Torque Wrenches for 7.3 Powerstroke Repairs: Precision Torque Every Time

Featured image for this comprehensive guide about Torque wrenches for 7.3 Powerstroke repairs

Image source: cdn1.byjus.com

The 7.3 Powerstroke engine isn’t just a motor; it’s a legend. Known for its brute strength, unparalleled reliability, and the distinctive rumble that announces its presence, this diesel powerhouse has earned its place in the hearts of truck enthusiasts and heavy-duty workers alike. Whether you’re towing heavy loads, navigating rugged terrain, or simply cruising down the highway, the 7.3 Powerstroke delivers performance that stands the test of time. But like any high-performance machine, maintaining its legendary status requires meticulous attention to detail, especially when it comes to repairs and rebuilds. This is where the unsung hero of your toolbox steps in: the torque wrench.

Far more than just a fancy ratchet, a torque wrench is a precision instrument. It ensures that every bolt, nut, and fastener on your 7.3 Powerstroke is tightened to the manufacturer’s exact specifications. Ignoring these critical specifications can lead to a cascade of problems, from leaking gaskets and compromised seals to catastrophic engine failure. For an engine as robust and demanding as the 7.3, guesswork simply isn’t an option. Investing in and properly utilizing torque wrenches for 7.3 Powerstroke repairs is not just good practice; it’s essential for preserving the integrity and longevity of your beloved diesel.

In this comprehensive guide, we’ll delve deep into why precision torque is paramount for your 7.3 Powerstroke, explore the different types of torque wrenches available, provide crucial torque specifications for common repairs, and offer actionable tips on how to choose, use, and maintain this indispensable tool. Get ready to elevate your mechanical skills and ensure your 7.3 Powerstroke continues to run strong for hundreds of thousands more miles.

Quick Answers to Common Questions

Why are torque wrenches essential for 7.3 Powerstroke repairs?

Using the right torque is absolutely critical to prevent stripped threads, gasket leaks, or even catastrophic failure on your 7.3 Powerstroke. Precision torque ensures every component is tightened exactly as the manufacturer intended, guaranteeing reliability.

What type of torque wrench is best for most 7.3 Powerstroke jobs?

A high-quality click-type torque wrench with a 1/2-inch drive and a range of 50-250 ft-lbs will handle most major 7.3 Powerstroke repairs. For smaller, more delicate components, a 3/8-inch drive wrench might also be necessary to get accurate readings.

Do I really need to torque every bolt when working on my 7.3?

While not every single fastener requires critical torque, vital components like injectors, glow plugs, cylinder head bolts, and turbo mounts certainly do. Always consult your service manual for specific 7.3 Powerstroke torque specs; guessing is never a good idea.

How often should I check or calibrate my torque wrenches for 7.3 Powerstroke repairs?

For professional use or frequent repairs, it’s recommended to have your torque wrenches calibrated annually or after any significant drops. For occasional DIYers, storing them properly (at their lowest setting) and ensuring they haven’t been abused will help maintain accuracy for your 7.3 Powerstroke.

Where can I find the correct torque specifications for my specific 7.3 Powerstroke?

Your official Ford/International 7.3 Powerstroke service manual is your ultimate authority for accurate torque specifications. Reputable repair manuals (like Haynes or Chilton) or reliable online resources for the 7.3 Powerstroke can also provide these crucial numbers.

📋 Table of Contents

- Why Precision Torque is Non-Negotiable for Your 7.3 Powerstroke

- Types of Torque Wrenches: Which One for Your 7.3?

- Essential Torque Specifications for Common 7.3 Powerstroke Repairs

- Choosing the Right Torque Wrench for Your 7.3 Powerstroke Toolkit

- Best Practices for Using and Maintaining Your Torque Wrench

- Advanced Tips and Common Mistakes to Avoid

- Conclusion

Why Precision Torque is Non-Negotiable for Your 7.3 Powerstroke

The 7.3 Powerstroke is a marvel of engineering, but its performance and durability are intrinsically linked to the precise assembly of its components. Every bolt plays a critical role, and the force applied to tighten it directly impacts the engine’s function and lifespan. Understanding this relationship is the first step in appreciating the value of torque wrenches for 7.3 Powerstroke repairs.

