Torque Specifications for 7.3 Powerstroke Cylinder Head: A Complete Guide

Featured image for this comprehensive guide about Torque specifications for 7.3 Powerstroke cylinder head

Image source: figures.academia-assets.com

The legendary 7.3L Powerstroke diesel engine is a testament to durability and raw power, an icon beloved by truck enthusiasts, heavy haulers, and everyday drivers alike. Known for its robust design and impressive longevity, this engine, found in countless Ford F-Series trucks and E-Series vans, requires meticulous attention to detail during any repair or rebuild to maintain its legendary status. Among the most critical procedures, none is more paramount than correctly torquing the cylinder heads.

Getting the torque specifications for 7.3 Powerstroke cylinder head right isn’t just a recommendation; it’s a fundamental requirement for the engine’s integrity and longevity. Incorrect torque can lead to a cascade of catastrophic failures, including blown head gaskets, warped cylinder heads, and costly engine damage. Whether you’re a seasoned diesel mechanic or an enthusiastic DIYer embarking on a head gasket replacement or a full engine overhaul, understanding and meticulously following the precise 7.3 Powerstroke cylinder head torque procedure is non-negotiable. This comprehensive guide will equip you with all the essential information, from preparation to the exact specifications for both OEM bolts and aftermarket ARP studs, ensuring your 7.3L runs strong for miles to come.

Quick Answers to Common Questions

Why are the torque specifications for 7.3 Powerstroke cylinder head so critical?

They ensure even clamping force across the head gasket, preventing leaks and maintaining optimal engine compression. Following them precisely is key to avoiding costly repairs down the road for your 7.3 Powerstroke cylinder head.

Do I need to replace my cylinder head bolts when dealing with 7.3 Powerstroke cylinder head torque?

Absolutely! The 7.3 Powerstroke uses Torque-To-Yield (TTY) bolts, which are designed to stretch during initial torquing. Reusing them can lead to insufficient clamping force and potential failure of your 7.3 Powerstroke cylinder head gasket.

Is there a specific torque sequence for 7.3 Powerstroke cylinder head bolts?

Yes, definitely! Following the correct spiral or cross-pattern sequence is crucial to distribute clamping force evenly and prevent head warpage, ensuring the longevity of your 7.3 Powerstroke cylinder head.

What’s a common mistake people make regarding 7.3 Powerstroke cylinder head torque?

A common error is not performing the final angle torque steps correctly, or omitting the final “retorque” after initial cycles. Missing these steps can compromise the seal and the integrity of your 7.3 Powerstroke cylinder head.

What happens if I don’t follow the 7.3 Powerstroke cylinder head torque specifications accurately?

Incorrect torque can lead to head gasket leaks, coolant or oil mixing, and even cylinder head warpage, costing you significant time and money. It’s vital for the health of your 7.3 Powerstroke cylinder head.

📋 Table of Contents

- Why Precision Matters: The Critical Role of 7.3 Powerstroke Cylinder Head Torque

- Essential Tools and Preparations for Cylinder Head Installation

- OEM Torque Specifications for 7.3 Powerstroke Cylinder Head Bolts

- Upgrading to ARP Head Studs: Different Specs, Superior Performance

- The Crucial 7.3 Powerstroke Cylinder Head Torque Sequence

- Common Mistakes and Best Practices for 7.3 Powerstroke Cylinder Head Torque

- Conclusion

Why Precision Matters: The Critical Role of 7.3 Powerstroke Cylinder Head Torque

The cylinder head on your 7.3 Powerstroke is a vital component that seals the combustion chamber and contains the valves, injectors, and glow plugs. It’s subjected to immense pressures and extreme temperatures during engine operation. The connection between the cylinder head and the engine block, maintained by numerous head bolts or studs, must be absolutely perfect to prevent combustion gases, coolant, and oil from leaking. This is where precise torque specifications for 7.3 Powerstroke cylinder head become the backbone of engine reliability.

