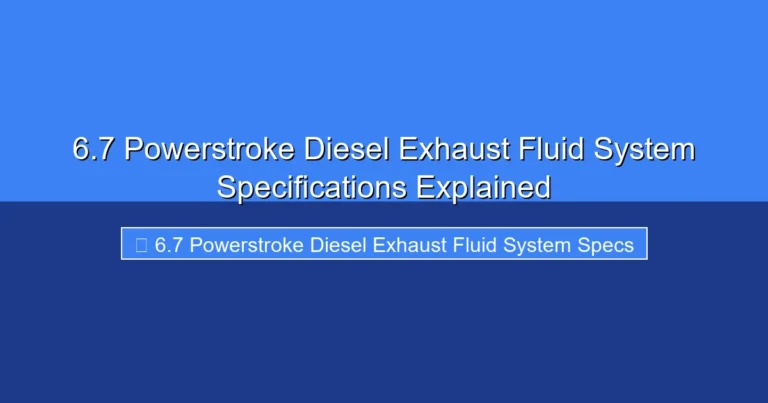

7.3 Powerstroke Piston Compression Specifications: Key Details

Featured image for this comprehensive guide about 7.3 Powerstroke piston compression specs

The legendary 7.3 Powerstroke engine, a workhorse of the automotive world, has earned its reputation for durability and raw power. Owners and enthusiasts often laud its longevity, but like any finely-tuned machine, its performance hinges on a multitude of factors, not least among them the intricate dance happening within its cylinders. One of the most critical indicators of an engine’s health and efficiency is its compression. Understanding 7.3 Powerstroke piston compression specs isn’t just for mechanics; it’s essential knowledge for anyone looking to maintain, diagnose, or even purchase one of these iconic diesel powerplants.

Piston compression is the bedrock of internal combustion. It’s the measure of how effectively your engine’s cylinders can create pressure, a fundamental requirement for the ignition and subsequent power generation that propels your truck down the road. When compression is optimal, your 7.3 Powerstroke runs smoothly, efficiently, and delivers the robust torque it’s famous for. But when compression falters, performance drops, fuel economy suffers, and more serious engine issues could be looming. This comprehensive guide will delve deep into the world of 7.3 Powerstroke piston compression specs, providing you with all the insights you need to keep your diesel beast roaring strong.

From understanding what healthy compression looks like to performing a meticulous 7.3 Powerstroke compression test, interpreting the results, and troubleshooting common problems, we’ll cover it all. Whether you’re a seasoned diesel enthusiast or a curious owner, mastering the nuances of your 7.3’s compression is a vital step toward maximizing its lifespan and ensuring every mile is a powerful one. Let’s get started on unlocking the secrets of your engine’s internal health!

Quick Answers to Common Questions

What are the typical 7.3 Powerstroke piston compression specs?

For a healthy 7.3 Powerstroke engine, you’re generally looking for compression readings in the range of 375-425 PSI per cylinder. Always refer to your specific model year’s service manual for the exact manufacturer’s specifications.

How much variation is acceptable between cylinders for 7.3 Powerstroke piston compression specs?

Ideally, you want minimal variation, but generally, a difference of no more than 10-15% between the highest and lowest cylinder readings is considered acceptable. Anything beyond that usually indicates a problem that needs investigation.

What does a low 7.3 Powerstroke piston compression reading signify?

A low compression reading on your 7.3 Powerstroke can point to several issues, such as worn piston rings, damaged valves, a leaking head gasket, or even issues with the injector cups. Further diagnostics are essential to pinpoint the exact cause.

Can I test my 7.3 Powerstroke piston compression specs myself at home?

Yes, if you’re comfortable with basic engine work and have the right tools, like a diesel compression tester with a glow plug adapter, you can perform this test yourself. Always follow your service manual’s instructions carefully for accurate and safe testing.

What’s an ideal 7.3 Powerstroke piston compression spec for optimal performance?

For peak performance and engine longevity, especially on a well-maintained or recently rebuilt 7.3 Powerstroke, consistent readings in the upper 300s to low 400s PSI across all cylinders are highly desirable. Consistency is just as important as the high numbers themselves.

