Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Featured image for this comprehensive guide about Torque specs for 6.0 Powerstroke cylinder head bolts

Image source: dieselplace.com

The 6.0 Powerstroke engine is a legend, albeit a somewhat infamous one. Known for its incredible power potential but also for certain vulnerabilities, it has been the subject of countless discussions among diesel enthusiasts and professional mechanics alike. Among the most critical components in this engine, the cylinder head bolts stand out. Why? Because their proper installation, specifically adhering to the correct torque specs for 6.0 Powerstroke cylinder head bolts, is absolutely paramount to the engine’s longevity and performance. Ignore these specifications at your peril, and you might just find yourself facing a costly head gasket failure or even more severe engine damage.

For any 6.0 Powerstroke owner or mechanic undertaking a cylinder head repair or replacement, understanding and meticulously following the factory or aftermarket 6.0 Powerstroke head bolt torque sequence and values isn’t just a recommendation—it’s a non-negotiable requirement. This comprehensive guide will delve deep into everything you need to know about these critical fasteners, from the original equipment manufacturer (OEM) specifications to the highly recommended aftermarket upgrades, ensuring your 6.0 Powerstroke runs reliably for years to come.

We’ll explore the science behind torque, distinguish between torque-to-yield (TTY) bolts and reusable studs, provide precise 6.0 Powerstroke torque specifications, and offer actionable tips to avoid common pitfalls. Whether you’re refreshing an old motor or building a high-performance beast, getting the cylinder head bolt torque right is the foundation of a successful project.

Quick Answers to Common Questions

Why are precise torque specs for 6.0 Powerstroke cylinder head bolts so critical?

Following exact torque specs for 6.0 Powerstroke cylinder head bolts is vital for even clamping force, preventing head gasket failures and ensuring the engine’s long-term reliability. It’s the key to keeping those notorious head gaskets sealed correctly.

What are the basic torque specs for 6.0 Powerstroke cylinder head bolts I should know?

The OEM torque specs for 6.0 Powerstroke cylinder head bolts typically involve multiple stages: an initial torque, then several angle turns. Always consult a service manual or trusted guide for the precise sequence and values, as it’s a multi-step process.

What happens if I don’t follow the recommended torque specs for 6.0 Powerstroke cylinder head bolts?

Incorrectly torquing these bolts can lead directly to catastrophic head gasket failure, coolant leaks, and even cylinder head warpage, causing costly damage and significant downtime. It’s simply not worth the risk of cutting corners here.

Do the torque specs for 6.0 Powerstroke cylinder head bolts change if I’m using aftermarket studs or bolts?

Absolutely! If you’re upgrading to aftermarket studs like ARP, their specific torque specs for 6.0 Powerstroke cylinder head bolts will differ significantly from OEM. Always follow the manufacturer’s instructions provided with your specific hardware.

Can I reuse my old 6.0 Powerstroke cylinder head bolts, and what prep is needed?

OEM 6.0 Powerstroke cylinder head bolts are “torque-to-yield” (TTY) and are designed for one-time use; they must be replaced with new ones. Always ensure all bolt holes and threads are meticulously clean and lubricated according to specifications before installation.

📋 Table of Contents

- The Achilles’ Heel: Why 6.0 Powerstroke Cylinder Heads Are So Problematic

- Decoding Torque: Understanding the Science Behind Head Bolt Fastening

- The Official Word: OEM Torque Specs for 6.0 Powerstroke Cylinder Head Bolts

- The Upgrade Path: ARP Head Studs and Their Torque Specifications

- Precision Matters: A Step-by-Step Torquing Procedure

- Beyond the Wrench: Critical Best Practices and Common Pitfalls

- Conclusion

The Achilles’ Heel: Why 6.0 Powerstroke Cylinder Heads Are So Problematic

Before we dive into the specific torque specs for 6.0 Powerstroke cylinder head bolts, it’s essential to understand *why* these fasteners are such a hot topic in the 6.0 Powerstroke community. The 6.0L engine, produced from 2003 to 2007, was a significant leap in technology for Ford’s Super Duty lineup. However, it quickly gained a reputation for certain reliability issues, with head gasket failure being perhaps the most notorious.

