How to Install a Performance Exhaust System on 6.0 Powerstroke: Boost Performance

Featured image for this comprehensive guide about How to install a performance exhaust system 6.0 Powerstroke

Image source: parkmuffler.com

How to Install a Performance Exhaust System on 6.0 Powerstroke: Boost Performance

If you’re a proud owner of a 6.0 Powerstroke, you already know the immense power and capability these engines offer. However, even the most robust machines have room for improvement. One of the most impactful and popular upgrades for this legendary diesel engine is installing a performance exhaust system. It’s not just about making your truck sound more aggressive; it’s about unlocking hidden power, improving efficiency, and enhancing the overall driving experience.

Many 6.0 Powerstroke owners seek to overcome common limitations of the factory exhaust, such as restrictive designs and excessive heat retention. A well-chosen aftermarket exhaust can transform your truck, providing benefits ranging from increased horsepower and torque to lower exhaust gas temperatures (EGTs), which can significantly extend the life of your engine. If you’re ready to take your Ford Super Duty to the next level, this comprehensive guide will walk you through everything you need to know about how to install a performance exhaust system 6.0 Powerstroke, ensuring you gain maximum performance and satisfaction.

This guide isn’t just a simple rundown; it’s a deep dive into the why and how of a 6.0 Powerstroke exhaust installation. We’ll cover choosing the right system, essential tools, a detailed step-by-step installation process, and crucial post-installation considerations. Get ready to turn wrenches and unleash the true potential of your diesel beast!

Quick Answers to Common Questions

What are the main benefits of installing a performance exhaust system on my 6.0 Powerstroke?

You’ll typically experience noticeable gains in horsepower and torque, improved exhaust flow, and often a boost in fuel efficiency. Plus, you get that awesome, aggressive exhaust note that truly unleashes your truck’s presence!

How difficult is it to install a performance exhaust system on a 6.0 Powerstroke for a DIY mechanic?

It’s generally a moderate DIY project that most mechanically inclined individuals can tackle with the right tools and patience. While it involves working under the truck, it’s very doable for a weekend warrior.

What basic tools will I need to tackle this performance exhaust system installation?

You’ll primarily need a good socket and wrench set, a cutting tool like a sawzall for removing the old system, penetrating oil, and safety equipment such as jack stands or a lift. A second pair of hands can also be incredibly helpful!

Roughly how much time should I set aside to install a performance exhaust system?

For a first-timer, plan for about 3-6 hours, depending on your experience and if you encounter any stubborn bolts. An experienced mechanic might get it done quicker, but it’s best not to rush it.

Do I need a special engine tune after installing a new performance exhaust system on my 6.0 Powerstroke?

While not always strictly required for all performance exhaust systems, many enthusiasts recommend a custom engine tune to fully optimize your engine’s performance gains and prevent potential check engine lights.

📋 Table of Contents

- Why Upgrade Your 6.0 Powerstroke Exhaust? Unlocking Hidden Potential

- Choosing the Right Performance Exhaust System for Your 6.0 Powerstroke

- Tools and Materials You’ll Need for the Installation

- Step-by-Step Guide: How to Install Your 6.0 Powerstroke Performance Exhaust

- Post-Installation Checks and Tuning Considerations

- Common Issues and Troubleshooting Tips

- Performance Data: Estimated Gains from a 6.0 Powerstroke Exhaust Upgrade

- Conclusion: Unleash Your 6.0 Powerstroke’s Roar!

Why Upgrade Your 6.0 Powerstroke Exhaust? Unlocking Hidden Potential

Before we dive into the nitty-gritty of installation, let’s understand why a performance exhaust upgrade is such a game-changer for your 6.0 Powerstroke. The factory exhaust system on most vehicles, including your Powerstroke, is designed to meet strict noise and emissions regulations. While effective at its intended purpose, this often means sacrificing optimal exhaust flow and efficiency.