📋 Table of Contents

- Understanding 7.3 Powerstroke Compression: Why It Matters So Much

- The Ideal 7.3 Powerstroke Piston Compression Specifications

- How to Perform a 7.3 Powerstroke Compression Test

- Interpreting Your 7.3 Powerstroke Compression Test Results

- Common Causes of Low 7.3 Powerstroke Compression

- Maintaining Optimal 7.3 Powerstroke Engine Health

- Data Table: 7.3 Powerstroke Compression Specifications Summary

- Conclusion: Empowering Your 7.3 Powerstroke’s Future

Understanding 7.3 Powerstroke Compression: Why It Matters So Much

At its heart, an internal combustion engine works by taking a mixture of fuel and air, compressing it, igniting it, and using the resulting expansion to push a piston. For a diesel engine like the 7.3 Powerstroke, this process is even more critical because ignition isn’t achieved by a spark plug, but by the intense heat generated from compressing the air to incredibly high pressures. This is why proper 7.3 Powerstroke piston compression specs are paramount for engine operation.

Learn more about 7.3 Powerstroke piston compression specs – 7.3 Powerstroke Piston Compression Specifications: Key Details

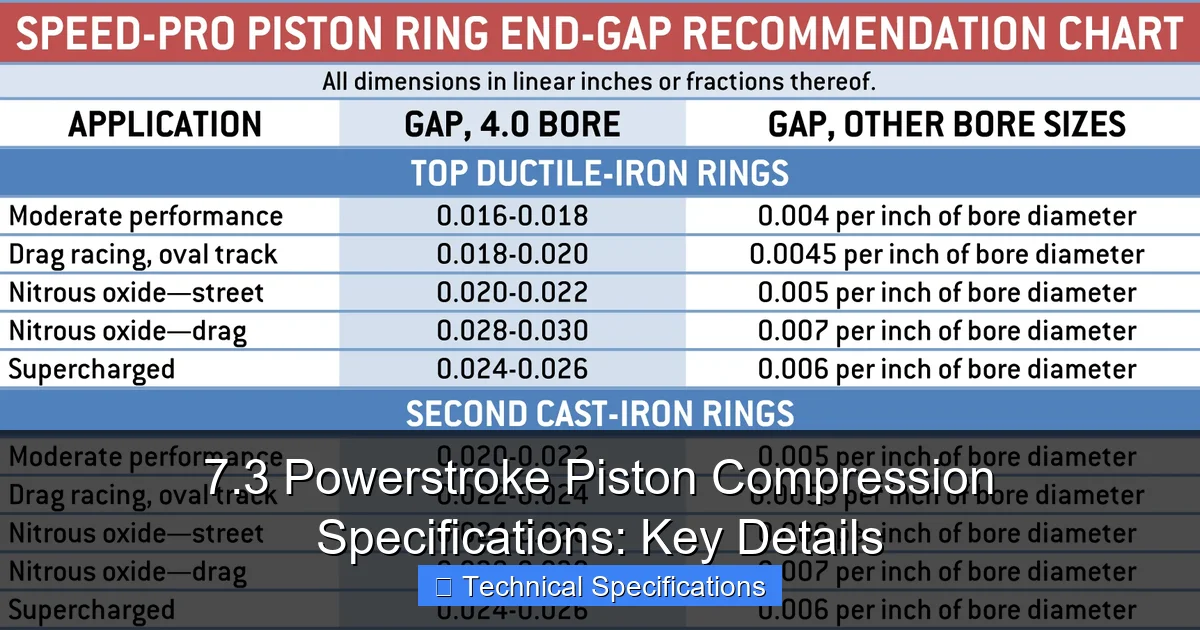

Image source: static.summitracing.com

When your engine has good compression across all cylinders, it means several things:

- Efficient Combustion: Sufficient compression leads to higher temperatures, ensuring complete and efficient combustion of the diesel fuel. This translates to better power output and fuel economy.

- Smooth Operation: Uniform compression across all cylinders results in a balanced engine. Imbalances caused by varying compression can lead to rough idling, vibrations, and uneven power delivery.

