6.0 Powerstroke PCM Specifications: Understanding the Powertrain Control Module

Featured image for this comprehensive guide about 6.0 Powerstroke PCM specifications

When you talk about the heart and brain of your 6.0 Powerstroke, you’re often referring to two critical components: the engine itself and the sophisticated electronic control unit that manages it. For the latter, we’re diving deep into the 6.0 Powerstroke PCM specifications. This isn’t just a black box under the hood; it’s the nerve center that orchestrates everything from fuel delivery to transmission shifts, ensuring your truck runs optimally, efficiently, and reliably.

Understanding the Powertrain Control Module (PCM) in your 6.0L Ford diesel is paramount for any owner, mechanic, or enthusiast. It’s where the complex dance of sensors, actuators, and software algorithms comes together to produce the raw power and distinctive rumble you love. Ignoring its importance or misunderstanding its role can lead to costly diagnostic errors, performance issues, and a lot of frustration.

This comprehensive guide will unravel the mysteries of the 6.0 Powerstroke PCM. We’ll explore its core functions, delve into its hardware and software specifications, discuss common failure symptoms, and provide actionable insights into diagnosis, replacement, and maintenance. By the end, you’ll have a much clearer picture of what makes your 6.0L roar and how to keep its electronic brain in top shape.

Quick Answers to Common Questions

What exactly is the 6.0 Powerstroke PCM?

The Powertrain Control Module (PCM) is essentially your truck’s central brain, overseeing critical engine and transmission functions. Understanding its 6.0 Powerstroke PCM specifications is key to your truck’s optimal performance.

What do the 6.0 Powerstroke PCM specifications tell me about my truck’s performance?

These specifications dictate how your engine runs, from fuel injection timing and turbo boost to transmission shifts and emissions. They directly impact everything from power output and throttle response to fuel efficiency.

Where can I typically locate the 6.0 Powerstroke PCM in my truck?

For the 6.0 Powerstroke, the PCM is usually found under the hood, mounted on the firewall on the driver’s side, often behind the brake booster. Knowing its location is useful when dealing with 6.0 Powerstroke PCM specifications or troubleshooting.

Can I “tune” or modify the 6.0 Powerstroke PCM specifications for better performance?

Yes, absolutely! Aftermarket tuners can reflash your PCM with new software, altering its 6.0 Powerstroke PCM specifications to enhance horsepower, torque, and even improve fuel economy. It’s a popular modification for enthusiasts!

What are some common symptoms of a failing 6.0 Powerstroke PCM?

You might experience rough idling, stalling, poor fuel economy, transmission shifting issues, or your check engine light constantly illuminated. If your truck is acting erratically, reviewing its 6.0 Powerstroke PCM specifications and health is a smart first step.

📋 Table of Contents

What Exactly is the 6.0 Powerstroke PCM?

At its core, the Powertrain Control Module (PCM) is a powerful, dedicated computer system designed to monitor and control various aspects of your vehicle’s engine and transmission. Think of it as the ultimate decision-maker, constantly processing data from an array of sensors throughout your 6.0 Powerstroke and then sending precise commands to actuators to adjust engine parameters in real-time.

For the Ford 6.0L Powerstroke diesel engine, the PCM is responsible for a vast array of critical functions, including:

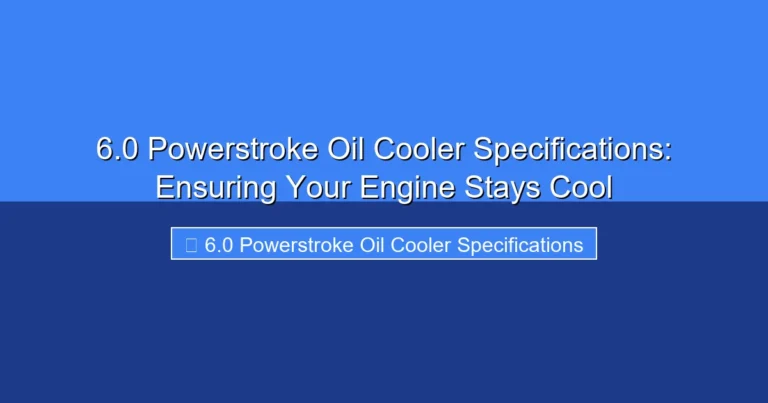

| Specification | Value / Detail | Notes / Relevance |

|---|---|---|

| Processor Architecture | 32-bit Microcontroller | Manages all engine and transmission control strategies. |

