Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Featured image for this comprehensive guide about Torque specs for 6.0 Powerstroke cylinder head bolts

Image source: dieselplace.com

The 6.0 Powerstroke engine, a robust and powerful heart for many Ford trucks, has a storied history. Known for its incredible torque and pulling power, it also gained a reputation for specific vulnerabilities, chief among them being its cylinder head gasket and head bolt system. If you own or work on a 6.0 Powerstroke, understanding the proper torque specifications for 6.0 Powerstroke cylinder head bolts isn’t just important—it’s absolutely critical to the longevity and reliability of the engine.

Far too many 6.0 Powerstroke owners have faced the dreaded “puking coolant” or overheating issues, often tracing back to failed head gaskets. While various factors contribute to these failures, inadequate or incorrect cylinder head bolt torque, combined with the design of the original equipment manufacturer (OEM) bolts, played a significant role. This comprehensive guide will dive deep into everything you need to know about torquing your 6.0 Powerstroke head bolts, from understanding the OEM approach to embracing the aftermarket solutions that have become the gold standard.

Whether you’re embarking on a full “bulletproofing” project, replacing a blown head gasket, or simply seeking to understand the intricacies of your 6.0L diesel, mastering the correct 6.0 Powerstroke head bolt torque specs is non-negotiable. We’ll cover the multi-step procedures, the critical role of lubrication, and the essential best practices that ensure your investment pays off in reliable power, rather than costly repairs. Let’s get those heads clamped down correctly!

Quick Answers to Common Questions

What are the actual torque specs for 6.0 Powerstroke cylinder head bolts?

The most commonly recommended torque spec involves a multi-stage process, often starting at 30 ft-lbs, then 75 ft-lbs, followed by a final 90-degree turn. Always consult the specific instructions provided with your head gasket or bolt set for the most accurate and up-to-date **torque specs for 6.0 Powerstroke cylinder head bolts**.

Why are the 6.0 Powerstroke cylinder head bolt torque specs so critical?

Getting the **6.0 Powerstroke cylinder head bolt torque specs** just right is absolutely crucial because improper torquing can lead to head gasket failure, coolant leaks, and even severe engine damage. It ensures an even clamping force, which is vital for sealing combustion pressure effectively.

Should I reuse my old 6.0 Powerstroke cylinder head bolts, or do I need new ones?

For the 6.0 Powerstroke, it’s highly recommended to replace your old cylinder head bolts with new ones, preferably ARP studs, when reassembling. Original TTY (torque-to-yield) bolts are designed to stretch during torquing and may not provide adequate clamping force if reused, making proper **torque specs for 6.0 Powerstroke cylinder head bolts** even more critical with new hardware.

Is there a specific tightening sequence for the 6.0 Powerstroke cylinder head bolts?

Yes, absolutely! Following a precise spiral or cross-hatch tightening sequence is just as important as the **torque specs for 6.0 Powerstroke cylinder head bolts** themselves. This ensures even pressure distribution across the head, preventing warping and promoting a proper, lasting seal.

What happens if I don’t follow the 6.0 Powerstroke cylinder head bolt torque specs precisely?

Deviating from the recommended **6.0 Powerstroke cylinder head bolt torque specs** can have serious consequences, ranging from immediate head gasket failure and coolant mixing with oil to long-term issues like cylinder head warping or cracking. It’s truly a “do it right the first time” scenario to protect your engine.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Head Bolt Dilemma

- OEM Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts (If Using Original Style Bolts)

- The Gold Standard: ARP Head Studs and Their Torque Procedures

- Beyond Torque: Essential Best Practices for 6.0 Head Gasket Success

- Tools of the Trade: Ensuring Accurate Torque

- Conclusion: The Investment in Proper Torque for Your 6.0 Powerstroke

Understanding the 6.0 Powerstroke Head Bolt Dilemma

To truly appreciate the importance of proper torque specs for 6.0 Powerstroke cylinder head bolts, we first need to understand the challenges inherent in the original design. The 6.0L Powerstroke engine, produced from 2003 to 2007, was a significant departure from its 7.3L predecessor. With higher injection pressures and complex systems, it pushed the boundaries of diesel technology, but not without some growing pains.