Learn more about Torque specs for 6.0 Powerstroke cylinder head bolts – Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Image source: 2carpros.com

OEM Head Bolt Design Flaws

One of the primary contributors to the original head gasket woes of the 6.0 Powerstroke was the design of the OEM cylinder head bolts themselves. Ford opted for “torque-to-yield” (TTY) bolts. While TTY bolts are common in many modern engines, they have specific characteristics that, in the context of the 6.0 Powerstroke’s design and operating conditions, proved to be a weak link:

| Step/Stage | Specification | Notes/Conditions |

|---|---|---|

| Preparation | Clean & lubricate | Ensure bolt threads, under-head, and block threads are clean and lubricated (e.g., with engine oil). |

| Stage 1 | 65 lb-ft (88 Nm) | Initial torque for all cylinder head bolts, following the specified factory sequence. |

| Stage 2 | Additional 90 degrees | After Stage 1, turn all bolts an additional 90 degrees, following the same sequence. |

| Stage 3 | Additional 90 degrees | After Stage 2, turn all bolts a final additional 90 degrees, following the same sequence. |

| Important Note | Torque-to-Yield (TTY) | These are one-time use bolts; always replace old cylinder head bolts with new ones. |

- Stretching Beyond Elastic Limit: TTY bolts are designed to be torqued to a specific value and then rotated an additional angle (e.g., 90 degrees). This process stretches the bolt beyond its elastic limit, causing it to deform permanently. This permanent stretch is what creates the high, consistent clamping force needed to seal the head gasket.

- Single-Use Design: Because TTY bolts permanently stretch, they are a single-use item. Reusing them significantly compromises their ability to provide adequate clamping force, leading to potential head gasket failure.

- Insufficient Clamping Force (Under Certain Conditions): In stock applications, the OEM TTY bolts often provided just enough clamping force. However, when combined with other issues prevalent in the 6.0 Powerstroke, such as failing EGR coolers pushing combustion gases into the coolant system, poorly designed oil coolers causing high oil temperatures, or aggressive engine tunes that increase cylinder pressure, the OEM bolts simply couldn’t maintain the necessary clamping force. This led to “head lift,” where the cylinder heads momentarily separate from the block under extreme pressure, allowing combustion gases to escape into the cooling system and ultimately destroying the head gasket.

- Corrosion and Contamination: Over time, especially if coolant system maintenance was neglected, corrosion and debris could build up in the bolt holes, affecting the accuracy of torque readings and the proper seating of the bolts.

The Cost of Failure

A blown head gasket on a 6.0 Powerstroke isn’t just an inconvenience; it’s a significant financial burden. The repair typically involves removing the cab of the truck, a labor-intensive process that can quickly accumulate thousands of dollars in shop fees. Beyond the labor, parts costs for new head gaskets, new head bolts (or studs), and often related components like EGR coolers, oil coolers, and potentially new or resurfaced cylinder heads, add to the hefty bill. This is why getting the torque specs for 6.0 Powerstroke cylinder head bolts right the first time is crucial—it’s preventative maintenance against future heartbreak and expense.

Decoding Torque: Understanding the Science Behind Head Bolt Fastening

Torque is more than just tightening a bolt; it’s a precise application of rotational force designed to create a specific amount of tension in a fastener. This tension, in turn, translates into a clamping force that holds components together. For something as critical as a cylinder head, inconsistent or incorrect clamping force can lead to disastrous consequences.

Learn more about Torque specs for 6.0 Powerstroke cylinder head bolts – Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Image source: ls1tech.com

Torque-to-Yield (TTY) vs. Reusable Bolts (or Studs)

As mentioned, the 6.0 Powerstroke originally came with TTY bolts. Understanding the distinction between TTY and reusable fasteners is fundamental to properly installing your cylinder heads and selecting the right 6.0 Powerstroke head bolt torque values.

- Torque-to-Yield (TTY) Bolts: These bolts are designed to be stretched plastically (permanently) during installation. They achieve very consistent clamping force because they are stretched just past their yield point. However, this means they cannot be reused. Once removed, they must be replaced with new TTY bolts. Their advantage is a consistent clamp with less sensitivity to bolt hole friction.