Learn more about Torque wrenches for 7.3 Powerstroke repairs – Torque Wrenches for 7.3 Powerstroke Repairs: Precision Torque Every Time

Image source: gfwdsupply.com

The Mighty 7.3 Powerstroke: A Legacy of Power

Introduced in 1994, the 7.3L Powerstroke V8 diesel engine became the backbone of Ford’s heavy-duty truck lineup. Its direct-injected, turbocharged design delivered impressive horsepower and torque figures for its era, quickly building a reputation for reliability and durability. It’s not uncommon to find 7.3 Powerstrokes with well over 300,000 or even 500,000 miles on the odometer, a testament to their robust construction. However, this longevity is only achievable when components are assembled and maintained to exacting standards. The tremendous forces generated within a diesel engine, combined with constant thermal cycles, place immense stress on every fastener. Without proper torque, these fasteners can fail, leading to significant and costly damage.

| Wrench Type & Drive Size | Typical Torque Range (ft-lbs) | Key 7.3 Powerstroke Applications | Accuracy & Key Features |

|---|---|---|---|

| Click Torque Wrench (1/2″ Drive) | 25 – 250 ft-lbs | Injector Hold-downs, Flywheel Bolts, Main Cap Bolts, Turbo Pedestal, Head Bolts (non-TTY). | ±3-4% accuracy. Audible/tactile “click” when set torque is reached. Durable and widely used. |

| Click Torque Wrench (3/8″ Drive) | 10 – 100 ft-lbs | Valve Cover Bolts, Sensor Bolts (EBP, ICP), Fuel Line Fittings, Smaller Component Brackets. | ±3-4% accuracy. Ideal for lower torque specs and confined spaces. |

| Digital Torque Wrench (1/2″ Drive) | 15 – 250 ft-lbs | Any critical fastener where high precision is paramount (e.g., Injector Cups, specific sensor mounts). | ±1-2% accuracy. LCD display, audible/visual alerts, peak/track mode, some offer angle measurement. |

| Beam Torque Wrench (1/2″ Drive) | 0 – 150 ft-lbs | Less critical fasteners, checking existing torque, wheel lug nuts. Not recommended for precise engine internals. | Visual scale, no calibration needed, simple and reliable, but prone to reading errors. |

| Digital Torque Adapter (1/2″ Drive) | 5 – 200 ft-lbs | Versatile for various fasteners; converts any standard ratchet into a digital torque tool. Useful in tight spots. | ±1-2% accuracy. Backlit LCD, audible alert, multiple unit settings. Cost-effective digital solution. |

The Dangers of Under-Torque and Over-Torque

Incorrect torque application is a common pitfall in engine repair, and both under-torquing and over-torquing carry severe risks:

- Under-Torque: When a fastener is not tightened enough, it lacks the clamping force required to hold components securely. This can lead to:

- Leaks: Gaskets (like head gaskets, valve cover gaskets, oil pan gaskets) won’t seal properly, causing oil, coolant, or fuel leaks.

- Vibration and Loosening: Parts can vibrate loose, leading to catastrophic failure (e.g., turbo mounting bolts, injector hold-down bolts).

- Reduced Performance: Air leaks in the intake or exhaust system can impact turbo spool and engine efficiency.

- Premature Wear: Components that are not properly secured can experience excessive movement and wear.

- Over-Torque: Tightening a fastener beyond its specified torque can be even more destructive:

- Stripped Threads: The threads in the block, head, or component can be damaged, requiring expensive repairs or replacement.

- Stretched or Broken Bolts: Bolts have an elasticity limit. Exceeding it permanently stretches the bolt, reducing its clamping force and potentially leading to breakage under load.

- Component Distortion: Over-torquing can warp or crack delicate components (e.g., valve covers, intake manifolds, even cylinder heads).

- Gasket Damage: Excessive compression can squeeze out or crush gaskets, leading to leaks, paradoxically similar to under-torquing.

Ensuring Longevity and Reliability

Using precision torque ensures that every component is held with the correct clamping force, distributing stress evenly and preventing relative movement between parts. This maximizes gasket sealing, maintains structural integrity, and ultimately extends the life of your 7.3 Powerstroke. It prevents costly re-dos, saves time, and gives you peace of mind that your repairs will last.