Learn more about Torque specs for 6.0 Powerstroke cylinder head bolts – Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Image source: 2carpros.com

The Original TTY Head Bolts: A Brief Explanation

Ford initially equipped the 6.0 Powerstroke with Torque-to-Yield (TTY) head bolts. These bolts are designed to be stretched plastically (beyond their elastic limit) during installation. This stretching creates a very consistent clamp load on the head gasket. The idea is that once stretched, the bolt maintains tension better across a range of temperatures and pressures. However, there are significant downsides for the 6.0L application:

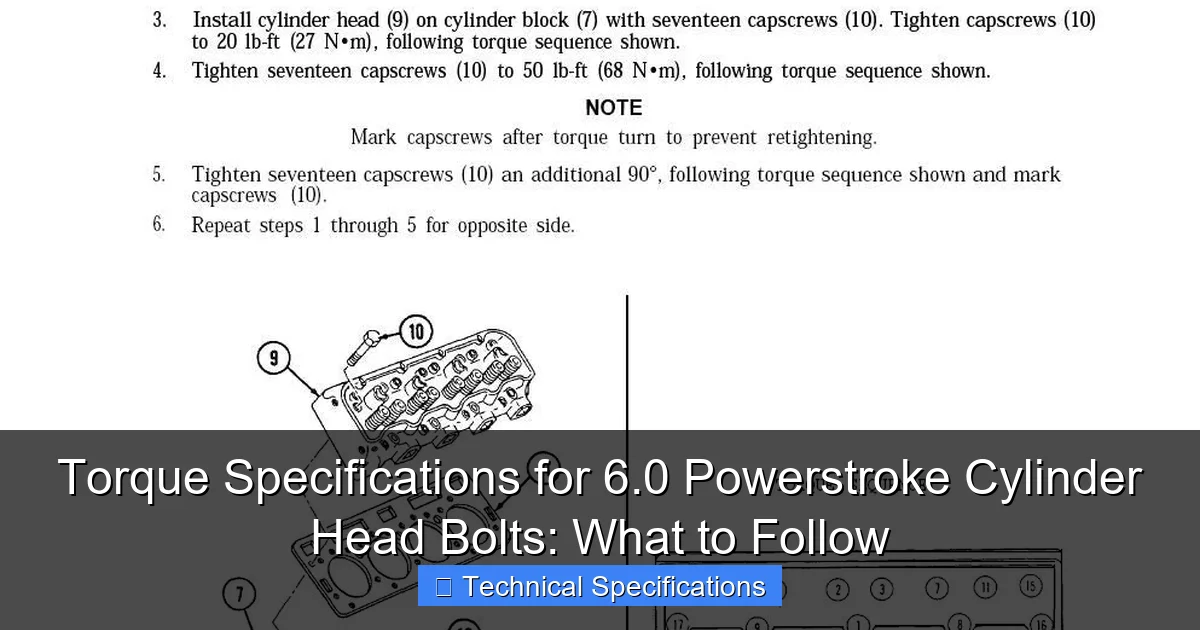

| Step | Torque Value (ft-lbs) | Angle Value (degrees) | Notes |

|---|---|---|---|

| 1 | 15 | N/A | Tighten all bolts in sequence (spiral from center out). |

| 2 | 30 | N/A | Re-tighten all bolts in sequence. |

| 3 | N/A | 90 | Turn each bolt an additional 90 degrees in sequence. |

| 4 | N/A | 90 | Turn each bolt an additional 90 degrees in sequence. |

| 5 | N/A | 45 | Turn each bolt an additional 45 degrees in sequence. |

| Important: Always use *NEW* cylinder head bolts. Apply engine oil to bolt threads and under the bolt head before installation. | |||

- One-Time Use: Once stretched, TTY bolts are weakened and cannot be reused. Any time the cylinder heads are removed, new TTY bolts are required.