- Reusable Bolts/Studs (e.g., ARP Head Studs): Aftermarket solutions, particularly head studs from companies like ARP (Automotive Racing Products), are designed differently. They are made from much stronger materials that allow them to be torqued to much higher values without reaching their yield point. This means they operate within their elastic range and can be reused multiple times. Studs, in particular, offer advantages over bolts:

- Superior Clamping Force: ARP studs provide significantly higher and more consistent clamping force than OEM TTY bolts, dramatically reducing the risk of head lift.

- Reduced Thread Engagement Issues: When installing bolts, you’re twisting the bolt into the block threads while simultaneously trying to stretch it. Studs are threaded into the block once, and then the cylinder head simply slides over them, making alignment easier. Nuts are then torqued down onto the studs, which isolates the stretching force to the stud itself and the nut, not the block threads.

- Reusability: A major cost-saving and convenience factor.

Why Torque Sequence Matters

Imagine tightening the lug nuts on a wheel. If you tighten them all in a random order, or just go around in a circle, the wheel might not sit perfectly flush, and some lugs might be tighter than others. The same principle applies, but on a much more critical scale, to a cylinder head. The specific torque sequence for 6.0 Powerstroke cylinder head bolts ensures that the clamping pressure is distributed evenly across the head gasket surface. This gradual, systematic tightening from the center outwards prevents distortion of the cylinder head and block, ensuring a perfect seal and preventing hot spots or pressure points that could lead to gasket failure.

The Official Word: OEM Torque Specs for 6.0 Powerstroke Cylinder Head Bolts

When using new OEM (or equivalent quality TTY) bolts, it is absolutely imperative to follow the factory 6.0 Powerstroke head bolt torque specifications. Remember, these are single-use bolts, so if you’re pulling your heads for any reason, you must replace them.

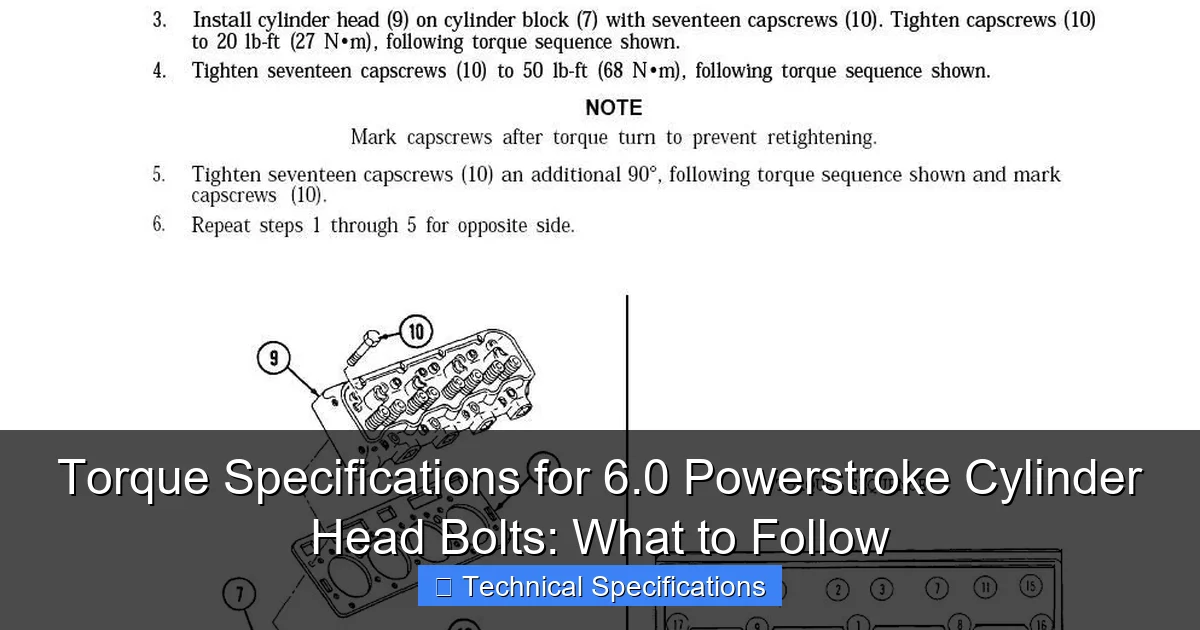

The OEM Ford/International procedure for torquing 6.0 Powerstroke cylinder head bolts is a multi-stage process involving both torque values and angle turns. This combination is how TTY bolts achieve their precise clamping force.

