6.0 Powerstroke Timing Specifications: Perfecting Your Engine’s Performance

Featured image for this comprehensive guide about 6.0 Powerstroke timing specs

6.0 Powerstroke Timing Specifications: Perfecting Your Engine’s Performance

The 6.0 Powerstroke engine, despite its sometimes-storied reputation, remains a powerful and capable workhorse when properly maintained. At the heart of its performance, efficiency, and longevity lies an intricate dance of precision – its engine timing system. For any owner or mechanic looking to truly understand and optimize this robust diesel, delving into the specifics of 6.0 Powerstroke timing specs isn’t just beneficial; it’s absolutely critical.

Unlike simpler engines where timing might refer solely to mechanical alignment, the 6.0 Powerstroke timing involves a sophisticated interplay of mechanical components, high-pressure oil, and advanced electronics. Every pulse of the injectors, every movement of the variable geometry turbo, and every rotation of the crankshaft is meticulously orchestrated. When this intricate choreography falls out of sync, even by a hair, the consequences can range from diminished performance and poor fuel economy to catastrophic engine damage. Understanding these “specs” isn’t about memorizing a single number, but grasping the complex relationships that govern your engine’s heartbeat.

This comprehensive guide will demystify the 6.0 Powerstroke timing specifications, exploring both the mechanical and electronic aspects that dictate its performance. We’ll dive into what constitutes proper timing, how to recognize symptoms of issues, effective diagnostic strategies, and crucial maintenance tips to ensure your 6.0 Powerstroke continues to run strong and efficient. Let’s unlock the secrets to perfect 6.0 Powerstroke timing and ensure your engine performs at its peak.

Quick Answers to Common Questions

Why are the 6.0 Powerstroke timing specs so crucial for performance?

Correct 6.0 Powerstroke timing specs ensure your engine runs efficiently, maximizing power output and fuel economy while minimizing wear and tear. It’s the foundation of optimal engine operation and longevity.

What are the common symptoms if my 6.0 Powerstroke timing specs are off?

You might experience rough idling, reduced power, poor fuel efficiency, excessive smoke from the exhaust, or even difficulty starting. These are clear signs your 6.0 Powerstroke timing specs need immediate attention.

Can I check or adjust my 6.0 Powerstroke timing specs at home?

While basic diagnostic checks are possible, precisely adjusting 6.0 Powerstroke timing specs often requires specialized tools and specific knowledge for accurate results. It’s usually best left to experienced technicians.

What kind of tools are typically needed to deal with 6.0 Powerstroke timing specs?

You’ll generally need diagnostic scanners to read sensor data, specific cam and crank alignment tools, and potentially an oscilloscope to accurately verify the 6.0 Powerstroke timing specs. It’s not a simple wrench-and-socket job.

Where can I find the factory 6.0 Powerstroke timing specs for my engine?

The most accurate 6.0 Powerstroke timing specs can be found in your vehicle’s official service manual, Ford repair guides, or reputable online technical resources specific to your engine’s year and build. Always consult trusted sources for precise information.

📋 Table of Contents

- The Intricacies of 6.0 Powerstroke Engine Timing

- Decoding Core 6.0 Powerstroke Timing Specifications

- Recognizing the Red Flags: Symptoms of Poor 6.0 Powerstroke Timing

- Diagnosing 6.0 Powerstroke Timing Issues: Tools and Techniques

- Beyond Mechanical: The Electronic Orchestration of 6.0 Powerstroke Timing

- Achieving Peak Performance: Maintenance and Preventative Measures for 6.0 Powerstroke Timing

- Conclusion: Mastering Your 6.0 Powerstroke’s Heartbeat

The Intricacies of 6.0 Powerstroke Engine Timing

At its core, engine timing refers to the precise synchronization of various engine components to ensure fuel ignition, valve opening and closing, and exhaust expulsion occur at the optimal moment within the engine cycle. For the 6.0 Powerstroke, this is an incredibly complex system, far beyond a simple distributor rotation. It’s a multi-layered process involving both mechanical and electronic elements.