- Susceptibility to Overheating: The 6.0 Powerstroke runs at higher cylinder pressures and temperatures. When combined with sustained high boost (often from aftermarket tuning), the original TTY bolts could stretch further, losing their clamp load.

- Head Gasket Vulnerability: When the clamp load diminishes, the head gasket is no longer adequately compressed, leading to hot exhaust gases escaping into the cooling system or coolant leaking into the cylinders. This is the root cause of the infamous “puking coolant” syndrome.

Why Head Gasket Failures Were So Common

The perfect storm for 6.0 Powerstroke head gasket failure involved several factors converging:

- Original TTY Head Bolts: As discussed, their design made them susceptible to stretching under extreme conditions.

- EGR Cooler Issues: Failed EGR coolers could dump hot exhaust gas into the coolant, increasing system pressure and temperature, further stressing the head gaskets and bolts.

- Oil Cooler Failures: Clogged oil coolers could lead to high Exhaust Gas Temperature (EGT) and elevated coolant temperatures, adding to the thermal stress.

- High Cylinder Pressures: Performance tuning, while increasing power, also significantly raises cylinder pressures, directly challenging the integrity of the head bolt clamp.

Understanding these historical challenges highlights why getting the 6.0 Powerstroke head bolt torque specs absolutely perfect is paramount, and why many opt for a more robust solution.

OEM Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts (If Using Original Style Bolts)

While most experienced 6.0 Powerstroke owners and mechanics will strongly recommend upgrading to aftermarket head studs, it’s crucial to understand the original equipment manufacturer (OEM) procedure if, for some reason, you are installing new OEM-style Torque-to-Yield (TTY) bolts. Remember, these bolts are single-use only.

Learn more about Torque specs for 6.0 Powerstroke cylinder head bolts – Torque Specifications for 6.0 Powerstroke Cylinder Head Bolts: What to Follow

Image source: ls1tech.com

The Multi-Step Tightening Process

The OEM procedure for torquing 6.0 Powerstroke cylinder head bolts involves a specific sequence and multiple stages:

- Initial Torque: All cylinder head bolts are first tightened to a specific foot-pound (ft-lbs) value. This ensures an even initial seating of the head.

- Angular Torque Steps: Following the initial torque, the bolts are then turned an additional number of degrees. This is where the “yield” aspect comes in, stretching the bolts to their plastic deformation point. An angle gauge is essential for accuracy here.

The standard OEM procedure for 6.0 Powerstroke head bolt torque (using new TTY bolts) is as follows:

- Step 1: Torque all head bolts to 65 ft-lbs in the specified sequence.

- Step 2: Rotate all head bolts an additional 90 degrees (1/4 turn) in the specified sequence.

- Step 3: Rotate all head bolts an additional 90 degrees (1/4 turn) in the specified sequence.

It is imperative to follow the correct tightening sequence (spiraling out from the center) as outlined in the Ford workshop manual for the 6.0 Powerstroke. Failure to do so can lead to uneven clamp load and head gasket failure.

Why TTY Bolts Are a One-Time Use

As mentioned, TTY bolts are designed to stretch beyond their elastic limit. Imagine stretching a rubber band until it’s permanently longer – it loses its original elasticity. The same principle applies to TTY bolts. Once they’ve been stretched:

- Their structural integrity is compromised.

- They will not provide the same clamp load if reused.

- They are more prone to breaking if re-torqued.

Therefore, if you’re using OEM-style bolts, always ensure they are brand new. Reusing old 6.0 Powerstroke head bolts is a guaranteed path to premature head gasket failure and further engine damage.

The Gold Standard: ARP Head Studs and Their Torque Procedures

For any serious 6.0 Powerstroke owner, or anyone seeking long-term reliability and peace of mind, upgrading to ARP (Automotive Racing Products) head studs is widely considered the ultimate solution. This “bulletproofing” modification directly addresses the weaknesses of the OEM head bolt system by providing a significantly stronger and more reliable clamping force on the cylinder heads.