| Memory (Flash ROM) | ~1 MB (Megabyte) | Stores base engine calibration, operating system software, and diagnostic trouble codes (DTCs). |

| Memory (RAM) | ~64 KB (Kilobytes) | Used for real-time data processing, sensor readings, and temporary calculations. |

| Communication Protocol | CAN Bus (Controller Area Network) | Primary communication method with other vehicle modules (e.g., FICM, ABS, TCM). |

| Operating Voltage | 12V DC Nominal | Powered directly by the vehicle’s standard electrical system. |

| Key Functions Controlled | Fuel Injection, Turbo VGT, EGR, Glow Plugs, Transmission Shift Strategy | Critical for engine performance, emissions compliance, and vehicle drivability. |

- Fuel Injection Timing and Quantity: While the Fuel Injection Control Module (FICM) provides the high voltage for the injectors, the PCM dictates exactly when and how much fuel is delivered based on engine load, RPM, temperature, and throttle input.

- Turbocharger Control: It manages the variable geometry turbocharger (VGT) vanes to optimize boost pressure across the entire RPM range, ensuring responsiveness and power delivery.

- Exhaust Gas Recirculation (EGR) System: The PCM modulates the EGR valve to precisely control the amount of exhaust gases reintroduced into the intake manifold, crucial for emissions reduction.

- Transmission Control: It oversees shift points, torque converter lock-up, and line pressure for the automatic transmission, ensuring smooth and efficient power transfer.

- Engine Protection: Monitors critical parameters like oil pressure, coolant temperature, and fuel pressure, implementing protective strategies (e.g., limp mode) if values fall outside safe operating ranges.

- Diagnostic & Emissions Monitoring: The 6.0 Powerstroke PCM continuously runs self-diagnostics, storing Diagnostic Trouble Codes (DTCs) if a fault is detected, and playing a key role in emissions compliance.

PCM vs. FICM: A Critical Distinction for the 6.0L

It’s vital to differentiate the PCM from the FICM (Fuel Injection Control Module), especially for 6.0L Powerstroke owners. While both are electronic control units, their roles are distinct:

- PCM: The “brain” that determines *when* and *how much* fuel to inject, and *how* the engine and transmission operate overall. It’s the master controller.

- FICM: The “muscle” that takes the PCM’s command for fuel injection and generates the necessary 48-volt signal to fire the fuel injectors. It’s a high-voltage power supply and driver module.

Many symptoms of engine trouble on a 6.0L can be attributed to either the PCM or the FICM, making accurate diagnosis critical. Understanding their respective functions is the first step in troubleshooting your 6.0 Powerstroke PCM specifications and overall engine health.

Key 6.0 Powerstroke PCM Specifications and Hardware

Delving into the specifics of the 6.0 Powerstroke PCM reveals a robust, purpose-built electronic module designed to withstand the harsh environment of an engine bay while performing complex computations. While exact chip-level specifications are proprietary to Ford and its suppliers (like Siemens VDO or Motorola), we can outline the general hardware architecture and its capabilities.

Internal Architecture and Processing Power

The 6.0 Powerstroke PCM utilizes a powerful microprocessor (often a 16-bit or 32-bit architecture) capable of executing millions of instructions per second. This processing power is crucial for real-time engine control, where split-second decisions based on rapidly changing sensor data are paramount.

- Processor: Typically an automotive-grade microcontroller, designed for reliability and performance in extreme temperatures and vibration. Its clock speed allows for the rapid calculation of fuel maps, ignition timing (in gasoline engines, but relevant for diesel injection timing), and turbo boost.

-

Memory: The PCM contains several types of memory:

- ROM (Read-Only Memory): Stores the core operating system and fundamental programming that cannot be easily altered.

- Flash Memory (EEPROM/Flash EPROM): This is where the vehicle-specific calibration data (tunes, maps) is stored. This memory can be reprogrammed or “flashed” with new software updates or custom tunes. This is the heart of the 6.0 Powerstroke PCM specifications that allow for performance modifications.

- RAM (Random Access Memory): Used for temporary storage of sensor data, calculations, and active diagnostic information. It’s volatile, meaning data is lost when power is removed.