Mechanical Timing: The Foundation

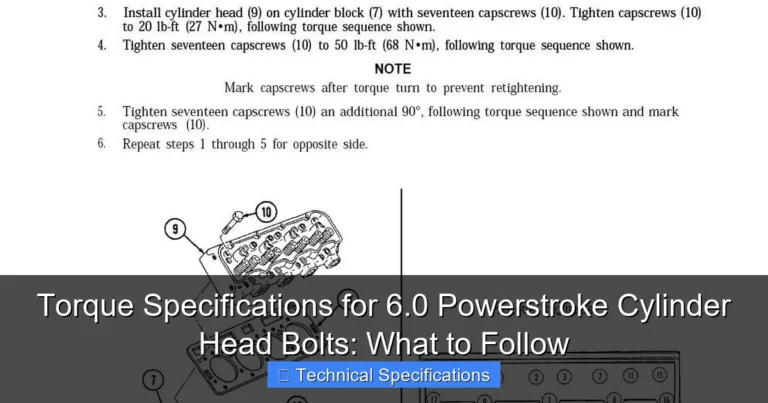

The foundation of 6.0 Powerstroke timing begins with the mechanical alignment of the crankshaft and camshafts. This relationship ensures that the intake and exhaust valves open and close in sync with the piston’s movement. On the 6.0 Powerstroke, this is achieved through a sturdy timing chain and gear assembly.

| Specification | Typical Value / Range | Units / Conditions | Notes / Impact |

|---|---|---|---|

| FICM Main Power Output | 47.5 – 48.5 | VDC (Volts DC) / KOEO or KOER | Critical for injector operation. Below 45V can cause misfires, hard starts, and poor timing. |

| ICP (Injection Control Pressure) – Idle | 500 – 750 | PSI / Engine Warm, Idle | Pressure required to actuate injectors. Low values indicate high-pressure oil system issues. |

| ICP (Injection Control Pressure) – WOT | 3000 – 3600 | PSI / Engine Warm, Wide Open Throttle | Maximum pressure for optimal injection duration and full power output. |

| CMP/CKP Synchronization Status | “YES” or “SYNC” | Status / Engine Cranking or Running | Essential for engine startup and running. No sync means no fuel injection. |

- Crankshaft: Directly connected to the pistons, its rotation dictates the engine’s cycle.

- Camshafts: Driven by the crankshaft via the timing chain, the camshafts control the opening and closing of the intake and exhaust valves. The 6.0 Powerstroke uses a single camshaft for both banks.

- Timing Chain & Gears: This robust assembly mechanically links the crankshaft to the camshaft, maintaining their critical synchronization. Correct installation of the timing chain and gears, aligning specific timing marks, is paramount for the engine’s fundamental operation. Failure to align these marks results in incorrect valve timing, leading to severe engine damage.

While specific degree values for valve opening/closing are engineered into the camshaft profile, the “spec” here is primarily about the correct initial mechanical alignment – ensuring the crankshaft and camshaft timing marks are perfectly aligned at Top Dead Center (TDC) of cylinder #1.

Electronic Timing: The Precision Control

Beyond the mechanical foundation, the 6.0 Powerstroke relies heavily on electronic controls for its operational timing. This is where the engine’s “smart” capabilities come into play, constantly adjusting parameters for optimal performance, emissions, and fuel economy.

- Injection Timing: This is arguably the most crucial aspect of 6.0 Powerstroke timing. Unlike older mechanical diesels, the 6.0’s fuel injection is entirely electronic, controlled by the Powertrain Control Module (PCM). The PCM determines precisely when and for how long each fuel injector fires, based on inputs from numerous sensors (Crankshaft Position Sensor (CKP), Camshaft Position Sensor (CMP), Engine Coolant Temperature (ECT), Manifold Absolute Pressure (MAP), etc.).

