Fuel Injector Testing Equipment for Ford Powerstroke: Diagnose Your Injectors

Featured image for this comprehensive guide about Fuel injector testing equipment for Ford Powerstroke

Image source: assets.publishing.service.gov.uk

If you’re a proud owner of a Ford Powerstroke diesel truck, you understand that it’s more than just a vehicle; it’s a workhorse, a legend, and a significant investment. From the legendary 7.3L to the robust 6.7L, Powerstroke engines are renowned for their power, torque, and reliability. However, at the heart of their impressive performance lies a complex and precisely engineered fuel system, with the fuel injectors playing a starring role. When these vital components start to falter, your truck’s performance, fuel economy, and even its very longevity can be severely compromised.

Diagnosing injector issues isn’t always straightforward. A rough idle, excessive smoke, or a sudden drop in fuel efficiency can point to a multitude of problems, but often, the culprit is a failing fuel injector. Simply guessing or replacing parts without proper diagnosis can lead to unnecessary expenses and frustration. This is where specialized fuel injector testing equipment for Ford Powerstroke engines becomes indispensable. Whether you’re a seasoned diesel mechanic, a dedicated DIY enthusiast, or someone just looking to understand their truck better, knowing how to test these critical components is key to maintaining your Powerstroke’s health and maximizing its lifespan.

This comprehensive guide will delve deep into the world of Powerstroke fuel injector diagnostics. We’ll explore the different types of injectors across various Powerstroke generations, the symptoms of their failure, and the essential tools and techniques required for accurate testing. From basic on-vehicle checks to professional-grade test benches, we’ll equip you with the knowledge to confidently approach injector-related problems. Get ready to uncover the secrets to keeping your Powerstroke running strong, efficient, and reliable for years to come.

Quick Answers to Common Questions

Why would I even need fuel injector testing equipment for Ford Powerstroke?

If your Powerstroke is running rough, losing power, or blowing excessive smoke, your injectors might be failing. This equipment helps you accurately diagnose if they’re the culprits before spending money on unnecessary repairs.

What kind of fuel injector testing equipment for Ford Powerstroke are we talking about?

We’re referring to specialized tools ranging from diagnostic scanners that read injector contribution and balance rates to dedicated bench testers that physically check spray patterns, flow rates, and leakage.

Is fuel injector testing equipment for Ford Powerstroke different from tools for other diesels?

Absolutely! Powerstroke engines, especially the 6.0L and 6.4L, often require specific adapters, software, and test procedures due to their unique injector designs and high-pressure common rail (or HEUI) systems.

Can I use fuel injector testing equipment for Ford Powerstroke at home, or do I need a professional?

Basic diagnostic scanners can be used at home to read codes and perform some live data checks. However, advanced bench testing, which involves removing and thoroughly evaluating injectors, is typically best left to experienced shops with specialized equipment.

How does fuel injector testing equipment for Ford Powerstroke actually help diagnose problems?

It provides crucial data by identifying issues like clogged nozzles, weak or irregular spray patterns, incorrect fuel delivery volumes, or electrical faults within the injector. This precise information tells you exactly which injector, if any, needs attention.

📋 Table of Contents

- Understanding Your Powerstroke Injectors: A Brief Overview

- Why Injector Testing is Crucial for Your Powerstroke’s Health

- Essential Fuel Injector Testing Equipment for DIY Enthusiasts

- Professional-Grade Fuel Injector Testing Equipment and Services

- Interpreting Test Results and Next Steps

- Choosing the Right Fuel Injector Testing Equipment for Your Needs

- Conclusion

Understanding Your Powerstroke Injectors: A Brief Overview

Before diving into testing methods, it’s crucial to understand the two primary types of fuel injection systems found in Ford Powerstroke engines: the Hydraulic Electronic Unit Injector (HEUI) system and the Common Rail Direct Injection system. Each system has unique operational principles, failure modes, and, consequently, different diagnostic requirements for their injectors.

Learn more about Fuel injector testing equipment for Ford Powerstroke – Fuel Injector Testing Equipment for Ford Powerstroke: Diagnose Your Injectors

Image source: fuelcellenergy.com

HEUI Injectors: The 7.3L and 6.0L Powerstroke Eras

The 7.3L and 6.0L Powerstroke engines utilize HEUI injectors. These ingenious injectors don’t rely solely on high-pressure fuel; instead, they use high-pressure engine oil to pressurize and inject fuel into the combustion chamber. The Engine Oil Pump (EOP) feeds oil to the High-Pressure Oil Pump (HPOP), which then sends pressurized oil through an Injector Control Pressure (ICP) sensor and an Injector Pressure Regulator (IPR) valve to the injectors. Inside each injector, this high-pressure oil acts on an intensifier piston, which in turn dramatically increases the fuel pressure for injection.