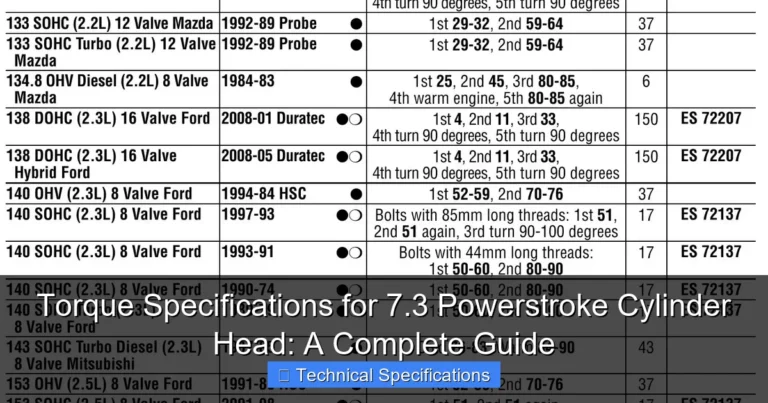

OEM 6.0 Powerstroke Cylinder Head Bolt Torque Specifications (New TTY Bolts ONLY)

Note: Always apply a light coat of clean engine oil to the bolt threads and under the bolt head flange prior to installation to ensure accurate torque readings. Do not use ARP lubricant with OEM bolts.

| Stage | Procedure |

|---|---|

| Stage 1 | Torque all cylinder head bolts to 20 ft-lbs (27 Nm). Follow the specified tightening sequence. |

| Stage 2 | Torque all cylinder head bolts to 45 ft-lbs (61 Nm). Follow the specified tightening sequence. |

| Stage 3 | Rotate all cylinder head bolts an additional 90 degrees (1/4 turn). Follow the specified tightening sequence. This step stretches the bolt to its yield point. |

| Stage 4 | Rotate all cylinder head bolts an additional 90 degrees (1/4 turn). Follow the specified tightening sequence. This completes the stretching process. |

It is crucial to use a good quality, calibrated torque wrench for the first two stages and an angle meter for the final two stages. Do not guess the angle turns; an angle meter ensures accuracy.

The Upgrade Path: ARP Head Studs and Their Torque Specifications

Given the historical issues with the OEM TTY bolts and head gasket failures, most serious 6.0 Powerstroke builders and owners opt for an aftermarket solution: ARP head studs. These studs are widely considered the gold standard for preventing head lift and ensuring the long-term integrity of the head gasket seal, especially in modified or hard-working engines.

Why ARP Head Studs Are Superior

- Higher Tensile Strength: ARP studs are made from premium alloy steels (e.g., 8740 chromoly or ARP 2000) that offer significantly greater tensile strength than OEM bolts. This allows them to withstand much higher cylinder pressures without yielding.

- Consistent Clamping: Because studs are threaded into the block and stay there, and only the nuts are torqued, the clamping force is applied more purely along the stud’s axis. This reduces stress on the block threads and provides a more consistent and robust clamp.

- Reusability: Unlike TTY bolts, ARP studs are designed to be reused, making future head work simpler and more cost-effective.

- Reduced Head Lift: The primary benefit is their ability to maintain superior clamping force under extreme operating conditions, virtually eliminating head lift issues even in highly tuned engines.

ARP 6.0 Powerstroke Cylinder Head Stud Torque Specifications

The torque specs for 6.0 Powerstroke cylinder head bolts (when using ARP studs) are different from the OEM specifications and are critically dependent on the type of lubricant used. ARP provides its own specialized lubricant (ARP Ultra-Torque Fastener Assembly Lubricant) which is essential for achieving accurate torque readings and the correct clamping force. Do NOT use engine oil if ARP lubricant is specified, as this will result in inaccurate torque and insufficient clamping.

| Stud Type | Lubricant | Torque Specification |

|---|---|---|

| ARP 8740 Chromoly Studs | ARP Ultra-Torque Fastener Assembly Lubricant | 210 ft-lbs (285 Nm) in three equal steps (70, 140, 210 ft-lbs). |

| ARP 8740 Chromoly Studs | 30wt Motor Oil (if ARP lube unavailable) | 190 ft-lbs (258 Nm) in three equal steps (63, 127, 190 ft-lbs). |

| ARP 2000 Studs | ARP Ultra-Torque Fastener Assembly Lubricant | 250 ft-lbs (339 Nm) in three equal steps (83, 167, 250 ft-lbs). |

| ARP 2000 Studs | 30wt Motor Oil (if ARP lube unavailable) | 220 ft-lbs (298 Nm) in three equal steps (73, 147, 220 ft-lbs). |

Crucial Reminder: Always refer to the specific instructions provided by ARP with your particular set of head studs, as specifications can occasionally vary or be updated. The above table serves as a general guideline for typical ARP installations for the 6.0 Powerstroke.