Learn more about How to install a performance exhaust system 6.0 Powerstroke – How to Install a Performance Exhaust System on 6.0 Powerstroke: Boost Performance

Image source: ssnperformance.com

Improved Exhaust Gas Flow

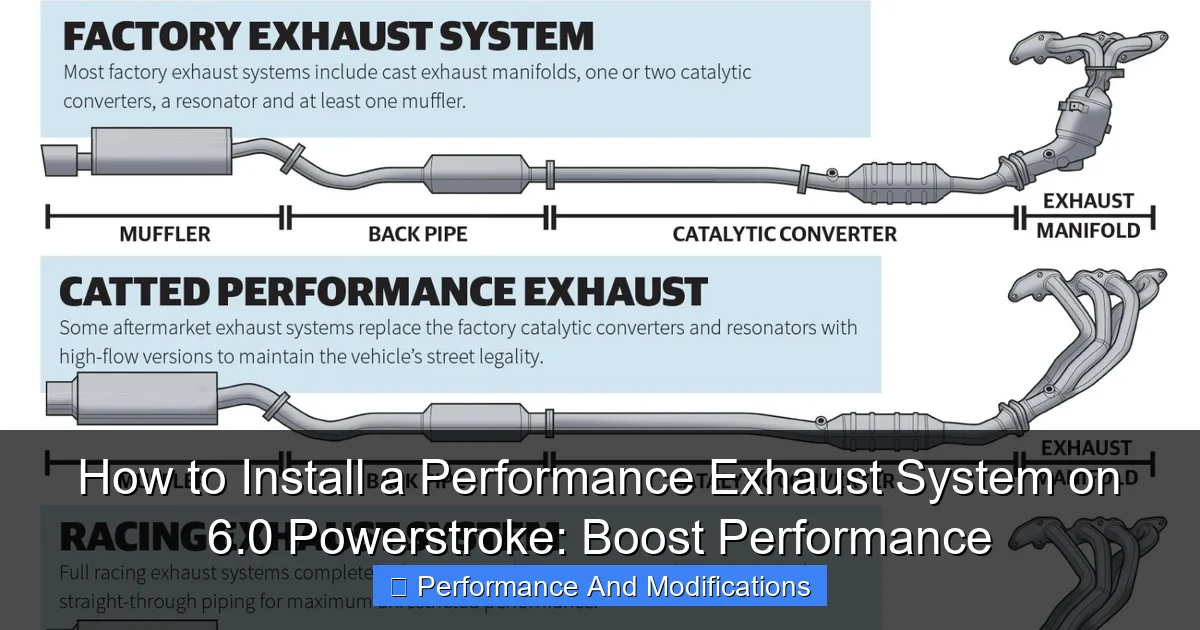

The primary benefit of a performance exhaust 6.0 Powerstroke is significantly improved exhaust gas flow. Factory systems often feature restrictive mufflers, small diameter piping, and catalytic converters that create backpressure. This backpressure can hinder the engine’s ability to efficiently expel exhaust gases, leading to decreased power and higher operating temperatures. An aftermarket system, typically with larger diameter, mandrel-bent tubing and less restrictive mufflers or a straight-pipe design, allows exhaust gases to exit more quickly and efficiently.

| Aspect of Modification | Description | Typical Value / Impact | Key Considerations for Installation |

|---|---|---|---|

| Installation Difficulty | General assessment for a DIY mechanic. | Moderate (requires basic mechanical skills) | Access to lift/jack stands is highly recommended; expect potential seized bolts on older vehicles. |

| Estimated Installation Time | Average time for a home mechanic with standard tools. | 2-4 Hours | Varies significantly with experience, rust levels, and availability of proper tools (e.g., cutting tools). |

| Performance Gains (HP/TQ) | Typical increases in horsepower and torque at the wheels. | +20-30 HP / +40-60 lb-ft TQ | Gains are most noticeable when paired with a performance tuner or other intake modifications. |

| Exhaust Gas Temperature (EGT) Reduction | Lowering exhaust gas temperatures for engine longevity and safety. | 100-200°F Lower | Crucial for towing heavy loads and preventing turbo/engine stress; contributes to overall engine health. |

| Fuel Economy Improvement | Potential increase in miles per gallon due to improved exhaust flow. | 1-2 MPG Increase | Highly dependent on driving style, specific exhaust system (e.g., muffler vs. delete), and engine tuning. |

| Sound Profile Change | Alteration in the exhaust note and overall engine sound. | Deeper, More Aggressive Tone | Muffler-delete systems will be loudest; resonator options can reduce drone for daily driving comfort. |