- Reduced Emissions: Efficient combustion also helps in reducing harmful emissions, keeping your vehicle compliant and environmentally friendlier.

- Engine Longevity: Healthy compression indicates that key engine components like piston rings, valves, and cylinder walls are in good condition. Maintaining these conditions contributes significantly to the overall lifespan of your 7.3 Powerstroke.

Conversely, a drop in compression, especially in one or more cylinders, is a tell-tale sign of an underlying issue that demands attention. Ignoring symptoms of low compression can lead to more severe and costly engine damage down the line. That’s why periodically checking your 7.3 Powerstroke compression specs through a compression test is a proactive measure for any diligent owner.

| Specification Item | Value | Unit | Notes / Conditions |

|---|---|---|---|

| Factory Standard Compression | 375 – 400 | PSI | Healthy / New Engine (WOT, engine warm) |

| Minimum Acceptable Compression | 300 | PSI | Indicates significant wear if below this |

| Maximum Variation Between Cylinders | 50 | PSI | Or 10% of the highest cylinder, whichever is less |

| Static Compression Ratio | 17.5:1 | Ratio | Engine design specification |

| Optimal Test Conditions | N/A | N/A | Engine warm, all glow plugs removed, WOT, fully charged battery |

The Ideal 7.3 Powerstroke Piston Compression Specifications

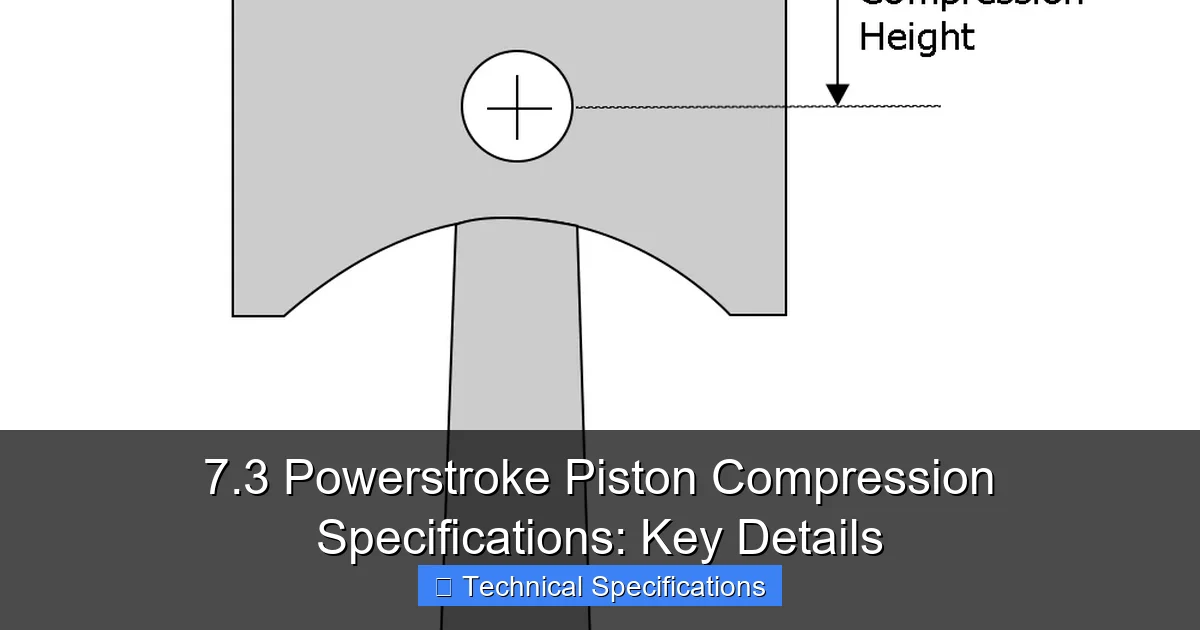

So, what exactly constitutes good compression for a 7.3 Powerstroke? While specific numbers can vary slightly based on mileage, engine wear, and testing conditions, there’s a widely accepted range that mechanics and enthusiasts look for. The 7.3 compression ratio, which is a fixed design characteristic, is typically around 17.5:1. However, what we’re measuring with a compression test is the absolute pressure in Pounds per Square Inch (PSI) that the piston can achieve.

