How to Use a Pressure Tester for 7.3 Powerstroke Injectors: Ensure Accurate Performance

Featured image for this comprehensive guide about How to use a pressure tester for 7.3 Powerstroke injectors

Image source: injectorsdirect.com

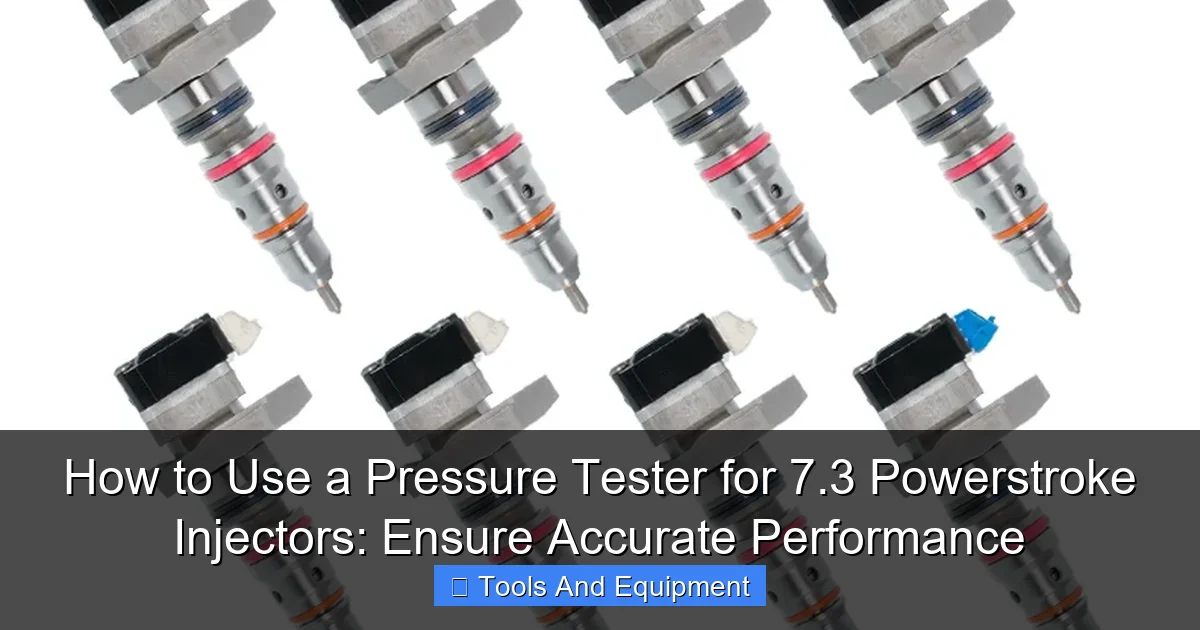

If you’re the proud owner of a Ford 7.3 Powerstroke, you know you’ve got a legendary workhorse under the hood. Known for its durability and immense torque, this iconic diesel engine has powered countless trucks through demanding tasks and long hauls. However, even legends need a little TLC, and the heart of the 7.3’s fuel delivery system – its injectors – are often the first place to look when performance starts to dip, fuel economy suffers, or that tell-tale rough idle emerges.

Faulty injectors can lead to a cascade of problems, from irritating smoke and power loss to costly engine damage if left unchecked. Diagnosing these issues accurately is paramount, and that’s where a specialized tool becomes indispensable: the 7.3 Powerstroke injector pressure tester. This isn’t just a fancy gadget; it’s a vital piece of equipment that empowers you to pinpoint injector woes with precision, saving you time, money, and headaches down the road.

In this comprehensive guide, we’ll dive deep into the world of 7.3 Powerstroke injector testing. We’ll explore why healthy injectors are so critical, demystify the pressure testing process, show you exactly how to use a pressure tester for 7.3 Powerstroke injectors, and help you interpret your results like a seasoned pro. Get ready to empower yourself with the knowledge to keep your 7.3 purring perfectly.