Learn more about Torque specifications for 7.3 Powerstroke cylinder head – Torque Specifications for 7.3 Powerstroke Cylinder Head: A Complete Guide

Image source: dieselpro.com

Understanding the Forces at Play

During operation, the 7.3 Powerstroke’s combustion chambers experience pressures that can exceed 2,000 psi, coupled with temperatures soaring past 1,000°F. The cylinder head gasket is designed to withstand these conditions, but it relies entirely on the clamping force provided by the head bolts. When bolts are tightened to the correct 7.3 Powerstroke head bolt torque, they stretch slightly, acting like springs to maintain a consistent clamping force across the gasket surface. This even pressure ensures a perfect seal, containing the explosive power of each combustion cycle and preventing fluid leaks.

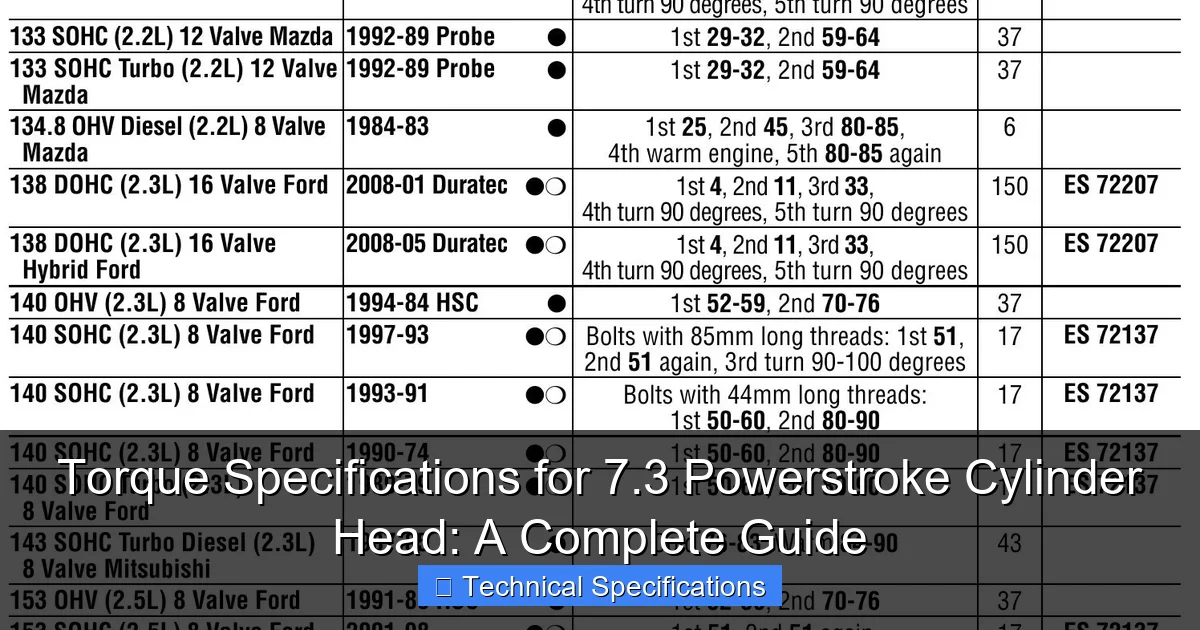

| Torque Stage / Bolt Type | Torque Value (ft-lbs) | Torque Value (N·m) | Notes / Remarks |

|---|---|---|---|

| Stage 1: Initial Torque (Factory Bolts) | 65 | 88 | Torque all cylinder head bolts in the specified sequence. |

| Stage 2: Final Torque (Factory Bolts) | 85 | 115 | Re-torque all bolts in sequence to final specification. |

| Re-Torque Requirement | N/A | N/A | No re-torque required after initial assembly for factory bolts. |

| Factory Bolt Condition | N/A | N/A | Stock bolts are generally reusable if not stretched. Inspect carefully. |

| Aftermarket Head Studs (e.g., ARP) | 210-220 | 285-298 | Always refer to the manufacturer’s specific instructions, including lubricant type and multi-stage process. |

Consequences of Incorrect Torque

Failing to adhere to the precise torque specifications for 7.3 Powerstroke cylinder head can lead to a host of expensive and frustrating problems:

- Blown Head Gaskets: The most common issue. Insufficient clamping force allows combustion gases to escape, rapidly destroying the gasket. This often results in coolant loss, white smoke from the exhaust, and engine overheating.

- Warped Cylinder Heads: Uneven torque can cause the cylinder head to distort under heat and pressure, leading to permanent damage that may require machining or replacement.