Input/Output (I/O) Capabilities

The sheer number of inputs and outputs highlights the complexity of the 6.0 Powerstroke PCM. It connects to dozens of sensors and actuators:

-

Inputs: Receives signals from sensors such as:

- Engine Oil Temperature (EOT)

- Coolant Temperature (ECT)

- Manifold Absolute Pressure (MAP)

- Barometric Pressure (BARO)

- Exhaust Back Pressure (EBP)

- Injection Control Pressure (ICP)

- Injector Pressure Regulator (IPR) duty cycle feedback

- Throttle Position Sensor (TPS)

- Mass Air Flow (MAF) (though less critical for diesel)

- Vehicle Speed Sensor (VSS)

- Transmission Fluid Temperature (TFT)

- Turbocharger Speed Sensor

- Camshaft Position (CMP) and Crankshaft Position (CKP) for timing

-

Outputs: Sends commands to actuators, including:

- Fuel Injectors (via FICM)

- Exhaust Gas Recirculation (EGR) valve

- Variable Geometry Turbo (VGT) actuator

- Injection Pressure Regulator (IPR) valve

- Fuel Pump Relay

- Cooling Fan Clutch

- Transmission solenoids (for shifting)

- Glow Plugs/Relay

- Check Engine Light (CEL) on the dash

Physical Characteristics and Location

The 6.0 Powerstroke PCM is typically housed in a durable, sealed aluminum or composite casing designed to protect its sensitive electronics from heat, moisture, and vibration. It’s often located on the firewall or under the dashboard on the passenger side, away from the direct heat of the engine, but still accessible for service. Its main electrical connector will be a multi-pin plug (or multiple plugs) securely fastened to the module, ensuring robust electrical contact.

The Critical Role of PCM Software and Calibration

While the hardware provides the computational backbone, it’s the software and its associated calibrations that truly define the performance and characteristics of your 6.0 Powerstroke PCM. Think of the hardware as the computer itself, and the software/calibration as the operating system and all the programs that tell it what to do.

Understanding Calibration and “Tunes”

PCM calibration refers to the specific set of data tables and parameters (often called “maps” or “tunes”) stored in the PCM’s flash memory. These maps dictate how the engine and transmission should behave under virtually every conceivable operating condition. They control:

- Fueling Strategies: How much fuel is injected, at what timing, and for what duration. This directly impacts power, fuel economy, and emissions.

- Turbocharger Control: The target boost pressure, how quickly the VGT vanes adjust, and boost limiting parameters.

- EGR Operation: The percentage of exhaust gas recirculation under different loads and RPMs.

- Transmission Shift Points: When the transmission shifts up or down, based on throttle input, vehicle speed, and load.

- Engine Protection Limits: What constitutes an unsafe condition (e.g., over-temperature, over-boost) and how the PCM should respond (e.g., derate engine, limp mode).

Factory (OEM) calibrations are designed to balance power, fuel economy, emissions compliance, and engine longevity. However, the 6.0 Powerstroke is well-known for responding positively to aftermarket tuning, which modifies these calibrations to achieve specific goals.

OEM Calibrations vs. Custom Tunes

The initial calibration loaded into your 6.0 Powerstroke PCM from the factory is engineered by Ford. Over time, Ford releases updated calibrations (often referred to as “flashes”) to address known issues, improve performance, or enhance emissions compliance. Keeping your PCM updated with the latest OEM flash can resolve many driveability concerns and improve reliability.

Custom tunes, on the other hand, are aftermarket modifications to the PCM’s calibration. These are popular for:

- Increased Horsepower & Torque: By optimizing fueling, boost, and timing.

- Improved Fuel Economy: Sometimes achievable with specific “economy” tunes.

- Enhanced Transmission Performance: Firmer shifts, adjusted shift points for towing or performance driving.

- Emissions System Deletion: (Note: This is illegal for street use in many jurisdictions and for federal compliance).

- Addressing Factory Deficiencies: Some tuners claim to improve upon Ford’s original calibration for specific known 6.0 Powerstroke issues.

When considering custom tunes, always choose reputable tuners experienced with the 6.0 Powerstroke PCM specifications. A poorly developed tune can severely damage your engine or transmission.