Increased Horsepower and Torque

By reducing backpressure and improving exhaust flow, your 6.0 Powerstroke engine can “breathe” better. This translates directly into tangible performance gains. Owners often report noticeable increases in both horsepower and torque after a diesel exhaust install. While exact figures vary depending on the specific system and other modifications, gains of 20-40 HP and 50-80 lb-ft of torque are not uncommon, making your truck feel more responsive and powerful, especially when towing or hauling heavy loads.

Lower Exhaust Gas Temperatures (EGTs)

One of the most critical benefits for a diesel engine like the 6.0 Powerstroke is the reduction in Exhaust Gas Temperatures (EGTs). High EGTs are a common concern for Powerstroke owners, as they can lead to premature wear and failure of critical engine components, particularly the turbocharger. A performance exhaust system, by allowing hot exhaust gases to escape more rapidly, helps to keep EGTs in check, promoting engine longevity and reliability. This is especially beneficial for trucks that work hard, tow frequently, or run custom tunes.

Enhanced Engine Sound and Aesthetics

Let’s be honest, part of the appeal of a 6.0 Powerstroke upgrade is the sound. A performance exhaust system often replaces restrictive mufflers with less restrictive designs or eliminates them entirely, giving your diesel a much deeper, more aggressive, and satisfying rumble. Beyond sound, many aftermarket systems offer polished tips and attractive finishes that enhance the truck’s overall aesthetic appeal, making it stand out from the crowd.

Choosing the Right Performance Exhaust System for Your 6.0 Powerstroke

The market offers a wide array of performance exhaust systems for the 6.0 Powerstroke, each with its own characteristics and benefits. Making the right choice involves understanding the different types available, materials, and what best suits your needs and local regulations.

Learn more about How to install a performance exhaust system 6.0 Powerstroke – How to Install a Performance Exhaust System on 6.0 Powerstroke: Boost Performance

Image source: eaperformance.com.au

Types of Exhaust Systems

When looking to install a performance exhaust system 6.0 Powerstroke, you’ll generally encounter two main categories:

- Cat-Back Exhaust Systems: These systems replace everything from the catalytic converter back to the tailpipe. They are generally the most common and street-legal option, as they retain the factory catalytic converter(s), thus complying with emissions regulations in most areas. A cat-back system will still provide significant improvements in flow, sound, and EGT reduction.

- Turbo-Back Exhaust Systems: These are the most comprehensive systems, replacing everything from the turbocharger back to the tailpipe. This often includes replacing or removing the catalytic converter and sometimes the DPF (Diesel Particulate Filter) if applicable (though the 6.0 Powerstroke typically doesn’t have a DPF, it’s good to be aware for other models). Turbo-back systems offer the maximum performance gains and EGT reduction due to the complete removal of all factory restrictions. However, be aware that removing emissions control devices (like catalytic converters) is illegal for street use in many jurisdictions and can result in significant fines and failure of emissions inspections. Always check your local laws before considering a turbo-back system that modifies or deletes emissions components.

Material Matters

The material of your exhaust system greatly impacts its durability, weight, and cost:

- Aluminized Steel: This is the most common and economical option. Aluminized steel offers good corrosion resistance, but it’s not as durable as stainless steel, especially in areas with road salt or harsh climates.

- 409 Stainless Steel: A step up from aluminized steel, 409 stainless offers superior corrosion resistance and durability at a moderate price point. It’s an excellent balance of performance and value for many owners.

- 304 Stainless Steel: This is the premium choice. 304 stainless steel provides the best corrosion resistance and longest lifespan, making it ideal for those in harsh environments or who plan to keep their truck for a very long time. It’s also the most expensive option.