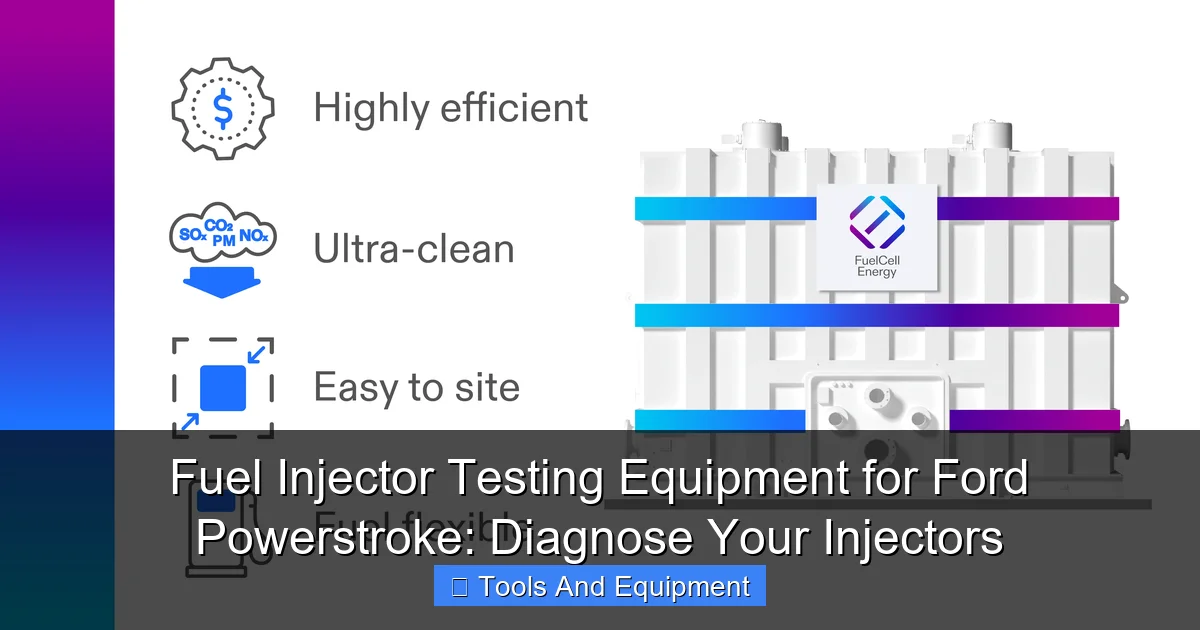

| Equipment Type | Primary Function | Powerstroke Compatibility | Typical Price Range |

|---|---|---|---|

| Advanced OBD-II Scan Tool (e.g., Ford IDS, Autel Maxisys) | Injector contribution test, cylinder balance, live data monitoring, misfire detection. | 6.0L, 6.4L, 6.7L (software/adapter dependent) | $500 – $3,000+ |

| Manual Handheld Injector Pop Tester | Checks injector opening pressure, basic spray pattern, leakage test. | All common Powerstroke injectors (6.0L, 6.4L, 6.7L) | $100 – $300 |

| Electronic Injector Contribution Tester (Specialized) | Precisely measures cylinder power contribution and individual injector performance. | Primarily 6.0L, 6.4L; some 6.7L support | $300 – $800 |

| Diesel Fuel Injector Flow Bench / Test Stand | Comprehensive testing: fuel delivery (various RPMs), return flow, spray pattern, response time, opening pressure. | Adaptable for all Powerstroke injectors (with specific adapters) | $3,000 – $15,000+ |

- 7.3L Powerstroke Injectors: Known for their robustness, issues often stem from O-ring leaks (internal or external), electrical solenoid failures, or coking of the nozzle tips.

- 6.0L Powerstroke Injectors: These are more complex and prone to “stiction” – a condition where internal parts, particularly the spool valve, stick due to oil contamination, inadequate lubrication, or wear. Electrical failures of the solenoid are also common.