How Updates and Flashes are Performed

Reprogramming or “flashing” the PCM involves connecting a diagnostic tool (like Ford’s IDS system, an aftermarket scanner, or a dedicated tuner device) to the vehicle’s OBD-II port. This tool then uploads new calibration data from a computer into the PCM’s flash memory.

During this process, it’s absolutely critical to maintain stable battery voltage and avoid interruptions, as a corrupted flash can render the PCM inoperable, requiring expensive replacement or specialized recovery.

Common 6.0 Powerstroke PCM Failure Symptoms and Diagnosis

The 6.0 Powerstroke PCM is a robust component, but like any electronic module, it can fail. Due to its central role, a failing PCM can manifest in a wide range of debilitating symptoms that significantly impact your truck’s operation.

Recognizing PCM Failure Symptoms

If your 6.0L Powerstroke is experiencing any of the following, a faulty PCM could be the culprit:

- No-Start or Intermittent Start: The engine cranks but won’t fire, or starts sporadically. This is a severe symptom.

- Rough Idle or Stalling: The engine runs unevenly, shakes, or stalls frequently, especially after starting.

- Limp Mode Activation: The truck enters a reduced power mode to protect the engine, often accompanied by a significant drop in performance.

- Check Engine Light (CEL) Illumination: The “Service Engine Soon” light comes on, often with no discernible driveability issue or with severe problems.

- Multiple, Unrelated Diagnostic Trouble Codes (DTCs): If you’re seeing a cascade of seemingly unrelated fault codes (e.g., sensor circuit high/low, communication errors, misfires), it can point to a PCM issue rather than individual sensor failures.

- Poor Fuel Economy: Significant and unexplained decrease in MPG.

- Transmission Shifting Problems: Harsh shifts, delayed shifts, or failure to shift gears correctly. Since the PCM controls the transmission, these can be direct indicators.

- Loss of Power or Lagging Performance: The engine feels weak, lacks its usual acceleration, or experiences significant turbo lag.

- Inoperative Gauges or Warning Lights: In some cases, a failing PCM can affect the instrument cluster’s ability to display accurate information.

- Engine Noise or Knocking: Incorrect fuel injection timing or quantity commanded by the PCM can lead to abnormal engine sounds.

Diagnostic Steps for PCM Issues

Diagnosing a faulty 6.0 Powerstroke PCM requires careful, systematic troubleshooting to rule out other components.

- Scan for Diagnostic Trouble Codes (DTCs): Use a high-quality OBD-II scanner capable of reading Ford-specific codes. Pay close attention to communication codes (U-codes) or multiple sensor codes.

- Check Power and Ground to the PCM: Ensure the PCM is receiving proper voltage and has a clean ground connection. Corroded terminals or faulty wiring can mimic PCM failure.

- Inspect Wiring Harnesses and Connectors: Look for chafed wires, loose connections, or corrosion at the PCM and sensor connectors. The 6.0 Powerstroke wiring harness can be a common failure point.

- Test Relevant Sensors: Although multiple DTCs might point to the PCM, individual sensor failures can also cause severe driveability issues. Test sensors like the ICP, IPR, EBP, MAP, and CMP for correct readings. A bad sensor sending incorrect data to the PCM can cause miscalculations.

- Distinguish from FICM Issues: As mentioned, many 6.0L starting and running problems stem from the FICM. Verify FICM voltage (should be 48V under load) and health before condemning the PCM.

- Check for Aftermarket Tuning Conflicts: If the vehicle has custom tunes, try flashing it back to a stock calibration to see if the issue resolves. A bad tune can cause erratic behavior.

- Voltage Drop Test: Perform voltage drop tests on critical circuits, especially the main power and ground feeds to the PCM.

**Important Note:** A true 6.0 Powerstroke PCM failure is relatively rare compared to sensor or wiring issues. Always exhaust all other diagnostic possibilities before deciding on a PCM replacement.

PCM Replacement, Reprogramming, and Maintenance Tips

Once you’ve definitively diagnosed a faulty 6.0 Powerstroke PCM, the next steps involve careful replacement, proper reprogramming, and adopting maintenance habits to prevent future issues.

When to Replace vs. Repair

For a factory PCM, repair is typically not a viable option. The internal components are often potted (sealed in epoxy) or require specialized equipment and expertise that most shops don’t possess. Therefore, replacement with a new, remanufactured, or properly functioning used unit is the standard procedure.