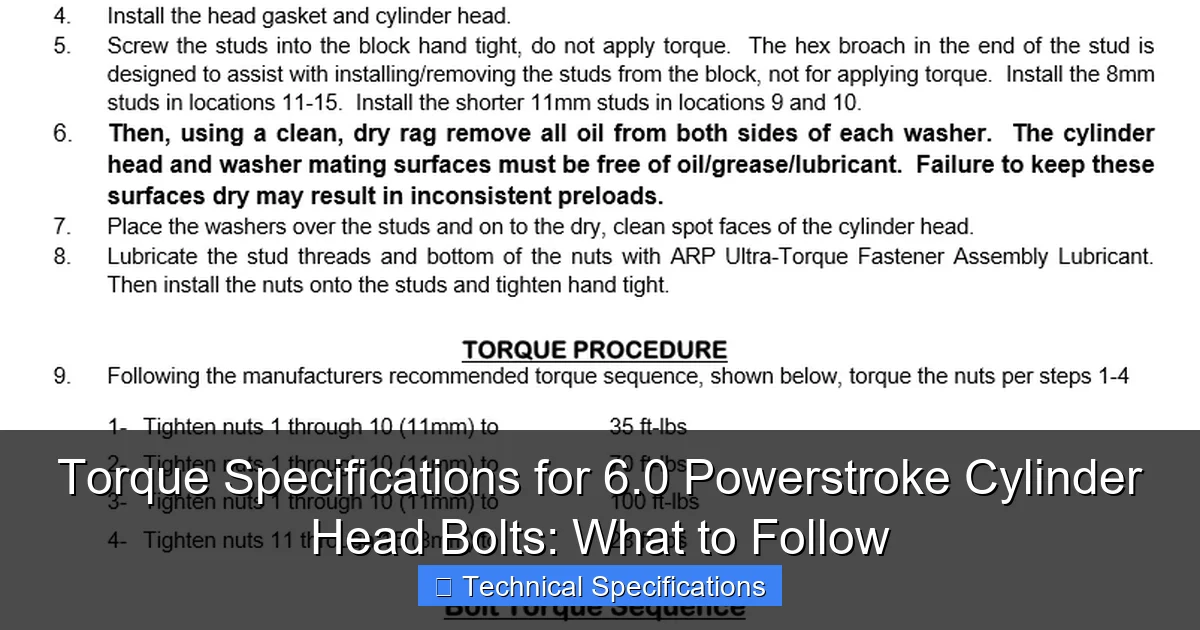

Precision Matters: A Step-by-Step Torquing Procedure

Whether you’re using OEM bolts or ARP studs, the actual process of torquing the fasteners is critical. It’s not just about hitting the right number; it’s about the entire methodology.

Preparation is Key

Before you even pick up a torque wrench, ensure the following:

- Clean Surfaces: The cylinder head, block surface, and head gasket must be immaculately clean and free of any debris, oil, or old gasket material. Even a tiny particle can create a high spot and compromise the seal.

- Clean Threads: The bolt holes in the block (for bolts) or the stud threads (for studs) must be perfectly clean. Use a thread chaser (NOT a tap, as taps remove material) to clean out any old Locktite, rust, or debris. This is absolutely critical for accurate torque readings.

- Proper Lubrication: Use the specified lubricant. For OEM TTY bolts, this is typically clean engine oil on the threads and under the bolt head. For ARP studs, use ARP Ultra-Torque Fastener Assembly Lubricant on the stud threads that engage the nut, and under the nut flange. Never use the wrong lubricant, as it dramatically affects the friction and therefore the actual clamping force achieved.

- New Gaskets: Always use new head gaskets. Reusing old ones is a recipe for disaster.