Fuel injector testing equipment for Ford Powerstroke HEUI systems often focuses on validating oil pressure, electrical integrity, and the internal function of the injector’s intensifier and spool valve.

Common Rail Injectors: The 6.4L and 6.7L Powerstroke Generations

With the 6.4L and 6.7L Powerstroke engines, Ford transitioned to Common Rail Direct Injection. In this system, a high-pressure fuel pump (HPFP) pressurizes fuel (sometimes exceeding 29,000 PSI or 2,000 bar) and delivers it to a common rail manifold. From this rail, precisely controlled electronic injectors, which are often piezoelectric or solenoid-based, deliver fuel directly into the combustion chamber at incredibly high pressures and multiple times per combustion cycle. This allows for extremely fine control over fuel delivery, leading to better emissions, fuel economy, and power.

- 6.4L Powerstroke Injectors: These are notorious for internal leakage (especially at the nozzle tips), leading to excessive return flow, DPF issues, and power loss. They are highly sensitive to fuel contamination.

- 6.7L Powerstroke Injectors: While more refined, issues can still arise from internal wear, nozzle clogging, electrical faults, and, critically, contamination from HPFP failures, which can send metal debris throughout the fuel system.

Fuel injector testing equipment for Ford Powerstroke common rail systems must be capable of handling extremely high pressures and precisely measuring fuel delivery and return flow to accurately diagnose issues.

Why Injector Testing is Crucial for Your Powerstroke’s Health

Ignoring potential fuel injector problems can lead to a cascade of expensive and damaging issues for your Powerstroke engine. Early and accurate diagnosis using reliable fuel injector testing equipment for Ford Powerstroke trucks can save you significant time, money, and headaches in the long run.

Learn more about Fuel injector testing equipment for Ford Powerstroke – Fuel Injector Testing Equipment for Ford Powerstroke: Diagnose Your Injectors

Image source: mrtlaboratories.com

Common Symptoms of Failing Powerstroke Injectors:

- Rough Idle or Misfire: One of the most common signs. An injector that’s not delivering fuel correctly will cause uneven combustion.

- Decreased Fuel Economy: Leaky or clogged injectors can dramatically increase fuel consumption.

- Excessive Smoke:

- White smoke: Often indicates unburnt fuel, especially common with HEUI injectors (7.3L/6.0L) when cold or due to low compression.

- Black smoke: Typically points to an over-fueling condition or poor spray pattern, common in all Powerstrokes but particularly noticeable in 6.4L/6.7L.

- Blue smoke: Usually indicates burning oil, but can sometimes be misdiagnosed with injector issues.

- Loss of Power/Acceleration: The engine isn’t getting the right amount of fuel for optimal combustion.

- Hard Starts (Hot or Cold): Especially prevalent in HEUI systems due to internal injector leaks or low high-pressure oil. Common rail engines can also suffer from hard starts due to low rail pressure from internal injector leaks.

- Check Engine Light (CEL) / Diagnostic Trouble Codes (DTCs): Modern Powerstrokes will often throw codes related to injector circuit malfunctions, balance rates, or fuel pressure issues.

- Increased Oil Levels: In some cases, a severely leaking HEUI injector can allow fuel to dilute the engine oil, leading to an increased oil level and potential engine damage.

The High Cost of Ignoring Injector Problems:

- Engine Damage: An injector with a poor spray pattern can “wash” oil off cylinder walls, leading to increased wear. Excessive fuel delivery can cause piston damage or even hydro-lock if enough raw fuel accumulates.

- DPF and Emissions System Issues: Over-fueling leads to excessive soot, clogging the Diesel Particulate Filter (DPF) and forcing more frequent, incomplete, or failed regenerations, shortening DPF life and leading to expensive replacements.

- Turbocharger Damage: Unburnt fuel can pass into the exhaust system, raising EGTs (Exhaust Gas Temperatures) and potentially damaging the turbocharger.

- HPFP Failure (Common Rail): Contaminated fuel or severe back-leakage from injectors can put undue stress on the high-pressure fuel pump, leading to its premature failure and potentially sending metal debris throughout the entire fuel system.

Proactive diagnosis and maintenance using the right fuel injector testing equipment for Ford Powerstroke engines is not just about fixing a symptom; it’s about safeguarding your entire engine and fuel system from catastrophic failure.