- Coolant and Oil Leaks: A compromised seal allows fluids to escape externally or internally, leading to contamination, fluid loss, and potential engine damage.

- Loss of Compression: Incomplete sealing of the combustion chamber reduces engine efficiency, power, and fuel economy.

- Stripped Threads or Broken Bolts: Over-torquing can damage the bolt threads in the block, requiring costly repairs, or even snap the head bolts themselves, leading to a much more difficult extraction process.

Given these severe repercussions, it’s clear that the exact 7.3 Powerstroke torque specs are not just guidelines but critical instructions for a successful, long-lasting engine repair.

Essential Tools and Preparations for Cylinder Head Installation

Before you even think about applying torque to your 7.3 Powerstroke cylinder head bolts, thorough preparation and the right tools are absolutely crucial. Rushing this stage is a common mistake that can easily lead to failure, regardless of how precisely you follow the torque values. A clean, properly inspected, and well-equipped environment sets the stage for success.

Learn more about Torque specifications for 7.3 Powerstroke cylinder head – Torque Specifications for 7.3 Powerstroke Cylinder Head: A Complete Guide

Image source: venturerider.org

The Right Torque Wrenches

Using a high-quality, properly calibrated torque wrench is non-negotiable. For the 7.3 Powerstroke cylinder head torque, you’ll need one capable of handling the specified foot-pound (ft-lb) and angle (degrees) values. There are a few types:

- Clicker Torque Wrenches: These are common and easy to use. Ensure yours is a reputable brand and, ideally, has been calibrated recently.

- Beam Torque Wrenches: More accurate and less prone to calibration drift, but require careful reading.

- Digital Torque Wrenches: Offer high accuracy and often include an angle-measurement function, which is incredibly useful for torque-to-yield (TTY) bolts.

For angle torque specifications, a dedicated angle gauge is essential if your torque wrench doesn’t have one built-in. Do not guess or eyeball angle measurements; precision here is just as important as the ft-lb setting for 7.3 Powerstroke head bolt torque.

Cleaning and Inspection

Every surface involved in the seal must be meticulously clean and free of debris:

- Engine Block Deck: Use a flat, fine abrasive pad or a gasket scraper (plastic preferred) to remove all old gasket material and carbon deposits. Ensure the surface is perfectly flat. Clean out any debris from the bolt holes with compressed air and a tap if necessary.

- Cylinder Head Surfaces: Clean both the bottom surface where the gasket seats and the bolt holes. Inspect for warpage; if the heads are not perfectly flat, they will need to be machined.

- Head Bolts/Studs: If reusing OEM bolts (not recommended for TTY), they must be thoroughly cleaned of oil and debris. Better yet, use new OEM TTY bolts or upgrade to ARP studs. For ARP studs, ensure the threads are clean.

Lubrication and Thread Preparation

Proper lubrication ensures that the applied torque translates directly into clamping force, rather than overcoming friction. This is critical for accurate 7.3 Powerstroke cylinder head torque.

- OEM Bolts: The original equipment manufacturer (OEM) procedure usually calls for lightly oiling the threads and the underside of the bolt heads with clean engine oil. This reduces friction and helps achieve the correct clamping force.

- ARP Head Studs: ARP provides specific moly lubricant for their studs. This lubricant is designed to provide extremely consistent friction, ensuring accurate torque readings. Do not use engine oil with ARP studs unless explicitly instructed by ARP for a specific application; their torque values are often based on their moly lube.

- Thread Sealant: Some head bolt holes on the 7.3 Powerstroke extend into water jackets. These require thread sealant (e.g., Loctite 567 or similar pipe thread sealant) to prevent coolant leaks. Consult your factory service manual for specific locations.

Never use anti-seize on head bolts or studs unless explicitly specified by the manufacturer, as it can significantly alter friction and lead to inaccurate torque readings and potential bolt failure. This is especially true for the sensitive 7.3 Powerstroke torque specs.

OEM Torque Specifications for 7.3 Powerstroke Cylinder Head Bolts

When using new OEM head bolts (which are typically Torque-to-Yield, or TTY, bolts), it’s imperative to follow a specific multi-step tightening procedure. TTY bolts are designed to be stretched to their yield point to provide optimal, consistent clamping force. This means they are single-use items; once tightened, they should not be reused. Reusing TTY bolts significantly increases the risk of head gasket failure because they’ve already stretched and cannot provide the same clamping force a second time.