- Calibrated Torque Wrench: Use a high-quality, recently calibrated torque wrench. For angle-to-yield bolts, an angle meter is also essential. For high-torque ARP studs, a robust 1/2″ or even 3/4″ drive torque wrench may be needed.

The Torquing Process (General Steps)

While specific steps vary slightly between OEM and ARP, the general principles remain the same:

- Install Fasteners:

- For OEM bolts: Hand-tighten all new cylinder head bolts until they are snug.

- For ARP studs: Thread the studs into the block until finger-tight (do not over-tighten the studs into the block). Slide the head gasket onto the studs, then carefully lower the cylinder head onto the studs. Finally, thread the ARP nuts onto the studs finger-tight.

- Follow the Torque Sequence: This is paramount. The sequence dictates the order in which you tighten each bolt/nut to ensure even clamping force and prevent distortion. The 6.0 Powerstroke typically uses a center-out, spiral pattern. You can usually find a diagram in a factory service manual or ARP instructions.

- Perform Stages: Follow the prescribed stages (e.g., 20 ft-lbs, 45 ft-lbs, then 90 degrees, then 90 degrees for OEM; or 70 ft-lbs, 140 ft-lbs, 210 ft-lbs for ARP). Complete each stage fully on all fasteners before moving to the next stage.

- Do Not Overtighten: Exceeding the specified torque can stretch or break bolts/studs, strip threads, or distort components. Under-tightening leads to head gasket failure.

- Final Check: After completing all stages, it’s often good practice (though not always explicitly stated by manufacturers) to go back over the fasteners in sequence one last time to ensure none have backed off slightly. For TTY bolts, this is generally not done as they are permanently stretched. For ARP studs, a final check at the maximum torque setting in sequence is acceptable.

Torque Sequence Diagram (Conceptual)

While we can’t provide an interactive diagram here, the typical **6.0 Powerstroke head bolt torque** sequence for both heads follows a pattern that starts in the center of the head and works its way outward in a spiral fashion. This ensures even pressure distribution. Always refer to a factory service manual or the instructions provided with your head gasket set or ARP studs for the exact numerical sequence for your specific engine and head type.

For a V8 engine like the 6.0 Powerstroke, each cylinder head will have a specific pattern, usually involving around 18-20 fasteners. The general principle is to tighten in a progressive, alternating pattern from the core of the cylinder head towards its perimeter.

Beyond the Wrench: Critical Best Practices and Common Pitfalls

Achieving the correct torque specs for 6.0 Powerstroke cylinder head bolts is a critical step, but it’s part of a larger picture. Several other factors contribute to the overall success and longevity of your 6.0 Powerstroke’s top end.

Calibrated Tools Are Non-Negotiable

A cheap, uncalibrated torque wrench is worse than useless; it provides a false sense of security. Invest in a high-quality, accurate torque wrench and consider having it professionally calibrated periodically, especially if you use it frequently. For TTY bolts, a good quality angle meter is equally important.

Thread Condition: Immaculate Matters

The condition of the threads in the block is paramount. If they are damaged, corroded, or contain residual thread locker or sealant, your torque readings will be inaccurate, and the clamping force will be inconsistent. Always chase the threads with a proper thread chaser (not a tap) to ensure they are clean and free of obstruction. If any block threads are damaged beyond repair, a threaded insert (like a Timesert or Helicoil) may be necessary, but this should be done by an experienced machinist.

The Right Lubrication for the Right Fastener

As repeatedly stressed, lubrication makes a huge difference. Using engine oil on ARP studs when ARP lubricant is specified can result in significantly under-torqued studs, leading to head gasket failure. Conversely, using ARP lubricant on OEM bolts might lead to over-torquing them. Always follow the manufacturer’s specific lubrication recommendations.

Never Re-use TTY Bolts

This cannot be stressed enough: TTY bolts are single-use. They are designed to permanently stretch during installation. Reusing them means they’ve already yielded, and they simply cannot provide the necessary clamping force a second time. It’s a false economy that will inevitably lead to head gasket failure.

Address Contributing Factors

While proper 6.0 Powerstroke head bolt torque is essential, it won’t prevent head gasket failure if other underlying issues aren’t addressed. These include:

- EGR Cooler: A failing EGR cooler can introduce combustion gases into the coolant, rapidly building pressure and stressing the head gaskets. Consider upgrading to a “bulletproof” EGR cooler or even a complete EGR delete (where legal).