Essential Fuel Injector Testing Equipment for DIY Enthusiasts

For the mechanically inclined Powerstroke owner, a range of diagnostic tools can help pinpoint injector issues without immediately resorting to a professional shop. While not as precise as dedicated test benches, these tools provide valuable insights and can often help confirm suspicions before further investment.

Basic Diagnostic Tools & On-Vehicle Tests:

- OBD-II Scan Tool with Enhanced Capabilities: Not just any generic scan tool will do. For Powerstrokes, you need a tool that can read manufacturer-specific codes, perform cylinder contribution tests, monitor injector balance rates (especially 6.7L), and display live data like fuel pressure (low and high side), ICP/IPR pressures, and fuel compensation values. Tools like FORScan (with an appropriate adapter), AutoEnginuity, or higher-end aftermarket scanners are excellent choices.

- Cylinder Contribution Test: Available on many scan tools, this test momentarily cuts fuel to individual cylinders and measures the resulting RPM drop. A cylinder with a smaller-than-expected drop indicates a weak injector.

- Injector Buzz Test (7.3L/6.0L HEUI): This diagnostic routine, initiated via a capable scan tool, cycles the injector solenoids rapidly. Listening for clear, crisp “buzzes” from each injector can help identify electrical issues or mechanical sticking.

- Injector Balance Rates (6.7L Common Rail): This live data parameter shows how much the ECM is adjusting fuel delivery to each cylinder to maintain smooth idle. High positive or negative values can point to a failing injector.

- Digital Multimeter: Essential for checking the electrical integrity of injector solenoids. You can measure resistance to check for open or short circuits. Always refer to your specific Powerstroke engine’s service manual for correct resistance values.

- Fuel Pressure Gauge (Low Pressure Side): A simple gauge connected to the low-pressure fuel system can confirm if the lift pump (or in-tank pump) is delivering adequate fuel pressure to the high-pressure pump. Low fuel pressure can mimic injector issues.

- Compression Tester: While not direct injector testing, a compression test can rule out other engine issues (like worn rings or valve problems) that might present similar symptoms to failing injectors.

Entry-Level Injector Testers for Off-Vehicle Checks:

- Diesel Injector Pop Tester (for mechanical injectors or preliminary checks): This is a basic tool that allows you to manually pump fuel through an injector (after removal) to observe its spray pattern and opening pressure. While useful for older, purely mechanical injectors, modern HEUI and Common Rail injectors require specific high-pressure oil/fuel to operate correctly, making a simple pop tester less effective for full diagnostics on Powerstrokes. However, some basic versions can be used for initial visual inspection of the nozzle on removed injectors.

- Common Rail Injector Leak-Off Test Kit: This is an excellent, relatively inexpensive piece of fuel injector testing equipment for Ford Powerstroke 6.4L and 6.7L owners. It involves connecting clear tubes to the return fuel ports of each injector. With the engine running (or cranking), you can visually compare the amount of fuel returning from each injector. Excessive return flow from one or more injectors indicates internal leakage and is a strong sign of a failing common rail injector.

While DIY testing offers a cost-effective starting point, remember that accuracy and safety are paramount. Always follow manufacturer guidelines and use appropriate personal protective equipment. These tools empower you to perform initial troubleshooting, but often, professional-grade equipment is needed for conclusive diagnostics.

Professional-Grade Fuel Injector Testing Equipment and Services

When the DIY approach reaches its limits, or for critical diagnostics, professional workshops utilize highly specialized and often very expensive fuel injector testing equipment for Ford Powerstroke engines. These systems offer unparalleled precision and comprehensive testing capabilities.

Advanced Test Benches: The Gold Standard

Professional injector test benches are sophisticated machines designed to simulate real-world engine conditions and precisely measure every aspect of injector performance. They are typically universal or specific to certain injection technologies (e.g., common rail). Leading manufacturers include Bosch, Hartridge, and Alliant Power.

- Flow Rate Measurement: These benches accurately measure how much fuel an injector delivers over a specific period at various pressures and pulse widths (engine RPMs). They check for under-fueling or over-fueling conditions.

- Spray Pattern Analysis: High-resolution cameras and observation chambers allow technicians to visually inspect the injector’s spray pattern for proper atomization, consistency, and any signs of streaking, dribbling, or uneven distribution. A bad spray pattern leads to incomplete combustion and excessive soot.