Quick Answers to Common Questions

What is How to use a pressure tester for 7.3 Powerstroke injectors?

How to use a pressure tester for 7.3 Powerstroke injectors refers to essential knowledge and techniques that can significantly improve your understanding and results.

Why is How to use a pressure tester for 7.3 Powerstroke injectors important?

Mastering How to use a pressure tester for 7.3 Powerstroke injectors provides practical benefits and helps you achieve better outcomes in various situations.

How does How to use a pressure tester for 7.3 Powerstroke injectors work?

How to use a pressure tester for 7.3 Powerstroke injectors involves specific methods and approaches that deliver effective results when applied correctly.

When should I use How to use a pressure tester for 7.3 Powerstroke injectors?

You can apply How to use a pressure tester for 7.3 Powerstroke injectors techniques whenever you need to improve your approach or achieve better results.

What are the benefits of How to use a pressure tester for 7.3 Powerstroke injectors?

Learning How to use a pressure tester for 7.3 Powerstroke injectors offers numerous advantages including improved efficiency, better results, and practical applications.

📋 Table of Contents

- Why Injector Health is Crucial for Your 7.3 Powerstroke: Keeping the Legend Alive

- Understanding the 7.3 Powerstroke Injector Pressure Tester: Your Diagnostic Partner

- Step-by-Step Guide: How to Use a Pressure Tester for 7.3 Powerstroke Injectors

- Interpreting Your Results: What the Numbers and Patterns Mean

- Beyond the Test Bench: Addressing Injector Issues & Preventative Care

- Essential Tools and Resources for 7.3 Powerstroke Enthusiasts

- Conclusion: Empowering Your 7.3 Powerstroke with Precision Diagnosis

Why Injector Health is Crucial for Your 7.3 Powerstroke: Keeping the Legend Alive

Your 7.3 Powerstroke is built tough, but its performance hinges on the precise operation of its fuel system, particularly the injectors. Unlike common rail systems, the 7.3 utilizes a Hydraulically Actuated Electronically Controlled Unit Injector (HEUI) system, which relies on high-pressure engine oil to atomize and inject fuel. When these sophisticated components falter, the entire engine suffers.

Learn more about How to use a pressure tester for 7.3 Powerstroke injectors – How to Use a Pressure Tester for 7.3 Powerstroke Injectors: Ensure Accurate Performance

Image source: injectorsdirect.com

Common Symptoms of Failing 7.3 Powerstroke Injectors

Recognizing the early warning signs of injector trouble can save you from more severe issues. Pay close attention to these indicators:

| Test Parameter | Ideal Reading / Observation | Problem Indication & Action |

|---|---|---|

| **Injector Pop-Off Pressure** | 2100-2400 PSI (145-165 Bar) | Below 1900 PSI (130 Bar): Weak spring or worn components. *Requires rebuild or replacement.* |

| **Spray Pattern** | Fine, atomized mist with a symmetrical conical shape. | Streaks, uneven pattern, or single stream: Clogged or worn nozzle. *Requires cleaning, rebuild, or replacement.* |

| **Nozzle Dribble/Leakage** | No immediate fuel drip or dribble after the pop-off. | Immediate or continuous drip: Worn nozzle seat. *Requires rebuild or replacement.* |

| **Visual Nozzle Condition** | Clean tip, no visible pitting, excessive carbon, or damage. | Pitting, heavy carbon, or physical damage: Indicates poor combustion or wear. *Affects performance, often requires replacement.* |

- Rough Idle: One of the most common signs, especially when cold.

- Excessive Smoke: White, blue, or black smoke from the exhaust can point to incomplete combustion due to poor injector spray.

- Loss of Power/Acceleration: A noticeable drop in engine responsiveness and overall power output.

- Decreased Fuel Economy: Injectors not spraying correctly can lead to wasted fuel.

- Engine Misfires or Hesitation: Irregular engine operation under load or acceleration.

