How to Use a Fuel Pressure Gauge on 7.3 Powerstroke: Accurate Testing Methods

Featured image for this comprehensive guide about How to use a fuel pressure gauge on 7.3 Powerstroke

Image source: nukeperformance.com

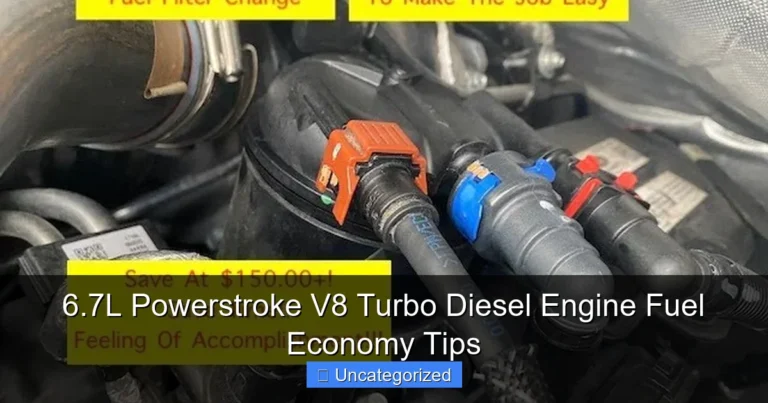

The iconic 7.3 Powerstroke engine is renowned for its reliability and durability, a workhorse that has powered countless Ford trucks for millions of miles. However, even the most robust engines require diligent maintenance and accurate diagnostics to keep them performing at their best. One of the most critical aspects of maintaining your 7.3 Powerstroke‘s health is ensuring optimal fuel pressure. Without the correct fuel pressure, your engine can suffer from a myriad of performance issues, ranging from decreased power and poor fuel economy to rough idling and even catastrophic failure.

Understanding how to use a fuel pressure gauge on 7.3 Powerstroke isn’t just a technical skill for mechanics; it’s an essential diagnostic capability for any serious owner. Unlike newer common rail diesels, the 7.3 Powerstroke utilizes a unique hydraulically actuated electronically controlled unit injector (HEUI) system, which relies heavily on precise fuel pressure to operate correctly. A simple test with a reliable fuel pressure gauge can quickly pinpoint potential problems, saving you significant time, money, and frustration down the road. This comprehensive guide will walk you through everything you need to know, from preparing your tools to interpreting your readings and diagnosing common issues, ensuring your legendary 7.3 keeps roaring.

Quick Answers to Common Questions

Why is checking fuel pressure on your 7.3 Powerstroke so important?

It’s crucial for diagnosing common issues like hard starts, low power, or rough idling, as incorrect fuel pressure directly impacts engine performance on your 7.3 Powerstroke.

What’s the ideal fuel pressure reading for a 7.3 Powerstroke?

You’re typically looking for around 60-65 PSI at idle, though anything between 45-70 PSI under load is generally acceptable for a healthy 7.3 Powerstroke.

Where exactly do I connect the fuel pressure gauge on my 7.3 Powerstroke?

You’ll usually connect the fuel pressure gauge to the Schrader valve, which is conveniently located on the fuel bowl housing on top of the engine on your 7.3 Powerstroke.

Besides the fuel pressure gauge, what other tools do I need for my 7.3 Powerstroke?

You’ll primarily need the gauge kit, which often includes the necessary adapters for the Schrader valve, and perhaps basic wrenches for access when using a fuel pressure gauge on your 7.3 Powerstroke.

What does it mean if my 7.3 Powerstroke fuel pressure gauge shows low or high readings?

Low pressure could indicate a failing fuel pump, clogged filter, or a leak, while consistently high pressure is less common but can point to a faulty pressure regulator on your 7.3 Powerstroke.

