major damage. Do not even turn the key to the “on” position, as this can activate the electric lift pump and circulate the contaminated fuel.

- If the Engine Has Been Started:

- Shut It Off Immediately: As soon as you notice rough running, unusual noises, or any other symptom, turn off the engine. Every second it runs on the wrong fuel increases the risk of damage.

- Do Not Drive Further: Have the vehicle towed to a reputable diesel mechanic.

- Drain the Fuel Tank: The contaminated fuel must be completely removed from the tank. This usually involves dropping the tank or using a specialized pump to extract the fuel.

- Flush the Entire Fuel System:

- Fuel Lines: All fuel lines (supply and return) need to be thoroughly flushed to remove any traces of jet fuel and potential contaminants.

- Fuel Rails: If your Powerstroke has a common rail system, the fuel rails must also be flushed.

- Fuel Filter Housing: Replace the fuel filters and thoroughly clean the filter housing.

- Inspect and Potentially Replace Components:

- Fuel Pump (Lift Pump): Depending on how long the engine ran, the low-pressure lift pump may have suffered damage and require inspection or replacement.

- High-Pressure Fuel Pump (HPFP/HPOP): This is the most vulnerable and expensive component. Even if the engine ran only for a short time, the HPFP should be thoroughly inspected by a professional. If metal shavings are found, the HPFP (and potentially the entire fuel system, as detailed above) will need replacement.

- Fuel Injectors: Injectors should be inspected, and if the engine ran on jet fuel for any significant period, it’s highly likely they will need to be replaced or rebuilt.

- Fuel Pressure Sensors: Inspect and clean or replace any fuel pressure sensors.

- Refill with Proper Diesel Fuel and Additives: Once the system is clean and all affected components are replaced or verified, refill with high-quality #2 diesel fuel. Consider adding a reputable diesel fuel additive designed for lubricity and cleaning to help mitigate any residual minor issues.

- Professional Assessment: Even if you manage to drain and flush the system, it is highly recommended to have a qualified diesel mechanic inspect the engine and fuel system thoroughly to catch any hidden damage before it escalates.

The key takeaway is speed and thoroughness. The sooner you act, and the more comprehensively you address the contamination, the higher the chance of saving your Powerstroke from extensive and costly damage from jet fuel in a Powerstroke engine.

Safer Alternatives and Best Practices for Your Powerstroke

Given the severe risks associated with using jet fuel in a Powerstroke engine, the path forward is clear: stick to what your truck was designed for and adopt best practices for fuel and maintenance. Your Powerstroke is a sophisticated piece of engineering, and treating it with the right fuel is paramount to its longevity and performance.

Always Use Approved Diesel Fuel

- Ultra-Low Sulfur Diesel (ULSD): In North America, this is typically #2 diesel fuel. Always ensure you are filling up with diesel at reputable stations. Avoid using #1 diesel (kerosene) for extended periods in warm weather, as its lower energy content and lubricity can also be detrimental, though less severe than jet fuel. #1 diesel is primarily for extreme cold weather to prevent gelling.

- Reputable Fuel Stations: Stick to busy, well-known fuel stations to ensure you are getting fresh, clean fuel that hasn’t been sitting in tanks for too long, reducing the risk of water contamination or stale fuel.

Leverage Quality Fuel Additives

While not a substitute for proper fuel, high-quality diesel fuel additives can offer significant benefits and peace of mind:

- Lubricity Enhancers: Many modern Powerstroke owners use additives to boost the lubricity of ULSD, providing extra protection for their high-pressure fuel pumps and injectors, especially for sensitive CP4 pumps found in 6.7L Powerstrokes.

- Cetane Boosters: These can improve the cetane rating of your diesel, leading to smoother combustion, reduced engine noise, and potentially better cold starting and fuel economy.

- Detergents/Cleaners: Additives with detergents help keep your fuel system and injectors clean, preventing deposits that can degrade performance and efficiency.

- Anti-Gel/Water Removers: Essential for cold climates to prevent fuel gelling and to disperse water contamination that can lead to corrosion and microbial growth.

Consult your Powerstroke owner’s manual or a trusted diesel mechanic for recommended additive types and brands compatible with your specific engine generation.