If you’re dealing with a specific software glitch that isn’t physical hardware damage, a reprogramming (“flash”) might resolve the issue without needing a full replacement. This is usually the first step if no physical damage or circuit issues are found.

The Replacement Process

Replacing the 6.0 Powerstroke PCM is a relatively straightforward physical swap, but the electronic implications are significant:

- Disconnect Battery: Always disconnect the negative battery terminal to prevent electrical shorts.

- Locate and Remove Old PCM: The PCM is typically mounted on the firewall or under the passenger side dash. Disconnect the electrical connectors and remove the mounting bolts.

- Install New/Remanufactured PCM: Secure the new module and reconnect the electrical connectors firmly.

- Reconnect Battery: Reattach the negative battery terminal.

- Reprogramming/Flashing: This is the most crucial step. A new or used PCM will almost certainly require programming with the correct calibration for your specific vehicle (VIN-matched) and potentially “PATS” (Passive Anti-Theft System) key programming. Without this, the engine will likely not start or will run incorrectly. This requires a Ford IDS tool or an advanced aftermarket scanner with programming capabilities.

Costs: A new or remanufactured 6.0 Powerstroke PCM can range from $500 to $1,500+, plus labor for installation and programming, which can add several hundred dollars. Always get a PCM that is pre-programmed for your VIN or have a reputable shop perform the programming.

Maintenance Tips for PCM Longevity

While you can’t “service” the PCM itself, several preventative measures can help ensure its long-term reliability and protect its delicate electronics:

- Maintain Good Battery Health: Low or unstable battery voltage can stress the PCM and other electronic modules. Ensure your batteries are in good condition and fully charged.

- Avoid Jump Starting with Running Vehicles: This can cause voltage spikes that damage sensitive electronics. Use a dedicated jump pack or another vehicle that is *not* running.

- Ensure Proper Grounding: Corroded or loose ground connections can cause erratic electrical behavior and damage modules. Periodically check and clean all engine and chassis ground points.

- Protect Wiring Harnesses: Regularly inspect wiring harnesses for chafing, rubbing, or damage, especially near hot engine components or sharp edges. Secure loose wires.

- Address Water Leaks Promptly: Water ingress into the cabin or engine bay can lead to corrosion and short circuits in electronic modules, including the PCM.

- Use Reputable Tuners: If you opt for custom tuning, choose a well-regarded tuner known for stable and safe calibrations. Avoid “cheap” or generic tunes that might push engine parameters beyond safe limits or have poor code quality.

- Keep Sensors in Good Condition: Since the PCM relies heavily on accurate sensor data, ensure your EBP, MAP, ICP, and other critical sensors are clean and functioning correctly. Faulty sensor inputs can force the PCM to make poor decisions or enter limp mode.

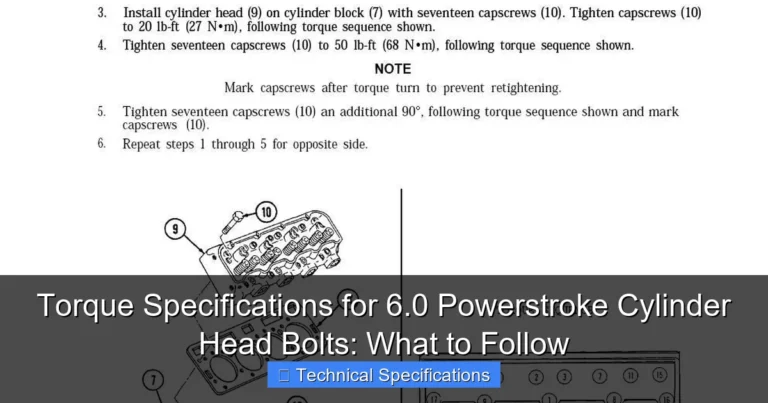

PCM vs. FICM: Core Function Comparison for the 6.0L Powerstroke

| Feature/Function | 6.0 Powerstroke PCM (Powertrain Control Module) | 6.0 Powerstroke FICM (Fuel Injection Control Module) |

|---|---|---|

| Primary Role | Main engine and transmission management “brain.” | High-voltage driver for fuel injectors. |

| Key Decisions | Fuel injection timing, quantity, boost control, EGR, transmission shifts, engine protection. | Receives injection commands from PCM, generates 48V to fire injectors. |