- Oil Cooler: A clogged oil cooler can lead to high oil and coolant temperatures, reducing the effectiveness of the head gaskets and causing excessive heat expansion. Always replace or thoroughly clean the oil cooler when doing head gasket work.

- Coolant Type: Use the correct Ford-approved coolant (gold or newer ELC) and maintain it diligently. Incorrect coolant or neglected coolant can lead to cavitation erosion, corrosion, and silicate dropout, all of which compromise the cooling system and put stress on head gaskets.

- Engine Tuning: Aggressive tunes that significantly increase cylinder pressure without proper supporting modifications (like ARP studs) are a common cause of head gasket failure.

- Injector Issues: Faulty injectors can cause cylinder wash-down or excessive heat, both of which can lead to head gasket problems.

Conclusion

The 6.0 Powerstroke engine, despite its challenges, remains a formidable powerplant capable of impressive performance and reliability—provided it’s built and maintained correctly. At the heart of that reliability, particularly concerning head gasket integrity, are the torque specs for 6.0 Powerstroke cylinder head bolts.

Whether you opt for new OEM TTY bolts or the highly recommended ARP head studs, understanding and meticulously following the correct 6.0 Powerstroke head bolt torque sequence and values is not just a best practice; it’s a critical investment in your engine’s future. Paying close attention to detail, using the right tools, proper lubrication, and addressing all contributing factors will ensure your 6.0 Powerstroke stands strong against the rigors of heavy-duty use, delivering the performance you expect without the dread of impending head gasket failure.

Don’t cut corners when it comes to your 6.0 Powerstroke cylinder heads. The effort and precision applied during this crucial assembly process will directly translate into thousands of miles of trouble-free operation and the peace of mind every diesel owner deserves.

Frequently Asked Questions

What are the specific torque specifications for 6.0 Powerstroke cylinder head bolts?

The official torque specifications for 6.0 Powerstroke cylinder head bolts involve a multi-stage process. This typically includes an initial torque value followed by several angle turns, which is crucial for proper clamping force. Always consult a factory service manual or a reputable repair guide for the exact sequence and values, as precision is paramount.

Why is it so critical to follow the 6.0 Powerstroke cylinder head bolt torque specs precisely?

Following the 6.0 Powerstroke cylinder head bolt torque specs precisely is paramount to prevent head gasket failures, a common issue with these engines. Incorrect torque can lead to uneven clamping force across the cylinder head, allowing combustion gases or coolant to leak. Adhering strictly to these specifications ensures a proper seal and long-term engine reliability.

Do I need to replace my 6.0 Powerstroke cylinder head bolts, or can I reuse them?

For 6.0 Powerstroke cylinder head bolts, it is highly recommended to replace the OEM bolts with new ones during any head gasket service. The factory bolts are “torque-to-yield” (TTY) fasteners, meaning they stretch permanently when torqued and cannot be accurately reused. Reusing them can lead to insufficient clamping force and subsequent head gasket failure.

What are the risks of not properly torquing the 6.0 Powerstroke cylinder head bolts?

Not properly torquing the 6.0 Powerstroke cylinder head bolts carries significant risks, primarily head gasket failure and potential engine damage. Uneven or insufficient torque can cause the cylinder head to lift, allowing coolant or combustion gases to escape, leading to overheating, loss of power, and costly repairs. Adhering to the specifications is essential for engine integrity.

Is the torque sequence important for 6.0 Powerstroke cylinder head bolts?

Yes, the torque sequence for 6.0 Powerstroke cylinder head bolts is extremely important. A specific tightening pattern, usually starting from the center and working outwards in stages, ensures even distribution of clamping force across the cylinder head. Deviating from this sequence can lead to uneven pressure, head warping, and premature head gasket failure.

What’s the difference in torque specs between OEM 6.0 Powerstroke cylinder head bolts and ARP studs?

There is a significant difference in torque specifications between OEM 6.0 Powerstroke cylinder head bolts and aftermarket ARP head studs. ARP studs use a different material and design, requiring specific torque values typically much higher than OEM bolts and often measured in ft-lbs rather than angle turns. Always follow the installation instructions provided directly by ARP for their products to ensure proper performance and avoid damage.