📋 Table of Contents

- Why Fuel Pressure Matters on Your 7.3 Powerstroke: The HEUI Connection

- Understanding Your Fuel Pressure Gauge & Necessary Tools

- Step-by-Step Guide: How to Connect a Fuel Pressure Gauge to Your 7.3 Powerstroke

- Performing the Fuel Pressure Test: Key Scenarios & Interpretations

- Diagnosing Common 7.3 Powerstroke Fuel Pressure Issues

- Optimizing Your 7.3 Powerstroke Fuel System: Maintenance & Upgrades

- Conclusion

Why Fuel Pressure Matters on Your 7.3 Powerstroke: The HEUI Connection

To truly appreciate the importance of maintaining optimal fuel pressure, it’s crucial to understand how the 7.3 Powerstroke‘s fuel system works. Unlike traditional diesel engines that rely solely on a high-pressure injection pump, the 7.3 utilizes a unique HEUI system. In this system, engine oil, pressurized by the High-Pressure Oil Pump (HPOP), is used to actuate the fuel injectors. However, this oil pressure alone isn’t enough; the injectors also require a constant, stable supply of fuel at a specific pressure to function correctly.

Learn more about How to use a fuel pressure gauge on 7.3 Powerstroke – How to Use a Fuel Pressure Gauge on 7.3 Powerstroke: Accurate Testing Methods

Image source: nukeperformance.com

The Role of Fuel Pressure in the HEUI System

- Injector Filling: Adequate fuel pressure ensures that the injector’s internal fuel reservoir is consistently and completely filled between injection events. If pressure is too low, the injector may not fill properly, leading to incomplete combustion.

- Combustion Quality: Correct fuel pressure allows the injectors to atomize fuel finely and consistently. Poor atomization due to low pressure can result in incomplete combustion, increased emissions, and carbon buildup.

- Engine Performance: Proper fuel delivery directly translates to horsepower and torque. Low fuel pressure can starve the engine, leading to a noticeable drop in power, sluggish acceleration, and reduced towing capacity.

- Injector Lifespan: Operating injectors with consistently low fuel pressure can cause them to work harder, leading to premature wear and failure. Maintaining the correct fuel pressure 7.3 is vital for injector longevity.

Common Symptoms of Incorrect Fuel Pressure

Your 7.3 Powerstroke isn’t shy about telling you when something’s amiss with its fuel pressure. Keep an eye out for these tell-tale signs:

| Test Condition / Observed Reading | Typical Pressure Range (PSI) | Diagnostic Insight / Potential Issue |

|---|---|---|

| Engine Idling (Warm) | 55-70 PSI | Indicates healthy baseline fuel system operation. Optimal range for injector lubrication and performance. |

| Under Heavy Load / Wide Open Throttle (WOT) | 45-60 PSI (Should not drop more than 10-15 PSI from idle) | Confirms the fuel pump’s ability to maintain adequate supply under demand. Significant drop (<40 PSI) suggests weak pump or restriction. |

| Consistent Low Pressure (<40 PSI) | (Any test condition) | Common causes include clogged fuel filter, failing fuel pump, or a restricted fuel supply line. Risks injector damage and poor performance. |

| No Pressure (0-10 PSI) | (Any test condition) | Indicates a critical failure. Check fuel pump, pump relay, blown fuse, or major fuel line blockage/leak. Engine will not run or run very poorly. |

| Excessively High Pressure (>75 PSI) | (Any test condition) | Less common, but can indicate a faulty fuel pressure regulator (stuck closed) or a restricted return line. Can over-stress pump and lines. |

- Rough Idling or Stalling: Especially when cold, low fuel pressure can cause an inconsistent idle or even make the engine stall.

- Loss of Power or Sluggish Acceleration: The most common symptom. If your truck feels weaker than usual, inadequate fuel delivery is a prime suspect.

- Poor Fuel Economy: Inconsistent combustion and the engine’s attempt to compensate for lean conditions can lead to increased fuel consumption.

- Hard Starts or No-Starts: If the fuel system can’t build or maintain sufficient pressure, the engine will struggle to start or may not start at all.

- Excessive Smoke: White smoke (unburnt fuel) or black smoke (incomplete combustion) can indicate issues with fuel delivery.

- Engine Hesitation or Misfires: Under load or acceleration, the engine might hesitate or feel like it’s missing.