- Hard Starts: Especially when the engine is cold, indicating potential issues with pop-off pressure or internal leakage.

- Increased Engine Noise: A noticeable “clatter” or “knock” that wasn’t there before.

Understanding the HEUI System and Injector Function

The 7.3 Powerstroke’s HEUI system is a marvel of engineering for its time. Here’s a quick breakdown of how it works and why injector integrity is paramount:

- The Injection Pressure Regulator (IPR) and Injection Control Pressure (ICP) sensor work together to regulate oil pressure from the High-Pressure Oil Pump (HPOP).

- This high-pressure oil (up to 3,000 PSI or more) is routed through the cylinder head to the injectors.

- Inside each 7.3 Powerstroke injector, the high-pressure oil acts on an intensifier piston, multiplying the force and generating an even higher pressure (up to 21,000 PSI) on the fuel.

- At the precise moment, the Powertrain Control Module (PCM) sends an electrical signal to the injector’s solenoid, which opens a poppet valve, allowing the high-pressure oil to actuate the intensifier piston.

- This forces fuel through the nozzle, creating a finely atomized spray into the combustion chamber.

Any disruption in this intricate process – be it a weak intensifier spring, a clogged nozzle, a leaking internal seal, or improper injector pop-off pressure – directly impacts fuel delivery, leading to the symptoms described above. Accurate 7.3 Powerstroke injector testing is the key to identifying these issues.

Understanding the 7.3 Powerstroke Injector Pressure Tester: Your Diagnostic Partner

A diesel injector tester is a specialized tool designed to evaluate the operational health of individual fuel injectors outside the engine. For your 7.3 Powerstroke, this typically means a bench-mounted unit that allows you to isolate and thoroughly inspect each injector.

Learn more about How to use a pressure tester for 7.3 Powerstroke injectors – How to Use a Pressure Tester for 7.3 Powerstroke Injectors: Ensure Accurate Performance

Image source: cdn11.bigcommerce.com

Components of a Typical Injector Pressure Tester

While designs can vary slightly, most pressure testers for 7.3 Powerstroke injectors share these core components:

- Hand Pump: A manual lever that allows you to gradually build pressure within the system.

- Pressure Gauge: Essential for monitoring the exact pressure at which the injector “pops” open and maintaining consistent pressure for leak tests.

- Fuel Reservoir/Container: Holds the specialized calibration fluid (or clean diesel) used for testing.

- Injector Holder/Mounting Fixture: A sturdy clamp or adapter designed to securely hold the injector during testing, typically with a drain tube to collect sprayed fluid.

- High-Pressure Line: Connects the pump to the injector fixture.

- Transparent Spray Chamber: A clear enclosure that allows you to safely observe the injector’s spray pattern and check for leaks.

Safety First: Essential Precautions Before You Begin

Working with high-pressure fuel systems, even on a bench, demands respect and adherence to safety protocols. Failing to do so can result in serious injury or damage.

- Wear Safety Glasses: Absolutely non-negotiable. Fuel spray under pressure can cause severe eye damage.

- Use Proper Test Fluid: Never use gasoline or other volatile fluids. Only use approved diesel calibration fluid or clean, filtered diesel fuel. Calibration fluid is preferred as it has better lubricating properties and a consistent viscosity.

- Ensure Ventilation: Work in a well-ventilated area to avoid inhaling diesel fumes.

- Keep Hands Clear: Never place your hands or fingers near the injector nozzle when pressurizing the system. High-pressure fluid can penetrate skin.

- Secure the Injector: Ensure the injector is firmly mounted in the fixture to prevent it from becoming a projectile.

- Cleanliness is Key: Diesel fuel systems are highly sensitive to contamination. Keep your workspace, tools, and the injectors themselves immaculately clean.