- Variable Geometry Turbo (VGT) Control: The VGT system’s timing (how quickly the turbocharger vanes adjust) is also electronically controlled. The PCM manipulates the VGT solenoid to adjust exhaust gas flow through the turbine, optimizing boost pressure for different engine loads and RPMs. This dynamic timing plays a significant role in power delivery and responsiveness.

The “specs” for electronic timing are dynamic and constantly recalculated by the PCM. They aren’t static numbers but rather target values and operational ranges that the engine attempts to achieve based on current conditions and pre-programmed maps.

Decoding Core 6.0 Powerstroke Timing Specifications

When we talk about 6.0 Powerstroke timing specs, we’re not just looking for a single number. Instead, we’re examining critical relationships, operational ranges, and diagnostic thresholds that indicate if the engine’s timing system is functioning as designed. Understanding these “specs” helps in diagnosis and maintenance.

Camshaft to Crankshaft Synchronization

The most fundamental “spec” is the correct mechanical alignment of the camshaft and crankshaft. This is checked during engine assembly or major repairs involving the front cover or timing chain. The factory service manual specifies exact timing marks on the camshaft gear and crankshaft gear that must align when the engine is at Cylinder #1 Top Dead Center (TDC) on the compression stroke. While not a numerical degree, this precise alignment is a non-negotiable “spec” for proper valve timing.

Camshaft Position Sensor (CMP) & Crankshaft Position Sensor (CKP) Signals

The PCM uses signals from these two sensors to monitor engine speed and position, which are fundamental for calculating injector timing. The “spec” here is the correlation between these two signals. A common diagnostic check involves monitoring CMP and CKP PIDs (Parameter Identifiers) with a scan tool. The PCM looks for a specific pattern and consistency in these signals. Divergence or erratic readings can indicate:

- A faulty sensor.

- Damaged reluctor wheels on the crankshaft or camshaft.

- Mechanical timing issues (e.g., a stretched timing chain allowing excessive play, causing the camshaft to lag).

Diagnostic Trouble Codes (DTCs) like P0340 (Camshaft Position Sensor Circuit Malfunction) or P0335 (Crankshaft Position Sensor Circuit Malfunction) are direct indicators of issues with these critical timing inputs. Specific DTCs like P0016 (Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor A)) directly point to a mechanical timing discrepancy.

Injector Control Pressure (ICP) & Injection Pressure Regulator (IPR)

While not direct “timing specs” in the traditional sense, the ICP and IPR are absolutely vital to the correct execution of injector timing. The 6.0 Powerstroke uses a High-Pressure Oil Pump (HPOP) to generate the extremely high oil pressure (ICP) required to fire the fuel injectors (HEUI system). The IPR valve modulates this pressure based on PCM commands.

- ICP Pressure Spec: At idle, expect ICP values around 500-750 PSI. Under wide-open throttle (WOT), values can easily exceed 3,500-4,000 PSI, reaching peaks of 26,000 PSI in some scenarios. The “spec” is for the ICP to be able to meet the PCM’s desired ICP (ICP_DES) under all operating conditions.

- IPR Duty Cycle Spec: The IPR duty cycle (the percentage of time the IPR valve is open) typically ranges from 15-25% at idle and can go up to 85% at WOT. If the IPR duty cycle is consistently high (e.g., above 60-70% at idle) to maintain desired ICP, it suggests a high-pressure oil leak or a failing HPOP, which will directly impact the PCM’s ability to achieve accurate injector timing.

Insufficient or erratic ICP directly affects when and how much fuel is injected, leading to misfires, hard starts, and a severe lack of power, all symptoms of compromised 6.0 Powerstroke timing performance.