Pipe Diameter and Muffler Design

Most 6.0 Powerstroke exhaust systems come in 4-inch or 5-inch diameters. Larger diameters generally allow for better flow and lower EGTs, but ensure the system is properly sized for your engine’s output. Muffler design also plays a crucial role in sound and flow. Options range from straight-through performance mufflers that offer a deep tone and minimal restriction to completely muffler-less “race” pipes for maximum flow and aggressive sound (again, check local noise ordinances).

Consider Your Goals and Budget

When selecting your exhaust system upgrade 6.0 Powerstroke, consider:

- Performance Goals: Are you looking for maximum power, or primarily EGT reduction and a better sound?

- Budget: Aluminized steel is cheapest, 304 stainless is most expensive.

- Local Regulations: Emissions and noise laws vary. Always ensure your chosen system complies with local requirements.

- Sound Preference: Listen to sound clips online if possible, as different brands and designs have unique tones.

Tools and Materials You’ll Need for the Installation

Before you begin the 6.0 Powerstroke exhaust installation, gather all necessary tools and materials. Having everything on hand will make the process much smoother and prevent unnecessary interruptions.

Essential Tools:

- Socket Wrench Set: Various sizes, including deep sockets, for manifold bolts, hangers, and clamps.

- Breaker Bar: For stubborn or rusted bolts.

- Torque Wrench: Essential for proper tightening of certain components.

- Penetrating Oil (e.g., WD-40, PB Blaster): Absolutely crucial for loosening rusted bolts and nuts. Apply generously beforehand.

- Pry Bar or Large Screwdriver: For prying off rubber exhaust hangers.

- Exhaust Hanger Removal Tool (Optional but Recommended): Makes removing rubber hangers much easier.

- Jack and Jack Stands or Vehicle Lift: For safely elevating the truck. Never work under a vehicle supported only by a jack.

- Safety Glasses and Gloves: Protect your eyes and hands from rust, debris, and sharp edges.

- Measuring Tape: To confirm pipe lengths and alignment.

- Sawzall or Angle Grinder with Cut-Off Wheel (if necessary): Some factory systems might need to be cut for removal, especially if they are a single welded piece.

- Wire Brush: To clean rust from bolts and mating surfaces.

Materials and Supplies:

- Your New Performance Exhaust System: Ensure all components are present and accounted for (pipes, mufflers, clamps, hangers, tips).

- Exhaust Sealant (Optional): For extra sealing at pipe connections, though good clamps usually suffice.

- Anti-Seize Compound: For threads of new clamps and bolts to prevent future seizing.

- Replacement Exhaust Hangers (Optional): If your existing rubber hangers are worn or damaged, consider replacing them. Many kits come with new hangers or suggest new ones.

Step-by-Step Guide: How to Install Your 6.0 Powerstroke Performance Exhaust

Now for the main event: learning how to install a performance exhaust system 6.0 Powerstroke. This process can be done in your driveway with basic tools, but a lift makes it considerably easier. Always prioritize safety!

Step 1: Safety First and Preparation

- Park on a Level Surface: Ensure your truck is on a flat, stable surface.

- Engage Parking Brake and Chock Wheels: Prevent the truck from rolling.

- Disconnect Battery (Optional but Recommended): For any electrical work or just as a general safety precaution.

- Elevate the Truck Safely: Use a jack to lift the front and rear of the truck, then secure it firmly on jack stands. Ensure it’s stable before going underneath.

- Allow Exhaust to Cool: Never work on a hot exhaust system. Give it plenty of time to cool down completely.

- Apply Penetrating Oil: Generously spray all nuts, bolts, and rubber hangers holding the factory exhaust in place. Let it soak for at least 30 minutes, or even overnight if possible for extremely rusted fasteners.

Step 2: Removing the Factory Exhaust System

- Locate and Loosen Clamps/Bolts: Starting from the catalytic converter (or turbocharger if installing a turbo-back system) work your way back. Loosen all clamps and bolts connecting the exhaust sections.