Step-by-Step Guide: How to Use a Pressure Tester for 7.3 Powerstroke Injectors

Now that you understand the “why” and “what,” let’s get down to the “how.” Follow these steps for accurate 7.3 Powerstroke injector testing.

Preparation: Removing and Cleaning Your Injectors

- Disconnect Battery: Always start by disconnecting the negative battery terminals.

- Relieve Fuel Pressure: Consult your service manual for the proper procedure.

- Remove Valve Covers: This is necessary to access the 7.3 Powerstroke injectors.

- Disconnect Electrical Connectors: Carefully unplug the injector harness connectors.

- Remove High-Pressure Oil Rail/Lines (if applicable): Some configurations may require this.

- Remove Injector Hold-Down Bolts: These secure the injectors in the cylinder head.

- Extract Injectors: Use an appropriate injector puller tool. Avoid prying, which can damage the injector or head. Label each injector by cylinder as you remove it.

- Initial Cleaning: Before testing, thoroughly clean the exterior of each injector. Use a brass brush, carb cleaner, or a dedicated injector cleaner to remove carbon buildup, oil, and debris. This prevents contamination of your test fluid and allows for better visual inspection. Pay close attention to the nozzle tip.

Setting Up Your Pressure Tester

- Mount the Tester: Place your pressure tester on a stable, level workbench.

- Fill the Reservoir: Pour clean calibration fluid or filtered diesel into the tester’s reservoir.

- Install the Injector: Securely mount the 7.3 Powerstroke injector into the tester’s holding fixture. Ensure it’s correctly seated and clamped.

- Bleed the System: Before your first test, pump the handle several times to purge any air from the system. You should see a steady stream of fluid from the nozzle.

Performing the Pop-Off Pressure Test

The injector pop-off pressure is the pressure at which the injector’s internal spring-loaded needle valve lifts, allowing fuel to spray. This is a critical indicator of spring tension and overall injector health.

- Pump Slowly: Gradually depress the pump handle on your tester. Watch the pressure gauge closely.

- Observe Pop-Off: The needle on the gauge will rise, then momentarily drop or flicker just as the injector sprays. The highest reading *just before* the spray begins is your pop-off pressure.

- Repeat for Accuracy: Perform this test 3-5 times for each injector, allowing the pressure to drop between tests. Note down the readings. Inconsistent readings can indicate stiction or internal issues.

Assessing the Spray Pattern

A proper spray pattern ensures efficient fuel atomization and complete combustion.

- Maintain Pressure: After achieving pop-off, continue to pump the handle at a moderate, consistent rate to maintain a steady spray.

- Observe the Spray: Look into the transparent spray chamber. A healthy 7.3 Powerstroke injector should produce a finely atomized, symmetrical cone-shaped mist. It should be uniform without visible streams, streaks, or a “shotgun” effect.

- Check for Consistency: Does the spray pattern look consistent across all repetitions and similar to other known-good injectors?

Checking for Leaks and Dribble

An injector that leaks or dribbles fuel, especially at lower pressures, can cause rough idle, poor emissions, and carbon buildup.

- Build Pressure Below Pop-Off: Slowly pump the tester until the pressure gauge reads just below the recorded pop-off pressure (e.g., 100-200 PSI below).

- Hold Pressure: Maintain this pressure for 10-15 seconds.

- Observe Nozzle Tip: Carefully watch the injector nozzle tip. There should be absolutely no fuel dripping, dribbling, or wetting of the nozzle tip. Any sign of fluid indicates an internal leak or a faulty nozzle seat.

Interpreting Your Results: What the Numbers and Patterns Mean

Once you’ve tested all your injectors, it’s time to make sense of the data. This interpretation is where you truly diagnose the issues.

