Sparkling Connections: Your Ultimate Guide on How to Clean Your Trailer Connector

Have you ever hitched up your trailer and found that your lights weren’t working? Or maybe your turn signals weren’t blinking properly? Before you panic and assume the worst, take a look at your trailer connector. It’s likely that dirt and grime have built up, causing a poor connection. Cleaning your trailer connector is an easy task that can save you time and frustration on your next journey.

In this step-by-step guide, we’ll show you how to clean your trailer connector and get your lights working like new again.

What You Will Need

Cleaning the trailer connector is an important task that you need to add to your maintenance routine to keep your trailer in top condition. You will need a few items to make cleaning the trailer connector a breeze. Firstly, you’ll need a cleaning solution or a dedicated contact cleaner designed for this purpose.

You can easily find these at your local auto parts store or online. You’ll also need a brush to remove any dirt and grime that has accumulated on the connector. It’s best to use a soft-bristled brush that won’t damage the connector.

A clean microfiber towel is also necessary for wiping away any excess solution and to polish the connector to a high shine. Finally, don’t forget to wear protective gloves to avoid any skin irritation or cuts. With all of these items ready, you’ll be able to clean your trailer connector like a pro!

Cleaning Agents

When it comes to cleaning agents, you’ll need a few basic supplies to get the job done right. First and foremost, you’ll need some all-purpose cleaner that can be used on a variety of surfaces around your home. This could be a store-bought cleaner or a homemade solution made using ingredients like vinegar, baking soda, and lemon juice.

Next, you’ll need some microfiber cleaning cloths or sponges that can be used for wiping down surfaces and scrubbing away dirt and grime. A good vacuum cleaner is also a must-have for cleaning floors, carpets, and upholstery. If you have hard floors, you’ll need a mop and bucket for deep cleaning and disinfecting.

Additionally, consider having a few specialty cleaning agents on hand for tougher jobs, such as oven cleaner, stainless steel polish, and tile and grout cleaner. With these basic supplies, you’ll be equipped to tackle household cleaning tasks with ease.

Cleaning Tools

When it comes to keeping your home or office clean, having the right tools can make all the difference. Here are the top cleaning tools you’ll need to get the job done effectively. First, a good vacuum cleaner is essential for removing dirt and debris from carpets and floors.

Look for one with strong suction power and a variety of attachments to clean hard-to-reach areas. A sturdy broom and dustpan are also important for sweeping up larger debris that a vacuum can’t handle. Additionally, microfiber cloths and sponges are great for wiping down surfaces and picking up dust and dirt without leaving streaks or residue.

For tougher cleaning jobs, like tackling grease and grime in the kitchen or bathroom, a heavy-duty scrub brush and cleaning solution will do the trick. The key is to invest in high-quality cleaning tools that will last and make your cleaning tasks easier.

Step One: Inspect Your Connector

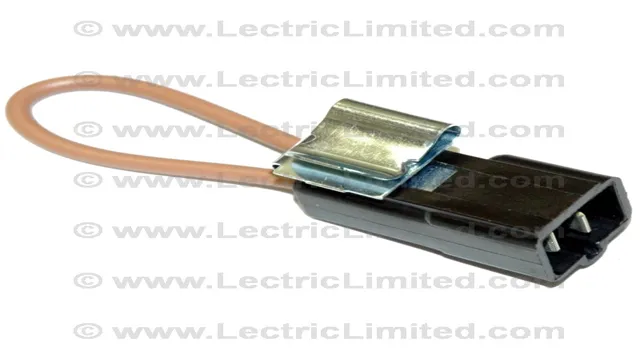

Cleaning your trailer connector is important to keep it in good working condition and to ensure a safe and secure connection to your vehicle. The first step in cleaning your trailer connector is to inspect it thoroughly. Check for any obvious signs of damage such as cracks, bent prongs, or corrosion.

If you notice any damage, it may be necessary to replace the connector. Once you have determined that the connector is in good condition, you can move onto the cleaning process. Using a soft-bristle brush or cloth, gently clean the connector and remove any dirt, grime, or debris that may have accumulated.

Be sure to pay special attention to the prongs and connectors, as these areas are the most likely to become dirty or corroded. Once you have cleaned the connector, you can apply a small amount of dielectric grease to help prevent corrosion and ensure a good connection. By following these simple steps, you can keep your trailer connector in great condition and enjoy safe and trouble-free towing.

Check for Damage

When it comes to ensuring the proper performance of your electronic devices, one of the first steps you should take is checking for damage in your connector. Inspect the connector thoroughly for any signs of wear and tear, such as frayed wires or bent pins. Even minor damage can lead to connectivity issues, so it’s important to address any damage as soon as possible to prevent further complications.

Additionally, always check that the connector is clean and free from any debris or corrosion, as this can also impact performance. Taking the time to properly inspect your connector will save you time and frustration in the long run, ensuring that your device is running at its optimum level.

Check for Corrosion

Corrosion is one of the biggest enemies of connectors and can lead to serious malfunctioning issues. That’s why it’s important to periodically inspect your connectors for any signs of corrosion. The first step is to visually inspect your connector for any discoloration, rust, or pitting.