- Backleakage (Return Flow) Measurement: Critical for common rail injectors, this test measures the amount of fuel that bypasses the nozzle and returns to the fuel tank. Excessive backleakage is a definitive sign of internal wear or seal failure.

- Opening Pressure & Response Time: The bench verifies that the injector opens at the correct pressure and responds within specified milliseconds to electrical signals.

- Electrical Solenoid Testing: Beyond simple resistance checks, these benches can test the solenoid’s dynamic response under load, ensuring it functions correctly during rapid cycling.

- Coding (IMA/IQA): For modern common rail injectors (like the 6.7L), test benches can often generate new injector compensation codes (IMA – Injector Mass Adjustment or IQA – Injector Quantity Adjustment). These codes are unique to each injector and tell the Engine Control Module (ECM) how to precisely adjust fuel delivery for optimal performance and emissions. When an injector is replaced, its new code must be programmed into the ECM.

Dedicated HEUI Injector Testers:

For 7.3L and 6.0L Powerstrokes, specialized HEUI test stands are crucial. These machines use high-pressure oil, mimicking the HPOP, to activate the injector. They can measure:

- Fuel Delivery Volume: At various oil pressures and electrical pulse widths.

- Spool Valve Function (6.0L): By monitoring internal pressures and response, these testers can detect “stiction” or other mechanical issues within the spool valve.

- Nozzle Performance: Spray pattern and opening pressure under HEUI conditions.

Specialized Diagnostic Software and OEM Tools:

Beyond the physical testing of injectors, high-end diagnostic software and OEM tools (like Ford’s IDS or FDRS) offer unparalleled capabilities for on-vehicle diagnostics. These tools provide in-depth access to the ECM, allowing technicians to:

- Run extensive diagnostic routines specifically designed for Powerstroke engines.

- Monitor hundreds of live data parameters simultaneously.

- Perform bidirectional controls, such as activating individual injectors or pumps.

- Update software and recalibrate components.

While the investment in such fuel injector testing equipment for Ford Powerstroke vehicles is substantial, the accuracy and comprehensiveness of professional testing significantly reduce misdiagnosis and ensure that the right repairs are made the first time.

Interpreting Test Results and Next Steps

Once you’ve performed your tests, whether DIY or professional, understanding what the results mean is paramount. Data points are just numbers until you can interpret them to make an informed decision about your Powerstroke’s fuel injectors.

What the Numbers and Observations Mean:

- Scan Tool Data (Cylinder Contribution, Balance Rates, Fuel Pressure):

- High/Low Contribution or Balance Rate: A cylinder consistently showing significantly higher or lower contribution, or a balance rate that’s far from zero (e.g., +/- 4 to 5 mm3 on a 6.7L, depending on specifications), points to an injector that’s over-fueling, under-fueling, or has a mechanical issue.

- Low Rail Pressure (6.4L/6.7L): If the commanded rail pressure isn’t met, even with a good high-pressure pump, excessive internal injector leakage (high return flow) is a common cause.

- Low ICP/IPR Pressure (7.3L/6.0L HEUI): Can indicate issues with the HPOP, IPR valve, but also internal injector leaks (through the O-rings or intensifier piston) allowing high-pressure oil to escape.

- Leak-Off Test (Common Rail): If one or more injectors fill their return vials significantly faster or with a much larger volume than others, that injector (or injectors) has excessive internal leakage and is a prime candidate for replacement.

- Solenoid Resistance (Multimeter): Readings outside of the manufacturer’s specified range (e.g., 0.8-1.5 ohms for a 6.0L, typically higher for common rail) indicate an electrical fault (open or short) within the solenoid.

- Test Bench Results (Professional Testing):

- Flow Rates (High/Low): An injector delivering too much or too little fuel at specified pressures and durations.

- Poor Spray Pattern: Instead of a fine, conical mist, you might see streams, drips, or an uneven distribution. This leads to incomplete combustion and soot.

- Excessive Backleakage: Confirms internal wear or seal failure, common in common rail injectors.

- Incorrect Opening Pressure: Indicates a faulty nozzle spring or internal component.

- Slow Response Time: Suggests solenoid issues or internal sticking.

When to Repair, When to Replace:

The decision to repair or replace a faulty injector depends on the Powerstroke generation, the nature of the fault, and the cost-effectiveness.

- HEUI Injectors (7.3L/6.0L):

- Repairable: External O-rings are a common and relatively inexpensive repair. Some 6.0L “stiction” issues can sometimes be mitigated with specialized oil additives, though this is often a temporary fix.