The Standard 7.3 Powerstroke Head Bolt Torque Procedure (OEM TTY Bolts)

The following sequence and steps are critical for correctly securing the 7.3 Powerstroke cylinder head with OEM bolts. Always refer to a current factory service manual for the most up-to-date information, as specifications can occasionally be revised.

Note: These specifications are for NEW OEM Torque-to-Yield (TTY) bolts. Ensure bolt threads and underside of heads are lightly oiled with clean engine oil, and use thread sealant on any bolts entering coolant passages as specified in the service manual.

| Step | Procedure | Torque/Angle Specification |

|---|---|---|

| 1 (Initial Snug) | Snug all 18 cylinder head bolts in the specified sequence (see “The Crucial 7.3 Powerstroke Cylinder Head Torque Sequence” section below). | 20 ft-lb (27 Nm) |

| 2 (First Pass) | Tighten all 18 cylinder head bolts in the specified sequence. | 65 ft-lb (88 Nm) |

| 3 (Second Pass – Inner Bolts) | Tighten the 10 inner cylinder head bolts (bolts 1-10 in the sequence) in the specified sequence. | 85 ft-lb (115 Nm) |

| 4 (Angle Pass – Inner Bolts) | Tighten the 10 inner cylinder head bolts (bolts 1-10) an additional angle, in the specified sequence. This is where the TTY bolt stretches. | 90 degrees (1/4 turn) |

| 5 (Second Pass – Outer Bolts) | Tighten the 8 outer cylinder head bolts (bolts 11-18) in the specified sequence. | 85 ft-lb (115 Nm) |

| 6 (Angle Pass – Outer Bolts) | Tighten the 8 outer cylinder head bolts (bolts 11-18) an additional angle, in the specified sequence. This is where the TTY bolt stretches. | 90 degrees (1/4 turn) |

Always perform each step completely on all bolts in the correct sequence before moving to the next step. This multi-stage process, incorporating both torque and angle, is essential for achieving the correct and even clamping force for the 7.3 Powerstroke cylinder head.

Upgrading to ARP Head Studs: Different Specs, Superior Performance

For enthusiasts, performance builders, or anyone seeking maximum reliability, upgrading from OEM head bolts to ARP (Automotive Racing Products) head studs is a highly recommended modification for the 7.3 Powerstroke. ARP head studs offer significant advantages, particularly in applications with increased boost pressure, higher horsepower, or for engines undergoing frequent disassembly.

Why Choose ARP Head Studs?

ARP head studs are engineered for superior strength and durability compared to traditional TTY bolts. Here’s why they are often preferred for the 7.3 Powerstroke cylinder head:

- Increased Clamping Force: ARP studs are designed to withstand much higher tensile loads, providing a greater and more consistent clamping force on the cylinder head. This is crucial for preventing head gasket issues, especially in modified or high-performance engines.

- Reusability: Unlike TTY bolts, ARP studs are fully reusable. This saves money and time during future engine work.

- Easier Assembly: Studs allow the cylinder head to be lowered precisely onto the block, aligning the gasket and head more easily than trying to drop bolts into blind holes.

- Reduced Block Thread Wear: Since the studs are torqued by nuts, the threads in the engine block are not subjected to the twisting friction of torquing, preserving their integrity.

ARP Torque Specifications for 7.3 Powerstroke Cylinder Head

It is absolutely critical to understand that ARP head studs have different torque specifications for 7.3 Powerstroke cylinder head than OEM bolts. The values are typically higher and the procedure is usually different. Always use the specific instructions provided by ARP with your stud kit. The most common kits for the 7.3 Powerstroke are the ARP 250-4202 or ARP 250-4201, both requiring specific torque procedures.