- Remove Rubber Hangers: Use your pry bar or exhaust hanger removal tool to carefully pry the rubber hangers off the metal pins attached to the frame. A little lubrication (silicone spray or soapy water) can help here.

- Disassemble and Remove Sections:

- You may need to support sections of the exhaust as you unbolt them to prevent them from falling.

- Some factory exhausts, particularly the tailpipe section, may be a single, large welded piece. You might need to cut this section into smaller, manageable pieces with a Sawzall or angle grinder to remove it from under the truck, especially if you have a crew cab or long bed. Be careful of fuel lines and wiring when cutting.

- Carefully lower and remove each section of the old exhaust. It might be heavy and awkward.

Step 3: Installing the New Performance Exhaust System

It’s generally easiest to begin installation from the front of the truck and work your way back. Do not fully tighten any clamps or bolts until the entire system is mocked up and properly aligned.

- Install the Front Pipe/Downpipe:

- If your kit includes a new downpipe from the turbo, connect it to the turbo outlet using the provided flange and bolts. Ensure a good seal with a new gasket if supplied.

- If it’s a cat-back system, connect the first pipe to the catalytic converter outlet.

- Hand-tighten clamps only.

- Connect Mid-Pipes and Muffler (if applicable):

- Slide the next pipe section into the front pipe, ensuring it aligns correctly.

- If your system includes a muffler, install it now, ensuring the flow direction is correct (indicated by an arrow on the muffler).

- Re-attach any rubber hangers to their frame mounting points.

- Hand-tighten all clamps.

- Install the Over-Axle Pipe:

- This section can sometimes be tricky. Carefully maneuver the pipe over the rear axle, ensuring adequate clearance from suspension components, brake lines, and the fuel tank.

- Connect it to the previous section and attach any relevant hangers.

- Hand-tighten clamps.

- Install the Tailpipe and Exhaust Tip:

- Slide the tailpipe into position, ensuring it exits cleanly from under the truck.

- Connect it to the over-axle pipe and attach all remaining rubber hangers.

- Install the exhaust tip, if it’s a separate component. Position it to your aesthetic preference.

- Hand-tighten all clamps.

Step 4: Alignment and Final Tightening

- Check Alignment and Clearance:

- Once the entire system is loosely assembled, stand back and visually inspect its alignment. Ensure it’s straight, centered, and has ample clearance from all frame components, suspension, fuel lines, wiring, and the spare tire.

- Jiggle the exhaust by hand to ensure no metal-on-metal contact anywhere.

- Make any necessary adjustments by rotating pipes within the clamps or slightly adjusting hanger positions.

- Tighten All Clamps and Bolts:

- Starting from the front (turbo/cat connection) and working your way back, progressively tighten all exhaust clamps and bolts.

- For manifold bolts (if removed), use a torque wrench to tighten to factory specifications.

- Ensure all clamps are securely fastened to prevent leaks and rattles. Don’t overtighten, as this can damage the pipes or clamps, but ensure they are snug.

Post-Installation Checks and Tuning Considerations

Congratulations, you’ve completed the physical installation of your new 6.0 Powerstroke performance exhaust! But the job isn’t quite finished. A few critical steps remain to ensure optimal performance and longevity.

Post-Installation Checks

- Lower the Truck and Start the Engine:

- Carefully lower your truck off the jack stands.

- Start the engine and listen for any exhaust leaks. You might hear a slight ticking or hissing sound if there’s a leak. A simple trick is to put your hand (wearing a glove!) near the connections to feel for escaping gas, or use soapy water to look for bubbles.

- If you find a leak, re-tighten the responsible clamp. If the leak persists, you might need to disassemble that section, re-seat the pipes, and re-tighten.

- Check for Rattles and Vibrations:

- With the engine running, listen for any new rattles, clunks, or vibrations. This often indicates contact between the exhaust pipe and the frame, heat shield, or other components.

- If you hear any, get back under the truck (safely!) and adjust the exhaust system to increase clearance. Sometimes a slight rotation of a pipe or adjusting a hanger can fix this.