Why ARP Studs Are Superior for the 6.0 Powerstroke

ARP head studs offer several advantages over the original TTY bolts:

- Superior Strength: ARP studs are manufactured from high-tensile strength alloys (like 8740 chromoly) that are far stronger than OEM bolts. They are designed to operate well within their elastic range, meaning they won’t yield or stretch plastically under extreme loads.

- Consistent Clamp Load: Because they don’t yield, ARP studs maintain a more consistent and higher clamp load, even under the high cylinder pressures and temperatures of a modified 6.0 Powerstroke. This is crucial for keeping the head gasket sealed.

- Reusable: Unlike TTY bolts, ARP studs are fully reusable (assuming they haven’t been damaged). This is a significant advantage for future engine work, saving time and money.

- Easier Installation: Studs remain in the block, allowing for easier head installation without fighting to align bolts through the head.

Investing in ARP head studs is a foundational step in ensuring the longevity of your 6.0 Powerstroke, especially if you plan on any performance enhancements.

Critical Factors for ARP Stud Torque: Lubrication Matters!

This is where many DIY mechanics can go wrong. The torque specs for 6.0 Powerstroke cylinder head bolts, specifically ARP studs, are heavily dependent on the lubricant used. Different lubricants create different amounts of friction under the nut, which means a given torque wrench reading will result in a different actual clamping force.

- ARP Ultra-Torque Fastener Assembly Lubricant: This is ARP’s proprietary lubricant and is *highly recommended* for use with their studs. It provides very consistent friction reduction, allowing for precise and repeatable clamping force. The published ARP torque specifications are typically for use with this specific lubricant.

- Motor Oil or Other Lubricants: If you use motor oil or another lubricant, the torque specifications will be different. Using the ARP Ultra-Torque spec with motor oil will result in an *under-torqued* stud, which can lead to gasket failure. You MUST consult ARP’s documentation for the specific torque value if you are not using their lubricant.

Always use the lubricant specified by ARP for your particular stud kit and follow the corresponding torque specifications. Do not guess or substitute.