If you’re experiencing any of these symptoms, a 7.3 Powerstroke fuel pressure test is often the first and most crucial diagnostic step.

Understanding Your Fuel Pressure Gauge & Necessary Tools

Before you dive into testing, it’s essential to have the right equipment. A good quality fuel pressure gauge on 7.3 Powerstroke is your primary tool, but you’ll need a few other items to ensure a safe and accurate test.

Learn more about How to use a fuel pressure gauge on 7.3 Powerstroke – How to Use a Fuel Pressure Gauge on 7.3 Powerstroke: Accurate Testing Methods

Image source: nukeperformance.com

Choosing the Right Fuel Pressure Gauge

When selecting a gauge, look for these features:

- Pressure Range: Your gauge should comfortably read pressures up to at least 100 PSI (pounds per square inch). While the target pressure for a 7.3 is lower, having a higher range prevents damage to the gauge during unexpected pressure spikes.

- Fluid-Filled: A fluid-filled gauge (usually glycerin) helps dampen needle fluctuations, providing a more stable and accurate reading, especially on a vibrating engine.

- Gauge Size: A larger gauge face is easier to read.

- Hose Length: Consider a gauge with a sufficiently long hose (3-6 feet) if you want to monitor pressure from the cab during a test drive or under load.

Essential Adapters and Connectors

The 7.3 Powerstroke typically has a Schrader valve test port on the fuel filter housing, similar to a tire valve stem. You’ll need an adapter that connects your fuel pressure gauge to this port. Most diesel fuel pressure test kits come with a variety of adapters, including the common 1/8-inch NPT to Schrader valve adapter needed for the 7.3.

Additional Tools & Safety Gear

- Basic Hand Tools: Wrenches (especially a 1/2-inch or 13mm for the fuel bowl drain), screwdrivers, and possibly pliers.

- Safety Glasses: Always protect your eyes when working with pressurized fuel.

- Gloves: Diesel fuel can be an irritant; gloves protect your hands.

- Rags/Shop Towels: To catch any spilled fuel during connection/disconnection.

- Fire Extinguisher: As a precaution when working with flammable liquids.

- OBD-II Scanner (Optional but Recommended): Useful for checking for diagnostic trouble codes (DTCs) and monitoring other engine parameters.

Step-by-Step Guide: How to Connect a Fuel Pressure Gauge to Your 7.3 Powerstroke

Connecting the gauge is a straightforward process, but it requires attention to detail to prevent fuel leaks and ensure accurate readings. Always work in a well-ventilated area and have your safety gear ready.

- Park on Level Ground & Engage Parking Brake: Safety first. Ensure your truck is secure.

- Locate the Fuel Filter Housing: Open the hood. The fuel filter housing is typically located on top of the engine, towards the front, a prominent black or silver canister.

- Identify the Schrader Valve Test Port: On the side of the fuel filter housing, you’ll find a small metal cap, often with a plastic or brass cover. This is your fuel pressure test port. Unscrew the cap.

- Relieve Fuel Pressure (Optional but Recommended):

- Locate the fuel pump fuse (usually in the under-hood fuse box, check your owner’s manual for the exact location, often labeled “Fuel Pump” or “FPM”).

- Remove the fuse.

- Start the engine and let it run until it stalls. This depletes the fuel pressure.

- Turn off the ignition.

- Alternatively, carefully depress the Schrader valve with a small screwdriver to release pressure, catching any fuel with a rag. Be prepared for a spray.

- Connect the Gauge Adapter: Thread the appropriate adapter (1/8-inch NPT to Schrader) onto the Schrader valve test port. Hand-tighten, then use a wrench to snug it up, but do not overtighten.

- Attach the Fuel Pressure Gauge: Connect your fuel pressure gauge hose to the adapter. Again, hand-tighten, then snug with a wrench. Ensure all connections are secure and leak-free.

- Reinstall Fuel Pump Fuse: If you removed it, put the fuse back into its slot.

You are now ready to perform the 7.3 Powerstroke fuel pressure test and gather your readings.