Learn more about 7.3 Powerstroke piston compression specs – 7.3 Powerstroke Piston Compression Specifications: Key Details

Image source: st.hotrod.com

For a healthy 7.3 Powerstroke engine, you should generally expect to see readings in the following range:

Typical 7.3 Powerstroke Compression PSI Readings

- New/Excellent Condition: Approximately 400-450 PSI per cylinder.

- Good Operating Condition: Generally, anything above 350 PSI is considered healthy for an engine with some miles on it.

- Acceptable (but worth monitoring): Readings between 300-350 PSI indicate an engine that’s still running but showing signs of wear. While it might still function, performance and longevity could be compromised, and you should monitor it closely.

- Minimum Serviceable: Most experts agree that a minimum of 275-300 PSI is required for the engine to reliably start and run. Below this, starting becomes difficult, especially in cold weather, and performance will be significantly degraded.

Crucially, consistency between cylinders is almost as important as the absolute numbers. A variance of more than 10-15% between the highest and lowest cylinder readings is a red flag, even if the absolute numbers are within an “acceptable” range. For instance, if you have one cylinder at 400 PSI and another at 300 PSI, that’s a 25% difference, indicating a problem on the lower cylinder despite it being technically above the “minimum serviceable” threshold. This is a clear indicator of low compression 7.3 Powerstroke issues in that particular cylinder.

Key Factors Influencing Compression Readings

- Engine Temperature: Compression tests should ideally be performed on a warm engine. A cold engine will generally produce slightly lower readings due to increased clearances.

- Battery Condition: A strong, fully charged battery is vital to ensure the engine cranks over quickly and consistently, allowing for accurate readings.

- Throttle Position: The throttle should be wide open during the test to allow maximum airflow into the cylinders.

- Fuel System Disablement: To prevent fuel from entering the cylinders and potentially washing down cylinder walls or causing hydrolock, the fuel system must be disabled.

How to Perform a 7.3 Powerstroke Compression Test

Performing a 7.3 Powerstroke compression test is a diagnostic procedure that, while requiring some specialized tools, is well within the capabilities of a competent DIY mechanic. Accuracy is key, so follow these steps carefully:

Tools You’ll Need:

- Diesel compression tester kit (must be rated for high diesel pressures, typically up to 1000 PSI).

- Wrench set (for removing glow plugs/injectors).

- Ratchet and extension.

- Air compressor (optional, for cleaning).

- Battery charger (to ensure a strong battery).

- Pen and paper for recording results.

Step-by-Step Guide:

- Warm Up the Engine: Run the engine until it reaches normal operating temperature. This ensures proper piston ring expansion and accurate readings. Then, shut it off.

- Disconnect Batteries: For safety, disconnect both negative battery terminals.

- Disable Fuel System: Unplug the Injector Drive Module (IDM) harness or disconnect the fuel pump relay. This prevents fuel from being injected during cranking.

- Remove Glow Plugs (Recommended): For easier access and less cranking resistance, it’s often recommended to remove all glow plugs. This allows the engine to spin more freely. Some kits might adapt to the injector cups, but glow plug removal is generally simpler for testing purposes.

- Remove Injector for Testing Cylinder: Carefully remove the fuel line and electrical connector for the injector in the cylinder you’re about to test. Then, remove the injector itself. *Always refer to your service manual for specific removal procedures and torque specs.*

- Install Compression Tester: Thread the appropriate adapter from your diesel compression tester kit into the injector bore of the cylinder you’re testing. Ensure it’s hand-tight and forms a good seal.

- Reconnect Batteries: Reconnect the negative battery terminals.

- Crank the Engine: Have an assistant crank the engine for 5-7 revolutions (or until the gauge stops climbing). Hold the throttle wide open during cranking.

- Record Reading: Note down the PSI reading on the gauge.

- Repeat for All Cylinders: Relieve the pressure from the tester, remove it, reinstall the injector (and glow plug, if removed) for the tested cylinder, and move to the next. Repeat steps 5-9 for all eight cylinders.