Recognizing the Red Flags: Symptoms of Poor 6.0 Powerstroke Timing

When the intricate harmony of the 6.0 Powerstroke timing system is disrupted, the engine will quickly let you know. Recognizing these symptoms early can prevent further damage and costly repairs.

Common Symptoms of Timing Issues:

- Hard Starts or No-Starts: If the engine cranks excessively before starting, or fails to start at all, incorrect injector timing or insufficient ICP are prime suspects. The PCM cannot synchronize fuel delivery if it doesn’t know where the crankshaft and camshaft are, or if it can’t achieve the necessary oil pressure.

- Rough Idle and Misfires: A lumpy, vibrating idle or intermittent misfires (a feeling of the engine “skipping”) can point to an injector not firing correctly due to poor injection timing, low ICP, or a mechanical timing issue affecting valve operation.

- Loss of Power: A noticeable decrease in acceleration and overall engine power is a classic symptom. Incorrect 6.0 Powerstroke timing, whether mechanical or electronic (including VGT timing), prevents the engine from efficiently converting fuel into horsepower.

- Poor Fuel Economy: When the engine isn’t timed correctly, it operates inefficiently, burning more fuel to produce less power. If your mileage suddenly drops without explanation, investigate timing.

- Excessive Smoke from Exhaust:

- White Smoke: Often indicates unburnt fuel, which can be a result of injectors firing too late or incomplete combustion due to poor injector timing or low compression (potentially from incorrect valve timing).

- Blue Smoke: While typically indicative of oil burning, severe mechanical timing issues could indirectly contribute if engine components are damaged.

- Black Smoke: Usually signifies too much fuel or not enough air. Incorrect injection timing can cause this if fuel is delivered at the wrong moment for complete combustion, or if VGT timing is off, leading to insufficient boost.

- Engine Noise: Unusual knocking, clattering, or rattling sounds, especially from the front of the engine, could indicate a loose or worn timing chain or tensioner, or other internal mechanical issues related to engine timing.

- Illuminated Check Engine Light (CEL): The PCM is highly vigilant about timing-related faults. Common DTCs include:

- P0016: Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor A) – A direct indicator of mechanical timing issues.

- P0340/P0341: Camshaft Position Sensor Circuit/Performance.

- P0335/P0336: Crankshaft Position Sensor Circuit/Performance.

- Codes related to ICP/IPR performance (e.g., P2290 ICP Too Low, P2291 ICP Too Low – Engine Cranking).

Any of these symptoms warrant immediate investigation. Ignoring them can lead to further, more severe engine damage, escalating repair costs significantly.

Diagnosing 6.0 Powerstroke Timing Issues: Tools and Techniques

Accurately diagnosing 6.0 Powerstroke timing issues requires a systematic approach, combining visual inspection, specialized tools, and interpreting live data from the PCM. Here’s how professionals typically tackle the challenge.

Essential Diagnostic Steps:

- Scan for Diagnostic Trouble Codes (DTCs):

- Always start by hooking up a high-quality OBD-II scanner capable of reading Powerstroke-specific codes. Note any codes related to camshaft position, crankshaft position, ICP, IPR, or VGT. These codes are your first clue.

- Monitor Live Data (PIDs):

- CMP & CKP Correlation: Use your scanner to monitor the CMP and CKP signals. Look for consistent and synchronized readings. Any significant deviation, sudden drops, or erratic behavior suggests a problem with the sensors, their reluctor rings, or the mechanical timing itself (e.g., a stretched timing chain).

- ICP & IPR Values: Monitor ICP_DES (Desired ICP) vs. ICP (Actual ICP) and IPR duty cycle. If the actual ICP struggles to meet the desired ICP, especially at high IPR duty cycles, you have a high-pressure oil system leak or a weak HPOP, directly impacting injector timing.

- VGT Duty Cycle & Boost Pressure: Observe how the VGT duty cycle changes with engine RPM and load, and whether boost pressure responds accordingly. Sluggish boost or over-boosting can indicate a problem with the VGT solenoid or turbocharger vanes, affecting the engine’s dynamic timing.