Performing the Fuel Pressure Test: Key Scenarios & Interpretations

To get a complete picture of your 7.3 Powerstroke‘s fuel system health, you need to test under various operating conditions. Each scenario provides different insights into potential problems.

1. Engine Off, Key On (KOEO)

This test checks if the fuel pump builds initial pressure. The fuel pump runs for about 20-30 seconds when the key is first turned to the “ON” position (without starting the engine) to prime the system.

- Procedure: Turn the ignition key to the “ON” position (do not start the engine). Observe the gauge.

- Expected Reading: The pressure should build to ~45-60 PSI and hold steady. It might slowly bleed down once the pump stops, which is normal to a degree, but a rapid drop indicates a leak.

- Interpretation:

- No Pressure or Very Low Pressure: Indicates a major issue with the fuel pump, a completely clogged filter, or a significant leak.

- Pressure Builds but Drops Rapidly: Suggests a leaky injector O-ring, fuel pressure regulator issue, or a leak in the fuel lines.

2. Engine at Idle

This is your baseline operational pressure. It shows how well the fuel pump maintains pressure under minimal engine demand.

- Procedure: Start the engine and let it warm up to operating temperature. Observe the gauge while the engine idles.

- Expected Reading: The pressure should be stable between 45-60 PSI.

- Interpretation:

- Below 45 PSI: Low fuel pressure at idle is a serious concern. This could indicate a weak fuel pump, clogged fuel filter, issues with the fuel pressure regulator, or air entering the system.

- Above 60 PSI: High fuel pressure is less common but can indicate a restricted fuel return line or a faulty fuel pressure regulator.

- Fluctuating Pressure: An unsteady needle can point to a failing fuel pump, air in the fuel system, or an inconsistent fuel pressure regulator.

3. Under Load / Wide Open Throttle (WOT)

This is arguably the most critical test, as it reveals how the fuel system performs under maximum demand, where problems often become most apparent.

- Procedure: If your gauge hose is long enough, route it safely into the cab. Drive the truck and observe the gauge during acceleration, especially at Wide Open Throttle (WOT). If you don’t have a long hose, you can perform a static WOT test (briefly, in park, revving the engine) but be aware this is less accurate than a road test.

- Expected Reading: Pressure should ideally remain above 40 PSI, even at WOT. Some dips are normal, but it should recover quickly. Many enthusiasts aim for 50-60 PSI under all conditions for optimal performance and injector longevity.

- Interpretation:

- Significant Drop (below 40 PSI): This is a red flag. It almost always points to an inability of the fuel pump to keep up with demand, a severely restricted fuel filter, or potentially a restrictive fuel line. This directly impacts power and can damage injectors.

- Consistent Low Pressure: If the pressure stays low across the board (idle and WOT), it confirms a systemic issue like a weak fuel pump or restricted primary filter.

Remember, the goal for a healthy 7.3 Powerstroke fuel system is to maintain stable pressure within the specified range under all conditions. Consistency is key.

7.3 Powerstroke Fuel Pressure Specifications

These are general guidelines. Minor variations may occur based on modifications or specific engine conditions.

| Condition | Ideal Pressure Range (PSI) | Common Issues if Outside Range |

|---|---|---|

| Key On, Engine Off (KOEO) | 45 – 60 PSI | Weak/failing fuel pump, major leak, clogged filter. |

| Engine Idling (Warm) | 45 – 60 PSI | Weak fuel pump, clogged filter, faulty regulator, air in system. |

| Under Load / WOT | Minimum 40 PSI (Ideally 50-60 PSI) | Insufficient fuel pump flow, severely clogged filter, restricted fuel lines. |

| Engine Off, Pressure Hold | Slow bleed-off is normal; rapid drop indicates leak. | Leaky injector O-rings, faulty check valve, fuel line leak. |

Diagnosing Common 7.3 Powerstroke Fuel Pressure Issues

Once you’ve collected your readings, the next step is to interpret them and pinpoint the root cause of any deviations. This section will help you in diagnose 7.3 fuel issues based on your gauge readings.