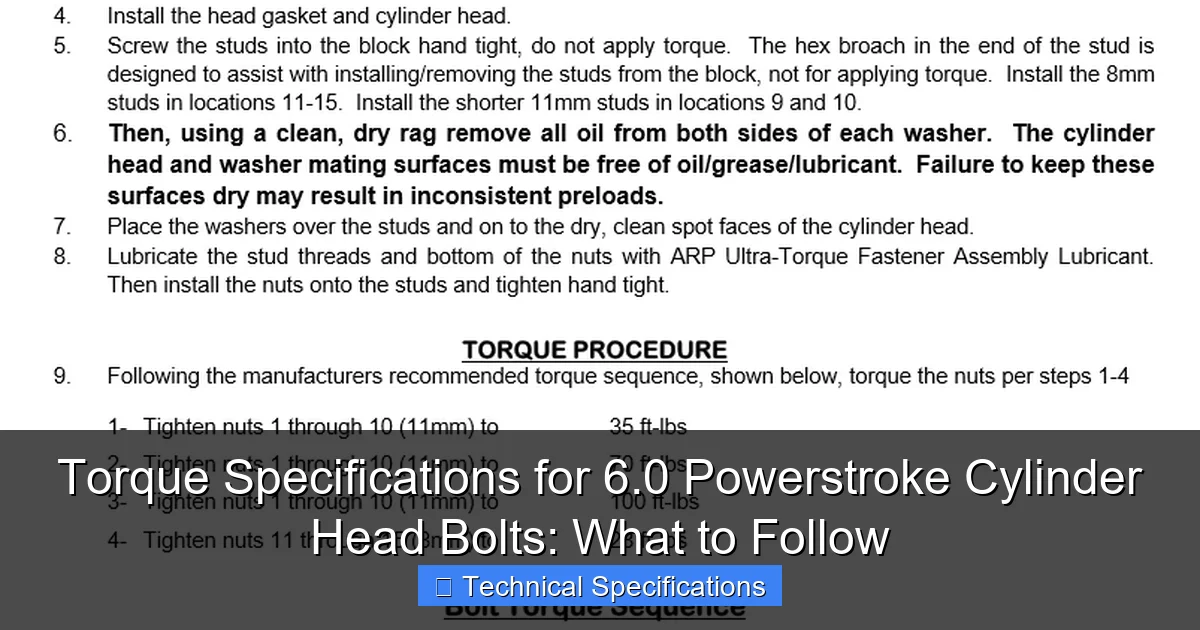

Step-by-Step ARP Head Stud Torque Procedure

The following procedure outlines the most common and widely accepted ARP head stud torque specs for the 6.0 Powerstroke using ARP Ultra-Torque Fastener Assembly Lubricant. Always refer to the instructions included with your specific ARP kit, as specifications can sometimes vary slightly by kit or revision.

ARP Head Stud Installation and Torque Procedure (Using ARP Ultra-Torque Lube):

- Prepare Studs: Hand-thread each ARP stud into the engine block until it bottoms out. Do not overtighten the studs themselves. They should be snug.

- Head & Gasket Placement: Install the new head gaskets and carefully lower the cylinder heads over the studs.

- Lubricate Washers & Nuts: Apply ARP Ultra-Torque Lube to both sides of the washers and to the threads of the ARP nuts.

- Install Washers & Nuts: Place a washer over each stud and hand-thread the nut onto the stud.

- Initial Torque: Torque all ARP nuts to 80 ft-lbs in the specified sequence (working from the center outwards in a spiral pattern).

- Second Torque Pass: Torque all ARP nuts to 150 ft-lbs in the specified sequence.

- Final Torque Pass: Torque all ARP nuts to 210 ft-lbs in the specified sequence.

Important Notes:

- Tightening Sequence: Always follow the specific tightening sequence provided in the Ford workshop manual or your ARP kit instructions. This ensures even clamping pressure.

- Torque Wrench Calibration: Use a high-quality, recently calibrated torque wrench.

- Cleanliness: Ensure all threads (in the block and on the studs/nuts) are immaculately clean and free of debris, oil, or coolant before lubrication and installation.

- Re-torque? ARP often recommends a re-torque after a few heat cycles (e.g., 500-1000 miles). Check your specific ARP instructions for this recommendation.

Following this precise procedure for your 6.0 Powerstroke head studs is key to preventing future head gasket issues.

Beyond Torque: Essential Best Practices for 6.0 Head Gasket Success

While proper torque specs for 6.0 Powerstroke cylinder head bolts are undoubtedly the cornerstone of a successful head gasket job, they are not the only factor. A meticulous approach to the entire cylinder head and gasket replacement process is crucial for long-term reliability. Neglecting any of these steps can compromise even the best torqued ARP studs.

Surface Preparation: The Foundation of a Seal

A perfectly flat and clean sealing surface is paramount. Head gaskets cannot seal against imperfections. This means:

- Cylinder Head Resurfacing: The 6.0 Powerstroke cylinder heads are prone to warping, especially after overheating. It is highly recommended to have both cylinder heads professionally inspected and resurfaced by a reputable machine shop. They should be checked for flatness and cracks.

- Block Deck Cleaning: The engine block deck surface must be spotlessly clean and free of old gasket material, carbon, rust, or debris. Use a non-abrasive method (like a plastic scraper) and follow up with a solvent. Ensure no foreign material falls into the cylinder bores or oil/coolant passages.

- Thread Cleaning: The bolt/stud holes in the block must be thoroughly cleaned. Use a thread chaser (not a tap, which can remove material) to ensure threads are clean and free of corrosion or LockTite residue. Blow out the holes with compressed air and eye protection. Any obstruction in the holes can lead to inaccurate torque readings and improper stud seating.

The Right Gaskets: OEM vs. Aftermarket

The choice of head gasket matters. While some swear by updated OEM Ford gaskets, many aftermarket options are available. Ensure you are using:

- Correct Type: For the 6.0 Powerstroke, Multi-Layer Steel (MLS) gaskets are standard.

- Reputable Brand: Stick to known, quality brands. Skimping on gaskets is false economy. Many “bulletproof” kits include improved aftermarket gaskets.