| Input Sources | Numerous engine/transmission sensors (EOT, ECT, MAP, EBP, ICP, TPS, VSS, etc.). | Mainly receives commands directly from the PCM. |

| Output Targets | FICM, VGT actuator, IPR valve, EGR valve, transmission solenoids, fuel pump relay. | Fuel Injectors (provides 48V power). |

| Software/Calibration | Contains primary engine and transmission calibration (“tune”). Can be custom programmed. | Contains its own firmware; some aftermarket FICMs offer “tunes” to optimize injection. |

| Common Symptoms of Failure | No-start, limp mode, multiple DTCs, transmission issues, poor overall engine management. | Hard starts, long cranks, misfires, rough idle, bucking, lack of power. |

| Location | Typically firewall or under passenger dash (specifics vary by year). | Top of the engine, under the turbocharger cover, next to the oil filter housing. |

Conclusion

The 6.0 Powerstroke PCM is far more than just a computer; it’s the intelligent core that makes your diesel engine come alive and perform its best. Understanding its specifications, functions, and critical role in engine management is essential for any 6.0L Powerstroke owner. From precisely metering fuel to controlling the turbo and transmission, the PCM is constantly working to deliver the power and efficiency you expect.

While the 6.0L Powerstroke has its quirks, often attributed to the emissions systems or other components, a healthy and properly calibrated PCM is foundational to mitigating common issues and ensuring reliable operation. Knowing how to recognize symptoms of PCM failure, distinguish it from other module problems (like the FICM), and perform proper diagnostics will save you time, money, and frustration.

By paying attention to maintenance fundamentals—like battery health, wiring integrity, and judicious use of aftermarket tuning—you can significantly extend the life and optimize the performance of your 6.0 Powerstroke PCM. Embrace the knowledge shared in this guide, and you’ll be well-equipped to keep your legendary 6.0L Powerstroke running strong for years to come.

🎥 Related Video: How To Order the Correct Ford PCM

📺 CARDONE Industries

Need a replacement PCM? Having trouble figuring out which part number you need? In this video we show you how to determine …

Frequently Asked Questions

What is the PCM in a 6.0 Powerstroke and what does it control?

The PCM, or Powertrain Control Module, is the computer brain of your 6.0 Powerstroke engine. It constantly monitors various sensors throughout the engine and vehicle, then uses this data to precisely control critical functions like fuel injection timing, turbocharger operation, transmission shifts, and emissions systems.

How do I identify the specific PCM for my 6.0 Powerstroke?

To identify the correct PCM for your 6.0 Powerstroke, you typically need to check the part number located on a sticker on the module itself, usually found under the hood on the driver’s side firewall. The specific year, transmission type, and emissions calibration of your truck are crucial factors that determine the correct PCM specifications and part number.

Are there different versions or specifications of the 6.0 Powerstroke PCM across model years?

Yes, there are indeed different versions of the 6.0 Powerstroke PCM, particularly between early (2003-2004) and late (2005-2007) model years due to updates in hardware and software. These variations often reflect changes in engine components, emissions requirements, and transmission control strategies, meaning PCMs are generally not interchangeable without reprogramming.

What are the key internal specifications of a 6.0 Powerstroke PCM that are relevant to performance?

While detailed processor specifications are proprietary, the key aspect relevant to performance is the PCM’s ability to be “flash tuned.” This means its internal programming (calibration) can be rewritten to modify parameters for increased horsepower, torque, fuel efficiency, and improved drivability, rather than its raw processing power.

Can the 6.0 Powerstroke PCM be tuned or reprogrammed for performance enhancements?

Absolutely, the 6.0 Powerstroke PCM is highly tunable, allowing for significant performance enhancements through custom programming. Tuning can optimize fuel delivery, injection timing, boost pressure, and transmission shift points, leading to substantial gains in horsepower, torque, and even improved fuel economy depending on the tune’s focus.

What are common symptoms of a failing 6.0 Powerstroke PCM and how can it be diagnosed?

Common symptoms of a failing 6.0 Powerstroke PCM include erratic engine behavior, misfires, stalling, no-start conditions, or various illuminated check engine light codes that don’t correspond to actual sensor failures. Diagnosis typically involves using a specialized scan tool to check for specific PCM-related diagnostic trouble codes and performing voltage checks on critical circuits.