Low Fuel Pressure (Most Common Problem)

If your gauge consistently reads below 40-45 PSI, especially under load, these are the primary culprits:

- Clogged Fuel Filter: This is the most frequent cause. A dirty fuel filter restricts flow, leading to low pressure.

- Action: Replace the fuel filter. This is a maintenance item and should be done regularly (every 10,000-15,000 miles or annually). Re-test after replacement.

- Weak or Failing Fuel Pump: The electric fuel pump (frame-mounted on most 7.3s) loses efficiency over time.

- Action: If a new filter doesn’t resolve the issue, and you have low KOEO and idle pressure, suspect the fuel pump. This requires a 7.3 fuel pump check and potential replacement.

- Faulty Fuel Pressure Regulator (FPR): Located on the fuel filter housing, the FPR maintains desired pressure by bleeding off excess fuel back to the tank. If it’s stuck open or has a weak spring, pressure will be low.

- Action: Inspect the FPR. Some can be rebuilt or replaced. A regulated return system often bypasses the factory FPR.

- Restricted Fuel Lines: Kinks, collapsed lines, or debris within the fuel lines can impede flow.

- Action: Visually inspect all fuel lines from the tank to the engine for damage or restrictions.

- Air Leaks in the Fuel System: Air introduced into the fuel can cause sputtering and inconsistent pressure.

- Action: Check all connections, O-rings on the fuel filter housing, and injector O-rings for leaks.

- Fuel Tank Issues: A clogged fuel tank pick-up screen (“Hutch Mod” often addresses this) or a faulty sending unit can restrict fuel flow.

- Action: This is a more involved diagnosis, often requiring dropping the fuel tank.

High Fuel Pressure

While less common, high fuel pressure 7.3 can also cause problems, though usually not as severe as low pressure.

- Stuck Fuel Pressure Regulator (FPR): If the FPR is stuck closed or is not bleeding off excess pressure, it can cause high readings.

- Action: Inspect and potentially replace or service the FPR.

- Restricted Fuel Return Line: If the fuel cannot properly return to the tank, pressure will build up.

- Action: Check the return line for kinks, blockages, or collapsed sections.

Fluctuating or Unstable Pressure

- Failing Fuel Pump: An intermittent pump can cause erratic readings.

- Air in the Fuel System: Leaks or a failing fuel tank pick-up can introduce air, leading to a bouncy needle.

- Intermittent Fuel Pressure Regulator: A regulator that isn’t consistently holding pressure can cause fluctuations.

- Clogged Screen at the Fuel Tank: A partially clogged pickup screen can cause pressure to drop under demand and recover when demand lessens.

Systematic Powerstroke fuel system troubleshooting based on these insights will help you narrow down the specific component needing attention.

Optimizing Your 7.3 Powerstroke Fuel System: Maintenance & Upgrades

Beyond troubleshooting, there are proactive steps you can take to ensure your 7.3 Powerstroke‘s fuel system remains healthy and even improve its performance.

Regular Maintenance is Key

- Replace Fuel Filter Regularly: This cannot be stressed enough. A fresh fuel filter is the single best preventative measure for maintaining correct fuel pressure 7.3. Follow manufacturer recommendations or replace every 10,000-15,000 miles.

- Use Quality Fuel: High-quality diesel with appropriate additives can help keep your fuel system clean and prevent premature wear.

- Monitor Fuel System for Leaks: Periodically check fuel lines, connections, and the fuel filter housing for any signs of leaks.

Popular Fuel System Upgrades for the 7.3 Powerstroke

Many 7.3 Powerstroke owners opt for upgrades to enhance fuel delivery, especially if they have performance modifications.

- Regulated Return Fuel System: The factory fuel system often creates a “dead-head” situation where fuel pressure can vary among injectors. A regulated return system reroutes fuel pressure to a central regulator before returning it to the tank, ensuring consistent pressure to all injectors. This is highly recommended for improved injector lifespan and performance.