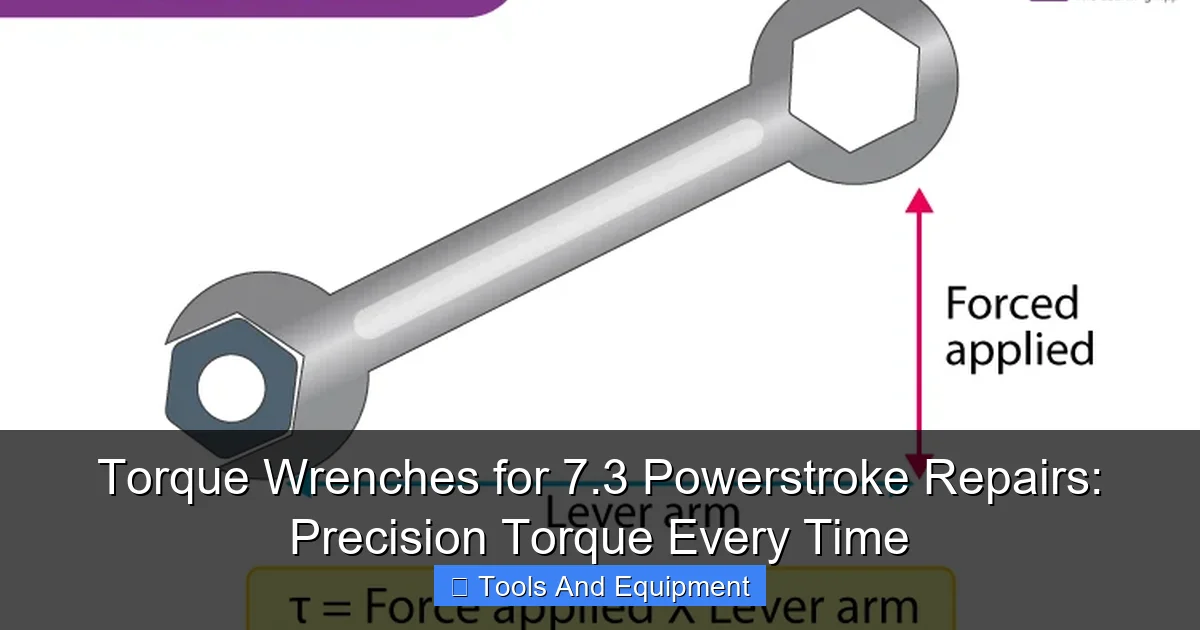

Types of Torque Wrenches: Which One for Your 7.3?

Choosing the right torque wrench is crucial for effective 7.3 Powerstroke repairs. Each type has its advantages and disadvantages, making some better suited for specific tasks than others.

Learn more about Torque wrenches for 7.3 Powerstroke repairs – Torque Wrenches for 7.3 Powerstroke Repairs: Precision Torque Every Time

Image source: image2.slideserve.com

Click-Type Torque Wrenches

The most common and widely recognized type, click-type torque wrenches use a spring-loaded mechanism that “clicks” and releases slightly when the preset torque value is reached. This provides an audible and tactile signal, preventing over-tightening.

- Pros:

- Easy to use and understand.

- Audible and tactile feedback reduces the chance of missing the target torque.

- Generally durable and reliable.

- Good for most common 7.3 Powerstroke torque specs.

- Cons:

- Accuracy can degrade over time without proper storage (always reset to zero or lowest setting).

- Can be less accurate at the very low or very high ends of their range.

- Requires re-calibration periodically.

Digital Torque Wrenches

Digital torque wrenches feature an electronic sensor and a digital display that shows the torque being applied in real-time. Many also offer audible and visual alerts (LEDs, buzzers) when the target torque is reached. Some advanced models can store readings and even provide angle measurements.

- Pros:

- Highly accurate across their full range.

- Easy to read display eliminates guesswork.

- Often have multiple units of measurement (ft-lb, in-lb, Nm).

- Some include angle measurement for Torque-to-Yield (TTY) bolts.

- Can offer peak hold and tracking modes.

- Cons:

- More expensive than click-type.

- Requires batteries.

- More delicate, susceptible to damage from drops.

Beam Torque Wrenches

The simplest and often most robust type, beam torque wrenches consist of a main beam with a scale and a secondary indicator beam. As torque is applied, the main beam flexes, and the indicator points to the torque value on the scale. There’s no “click” or electronic signal; you simply read the needle.