Ideal Pop-Off Pressure Ranges for 7.3 Injectors

The specific pop-off pressure can vary slightly depending on the year and AD code of your 7.3 Powerstroke injectors. Generally, stock values fall within these ranges:

- Standard (Early 94-97): Approximately 2100-2300 PSI (often using AB, AD codes)

- Later (99-03): Approximately 2300-2600 PSI (often using AD, AE, AF codes)

What deviations indicate:

- Low Pop-Off Pressure: This is a strong indicator of a weak or worn internal spring, allowing the nozzle to open prematurely. This leads to poor atomization and incomplete combustion.

- High Pop-Off Pressure: Less common, but can suggest a sticking needle valve or excessive spring tension.

- Inconsistent Pop-Off Pressure: Readings that vary wildly from test to test on the same injector often point to stiction (internal friction) within the injector, possibly due to oil contamination or wear.

Decoding Spray Patterns: From Cone to Catastrophic

The visual inspection of the spray pattern is highly revealing:

- Ideal Spray: A finely atomized, symmetrical cone-shaped mist. It should look like a perfectly formed cloud with no visible streams.

- Streaky Spray: Visible lines or streams within the spray pattern. This suggests partially clogged nozzle holes or wear.

- Off-Center/Uneven Spray: The cone is not symmetrical or sprays more heavily on one side. This can be due to nozzle damage or uneven wear.

- “Shotgun” or Wide Spray: A very wide, poorly atomized spray, sometimes lacking the distinct cone shape. Indicates significant nozzle wear or damage.

- No Spray: The injector simply doesn’t pop off or produce any fuel. This is a clear sign of a completely stuck or failed injector.

What Dribble and Leaks Reveal

- Dribbling or Leaking: Any fuel dripping from the nozzle tip at pressures below pop-off (or even after the spray has stopped) is a critical failure. This means the nozzle cannot hold pressure, leading to fuel entering the cylinder at the wrong time, causing carbon buildup, smoke, and poor combustion. It can also dilute engine oil if the leak is severe.

- External Leaks: While less common during bench testing (as internal leaks are the focus), inspect for any visible leaks around the injector body or seals during the test.

7.3 Powerstroke Injector Specifications & Common Issues Table

This table provides a general overview. Always consult a factory service manual for exact specifications for your specific year and injector code.

| Injector Type/Code (Example) | Engine Year Range | Stock Pop-Off Pressure Range (PSI) | Common Issues Indicated by Test |

|---|---|---|---|

| AD (most common) | 1994.5 – 2003 | 2300 – 2600 | Stiction, low pop-off (weak spring), poor spray pattern (clogged/worn nozzle) |

| AE (larger volume, some late 99-03) | 1999 – 2003 | 2400 – 2700 | Similar to AD; stiction, nozzle wear, internal leaks |

| AB (early models) | 1994.5 – 1997 | 2100 – 2300 | Weak springs, inconsistent pop-off due to age, poor atomization |

Beyond the Test Bench: Addressing Injector Issues & Preventative Care

After you’ve identified which injectors are failing and how, what’s next? You have a few options, and proactive maintenance can help prevent future problems.

Repairing or Replacing Your 7.3 Powerstroke Injectors

Based on your test results, you’ll need to decide on the best course of action:

- Injector Rebuild Kits: For minor issues like worn o-rings (which cause external oil/fuel leaks, not typically detected by a pressure tester but good to replace), you can often purchase rebuild kits. For internal issues like nozzle wear or stiction, complete professional rebuilding or replacement is usually required.

- Nozzle Replacement: If only the spray pattern is bad due to a worn or clogged nozzle, new nozzles can be installed by a qualified shop.

- Remanufactured Injectors: This is a popular and cost-effective option. Reputable companies professionally rebuild 7.3 Powerstroke injectors to meet or exceed OEM specifications, often with updated components.

- New Injectors: The most expensive option, but ensures brand-new components and performance.

Important Note: It’s generally recommended to replace or rebuild all eight injectors at once. Even if only one or two are failing, the others are likely not far behind, and replacing them together ensures balanced fuel delivery across all cylinders.