- Electric Fuel Pump Upgrade: The factory fuel pump is adequate for stock trucks, but a higher-flow aftermarket pump (e.g., from AirDog, FASS, or Walbro) can provide more consistent and higher pressure, particularly beneficial for trucks with performance tunes or larger injectors. This also addresses common “7.3 fuel pump check” failures by replacing an older pump.

- Bigger Fuel Lines: For heavily modified trucks, upgrading to larger diameter fuel lines can reduce restriction and support higher fuel flow.

- Fuel Bowl Delete: While the factory fuel filter housing (often called the “fuel bowl”) works, some owners opt to delete it for a simpler system, often moving to an external filter/water separator setup that can be easier to service and flow better.

These upgrades can significantly improve fuel pressure stability and delivery, contributing to better engine performance and longevity, especially when dealing with aftermarket tunes or larger injectors that demand more fuel.

Conclusion

Mastering how to use a fuel pressure gauge on 7.3 Powerstroke is a valuable skill that empowers you to keep your legendary engine running strong. From initial diagnostics of rough running and power loss to proactive monitoring for peak performance, understanding your fuel pressure is fundamental. We’ve covered the critical role of fuel pressure in the unique HEUI system, the tools you’ll need, detailed step-by-step connection procedures, and most importantly, how to interpret your readings under various operating conditions.

Remember, the ideal fuel pressure specifications 7.3 are between 45-60 PSI, holding strong even under heavy load. If your readings fall outside this range, you now have the knowledge to systematically diagnose 7.3 fuel issues, whether it’s a simple clogged filter, a failing fuel pump, or a faulty regulator. By incorporating regular fuel pressure checks into your maintenance routine and considering appropriate upgrades, you’ll ensure your 7.3 Powerstroke continues to deliver the reliable power and performance it’s famous for, mile after glorious mile. Don’t let your truck leave you guessing; empower yourself with the gauge and the knowledge.

🎥 Related Video: Fuel Pressure Testing. How To Do It! #shorts #innova #gasolineengine

📺 Toolever

When the car cannot start or the engine misfires or keeps stalling out, try doing a fuel pressure test to find out if there are issues in …

Frequently Asked Questions

Why is checking fuel pressure important for my 7.3 Powerstroke?

Maintaining proper fuel pressure is crucial for the optimal performance and longevity of your 7.3 Powerstroke engine. Incorrect fuel pressure can lead to issues like hard starting, loss of power, poor fuel economy, and even damage to expensive components such as the injectors and fuel pump.

What is the ideal fuel pressure range for a 7.3 Powerstroke?

For a stock 7.3 Powerstroke, the ideal fuel pressure typically falls within the 45-65 PSI range at idle. It’s essential to ensure your fuel pressure gauge readings stay within this specification to guarantee proper fuel delivery to the injectors.

Where do I connect a fuel pressure gauge on a 7.3 Powerstroke?

The most common and recommended location to connect a fuel pressure gauge on a 7.3 Powerstroke is at the fuel bowl, specifically utilizing the Schrader valve on top of the fuel pressure regulator. This location provides an accurate measurement of the pressure directly before the fuel enters the cylinder heads.

What tools are needed to accurately test fuel pressure on my 7.3 Powerstroke?

To accurately test fuel pressure on your 7.3 Powerstroke, you will primarily need a specialized fuel pressure gauge kit that includes a gauge and the correct adapters for your fuel bowl’s Schrader valve or regulator port. Basic hand tools like a wrench may also be useful for ensuring a secure connection.

When should I check the fuel pressure on my 7.3 Powerstroke?

You should check your 7.3 Powerstroke’s fuel pressure whenever you experience symptoms like hard starting, stalling, loss of power under acceleration, or a rough idle. Regular checks are also beneficial as part of routine maintenance or after replacing fuel system components to confirm proper operation.

Can I permanently install a fuel pressure gauge on my 7.3 Powerstroke?

Yes, many 7.3 Powerstroke owners opt to permanently install a fuel pressure gauge for continuous monitoring of their fuel system’s health. This usually involves installing a sending unit or a direct-read gauge in a convenient location, such as tapping into the fuel bowl or a dedicated fuel line port.