Pay special attention to the pins and sockets which are the most vulnerable areas for corrosion. If you notice any of these signs, it’s time to take action and clean your connector. Ignoring corrosion could lead to a complete failure of your electrical or electronic system which could be costly to repair.

Therefore, it’s essential to regularly check for corrosion and maintain the connectors to ensure their longevity and reliability.

Step Two: Disconnect Your Connector

To clean your trailer connector effectively, it’s essential to know how to disconnect it properly first. The process of disconnecting your trailer connector may vary depending on the type of connector you have. Some connectors may require a simple twist or a push-and-pull motion, while others may require a screwdriver or pliers to unscrew or unclip the connector.

Whatever the method, it’s best to be cautious while disconnecting the connector to avoid damaging the wiring or the connector itself. Once the connector is disconnected, you can inspect the pins, clean them with a wire brush or rubbing alcohol, and gently lubricate the pins with dielectric grease. Finally, before reconnecting the connector, make sure it’s dry and that there is no debris or corrosion present.

Once you’ve cleaned and reconnected the trailer connector, you’re ready to hit the road with a safe and reliable connection between your vehicle and the trailer.

Turn Off Your Vehicle

As part of safe charging practices for electric cars, it’s important to disconnect your vehicle’s connector before plugging it in. But before you do that, make sure your car is turned off. This helps prevent any unwanted electrical surges or accidents.

To disconnect the connector, you’ll first need to locate the release button or lever. Usually, it’s located near the top of the connector and can be pressed with your thumb or pulled with your fingers. Once released, gently remove the connector from the charging port.

It’s important to handle the connector with care and avoid any unnecessary movements, as it can cause damage to both your car and the charging station. By following these simple steps and turning off your car before disconnecting, you’re ensuring a safe and efficient charging experience every time.

Detach the Connector

When it comes to disconnecting your connector, it’s important to follow certain steps to avoid damaging anything. The second step is to detach the connector, which is usually a quick and easy process. Take a look at the connector and locate the release button or tab.

Gently press or pull on this button/tab to release the connection. Some connectors may require a bit more force, so be careful not to pull too hard and damage the connector or any wires. Once the connector is released, you can safely move onto the next step of your project.

Remember to always take your time and double-check that everything is disconnected properly before continuing. This ensures that you don’t accidentally damage any wires or components during the process.

Step Three: Clean the Connector

To ensure your trailer connector is providing a solid electrical connection, it’s important to clean it regularly. Dirt, grime, and corrosion can build up over time and cause issues with your trailer lights not functioning properly. The first step to cleaning the connector is to make sure any power is disconnected.

Then, using a clean cloth or brush, gently wipe away any debris on the outside of the connector. To get into the small crevices, you can use a small wire brush or toothbrush. Next, use electronic contact cleaner to remove any corrosion on the inside of the connector.

Be sure to let it dry completely before reconnecting. Finally, applying dielectric grease can help prevent future corrosion and improve the electrical connection. By following these steps, you can keep your trailer connector in top shape and avoid any issues on the road.

Apply Cleaning Agent

Now it’s time to move on to the third step in cleaning your connector – applying the cleaning agent. When selecting a cleaning agent, it’s important to choose one that specifically states it is safe to use on electrical connectors. Using the wrong cleaner can damage the connector and cause more issues.

Once you have your cleaning agent of choice, you can apply it to a clean microfiber cloth and gently wipe the contact points of the connector. Remember, don’t use too much cleaning agent – just a small amount should suffice. Take your time and ensure that you’re removing any built-up grime or dirt that may be causing connectivity issues.

Once you’ve finished cleaning, you can allow the connector to dry completely before moving on to testing it to ensure it’s functioning correctly. By taking the time to properly clean your connector, you can help ensure that it continues to function optimally for years to come.

Use Cleaning Tools

To ensure the proper functioning of our electronic devices, it’s essential to clean the connectors properly. The first step is to gather the required cleaning tools such as microfiber cloth, cotton swabs, and rubbing alcohol. These tools are readily available, and it won’t take much to have them at our disposal.

Then turn off the device before cleaning the connector to prevent any potential damage. Use a microfiber cloth to wipe away any dust or dirt from the connector. At this point, it’s important to be thorough.

Use the cotton swab dipped in rubbing alcohol to clean the connector pins. The alcohol breaks down any built-up residue, which ensures the best possible connection. Be careful not to use too much pressure or moisture to prevent any damage to the connector.

Once done cleaning, make sure to give it enough time to air dry before turning the device back on and using it again. Regular connector cleaning is essential to avoid poor connections, which might lead to device malfunction. Taking time often to clean our devices will keep them running efficiently and increase their lifespan.

Dry the Connector

Now that you’ve wiped away any visible dirt or debris, it’s time to dry the connector. You want to ensure that there’s no moisture left behind before you try to use it again. One option is to let it air dry naturally, but if you need to use it right away, you can use a clean, dry cloth to gently dry the connector.

Be sure not to use anything abrasive or rough that might scratch the surface. Another option is to use compressed air to blow away any moisture that may be trapped inside the connector. Just be careful not to blow too hard or too close, as this can damage the delicate connectors inside.