Note: These specifications are for ARP head studs with ARP Ultra-Torque Fastener Assembly Lubricant (moly lube). If using clean engine oil, the torque values will be different and typically lower. Always use the lubricant specified by ARP for their torque figures.

| Step | Procedure (using ARP Moly Lube) | Torque Specification |

|---|---|---|

| 1 (Initial Snug) | Install all studs finger-tight into the block. Place cylinder head over studs. Apply ARP Moly Lube to the stud threads that will receive the nuts and to both sides of the washers. Install washers and nuts. Snug all nuts in the specified sequence (see “The Crucial 7.3 Powerstroke Cylinder Head Torque Sequence”). | 30 ft-lb (41 Nm) |

| 2 (First Pass) | Tighten all 18 cylinder head stud nuts in the specified sequence. | 60 ft-lb (81 Nm) |

| 3 (Final Pass) | Tighten all 18 cylinder head stud nuts in the specified sequence to their final torque. | 125 ft-lb (169 Nm) |

Again, this is a multi-step process, and each step must be completed across all nuts in the correct sequence before moving to the next. The increased torque values for ARP studs, combined with their superior material, provide the robust clamping force necessary for high-performance 7.3 Powerstroke engine rebuilds.

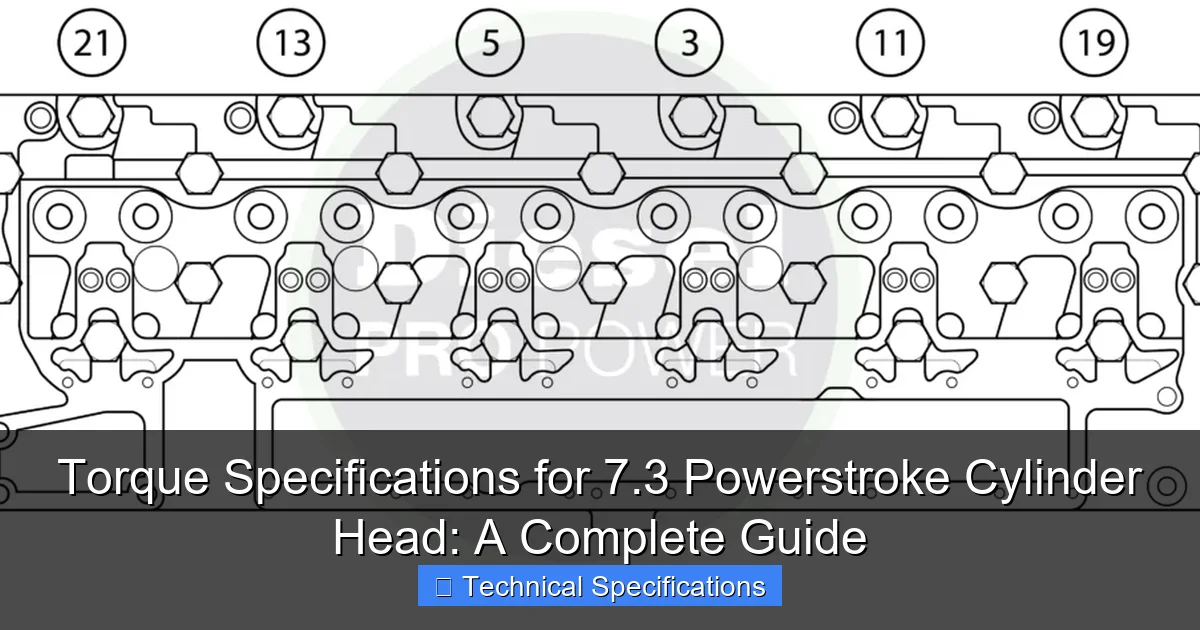

The Crucial 7.3 Powerstroke Cylinder Head Torque Sequence

Regardless of whether you are using OEM bolts or ARP studs, following the correct tightening sequence is just as vital as applying the correct torque values. The sequence ensures that the clamping force is applied evenly across the cylinder head and gasket, preventing distortion and ensuring a uniform seal. Ignoring this sequence can lead to immediate or eventual head gasket failure, even if the torque values themselves are correct.

Understanding the Pattern

The 7.3 Powerstroke cylinder head torque sequence typically starts from the center of the head and works its way outwards in a spiral or crosshatch pattern. This method pushes any excess gasket material or air outwards, away from the critical sealing surfaces, and progressively loads the cylinder head evenly, preventing warping or uneven pressure distribution.