Coolant and Oil System Integrity

Head gasket failure in the 6.0 Powerstroke is often a symptom of underlying issues. Address these proactively during your repair:

- EGR Cooler: Upgrade to a “delete” kit or a high-quality aftermarket EGR cooler (e.g., BPD) to prevent future failures that can pressurize the cooling system.

- Oil Cooler: Replace the engine oil cooler. A clogged oil cooler is a very common issue on the 6.0L and leads to high Exhaust Gas Temperature (EGT) and elevated coolant temperatures, stressing the new head gaskets. Consider a “full flow” external oil cooler system if budget allows.

- Coolant Flush: Thoroughly flush the entire cooling system to remove any contaminants, old coolant, or silicate drop-out. Refill with the correct ELC (Extended Life Coolant).

- HPOP (High-Pressure Oil Pump): Inspect the HPOP screen and consider replacing it if there’s any doubt. This is critical for injector performance.

- FICM (Fuel Injection Control Module): Ensure your FICM is functioning correctly (check voltage). A weak FICM can cause injector issues and contribute to cylinder pressure spikes.

Degas Bottle and Radiator Cap Checks

After all the work on your 6.0 Powerstroke cylinder heads and gaskets, don’t overlook these simple but critical components:

- Degas Bottle: Inspect the coolant degas bottle for cracks, discoloration, or signs of stress. Replace if necessary.

- Radiator Cap: The radiator cap is a pressure relief valve. A faulty cap can either not hold pressure or release it prematurely, affecting the entire cooling system. Always install a new OEM-spec radiator cap.

By addressing these peripheral components and ensuring meticulous preparation, you significantly increase the chances of long-term success for your 6.0 Powerstroke head gasket and stud installation.

Tools of the Trade: Ensuring Accurate Torque

Achieving the correct torque specs for 6.0 Powerstroke cylinder head bolts requires more than just knowing the numbers; it demands the right tools and knowing how to use them. Precision is paramount in this crucial engine build step.

The Importance of a Calibrated Torque Wrench

Your torque wrench is your most critical tool for this job. Here’s what you need to know:

- Quality Matters: Invest in a good quality click-type or digital torque wrench. Avoid cheap, unbranded tools for such a vital application.

- Calibration: Torque wrenches can lose accuracy over time. If your wrench hasn’t been calibrated in a while (or ever), consider having it checked by a professional. Some tool manufacturers offer calibration services. For home users, a basic check can be done with known weights.

- Correct Range: Ensure your torque wrench’s range covers the required 210 ft-lbs for ARP studs comfortably. Using a wrench at its extreme upper or lower limits can reduce accuracy. A 1/2″ drive torque wrench is usually sufficient, but ensure its maximum capacity exceeds the highest required torque spec.

- Proper Use: Always pull the torque wrench smoothly and steadily. Do not jerk it. When the wrench clicks, stop immediately. Avoid over-torquing.

- Storage: When not in use, always set a click-type torque wrench back to its lowest setting to relieve spring tension and maintain accuracy.

Angle Gauges and Why They’re Necessary (for TTY Bolts)

If you are, against advice, using new OEM-style TTY bolts, an angle gauge is indispensable:

- Accurate Angle Turns: TTY bolts require tightening to a specific angle (e.g., an additional 90 degrees). Without an angle gauge, eyeballing this is highly inaccurate and will lead to inconsistent clamp loads.

- Types: Angle gauges attach to your socket wrench or breaker bar. Mechanical dial-type gauges are common and effective.

For ARP studs, which use pure foot-pound torque, an angle gauge is generally not needed unless specific ARP instructions call for it, which is rare for the 6.0 Powerstroke application.

Proper Socket Selection

This may seem basic, but using the correct socket is important:

- 6-Point Sockets: Always use 6-point sockets for head bolts/nuts. 12-point sockets are more prone to rounding off fasteners, especially when high torque is applied.

- Deep Sockets: Ensure the socket is deep enough to fully engage the nut/bolt head without bottoming out on the stud or cylinder head casting.

- Quality Material: Use good quality, impact-grade sockets that won’t flex or crack under high torque.