- Pros:

- Extremely durable with no internal mechanisms to wear out.

- Highly accurate, especially if properly sighted.

- No calibration required (inherently accurate).

- Least expensive option.

- Cons:

- Requires direct visual line of sight to read.

- Can be difficult to use in confined spaces.

- No tactile or audible feedback; easy to over-torque if not careful.

- Not ideal for production work or quick torquing.

Torque-to-Yield (TTY) Fasteners and Angle Gauges

Many modern engines, including some applications on the 7.3 Powerstroke (especially in high-stress areas), use Torque-to-Yield (TTY) bolts. These bolts are designed to be stretched into their elastic range, providing a very consistent clamping force. Their tightening procedure involves two stages:

- Initial torque to a specific value (e.g., 60 ft-lb).

- Followed by an additional turn measured in degrees (e.g., 90 degrees, 45 degrees).

For the second stage, a torque angle gauge is essential. Some digital torque wrenches integrate this function, but a standalone angle gauge is an inexpensive and vital tool if you’re dealing with TTY fasteners on your 7.3 Powerstroke engine, such as cylinder head bolts.

Essential Torque Specifications for Common 7.3 Powerstroke Repairs

Knowing the type of torque wrench to use is only half the battle; knowing the correct torque specifications is equally vital. Always refer to a factory service manual or a reputable repair guide for the most accurate and up-to-date specs for your specific year and model. Here’s a table of common 7.3 Powerstroke torque specifications, but remember, these are for general reference and can vary.

Common 7.3 Powerstroke Torque Specifications

Note: Always consult your specific model year’s factory service manual for precise torque values. Some fasteners may require a specific tightening sequence or lubrication.

| Component | Fastener | Torque Specification (Approximate) | Notes |

|---|---|---|---|

| Cylinder Head Bolts | Main Head Bolts | See TTY Procedure | Typically Torque-to-Yield (TTY). Requires specific sequence and angle turns. Consult manual precisely. |

| Injector Hold-Down Bolts | Injector Retainer Bolts | 24 ft-lbs (33 Nm) | Crucial for proper injector seating and sealing. |

| Valve Cover Bolts | Valve Cover Bolts | 96 in-lbs (8 ft-lbs or 11 Nm) | Easy to over-tighten, which can crack covers or deform gaskets. |

| Turbocharger Pedestal Bolts | Mounting Bolts | 30 ft-lbs (41 Nm) | Ensures proper turbo alignment and prevents exhaust leaks. |

| Up-Pipe Collector Bolts | Exhaust Bolts | 22 ft-lbs (30 Nm) | Prone to loosening, check periodically. |

| Oil Pan Bolts | Oil Pan Bolts | 18 ft-lbs (24 Nm) | Tighten in a specific sequence to prevent leaks. |

| Oil Filter Housing Bolts | Housing Bolts | 18 ft-lbs (24 Nm) | |

| Fuel Filter Housing Bolts | Housing Bolts | 18 ft-lbs (24 Nm) | |

| Glow Plug | Glow Plug | 14 ft-lbs (19 Nm) | Do NOT overtighten, can damage threads in cylinder head. |

| Water Pump Bolts | Mounting Bolts | 18 ft-lbs (24 Nm) | |

| Fan Clutch Bolts | Mounting Bolts | 25 ft-lbs (34 Nm) | |

| Power Steering Pump Bolts | Mounting Bolts | 18 ft-lbs (24 Nm) | |

| Crankshaft Position Sensor (CPS) | CPS Bolt | 18 ft-lbs (24 Nm) | Critical for engine timing. |

Head Gaskets and Cylinder Head Bolts

Perhaps the most critical torque application on the 7.3 Powerstroke is the cylinder head bolts. These are almost always Torque-to-Yield (TTY) fasteners and require a multi-stage tightening procedure involving both torque values and specific angle turns. Incorrectly torquing these can lead to head gasket failure, coolant leaks, and overheating. This is one area where a quality digital torque wrench with angle measurement or a standalone angle gauge is absolutely indispensable.