Step-by-Step Sequence Guide

The 7.3 Powerstroke cylinder head has 18 bolts/studs per head. The sequence is the same for both the left and right cylinder heads. Below is a representation of the standard tightening sequence. Imagine looking down at the cylinder head from the top of the engine:

Cylinder Head Torque Sequence (Driver’s Side Head, Left Bank)

(Front of Engine)

18 16 8 6 4 2 10 12 14

o o o o o o o o o

o o o o o o o o o

17 15 7 5 3 1 9 11 13

(Rear of Engine)

Cylinder Head Torque Sequence (Passenger’s Side Head, Right Bank)

(Front of Engine)

17 15 7 5 3 1 9 11 13

o o o o o o o o o

o o o o o o o o o

18 16 8 6 4 2 10 12 14

(Rear of Engine)

Detailed Sequence Steps:

- Start with bolt #1, which is typically the innermost bolt near the center of the cylinder head.

- Move to bolt #2, diagonally opposite or adjacent, following the specified pattern.

- Continue through all 18 bolts for each torque pass (e.g., initial snug, first pass, second pass, angle pass for OEM bolts; or initial snug, first pass, final pass for ARP studs).

- It is absolutely essential to complete an entire pass on all bolts/nuts in the correct sequence before moving to the next torque/angle specification. Do not complete all steps on one bolt before moving to the next bolt.

This sequential approach to applying 7.3 Powerstroke head bolt torque ensures a gradual and even compression of the head gasket, which is critical for preventing hot spots, coolant leaks, and ultimately, head gasket failure. Think of it as gently squeezing a sandwich from the inside out to ensure all layers settle perfectly.

Common Mistakes and Best Practices for 7.3 Powerstroke Cylinder Head Torque

Even with all the correct information, mistakes can happen. Being aware of common pitfalls and adhering to best practices can significantly improve your chances of a successful 7.3 Powerstroke cylinder head installation and a long-lasting engine. This is where attention to detail pays dividends for your beloved diesel.

Over-Torquing and Under-Torquing Pitfalls

- Under-Torquing: This is the most common cause of head gasket failure. Insufficient clamping force allows the gasket to leak, leading to blown head gaskets, coolant/oil contamination, and overheating.

- Over-Torquing: While less common for head gaskets, over-torquing can stretch bolts past their yield point (especially with TTY bolts), potentially breaking them or permanently damaging the threads in the engine block. It can also warp the cylinder head or block deck.

The goal is to hit the specified 7.3 Powerstroke torque specs precisely, not too little and not too much. This underscores the need for a good quality, calibrated torque wrench and an angle gauge.

The Importance of Fresh Gaskets and Clean Surfaces

- Always Use New Head Gaskets: Head gaskets are designed to crush and seal once. Reusing old head gaskets is an absolute gamble and almost guarantees failure. Invest in quality new gaskets for your 7.3 Powerstroke engine rebuild.

- Scrupulous Cleaning: We cannot stress this enough. Any speck of old gasket material, rust, dirt, or oil on the block deck or cylinder head mating surfaces will compromise the seal. Take your time to clean these surfaces to a mirror finish.

- Clean Bolt Holes: Ensure the bolt holes in the block are completely clean and dry (unless sealant is required). Any fluid or debris in a blind hole can create a hydraulic lock, giving false torque readings and potentially cracking the block.

Re-Torquing: When and Why?

For most modern engines using TTY bolts, including the 7.3 Powerstroke with OEM bolts, a re-torque after initial assembly and a heat cycle is generally not required or even recommended. TTY bolts are designed to maintain their clamping force once stretched. Attempting to re-torque them can actually overstretch and weaken them.

However, if you’ve installed ARP head studs, some mechanics and manufacturers recommend a re-torque after the engine has gone through a few heat cycles (e.g., run for an hour, allowed to cool completely). This allows the gasket to fully compress and settle. Check ARP’s specific instructions for your stud kit, as recommendations can vary. If re-torquing, back off the nuts one at a time (never all at once) and then re-torque to the final specification in the correct sequence.

Final Checks and Post-Installation Tips

- Fluid Levels: After installation, refill your coolant and engine oil.

- Leak Inspection: Before starting the engine, visually inspect for any signs of leaks.

- Initial Start-up: Start the engine and carefully monitor coolant temperature, oil pressure, and check for any unusual noises or leaks.