- Take it for a Test Drive:

- Go for a short drive, paying attention to the new sound and feel of the truck.

- After the drive, re-check all clamps and hangers. Heat cycling can sometimes cause things to loosen slightly. Re-tighten as needed.

Tuning Considerations for Your 6.0 Powerstroke

While a performance exhaust provides significant benefits on its own, pairing it with appropriate engine tuning can unlock even more potential from your 6.0 Powerstroke upgrade. This is particularly true if you’ve installed a turbo-back system that removes emissions components.

- Engine Tuning: A custom tune can optimize fuel delivery, turbocharger response, and shift points to take full advantage of the reduced backpressure and increased exhaust flow. This can lead to even greater horsepower and torque gains, improved throttle response, and better fuel efficiency.

- EGT Management: While the exhaust itself lowers EGTs, a proper tune can further optimize this, especially if you’re planning on heavy towing or performance driving.

- Check Engine Lights (CEL): If your performance exhaust system removed sensors (e.g., O2 sensors, if your specific 6.0 model had them in the exhaust stream for certain functions or if you’re deleting cats), a custom tune is essential to prevent check engine lights and ensure the engine operates correctly.

Consult with a reputable diesel tuner who specializes in the 6.0 Powerstroke to discuss tuning options after your exhaust system upgrade 6.0 Powerstroke.

Common Issues and Troubleshooting Tips

Even with careful installation, you might encounter a few minor hiccups. Here are some common issues and how to troubleshoot them when you install performance exhaust system 6.0 Powerstroke.

Exhaust Leaks

- Symptom: Hissing sound, black sooty residue around connections.

- Fix: Loosen affected clamps, ensure pipes are fully seated and aligned, then re-tighten. Sometimes, a small amount of exhaust sealant can help, but proper fitment and tight clamps are key.

Rattles or Vibrations

- Symptom: Metal-on-metal contact sounds, unusual vibrations felt in the cabin or steering wheel.

- Fix: Get under the truck and visually inspect the entire exhaust path. Look for areas where the pipe is too close to the frame, heat shields, crossmembers, or other components. Adjust the hangers, rotate pipe sections, or gently bend hangers to create more clearance. Ensure the tailpipe is not touching the spare tire.

Check Engine Light (CEL)

- Symptom: CEL illuminated on the dashboard.

- Fix: This is most common if you’ve installed a system that removes emissions components (like catalytic converters) without a corresponding tune. The engine’s computer will detect missing sensors or out-of-range readings. A custom ECM tune specifically for your exhaust setup is almost always required to address this. Consult a professional diesel tuner.

Poor Fitment

- Symptom: Pipes don’t line up easily, excessive force is needed to connect sections.

- Fix: Double-check that you have the correct system for your truck’s cab and bed configuration (e.g., Crew Cab Short Bed, Extended Cab Long Bed). Sometimes, parts are mislabeled, or a small manufacturing tolerance means you need to loosen almost everything and start the alignment process again, slightly adjusting each section. Don’t force components too much, as this can lead to stress points and future cracks.

Excessive Noise or Drone

- Symptom: The exhaust is louder than desired, or there’s an unpleasant “drone” inside the cabin at certain RPMs.

- Fix: This is subjective. If it’s too loud, consider adding a resonator or a more restrictive muffler. Some systems offer different muffler options. Drone can sometimes be mitigated by adjusting the tailpipe exit angle or adding an exhaust tip designed to break up sound waves.