- Reassemble and Reconnect: Once all tests are complete, reinstall all injectors, glow plugs, fuel lines, and electrical connectors. Reconnect the IDM harness/fuel pump relay and both battery terminals.

- Clear Codes (If Necessary): You may have triggered some diagnostic trouble codes (DTCs) by unplugging components. Use an OBD-II scanner to clear these.

Taking your time and being meticulous during this process will yield the most accurate and useful results regarding your 7.3 Powerstroke piston compression specs.

Interpreting Your 7.3 Powerstroke Compression Test Results

Once you’ve meticulously performed the compression test and recorded all the readings, the real diagnostic work begins. Understanding what those numbers mean, both individually and in relation to each other, is crucial for identifying potential issues with your 7.3 Powerstroke. This is where your recorded 7.3 Powerstroke piston compression specs become invaluable.

What to Look For:

- Overall Low Readings: If all cylinders are showing significantly lower than the “good operating condition” range (e.g., all around 250-300 PSI), it often points to general engine wear. This could be worn piston rings on all pistons, consistent valve seat wear, or overall degradation due to high mileage or lack of maintenance. While the engine might still run, its efficiency and power will be compromised.

- One or Two Low Cylinders: This is a very common scenario. If one or two cylinders are significantly lower than the others (more than 10-15% variance), it pinpoints a specific problem area.

- Cylinder-to-Cylinder Variation: As mentioned, consistency is key. Even if your average PSI is good, a large spread between the highest and lowest cylinders indicates trouble. This often manifests as a rough idle, misfires, or noticeable power loss.

- Zero or Near-Zero Reading: A cylinder with zero or very low compression (e.g., under 100 PSI) indicates a severe problem. This could be a bent valve, a heavily damaged piston, a blown head gasket, or even a hole in the piston. This engine will likely run very poorly, if at all, and require immediate attention.

Pinpointing the Cause (Wet Test):

If you have one or more cylinders showing low compression, a “wet test” can help narrow down the problem:

- Inject a small amount (about a tablespoon) of clean engine oil into the spark plug/injector bore of the low-compression cylinder.

- Reinstall the compression tester.

- Crank the engine again and re-record the PSI.

Interpreting the Wet Test:

- If compression significantly increases: This indicates worn piston rings. The added oil temporarily seals the rings, allowing for better compression.

- If compression does NOT significantly increase: This suggests the problem lies with the valves (burnt, bent, or improperly seated), a damaged cylinder head, or a blown head gasket. The oil won’t help seal these types of leaks.

Understanding these diagnostic steps turns your raw 7.3 Powerstroke piston compression specs into actionable insights for repair.

Common Causes of Low 7.3 Powerstroke Compression

Identifying the symptoms of low compression is one thing; understanding the root cause is another. When your 7.3 Powerstroke compression test reveals a problem, it’s typically due to wear or damage to critical engine components. Here are the most common culprits:

1. Worn Piston Rings:

The piston rings are designed to create a seal between the piston and the cylinder wall. Over time and with high mileage, these rings can wear down, lose their tension, or get stuck in their grooves due to carbon buildup. This allows combustion gases to escape past the piston into the crankcase (blow-by), resulting in a loss of compression. This is often indicated by increased crankcase pressure, excessive oil consumption, and a positive result from the “wet test.”

2. Valve Train Issues:

The intake and exhaust valves must seal perfectly against their seats to maintain compression. Problems here can include:

- Burnt or Bent Valves: Excessive heat can warp valves, or an impact (e.g., from a timing chain issue, though less common on the 7.3 due to its gear-driven cam) can bend them, preventing a proper seal.

- Worn Valve Seats: The surface where the valve rests can wear down, leading to leakage.

- Weak Valve Springs: If a valve spring is weak or broken, the valve may not close fully or quickly enough.

- Carbon Buildup: Excessive carbon deposits on the valve faces or seats can prevent them from sealing completely.

Valve train issues often lead to a consistent low reading that doesn’t improve significantly with a wet test.