- Cylinder Contribution Test: Many advanced scanners can perform a cylinder contribution test. This test helps identify individual cylinders that are misfiring or performing poorly, narrowing down potential issues related to specific injectors or their associated injector timing.

- Visual Inspection:

- While not always easy due to component location, a visual inspection can sometimes reveal obvious issues. Check for loose electrical connections to sensors (CMP, CKP, ICP, IPR, VGT solenoid). Look for signs of oil leaks around sensors or wiring harnesses.

- If mechanical timing is suspected (e.g., P0016 DTC), a more invasive inspection of the timing chain and gears might be necessary, requiring removal of the front cover. This is a significant job and usually reserved for confirmed mechanical timing faults.

- Oil Pressure Checks:

- Since the 6.0 Powerstroke is a HEUI (Hydraulically Electronic Unit Injector) system, engine oil health and pressure are paramount. Low base oil pressure can affect the HPOP’s ability to generate sufficient ICP. Check engine oil level and condition.

- Fuel System Checks:

- Ensure adequate fuel pressure from the low-pressure fuel pump. While not directly a “timing spec,” insufficient fuel delivery will certainly mimic timing issues and prevent proper combustion.

Remember, proper diagnosis often involves ruling out simpler, less expensive issues before diving into complex repairs. Always refer to the factory service manual for specific testing procedures and expected values for sensors and components.

Beyond Mechanical: The Electronic Orchestration of 6.0 Powerstroke Timing

The 6.0 Powerstroke is a marvel of electronic control, and its “timing” is as much about precise electrical signals and oil pressure as it is about gear alignment. Three key electronic components are paramount in this orchestration: the FICM, the HPOP, and the VGT system.

FICM (Fuel Injection Control Module): The Injector Conductor

The FICM is a dedicated computer that provides the high voltage (typically 48-52 volts) necessary to fire the 6.0 Powerstroke’s fuel injectors. It receives its commands from the PCM regarding precisely when and for how long to fire each injector. Think of the PCM as the composer and the FICM as the conductor for the injector orchestra.

- Impact on Timing: If the FICM is weak or failing, it cannot deliver the required voltage consistently or quickly enough. This directly affects injector timing, leading to delayed or incomplete injector firing. Symptoms include hard starts, rough idle, misfires, and a general lack of power. Low FICM voltage (below 45V during operation) is a major red flag.

- Key Specification: Maintain FICM voltage at or above 48V (ideally 48.5V-49V). Testing FICM voltage under load is crucial.

HPOP (High-Pressure Oil Pump) & IPR (Injection Pressure Regulator): The Oil Pressure Maestro

As mentioned, the 6.0 Powerstroke’s injectors are hydraulically actuated by high-pressure engine oil. The HPOP generates this immense pressure, and the IPR valve precisely regulates it according to the PCM’s demands.

- Impact on Timing: Without sufficient and consistent high-pressure oil (ICP), the injectors cannot fire at all, or they fire weakly and out of sync. A failing HPOP, a leaky dummy plug, standpipe, or an O-ring on an injector will cause a loss of ICP. The IPR valve failing to regulate pressure accurately will also compromise injector timing.

- Key Specification: As discussed, actual ICP should closely match desired ICP (ICP_DES). IPR duty cycle should be within specified ranges (e.g., 15-25% at idle). Any sustained deviation points to issues that severely impact the effectiveness of the PCM’s commanded injector timing.

VGT (Variable Geometry Turbocharger) Control: The Airflow Director

The VGT system allows the turbocharger to adjust its exhaust-driven turbine vanes to optimize boost pressure across a wide RPM range. This dynamic adjustment is essential for responsive power delivery, especially at lower RPMs.