- Break-in: Avoid heavy loads or sustained high RPMs for the first few hundred miles to allow the new head gaskets and other components to properly seat and break in.

- Monitor: Keep a close eye on your coolant level and engine temperature for the first few weeks of operation.

By following these best practices, you significantly increase the chances of a trouble-free rebuild for your 7.3 Powerstroke cylinder head.

Conclusion

The 7.3 Powerstroke is an engineering marvel, a workhorse that has earned its reputation for reliability and power. But like any high-performance machine, its longevity hinges on meticulous maintenance and precise adherence to factory specifications, particularly when it comes to critical components like the cylinder heads. Understanding and flawlessly executing the torque specifications for 7.3 Powerstroke cylinder head is not merely a step in a repair process; it’s the foundation upon which the engine’s continued performance and durability rest.

Whether you opt for new OEM Torque-to-Yield bolts or upgrade to robust ARP head studs, the principles remain the same: proper preparation, the right tools, exact torque values, and, crucially, the correct tightening sequence. Overlooking any of these elements can transform a routine repair into a costly nightmare, leading to premature head gasket failure, engine overheating, and a significant dent in your wallet. By taking your time, performing thorough cleaning, utilizing a calibrated torque wrench, and following this comprehensive guide, you are ensuring the heart of your Ford F-Series or E-Series beats strong and true for hundreds of thousands more miles.

Your 7.3 Powerstroke deserves the best, and providing it with the precise 7.3 Powerstroke head bolt torque it needs is an investment in its future. Armed with this knowledge, you’re not just tightening bolts; you’re securing the legacy of one of the greatest diesel engines ever built. Drive confidently, knowing your cylinder heads are sealed with professional precision.

Frequently Asked Questions

Why are accurate torque specifications crucial for the 7.3 Powerstroke cylinder head?

Accurate torque specifications are absolutely vital because they ensure an even clamping force across the cylinder head gasket, preventing leaks and maintaining proper combustion chamber sealing. Incorrect torque can lead to head gasket failure, coolant or oil leaks, and even catastrophic engine damage to your 7.3 Powerstroke.

What are the specific torque specifications for the 7.3 Powerstroke cylinder head bolts?

The 7.3 Powerstroke cylinder head bolts are typically torqued using a multi-step sequence, often involving initial torque values followed by angle turns (torque-to-yield method). While precise values can vary slightly by year or bolt type (OEM vs. ARP), always consult your specific service manual or the bolt manufacturer’s instructions for the exact sequence for your 7.3 Powerstroke cylinder head.

Is there a specific tightening sequence for the 7.3 Powerstroke cylinder head bolts?

Yes, there is a critical tightening sequence for the 7.3 Powerstroke cylinder head bolts that must be followed precisely. This sequence ensures even pressure distribution across the head, preventing warpage and ensuring a proper seal. Typically, it involves working from the center bolts outwards in a specific pattern, but you should always refer to your service manual for the exact diagram.

Should I replace my 7.3 Powerstroke cylinder head bolts when reinstalling the heads?

It is highly recommended to replace the 7.3 Powerstroke cylinder head bolts with new ones, especially if they are the original Torque-to-Yield (TTY) bolts. TTY bolts are designed to stretch during their initial tightening and can lose their clamping force if reused, significantly increasing the risk of head gasket failure. Aftermarket options like ARP head studs are also a popular and reusable upgrade for the 7.3 Powerstroke.

What tools are essential for accurately torquing 7.3 Powerstroke cylinder head bolts?

To accurately torque your 7.3 Powerstroke cylinder head bolts, you will need a high-quality torque wrench (preferably a click-type or digital wrench with sufficient range for the required foot-pounds) and an angle torque gauge if your specifications include angle turns. You’ll also need the correct size socket for your head bolts, which is typically a 12-point socket.

What are the potential consequences of over- or under-torquing 7.3 Powerstroke cylinder head bolts?

Over-torquing 7.3 Powerstroke cylinder head bolts can stretch or break the bolts, strip threads in the engine block, or even warp the cylinder head itself. Conversely, under-torquing can lead to insufficient clamping force, resulting in head gasket leaks, coolant loss, oil contamination, or reduced engine compression and performance. Both scenarios can cause significant and costly engine damage.