Performance Data: Estimated Gains from a 6.0 Powerstroke Exhaust Upgrade

While exact numbers can vary significantly based on the specific exhaust system, other engine modifications, and tuning, here’s a general idea of the estimated performance improvements you can expect after a high-quality performance exhaust 6.0 Powerstroke installation:

| Performance Metric | Stock 6.0 Powerstroke (Typical) | With Performance Exhaust (Estimated) | Estimated Gain / Improvement |

|---|---|---|---|

| Horsepower (HP) | 325 HP | 345 – 365 HP | +20 to +40 HP |

| Torque (lb-ft) | 560 lb-ft | 610 – 640 lb-ft | +50 to +80 lb-ft |

| Exhaust Gas Temperatures (EGTs) | ~1200-1400°F (Under Load) | ~1000-1200°F (Under Load) | 100-200°F Reduction |

| Fuel Economy (MPG) | 13-16 MPG (Combined) | 14-17 MPG (Combined) | +0.5 to +1.5 MPG (Variable) |

Note: These figures are estimates and can vary based on vehicle condition, specific exhaust system, driving habits, and other modifications. Horsepower and torque gains are often more significant when combined with appropriate engine tuning. EGT reduction is a critical benefit for engine longevity.

Conclusion: Unleash Your 6.0 Powerstroke’s Roar!

Upgrading your 6.0 Powerstroke exhaust system is one of the most rewarding modifications you can undertake. Not only does it significantly improve the sound and aesthetic appeal of your truck, but it also delivers tangible performance benefits, including increased horsepower and torque, and crucially, lower EGTs for enhanced engine reliability. By following this comprehensive guide on how to install a performance exhaust system 6.0 Powerstroke, you’ve gained the knowledge and confidence to tackle this project yourself.

Remember, patience, the right tools, and a focus on safety are your best allies during installation. Take your time, double-check all connections, and enjoy the satisfaction of knowing you’ve unlocked the true potential of your diesel powerhouse. Once installed, you’ll immediately notice the difference: a deeper rumble, more responsive acceleration, and the peace of mind that comes with a cooler running engine. Get ready to experience your 6.0 Powerstroke in a whole new, exhilarating way!

🎥 Related Video: PROOF Exhaust tips DO change the sound of your car 🧢

📺 Straight Piped by: Gexhaust

Frequently Asked Questions

Why should I install a performance exhaust system on my 6.0 Powerstroke?

Installing a performance exhaust system on your 6.0 Powerstroke can significantly enhance its horsepower and torque by reducing exhaust back pressure, allowing the engine to breathe more efficiently. You’ll also likely experience lower exhaust gas temperatures (EGTs), a more aggressive exhaust note, and potentially improved fuel economy.

Is special equipment required to install a performance exhaust system on a 6.0 Powerstroke?

While basic hand tools such as wrenches, sockets, and a cutting tool (like a sawzall) are typically sufficient, having access to a vehicle lift or sturdy jack stands will make the installation much safer and easier for your 6.0 Powerstroke. A can of penetrating oil and a pry bar can also be invaluable for removing stubborn factory components.

How long does it typically take to install a performance exhaust system on a 6.0 Powerstroke?

For individuals with moderate mechanical experience, installing a performance exhaust system on a 6.0 Powerstroke generally takes between 2 to 4 hours. This timeframe can vary based on the condition of your existing exhaust, the specific kit, and the tools you have available.

Do I need to tune my 6.0 Powerstroke after installing a new performance exhaust system?

While not strictly necessary for all systems (especially cat-back designs), a custom tune is highly recommended to fully optimize the benefits of a performance exhaust system on your 6.0 Powerstroke, particularly turbo-back kits. A tune can recalibrate your engine’s parameters to take full advantage of the improved exhaust flow, potentially further increasing horsepower and improving drivability.

What are the potential challenges when installing a performance exhaust on a 6.0 Powerstroke?

Common challenges include rusted or seized bolts, especially on older 6.0 Powerstroke models, which can require significant effort, heat, or cutting for removal. Maneuvering the long exhaust pipes around the truck’s frame, crossmembers, and suspension components can also be tricky without adequate clearance or an extra set of hands.

Will installing a performance exhaust system impact my 6.0 Powerstroke’s emissions or warranty?

Installing certain performance exhaust systems, particularly those that modify or remove catalytic converters or DPFs, may affect your 6.0 Powerstroke’s emissions compliance and could potentially void portions of your factory warranty. It is crucial to check local regulations and your vehicle’s warranty policy before making such modifications.