- Impact on Timing: While not directly dictating combustion timing, the VGT’s “timing” (how quickly and accurately it adjusts) significantly affects the engine’s ability to achieve optimal combustion. If the VGT vanes stick or the VGT solenoid fails, boost pressure will be inconsistent or insufficient. This leads to a lack of power, increased exhaust gas temperatures, and potentially black smoke, as the fuel injected by the PCM (based on target air mass) won’t have enough air to burn completely.

- Key Specification: The VGT duty cycle should respond quickly and smoothly to changes in engine load and RPM, and boost pressure should build consistently to target values.

Understanding these electronic components isn’t just about their individual function, but how they collectively enable the PCM to achieve its commanded 6.0 Powerstroke timing specifications for optimal engine operation.

Achieving Peak Performance: Maintenance and Preventative Measures for 6.0 Powerstroke Timing

Proactive maintenance is the cornerstone of keeping your 6.0 Powerstroke timing system operating perfectly and extending your engine’s life. Neglecting key maintenance items can lead to premature failure of critical, and often expensive, components.

Table: Common Timing-Related Issues & Preventative Measures

| Issue Area | Potential Problem | Impact on Timing | Preventative Measure / Best Practice |

|---|---|---|---|

| Mechanical Timing | Stretched timing chain, worn gears | Cam/Crank synchronization lost (P0016), poor valve timing | Use high-quality engine oil, regular oil changes. Inspect during major front-cover service. |

| High-Pressure Oil System | HPOP failure, IPR valve failure, ICP sensor failure, HPO leaks (dummy plugs/standpipes) | Insufficient/erratic ICP, poor injector timing, hard/no starts, misfires | Strict adherence to oil change intervals, use API CJ-4 or newer rated 5W-40 or 15W-40 oil, replace dummy plugs/standpipes preventatively. |

| FICM | Low voltage output, internal failure | Weak/delayed injector firing, misfires, poor cold starting, reduced power | Monitor FICM voltage regularly (especially cold), replace/repair if consistently below 48V. |

| Fuel Injectors | Sticking, worn, or faulty injectors | Incorrect fuel delivery, misfires, smoke, poor fuel economy (even with perfect timing commands) | Use high-quality fuel, consider adding a fuel additive designed for diesel injectors, replace fuel filters regularly. |

| VGT Turbocharger | Sticking vanes, failing VGT solenoid | Poor boost response, lack of power, black smoke, high EGTs | Warm up/cool down engine properly, avoid excessive idling, inspect VGT solenoid periodically. |

| Sensors (CMP, CKP, ICP) | Electrical malfunction, contamination | Erratic or missing signals to PCM, incorrect engine timing calculations | Inspect wiring harnesses for damage, replace sensors preventatively at high mileage if experiencing intermittent issues. |

Actionable Tips for Optimal 6.0 Powerstroke Timing:

- Adhere to Oil Change Intervals Religiously: The 6.0 Powerstroke is incredibly sensitive to oil quality and level. High-pressure oil is the lifeblood of its injection system. Use only recommended API CJ-4 or newer rated 5W-40 or 15W-40 diesel engine oil. Change your oil and filter every 5,000-7,500 miles, or as recommended by your owner’s manual for severe duty.

- Regular Fuel Filter Replacements: Clogged fuel filters starve the injectors of fuel, which can mimic timing issues. Replace both fuel filters (primary frame-mounted and secondary engine-mounted) every 10,000-15,000 miles, or as specified by Ford.

- Monitor Critical Parameters: Investing in an OBD-II scanner capable of displaying live data (e.g., Torque Pro, Forscan, or a dedicated diagnostic tool) is invaluable. Regularly monitor FICM voltage, ICP_DES vs. ICP, IPR duty cycle, and CMP/CKP correlation. Catching deviations early can prevent major failures.

- Address Codes Promptly: Never ignore a Check Engine Light, especially if it’s accompanied by performance issues. Timely diagnosis and repair can prevent a minor issue from snowballing into an expensive engine rebuild.