3. Head Gasket Failure:

The head gasket seals the combustion chambers and prevents coolant and oil from mixing. A blown or failing head gasket can allow compression to escape between cylinders (cross-cylinder leakage) or into the cooling system. Symptoms include white smoke from the exhaust (coolant burning), coolant disappearing without a visible leak, engine overheating, and sometimes coolant in the oil or oil in the coolant. A compression test might show low readings in adjacent cylinders, or a specialized leak-down test can confirm this.

4. Cylinder Wall Wear or Damage:

The cylinder walls are critical for the piston rings to seal against. Excessive wear (ovality) or scoring (deep scratches) on the cylinder walls, often caused by abrasive contaminants or lubrication failure, will prevent the piston rings from forming an effective seal, leading to lost compression. This typically requires significant engine disassembly to repair.

5. Other Less Common Issues:

- Cracked Cylinder Head or Block: Severe cases of overheating or component failure can lead to cracks, allowing compression to escape.

- Piston Damage: A hole in the piston (due to pre-ignition or severe injector issues) or a broken piston can lead to a complete loss of compression in that cylinder.

Understanding these potential causes based on your 7.3 Powerstroke piston compression specs is the first step toward an accurate repair plan.

Maintaining Optimal 7.3 Powerstroke Engine Health

Preventative maintenance is the cornerstone of keeping your 7.3 Powerstroke running strong for hundreds of thousands of miles. While some wear is inevitable, diligent care can significantly extend the life of your engine and help maintain those crucial 7.3 Powerstroke piston compression specs. Think of it as an investment in your truck’s future performance and reliability.

Key Maintenance Practices for Compression Health:

- Regular Oil Changes with Quality Oil: This is perhaps the most critical maintenance item for any engine, especially a diesel. Fresh, high-quality diesel-specific oil (e.g., a good 15W-40 or 5W-40 synthetic) ensures proper lubrication of all moving parts, including piston rings and valve train components. Dirty or degraded oil can lead to increased wear, carbon buildup, and ultimately, a decline in compression. Follow Ford’s recommended oil change intervals, or even shorten them if your truck sees heavy use.

- Maintain a Healthy Fuel System: Clean fuel injectors are vital. Clogged or malfunctioning injectors can lead to poor fuel atomization, incomplete combustion, and excessive carbon buildup on valves and piston tops. This carbon can prevent valves from seating properly and even score cylinder walls. Use quality fuel filters and consider periodic fuel system cleaners designed for diesels. Ensuring your injectors are firing correctly is paramount for your 7.3 Powerstroke engine health.

- Keep Your Air Intake System Clean: A clean air filter is essential to prevent dirt and abrasive particles from entering the engine. These particles can cause significant wear to cylinder walls and piston rings, directly impacting compression. Inspect and replace your air filter regularly.

- Monitor Cooling System Health: Overheating is a silent killer for diesel engines. It can warp cylinder heads, damage head gaskets, and accelerate wear on various components. Ensure your coolant is at the correct level, free of contaminants, and that your radiator, thermostat, and water pump are functioning correctly. Regular coolant flushes are also beneficial.

- Address Engine Codes Promptly: Don’t ignore a check engine light or any unusual engine behavior. Even seemingly minor issues can cascade into larger problems that affect compression. Use an OBD-II scanner to read codes and address the underlying problem.

- Consider an Occasional Compression Test: While not part of routine maintenance, performing a 7.3 Powerstroke compression test every 75,000-100,000 miles (or if you suspect an issue) can provide a baseline and early warning of impending problems. This proactive approach can save you from costly repairs down the road.

- Drive Smart: Avoid excessive idling, especially in colder temperatures, as it can lead to carbon buildup. Allow your engine to reach operating temperature before putting it under heavy load.

By adhering to these best practices, you’re not just maintaining your truck; you’re safeguarding the very core of its performance – its piston compression – ensuring your 7.3 Powerstroke remains a powerful and reliable companion for years to come. Staying on top of these items will contribute immensely to your overall 7.3 Powerstroke engine health.