Preventative Maintenance for Long-Lasting Injector Health

A few simple practices can significantly extend the life of your 7.3 Powerstroke injectors:

- Use High-Quality Fuel: Always fill up at reputable stations. Poor quality fuel can lead to deposits and wear.

- Regular Fuel Filter Changes: Clogged fuel filters restrict flow and can force the fuel pump to work harder, leading to contamination reaching the injectors. Adhere to your manufacturer’s recommended intervals.

- Utilize Fuel Additives: A good quality diesel fuel additive, especially those designed for injector cleaning and lubrication (e.g., anti-stiction additives), can help prevent common 7.3 Powerstroke injector problems.

- Maintain Engine Oil Quality: Since the HEUI system relies on engine oil, ensuring clean, high-quality oil with proper viscosity is crucial. Regular oil changes with suitable oil are non-negotiable.

- Monitor Oil Level: Low oil pressure can directly impact injector operation.

Essential Tools and Resources for 7.3 Powerstroke Enthusiasts

Beyond the pressure tester for 7.3 Powerstroke injectors, having a few other tools and knowing where to find reliable resources will make your diagnostic and repair journey smoother.

Additional Diagnostic Tools for Your 7.3

- OBD-II Scan Tool: A capable scan tool (like Forscan or AutoEnginuity with specific Ford PIDs) can read diagnostic trouble codes (DTCs), monitor live data (ICP pressure, IPR duty cycle, injector contribution tests), and aid in identifying which cylinders might be problematic.

- Multimeter: For checking injector solenoid resistance and electrical continuity in the wiring harness.

- Compression Tester: To rule out internal engine issues that might mimic injector problems.

- Injector Buzz Test: Most advanced scan tools can perform an injector buzz test, which cycles the injector solenoids to check their electrical function. This is a quick preliminary check.

Where to Find Reliable 7.3 Injector Parts and Services

When it comes to replacing or rebuilding your 7.3 Powerstroke injectors, choose reputable suppliers known for quality:

- OEM (Original Equipment Manufacturer): Ford/Motorcraft parts are always a safe bet for quality, though often the most expensive.

- Alliant Power: A major supplier of OEM-quality aftermarket diesel fuel system components, including injectors for the 7.3.

- Swamps Diesel: Highly respected in the Powerstroke community for their expertise and high-performance, as well as stock, injector solutions.

- Rosewood Diesel Shop: Another well-regarded specialist offering quality stock and performance injectors.

- Local Diesel Specialists: Find a reputable shop in your area that specializes in Powerstroke or diesel fuel injection systems. Their expertise can be invaluable.

Investing in quality parts and professional service (when needed) will ensure your 7.3 Powerstroke continues to perform reliably for years to come.

Conclusion: Empowering Your 7.3 Powerstroke with Precision Diagnosis

The 7.3 Powerstroke is a legendary engine, but its longevity and performance rely heavily on the health of its fuel injectors. Issues like rough idle, excessive smoke, and power loss are often direct symptoms of failing injectors, and accurately diagnosing these problems is crucial to maintaining your truck’s legendary status.

By understanding and mastering how to use a pressure tester for 7.3 Powerstroke injectors, you’re not just performing a repair; you’re investing in the future of your vehicle. This tool empowers you to precisely identify issues with injector pop-off pressure, spray patterns, and internal leaks, transforming guesswork into informed decisions. Couple this diagnostic power with diligent preventative maintenance, and you’ll ensure your 7.3 Powerstroke remains a dependable, powerful workhorse for countless miles ahead. Don’t let injector problems sideline your legend – take control with precision testing today!

Frequently Asked Questions

What is How to use a pressure tester for 7.3 Powerstroke injectors?

How to use a pressure tester for 7.3 Powerstroke injectors is an important topic with many practical applications and benefits.

How can How to use a pressure tester for 7.3 Powerstroke injectors help me?

Understanding How to use a pressure tester for 7.3 Powerstroke injectors can improve your knowledge and provide practical solutions.