- Quality Parts for Repairs: When replacing timing-critical components (FICM, HPOP, IPR, sensors, injectors), always opt for high-quality OEM or reputable aftermarket parts. Skimping on these can lead to recurring problems and unreliable 6.0 Powerstroke timing.

- Professional Assessment: If you suspect deep-seated 6.0 Powerstroke timing issues (e.g., mechanical timing chain problems), seek professional diagnosis. These repairs require specialized tools and expertise to ensure proper alignment and function.

Conclusion: Mastering Your 6.0 Powerstroke’s Heartbeat

The 6.0 Powerstroke timing specifications are not a simple set of numbers to be memorized; they represent a sophisticated symphony of mechanical precision and electronic orchestration. From the foundational alignment of the crankshaft and camshaft to the lightning-fast, high-voltage pulses of the FICM and the immense pressure generated by the HPOP, every component plays a vital role in ensuring your engine runs efficiently, powerfully, and reliably.

Understanding these intricacies empowers you as a 6.0 Powerstroke owner. By recognizing the subtle symptoms of impending issues, utilizing diagnostic tools effectively, and adhering to a rigorous maintenance schedule, you can proactively safeguard your engine’s health. The goal isn’t just to fix problems when they arise, but to prevent them altogether, ensuring the complex system that governs engine timing remains perfectly synchronized.

By investing time in understanding the unique demands of your 6.0 Powerstroke timing system, you’re not just maintaining a truck; you’re preserving a legend. Keep its heart beating strong, and your 6.0 Powerstroke will continue to deliver the performance and reliability it was designed for, mile after glorious mile. Perfecting your 6.0 Powerstroke timing specs is key to unlocking its full potential.

Frequently Asked Questions

What are 6.0 Powerstroke timing specs and why are they crucial for engine performance?

6.0 Powerstroke timing specifications refer to the precise synchronization of the crankshaft and camshaft, ensuring the valves open and close at the exact moment relative to piston position. Correct timing is absolutely critical for optimal combustion, fuel efficiency, power output, and overall engine longevity.

How do I check the timing on my 6.0 Powerstroke engine?

Checking the timing on a 6.0 Powerstroke typically involves inspecting the alignment of timing marks on the crankshaft and camshaft gears, or using diagnostic tools to monitor sensor data. For accurate assessment, it’s often recommended to use a scan tool to review Crankshaft Position (CKP) and Camshaft Position (CMP) sensor readings, looking for any discrepancies.

What are the common symptoms of incorrect 6.0 Powerstroke timing?

Symptoms of incorrect 6.0 Powerstroke timing can include rough idle, reduced power, poor fuel economy, hard starting, or even misfires. You might also notice unusual engine noises or an illuminated “Check Engine” light, often accompanied by specific diagnostic trouble codes related to timing or sensor correlation.

Are there specific tools required for adjusting 6.0 Powerstroke timing?

Yes, adjusting the 6.0 Powerstroke timing often requires specialized tools, including timing alignment pins or plates to properly lock the crankshaft and camshaft in their correct positions. A torque wrench is also essential for reassembling components to manufacturer specifications, ensuring proper tension and preventing future issues.

Can incorrect 6.0 Powerstroke timing cause severe engine damage?

Absolutely, incorrect 6.0 Powerstroke timing can lead to catastrophic engine damage, especially if the timing is significantly off. In extreme cases, pistons can collide with valves, resulting in bent valves, damaged pistons, and even a completely ruined engine that requires extensive and costly repairs.

When should I consider having my 6.0 Powerstroke timing checked?

You should consider having your 6.0 Powerstroke timing checked if you experience any of the symptoms mentioned above, or after any major engine work that involved removing the front cover or disturbing the timing components. It’s also a good idea as part of a comprehensive engine diagnosis for unexplained performance issues or before purchasing a used 6.0 Powerstroke.