Injector Hold-Down Bolts

Properly torquing injector hold-down bolts ensures that your injectors are seated correctly and don’t leak compression or fuel. Under-torquing can lead to leaks, while over-torquing can damage the injector body or cylinder head bore. Precision here is key for engine performance and fuel efficiency.

Turbocharger Installation

When installing or reinstalling your turbocharger, all mounting bolts and up-pipe connections need to be torqued correctly. Loose connections can cause exhaust leaks, reduce boost pressure, and increase EGTs. Over-torquing can warp flanges or damage threads. Using torque wrenches for 7.3 Powerstroke repairs involving the turbo ensures optimal boost and prevents costly issues.

Oil Pan and Valve Cover Bolts

While seemingly less critical than internal engine components, oil pan and valve cover bolts still require correct torque. Under-torquing leads to messy leaks, while over-torquing can warp the covers, damage the gaskets, or strip the threads in the aluminum components. These often have lower torque values, requiring a smaller, accurate torque wrench, possibly in inch-pounds.

Choosing the Right Torque Wrench for Your 7.3 Powerstroke Toolkit

Selecting the ideal torque wrench(es) involves considering several factors to ensure you have the right tool for the job. Remember, your 7.3 Powerstroke needs tools that can handle both delicate and heavy-duty tasks.

Torque Range Considerations

Your 7.3 Powerstroke has fasteners with a wide range of torque specifications, from low inch-pounds (e.g., valve cover bolts) to high foot-pounds (e.g., crank pulley bolts, cylinder head bolts). No single torque wrench can accurately cover this entire range. You’ll likely need at least two:

- Small Range (1/4″ or 3/8″ drive): For lower torque values, typically 20-250 in-lbs (approx. 2-20 ft-lbs). Ideal for valve covers, sensor bolts, electrical connections.

- Medium/Large Range (1/2″ drive): For higher torque values, typically 20-250 ft-lbs. This will be your workhorse for most engine components like injector hold-downs, turbo bolts, and many suspension components.

For specialized very high torque applications, a 3/4″ drive torque wrench might be necessary, but this is less common for typical 7.3 Powerstroke engine maintenance.

Accuracy and Calibration

A torque wrench is only as good as its accuracy. Look for wrenches that meet or exceed ASME B107.14 standards. Most reputable brands offer accuracy within +/- 3-4% clockwise. Digital wrenches often boast higher accuracy, sometimes +/- 1%. Regardless of type, ensure your wrench is regularly calibrated. Some manufacturers offer calibration services, or you can find independent calibration labs. A wrench that’s out of calibration is no better than guessing.

Drive Size

Match the drive size (1/4″, 3/8″, 1/2″, 3/4″) to the sockets and fasteners you’ll be working with. As mentioned, 3/8″ and 1/2″ drive wrenches will be the most versatile for your 7.3 Powerstroke. Having adapters can be useful, but avoid using too many, as they can sometimes affect accuracy or create leverage issues.

Material and Durability

Look for torque wrenches made from high-quality steel or chrome vanadium. They should feel solid and well-constructed. The handle should provide a comfortable and secure grip. Given the demanding environment of an engine repair shop or home garage, durability is key. Read reviews and consider brands known for their robust tools.

Brand Reputation and Warranty

Don’t skimp on quality when it comes to precision tools. Brands like Snap-on, Proto, CDI (a Snap-on company), Craftsman, Tekton, and GearWrench are generally well-regarded. A good warranty indicates a manufacturer’s confidence in their product. A lifetime warranty or a multi-year warranty on accuracy is a good sign.

Best Practices for Using and Maintaining Your Torque Wrench

Even the best torque wrench is useless if not used and maintained correctly. Adhering to these best practices will ensure accurate results and extend the life of your tool, critical for any successful 7.3 Powerstroke repair.

Pre-Use Checks and Calibration

- Read the Manual: Every torque wrench has specific instructions. Familiarize yourself with them.

- Inspect for Damage: Before each use, check for any visible damage, cracks, or loose parts. Ensure the adjustment mechanism moves smoothly.

- Reset Click-Type Wrenches: For click-type wrenches, always cycle the wrench through its full range a few times to redistribute internal lubrication, especially if it hasn’t been used in a while.

- Set to Zero (or Lowest Setting): After use, always return a click-type torque wrench to its lowest setting (or zero, if applicable). This relieves tension on the internal spring, preserving its calibration and accuracy over time. Never store a click-type wrench under tension.