Regular Fuel System Maintenance

- Fuel Filter Replacement: This is non-negotiable. Powerstroke engines have primary and secondary fuel filters (sometimes integrated). Replace them according to your manufacturer’s schedule, or more frequently if operating in dusty conditions or with questionable fuel sources. A clogged fuel filter starves your engine and puts undue stress on the fuel pump.

- Water Separator Draining: Many Powerstrokes come equipped with a fuel/water separator. Regularly drain any accumulated water to prevent corrosion and microbial growth in your fuel system.

- Inspect for Leaks: Periodically check fuel lines and connections for any signs of leaks, which can indicate failing seals or damaged components.

Educate Yourself and Avoid “Miracle” Fuels

The temptation to find a cheaper or supposedly more powerful alternative to standard diesel is understandable, but often leads to costly mistakes. Be wary of unverified claims about alternative fuels or “special blends.” Trust in the engineering and specifications provided by Ford for your Powerstroke engine.

By adhering to these best practices, you ensure that your Powerstroke receives the fuel it needs to perform reliably and efficiently for hundreds of thousands of miles, safely avoiding the catastrophic pitfalls of using incompatible fuels like jet fuel in a Powerstroke engine.

Conclusion

The allure of unconventional fuels like jet fuel for a robust diesel engine such as the Powerstroke is, at first glance, understandable. Visions of enhanced performance or cost savings can cloud judgment. However, as we’ve thoroughly explored, the scientific and engineering realities paint a starkly different picture. Using jet fuel in a Powerstroke engine is not a shortcut to power or efficiency; it’s a direct route to severe, expensive, and potentially irreversible damage.

From the critical differences in cetane rating and lubricity to the distinct energy content and additive packages, jet fuel is fundamentally incompatible with the precision-engineered fuel system of a Powerstroke. The consequences range from immediate performance degradation like rough running and power loss, to catastrophic failures of vital components such as injectors and high-pressure fuel pumps. For owners of newer 6.7L Powerstrokes, the risk of a CP4 pump failure due to poor lubrication is a particularly terrifying and financially devastating prospect.

Your Powerstroke engine is a significant investment, built for durability and demanding tasks. Protecting that investment means respecting its design and providing it with the fuel it was specifically engineered to burn: high-quality #2 Ultra-Low Sulfur Diesel. Coupled with consistent use of reputable fuel additives and diligent adherence to the manufacturer’s recommended maintenance schedule, you ensure your truck delivers the reliability and performance you expect, mile after mile, year after year. Don’t fall prey to myths; empower yourself with knowledge and make the right fuel choices for your Powerstroke.

Frequently Asked Questions

Can I use jet fuel in a Powerstroke engine?

Generally, no. While a Powerstroke engine might run briefly on jet fuel, it’s not designed for it and can lead to significant issues. Jet fuel lacks the proper lubrication and cetane rating crucial for a diesel engine’s health.

What are the main differences between jet fuel and diesel for a Powerstroke?

Jet fuel (like Jet A-1) is a refined kerosene, typically lighter and less dense than diesel fuel. Diesel fuel possesses a higher lubricity and a higher cetane rating, both essential for the proper operation and longevity of a Powerstroke engine’s injection system.

What kind of damage can jet fuel cause to a Powerstroke engine?

Using jet fuel can severely damage your Powerstroke engine’s high-pressure fuel pump (HPFP) and injectors due to inadequate lubrication. It can also lead to premature wear, poor combustion, and potential engine failure over time.

Will my Powerstroke run better or have more power with jet fuel?

No, quite the opposite. Your Powerstroke engine will likely run rough, experience a loss of power, and suffer from poor fuel economy. Jet fuel’s different combustion properties are not optimized for a diesel engine.

What should I do if I accidentally put jet fuel in my Powerstroke’s tank?

Do not start the engine. If you’ve accidentally added jet fuel, the best course of action is to have the tank drained and flushed by a professional mechanic immediately. Running the engine, even for a short time, could cause expensive damage.

Are there any circumstances where jet fuel is acceptable for a Powerstroke?

No, there are no recommended or safe circumstances for using jet fuel in a stock Powerstroke engine. It is not a suitable substitute for diesel fuel and should be avoided to prevent costly repairs and maintain engine reliability.