- Replace: Internal electrical failures (open/shorted solenoids) or severe mechanical wear (e.g., intensifier piston, spool valve) usually necessitate replacement with new or remanufactured injectors.

- Common Rail Injectors (6.4L/6.7L):

- Repairable: Generally, modern common rail injectors are considered non-serviceable by most workshops due to the extreme precision required. However, some specialized facilities can perform nozzle replacements or internal resealing if the body is in good condition.

- Replace: Any internal leakage (high return flow), electrical faults, or significant spray pattern degradation almost always requires replacement. It’s often recommended to replace them in sets or at least on the affected bank if multiple injectors show similar wear, due to the high stress and precision of the system.

Always consider the overall cost. A professional remanufactured injector often comes with a warranty and is significantly cheaper than new, while offering near-new performance. Be wary of cheap, unbranded “rebuilt” injectors, as they can cause more problems down the line.

Comparative Table: Powerstroke Injector Issues & Testing Methods

| Powerstroke Engine | Common Injector Issue | Symptoms | Recommended Testing Method/Equipment |

|---|---|---|---|

| 7.3L (HEUI) | O-ring failure, coking, electrical issues | Hard start (hot/cold), misfire, poor idle, excessive smoke | Cylinder contribution test (scan tool), Buzz test, HEUI tester (for flow/spray), Multimeter for solenoid resistance |

| 6.0L (HEUI) | Stiction (spool valve), electrical open/short, internal leaks | Rough idle, misfire, power loss, hard/no start, increased oil level (fuel dilution) | Cylinder contribution test (scan tool), Buzz test, HEUI test bench (for spool valve function, flow/spray), Multimeter |

| 6.4L (Common Rail) | Internal leaks, spray pattern degradation, high-pressure pump contamination damage | Black smoke, DPF issues, power loss, excessive fuel consumption, hard start | Injector leak-off test, dedicated common rail test bench (flow & spray pattern), Scan tool (balance rates, rail pressure monitoring) |

| 6.7L (Common Rail) | Internal leaks, clogged nozzles, electrical issues, high-pressure pump contamination damage | Misfire, rough idle, regeneration issues, power derate, hard start | Injector leak-off test, dedicated common rail test bench, Scan tool (injector balance rates, fuel pressure monitoring), Multimeter |

Choosing the Right Fuel Injector Testing Equipment for Your Needs

Deciding which fuel injector testing equipment for Ford Powerstroke is right for you boils down to a few key considerations: your budget, your mechanical skill level, how frequently you’ll use the equipment, and the specific Powerstroke generation you’re working on.

Consider Your Budget and Frequency of Use:

- Occasional DIYer (Single Truck Owner): If you own one Powerstroke and want to be proactive with maintenance, investing in a good quality OBD-II scan tool with Powerstroke-specific capabilities (like FORScan or AutoEnginuity) and a common rail leak-off test kit (if applicable to your truck) is a wise starting point. These tools offer significant diagnostic power for a relatively modest investment (typically a few hundred dollars). A multimeter is also a must-have for any DIY mechanic.

- Dedicated Enthusiast/Small Fleet Owner: For someone who works on multiple Powerstrokes or regularly tackles more complex issues, upgrading to a more advanced scan tool (e.g., Snap-On, Autel, Launch X431 with diesel functions) might be justified. You might also consider investing in a basic injector pop tester for visual nozzle inspection (though limited for modern Powerstrokes) or exploring more robust HEUI oil pressure testers.

- Professional Mechanic/Shop: For those whose livelihood depends on accurate and efficient diagnostics, the investment in full-fledged professional fuel injector testing equipment for Ford Powerstroke engines is non-negotiable. This includes dedicated HEUI testers, advanced common rail test benches, and OEM-level diagnostic software. These can range from several thousand to tens of thousands of dollars, but the ability to precisely diagnose and re-code injectors quickly pays for itself in a professional setting.

Powerstroke Generation Matters:

- 7.3L & 6.0L (HEUI): Your primary focus should be on diagnosing high-pressure oil system integrity (ICP/IPR values), electrical solenoid function (Buzz Test, multimeter), and cylinder contribution. A specialized HEUI tester is ideal for off-vehicle testing.