- Check Calibration Dates: If your wrench has a calibration sticker, note the date. Professional calibration is recommended annually or every 2,500-5,000 cycles, whichever comes first.

Proper Technique for Accurate Torque

- Clean Threads: Ensure bolt threads and mating surfaces are clean and free of rust, dirt, or old thread locker. Debris can cause inaccurate torque readings.

- Lubrication: Always follow the manufacturer’s recommendations regarding thread lubrication. Some torque specs are for dry threads, others for lubricated threads (often indicated by “wet torque”). Applying lubricant when not specified will result in over-torquing, even if the wrench clicks at the right setting.

- Smooth and Steady Pull: Apply force smoothly and steadily to the wrench handle, without jerking or sudden movements. This prevents kinetic energy from contributing to an inaccurate “click” or reading.

- Hold Correctly: Always grip the torque wrench by the designated handle, usually near the end of the handle. Do not hold it in the middle or apply force to the head, as this can change the effective lever arm and skew the reading.

- Multiple Passes: For critical fasteners (like head bolts or manifold bolts), it’s often best to torque in stages (e.g., 50%, 75%, then 100% of the final torque) and in a specific sequence to ensure even clamping force.

- Listen and Feel: For click-type wrenches, ensure you hear and feel a distinct click. Don’t continue pulling after the click. For beam or digital wrenches, stop pulling as soon as the target value is reached.

Post-Use Care and Storage

- Clean Your Wrench: Wipe down the torque wrench to remove any grease, dirt, or chemicals.

- Protect from Drops: Torque wrenches are precision instruments. A single drop can throw off their calibration. Store them securely in their protective case or on a dedicated rack.

- Environment: Store in a dry, temperate environment. Extreme heat or cold can affect internal components and lubricants.

The Importance of Re-Calibration

Even with perfect storage and use, torque wrenches drift out of calibration over time. As mentioned, annual or cycle-based re-calibration is highly recommended, especially for professional mechanics or frequent users. For critical engine components on your 7.3 Powerstroke, such as during a complete rebuild or head gasket job, having a recently calibrated wrench provides invaluable assurance. Think of calibration as a regular check-up for your most vital precision tool.

Advanced Tips and Common Mistakes to Avoid

Beyond the basics, a few advanced insights can further improve your torque wrench usage and help you sidestep common pitfalls when working on your 7.3 Powerstroke diesel engine.

Don’t Use a Torque Wrench as a Breaker Bar

This is a cardinal rule. A torque wrench, especially a click-type or digital one, is designed to apply a specific amount of rotational force, not to loosen stuck bolts. Using it as a breaker bar to loosen tight fasteners can severely damage the internal calibration mechanism, rendering it inaccurate. Always use a dedicated breaker bar or a standard ratchet for loosening.

Cleaning Fasteners and Threads

We touched on this earlier, but it bears repeating: the condition of the threads and mating surfaces drastically affects torque accuracy. Rust, dirt, old thread locker, or even slight burrs can create friction, causing the wrench to click or read the target torque before the actual clamping force is achieved. Always clean threads with a wire brush or tap/die, and ensure mating surfaces are spotless. For critical applications, consider chasing threads with a tap to ensure they are perfectly clean and free-running.

Lubrication vs. Dry Torque

This is a critical distinction. Torque specifications are derived assuming either dry threads or lubricated threads. If a spec is for dry threads and you apply oil or anti-seize, you will significantly over-torque the fastener, even if your wrench clicks at the correct setting. The lubricant reduces friction, meaning more of the applied force translates to clamping force, rather than overcoming friction. Always follow the manual’s recommendation on whether to lubricate fasteners or install them dry. When lubrication is specified, use the exact type recommended (e.g., engine oil, specific thread lubricant, or anti-seize).

Torque Sequence Matters

For components with multiple fasteners (like cylinder heads, valve covers, intake manifolds, or exhaust manifolds), there is almost always a specific tightening sequence. This sequence ensures even clamping pressure across the entire component, preventing warping, leaks, and uneven stress distribution. Always consult your service manual for the correct sequence, which often involves working from the center outwards in a spiral pattern.