Using our high-quality cleaning kit, which includes a gentle cleaning solution and soft brush, will make the process easier and safer for you. Simply wet the brush with cleaning solution and gently scrub the connector, then use a dry cloth to wipe away any remaining moisture. With these methods, your connector will be dry and ready for use in no time.

Step Four: Reconnect Your Connector

Now that the trailer connector is thoroughly cleaned, it’s time to reconnect it and ensure that it’s working as it should. Start by aligning the connector with the socket and pushing it in firmly. If the connection feels loose, try wiggling the connector up and down while pushing it in to help the pins make better contact.

Once the connector is securely in place, test it by turning on the vehicle’s lights and checking that all the trailer’s lights are working properly. If any issues persist, double-check that the pins are all clean and properly aligned, and consider replacing any damaged pins or wires. By following these steps, you can help ensure that your trailer connector functions properly and provides a safe and reliable connection for all your towing needs.

Align the Pins

Now that you’ve carefully inspected and cleaned the connector pins, it’s time to reattach the connector. When reconnecting the connector, it’s important to align the pins properly. This will ensure that the electrical connection is properly established, which is essential for the device to function correctly.

You may need to refer to the user manual or a reference guide to ensure that you align the pins correctly. Once you’ve aligned the pins, gently push the connector back into place. Make sure that it clicks or snaps into place, indicating that it is securely attached.

Congratulations on successfully reconnecting your connector!

Push the Connector In

After you’ve cleaned your connector, the next step is to push it back in place. This may seem like a trivial step, but it’s essential for ensuring that your device is functioning properly. Carefully align the connector with the port and press it in gently.

Avoid using excessive force as it can damage the connector or port, leading to more severe problems. The connector should fit snugly in the port, and you should hear a satisfying click or feel it lock into place. Once you’ve reconnected your connector, power on your device and confirm that it’s working correctly.

By following these steps, you can ensure that your device runs efficiently, and you won’t need to stress about any disruptions caused by a loose connector.

Step Five: Test the Connector

Now that you’ve cleaned your trailer connector, it’s time to test it out. Testing your connector will help you determine if all the connections are working correctly and will prevent any potential safety hazards on the road. To test the connector, simply hook up your trailer to your towing vehicle and turn on your lights.

Check to see if your brake lights, turn signals, and running lights are all functioning properly. If everything checks out, you’re good to hit the road. However, if you notice any issues with your lights, it could be a sign that your connector still needs some work.

Double-check all the connections and make sure everything is secure and in the right place. With a little patience and attention to detail, you’ll be able to get your trailer connector in good working order in no time. Don’t forget to keep up with regular maintenance and cleaning to ensure your trailer connector stays in top shape for future road trips.

Turn on Your Vehicle

Now that you have successfully connected your towing vehicle to the trailer, it’s time to test the connection. First, turn on your vehicle and activate the brake lights. This will ensure that the brake signal is properly transmitted to the trailer.

Next, you need to test all the signals including the turn signals, reverse lights, and hazards to ensure that they are functioning properly. This is important for both your safety as well as that of other drivers on the road. If any of the signals are not working, you may need to troubleshoot the problem before hitting the road.

Remember, safety is key when towing a trailer, so make sure you double-check everything before you start your journey.

Check for Proper Functioning

After connecting the wires, it’s crucial to check if everything is functioning correctly. To do this, you need to test the connector. Start by turning on the device and checking if it’s responding.

Ensure that the connectors are secure and that the wires are correctly plugged in. Look for any loose connections or broken wires. If you do find any issues, address them before proceeding.

Additionally, you might want to use a tool to check the voltage and resistance levels, which will give you a more accurate reading of the system’s performance. Keep testing until you’re confident everything is working correctly. By completing this step, you reduce the risk of any hazardous situations or malfunctioning equipment.

Take the time to check everything now so you won’t have to worry later.

Conclusion: Keep Your Connector in Top Condition

In short, when it comes to cleaning your trailer connector, a little TLC goes a long way. Just like any relationship, regular maintenance and attention will keep things running smoothly. So, take the time to give your connector a good scrub, remove any dirt or debris, and make sure the contacts are shiny and bright.

With a little bit of effort, you’ll be back on the road in no time, and your connector will be singing your praises with every turn of the wheel. Happy cleaning!”

FAQs

Why is it important to clean trailer connector?

It is important to clean trailer connector because dirt and debris buildup can cause poor conductivity and eventually lead to electrical failures.

What is the best way to clean a trailer connector?

The best way to clean a trailer connector is to use a specialized contact cleaner or isopropyl alcohol and a soft-bristled brush to remove any dirt or corrosion.

How often should you clean your trailer connector?

It is recommended to clean your trailer connector every time you disconnect it from your vehicle, especially if it has been exposed to dirt or water.

What should I do if my trailer connector is corroded?

If your trailer connector is corroded, you can use a wire brush or sandpaper to remove the corrosion and then clean it with a contact cleaner or isopropyl alcohol. If the corrosion is severe, you may need to replace the connector.