Data Table: 7.3 Powerstroke Compression Specifications Summary

For quick reference, here’s a summary of the expected 7.3 Powerstroke piston compression specs:

| Condition | Typical PSI Range (all cylinders) | Cylinder Variation (Max.) | Notes |

|---|---|---|---|

| New / Excellent | 400 – 450 PSI | < 10% | Peak performance and efficiency. |

| Good Operating | 350 – 400 PSI | < 10% | Healthy engine with some mileage. Reliable and strong. |

| Acceptable / Borderline | 300 – 350 PSI | 10% – 15% | Engine showing signs of wear. Monitor closely, plan for future work. |

| Minimum Serviceable | 275 – 300 PSI | 15% – 20% | Engine will likely start, but performance is degraded, especially cold. |

| Low / Critical | < 275 PSI in any cylinder | > 20% | Significant performance issues, hard starting, major repair likely needed. |

Remember, these numbers are general guidelines. Always consult your vehicle’s specific service manual for precise manufacturer specifications and procedures.

Conclusion: Empowering Your 7.3 Powerstroke’s Future

The 7.3 Powerstroke is more than just an engine; it’s a testament to robust engineering and enduring performance. By truly understanding its critical components, especially the nuanced world of 7.3 Powerstroke piston compression specs, you empower yourself to be a more informed and proactive owner. From recognizing the signs of optimal health to meticulously diagnosing potential issues, the knowledge gained from this guide is a powerful tool in your maintenance arsenal.

A well-maintained 7.3 with healthy compression will reward you with reliable power, efficient operation, and the legendary longevity these engines are known for. Don’t wait for a noticeable loss of power or a check engine light to prompt an investigation. Integrate the understanding of your 7.3 Powerstroke compression ratio and the importance of a regular 7.3 Powerstroke compression test into your maintenance philosophy. This proactive approach will not only extend the life of your truck but also ensure every drive is as strong and satisfying as the day it rolled off the factory floor.

So, take action! Gather your tools, perform that compression test, and interpret those results. Armed with this knowledge, you’re not just fixing problems; you’re ensuring the enduring legacy of your 7.3 Powerstroke for countless miles and adventures to come. Your diesel beast deserves nothing less than optimal engine compression, and now you have the insights to deliver it.

🎥 Related Video: How to do a compression test on your engine

📺 CNET Cars

Cooley shows you how to do the king of all engine tests. Subscribe to Roadshow: http://bit.ly/1Z3Ff7G Visit us online at http://www.

Frequently Asked Questions

What are the ideal 7.3 Powerstroke piston compression specs I should aim for?

For a healthy 7.3 Powerstroke engine, ideal compression readings typically fall between 350-420 PSI (pounds per square inch). All cylinders should also be within a reasonable variance of each other, usually no more than 10-15% difference.

What do inconsistent or low compression readings signify in a 7.3 Powerstroke engine?

Inconsistent or significantly low compression readings often point to internal engine issues. These could include worn piston rings, damaged valves, faulty head gaskets, or even cracks in the cylinder head or block.

How do you perform a compression test on a 7.3 Powerstroke engine?

To perform a compression test, you’ll need to remove the glow plugs from all cylinders. Install a diesel compression gauge into each glow plug port, one at a time, and then crank the engine for several revolutions while holding the throttle wide open.

What is the minimum acceptable 7.3 Powerstroke piston compression reading for continued operation?

While ideal readings are higher, a generally accepted minimum compression for a 7.3 Powerstroke to run reasonably well is around 300 PSI. However, any cylinder significantly below this, especially with a large variance from others, indicates a problem that needs addressing.

Should I perform a 7.3 Powerstroke piston compression test on a hot or cold engine?

It is generally recommended to perform a 7.3 Powerstroke compression test on a warm engine, but not necessarily hot. This allows for components to expand to their normal operating clearances, providing more accurate and consistent results.

What tools are essential for checking 7.3 Powerstroke piston compression specs?

You will primarily need a diesel compression test kit with adapters that fit the 7.3 Powerstroke glow plug bores. A wrench to remove the glow plugs, and a fully charged battery to ensure sufficient cranking speed, are also crucial.