When to Replace Fasteners

Some fasteners, particularly Torque-to-Yield (TTY) bolts, are designed for single use. Once stretched beyond their elastic limit during the initial tightening, they lose their ability to provide consistent clamping force if reused. Cylinder head bolts on the 7.3 Powerstroke are often TTY and must be replaced during any head gasket job. Other fasteners, if showing signs of wear, stretching, or damaged threads, should also be replaced to ensure the integrity of your repair. Never reuse a compromised fastener on your 7.3 Powerstroke engine.

Conclusion

The 7.3 Powerstroke is a testament to robust engineering, but its legendary status is maintained through diligent and precise workmanship. When performing any repair, big or small, the proper application of torque is not just a recommendation—it’s a fundamental requirement for the engine’s health, reliability, and longevity. Guessing with a standard wrench is a gamble you simply cannot afford to take with such a critical and complex piece of machinery.

Investing in quality torque wrenches for 7.3 Powerstroke repairs, understanding their different types, meticulously following torque specifications, and adhering to best practices for their use and maintenance will pay dividends in the long run. It prevents costly failures, ensures optimal performance, and gives you the confidence that your hard work will stand up to the rigorous demands of your diesel truck. Treat your torque wrench as the precision instrument it is, and your 7.3 Powerstroke will reward you with many more miles of powerful, reliable service. Precision torque every time means peace of mind, and for a 7.3 Powerstroke owner, that’s priceless.

🎥 Related Video: 4 Tools Every Technician Needs

📺 Royalty Auto Service

You gotta have these! #mechanic #automotive #autorepair #tools #car #carrepair.

Frequently Asked Questions

Why is using a torque wrench essential for 7.3 Powerstroke repairs?

Using a torque wrench is critical for the 7.3 Powerstroke to ensure proper fastener tension, which prevents over-tightening leading to stripped threads or broken bolts, and under-tightening causing leaks or component failure. It ensures that gaskets seal correctly and that critical engine components are held together with the manufacturer’s specified force for optimal performance and longevity.

What type of torque wrench is best suited for various 7.3 Powerstroke maintenance tasks?

A click-type torque wrench is a popular choice for its audible and tactile feedback, making it easy to use for many 7.3 Powerstroke tasks. For ultimate precision on critical components, a digital torque wrench offers high accuracy and often features peak hold and angle measurements. Having a combination of a larger 1/2-inch drive click wrench and a smaller 3/8-inch drive for lower torque settings is often ideal.

What torque range should I look for when purchasing a torque wrench specifically for 7.3 Powerstroke engine work?

For comprehensive 7.3 Powerstroke engine work, you’ll likely need a torque wrench with a wide range to cover various specifications. A good starting point would be a 1/2-inch drive wrench capable of 50-250 ft-lbs, and a 3/8-inch drive wrench for the lower 10-100 ft-lbs range. Always consult your specific 7.3 Powerstroke service manual for the exact torque specifications of the repairs you plan to undertake.

How often should a torque wrench be calibrated, especially when used for a 7.3 Powerstroke?

For consistent accuracy in 7.3 Powerstroke repairs, it’s recommended to calibrate your torque wrench annually or after approximately 2,500-5,000 cycles of use. If the wrench has been dropped, subjected to extreme temperatures, or stored improperly (e.g., left under tension), it should be recalibrated immediately to ensure its readings remain precise.

Are there any specific 7.3 Powerstroke repairs where a torque wrench is absolutely mandatory?

Absolutely, several 7.3 Powerstroke repairs critically depend on precise torque. These include cylinder head bolt tightening, injector hold-down bolts, glow plug installation, main and rod bearing cap bolts, and many fasteners related to the fuel and exhaust systems. Incorrect torque on these components can lead to catastrophic engine damage, leaks, or performance issues.

Can I get by with just one torque wrench for all my 7.3 Powerstroke repairs?

While a single, high-quality torque wrench might cover a significant portion of 7.3 Powerstroke repair needs, it’s often more practical and accurate to have at least two. Different fasteners on the engine have vastly different torque specifications, ranging from very low (e.g., electrical connections) to very high (e.g., cylinder head bolts). Using a wrench near the bottom or top of its range can reduce accuracy, so a 3/8-inch drive for lower torques and a 1/2-inch drive for higher torques is generally recommended for the 7.3 Powerstroke.