By equipping yourself with the right, well-maintained tools and understanding their proper application, you significantly increase the likelihood of correctly applying the torque specifications for 6.0 Powerstroke cylinder head bolts, setting the stage for a successful engine rebuild.

Conclusion: The Investment in Proper Torque for Your 6.0 Powerstroke

The journey to understanding and applying the correct torque specifications for 6.0 Powerstroke cylinder head bolts is a testament to the meticulous nature required for maintaining this iconic diesel engine. From deciphering the complexities of original TTY bolts to embracing the robust solution offered by ARP head studs, it’s clear that precision and attention to detail are paramount.

We’ve explored why the original system faltered, the specific, multi-step OEM torque procedures, and the widely adopted, more reliable ARP head stud torque sequence. The difference between a properly torqued set of head studs and a rushed, inaccurate job can literally be thousands of dollars in future repairs and countless hours of frustration. Remember, lubrication is not a minor detail; it’s a critical factor that directly impacts the clamping force and, consequently, the reliability of your 6.0 Powerstroke cylinder head gaskets.

Beyond the numbers on the torque wrench, the success of your 6.0 Powerstroke head gasket replacement hinges on a holistic approach. Meticulous surface preparation, thoughtful component upgrades (like EGR and oil coolers), and using the right, calibrated tools all contribute to a lasting repair. Investing the time, effort, and resources into doing the job right the first time is not just a recommendation; it’s an economic imperative for any 6.0 Powerstroke owner.

By diligently following the guidelines outlined in this comprehensive guide, you’re not just tightening bolts; you’re building a foundation of reliability and ensuring your 6.0 Powerstroke continues to deliver the power and performance it was designed for, without the common pitfalls of its past. Drive confidently, knowing your heads are clamped down right.

🎥 Related Video: Torque ARP studs on 6.0

📺 JamesRRossII

What you need to do before tightening studs.

Frequently Asked Questions

What are the factory torque specifications for 6.0 Powerstroke cylinder head bolts?

The factory torque specifications for 6.0 Powerstroke cylinder head bolts typically involve a multi-stage process rather than a single torque value. This usually begins with an initial torque, followed by several angle turns (e.g., 90 degrees), which can be found in the Ford service manual or a reputable repair guide.

Is there a specific tightening sequence for the 6.0 Powerstroke cylinder head bolts?

Yes, following a specific tightening sequence is absolutely critical for 6.0 Powerstroke cylinder head bolts. This ensures even clamping pressure across the cylinder head, which is essential for preventing warpage and achieving a proper head gasket seal. Always refer to the manufacturer’s specified pattern.

Should I replace the 6.0 Powerstroke cylinder head bolts when reinstalling the cylinder heads?

It is highly recommended to replace the 6.0 Powerstroke cylinder head bolts with new ones, as the factory bolts are “torque-to-yield” (TTY) bolts. These bolts stretch permanently during their initial tightening, and reusing them can lead to insufficient clamping force and potential head gasket failure.

What are the risks if I don’t follow the correct torque specs for my 6.0 Powerstroke cylinder head bolts?

Failing to adhere to the precise torque specs for 6.0 Powerstroke cylinder head bolts can lead to significant engine damage. This includes uneven clamping, which can cause head gasket leaks, cylinder head warpage, and even catastrophic engine failure over time due to compromised sealing.

Are the torque specifications different for ARP head studs versus factory 6.0 Powerstroke cylinder head bolts?

Yes, the torque specifications are absolutely different for ARP head studs compared to factory 6.0 Powerstroke cylinder head bolts. ARP studs come with their own specific torque values and lubrication requirements, which are typically higher and designed for their superior clamping force. Always follow ARP’s provided instructions meticulously.

Do I need to use thread locker or lubricant on the 6.0 Powerstroke cylinder head bolts?

For factory 6.0 Powerstroke cylinder head bolts, it’s crucial to follow the manufacturer’s recommendation regarding lubrication, which often specifies using clean engine oil on the threads and under the bolt head. Never use thread locker unless explicitly instructed, as it will skew the torque readings and prevent proper clamping force.