- 6.4L & 6.7L (Common Rail): High-pressure fuel system integrity (rail pressure, cascade tests), injector return flow (leak-off test), and injector balance rates are paramount. A common rail test bench is the definitive tool for off-vehicle diagnostics.

The DIY vs. Professional Shop Dilemma:

Even with good DIY tools, there will be times when professional expertise is needed. Consider the following:

- Complexity of the Issue: Some problems are just too complex or require too much specialized equipment (e.g., injector re-coding for 6.7L) for a DIYer.

- Time vs. Cost: While a shop charges for diagnosis, they often have the tools to get it right faster, saving you days or weeks of trial and error.

- Warranty: Professional repairs often come with a warranty on parts and labor, providing peace of mind.

Ultimately, a blend of DIY and professional assistance is often the most practical approach. Use your DIY fuel injector testing equipment for Ford Powerstroke to narrow down possibilities, gather information, and perform basic checks. When you hit a wall or suspect a complex internal injector failure, don’t hesitate to consult a reputable diesel specialist who possesses the high-end equipment to provide a definitive diagnosis.

Conclusion

The Ford Powerstroke engine is an icon of diesel power, and its fuel injectors are the unsung heroes of its performance and efficiency. When these critical components begin to show signs of trouble, the right diagnostic approach can make all the difference between a minor repair and a major engine overhaul. Understanding the nuances of HEUI versus Common Rail systems, recognizing the tell-tale symptoms of failure, and knowing which fuel injector testing equipment for Ford Powerstroke to employ are essential skills for any owner or technician.

Whether you’re armed with a basic scan tool and a multimeter for initial DIY troubleshooting, or you’re leveraging professional-grade test benches for comprehensive diagnostics, the goal remains the same: accurately identify injector problems to restore your Powerstroke’s legendary power and reliability. Don’t let a misfiring injector lead to more severe engine damage or costly DPF issues. Invest in the knowledge and the tools to keep your truck running strong.

By taking a proactive stance on injector health, you’re not just fixing a part; you’re safeguarding your entire investment and ensuring that your Ford Powerstroke continues to deliver dependable performance for countless miles to come. So, equip yourself with the right knowledge and tools, and diagnose your injectors with confidence!

Frequently Asked Questions

Why is fuel injector testing important for my Ford Powerstroke engine?

Ford Powerstroke engines rely heavily on precise fuel delivery for optimal performance and longevity. Testing your injectors allows you to accurately diagnose issues like clogs, leaks, or inconsistent spray patterns, which can lead to costly engine damage if left unaddressed. It helps maintain engine efficiency and prevents unnecessary part replacements.

What types of problems can fuel injector testing equipment for Ford Powerstroke diagnose?

This specialized equipment can diagnose a wide range of injector problems, including insufficient flow, incorrect spray patterns, internal or external leaks, slow response times, and inconsistent fuel delivery between cylinders. Identifying these issues is crucial for resolving symptoms like rough idle, misfires, poor fuel economy, and loss of power.

Can a DIY mechanic use Powerstroke injector testing equipment effectively?

Many modern Powerstroke injector testing units are designed with user-friendliness in mind, offering clear instructions and semi-automated testing cycles. While professional-grade systems may have a steeper learning curve, there are accessible options available that are suitable for experienced DIY mechanics looking to perform accurate diagnostics and save on shop labor.

What’s the key difference between a static and dynamic test performed by this equipment?

A static test checks for leaks when the injector is pressurized but not actively firing, ensuring no fuel drips unnecessarily. A dynamic test, on the other hand, cycles the injector to observe its spray pattern, measure its flow rate, and assess its response time under simulated operating conditions, providing a comprehensive performance evaluation.

Are there any additional items I’ll need alongside fuel injector testing equipment for my Ford Powerstroke?

Yes, beyond the main testing unit, you’ll typically need specific Powerstroke injector adapters relevant to your engine generation, a clean test fluid or diesel fuel source, and collection vessels for accurately measuring fuel volume. Some systems may also require a shop air compressor or a specialized cleaning solution for ultrasonic cleaning.

How often should I consider using this Powerstroke fuel injector testing equipment?

Injector testing is generally not a routine maintenance item unless you are experiencing specific engine symptoms. If your Powerstroke is showing signs of poor performance, such as misfires, rough idling, decreased fuel economy, or unusual smoke, then testing the injectors becomes a critical diagnostic step. It’s also recommended if you’re installing used injectors or rebuilding an engine.