Mastering the Art of Aligning Your Starter with Flywheel – A Step by Step Guide

Have you ever tried starting your car, only to hear a high-pitched screeching noise? This could be a sign that your starter and flywheel are misaligned. If it’s the case, then you’ll inevitably need to know how to align them if you want to get your vehicle back on the road. Aligning your starter with the flywheel is a crucial process, and it requires a bit of know-how.

Fortunately, with the right approach, it is a relatively simple task that you can do yourself. All you need is a few tools and a little know-how. Some people assume that they cannot do it unless they are mechanics or DIY enthusiasts.

However, with the right instructions and mindset, you can align starters with flywheels with ease. All it takes is a bit of patience and attention to detail. And it could save you money and time otherwise wasted on consulting a mechanic.

In this blog post, we will give you a step-by-step guide on how to align a starter with a flywheel. We’ll also cover the potential obstacles you may face and provide tips to help you get it done quickly and without breaking a sweat. So, whether you’re a beginner or a seasoned pro, keep reading to learn how to align your starter with a flywheel.

Tools You’ll Need

If you’re looking to align your starter with the flywheel, there are a few tools you’ll need to make sure you’re prepared. Firstly, you’ll need a set of wrenches that fit the bolts that hold your starter and flywheel in place. You might also need a socket and ratchet to loosen and tighten these bolts, depending on your particular vehicle.

In addition to these tools, you’ll want to have safety goggles and gloves to protect your hands and eyes, as well as a flashlight or work light to ensure you have a clear view of the engine. With these tools in hand, you can start the process of aligning the starter with the flywheel and getting your vehicle back up and running smoothly. Remember, taking the time to properly align these components can prevent costly damage down the road and keep your car running smoothly for years to come.

Socket Wrench

Socket wrench is a hand tool that every DIY enthusiast should have in their toolkit. This versatile tool allows you to tighten and loosen bolts and nuts with ease. When it comes to selecting a socket wrench, you’ll find a wide range of options on the market.

It’s important to choose one that fits your specific needs. A good quality socket wrench set can last a lifetime if taken care of properly, so it’s definitely worth investing in a high-quality one. You’ll need sockets that fit the bolts and nuts you wish to work on, as well as a handle with a comfortable grip.

A ratcheting socket wrench is a convenient option that enables quick tightening or loosening of bolts. Furthermore, it’s recommended to opt for a set with a variety of socket sizes, ranging from small to large, so that you have the flexibility to tackle a broad range of projects.

Socket Set

If you’re planning on doing some repairs or maintenance on your car or any mechanical item, having a good socket set is essential. A socket set typically includes a range of sockets, ratchets, extension bars, and other accessories. These tools come in different sizes and types, so it’s important to choose a set that suits your needs.

One of the primary factors to consider is the type of bolts or nuts you will be working with. Most socket sets are designed for standard, metric, or both, so ensure that you get the right one. Another consideration is the quality of the set, as you don’t want to go for the cheapest option and have tools that break easily.

A good socket set can last for years when properly cared for, and it’s an investment that will pay for itself in the long run.

Torque Wrench

If you plan on tackling some automotive repairs or maintenance, investing in a torque wrench is essential. This tool is designed to measure the amount of force applied to a bolt so that you can ensure that it’s tightened to the manufacturer’s specifications. To use a torque wrench, you’ll need a few additional tools as well.

First and foremost, you’ll need a set of sockets that fit the bolts you’re working on. You’ll also need a ratchet or breaker bar to turn the wrench and a combination wrench for holding the bolt steady while you turn the nut. Additionally, it’s always helpful to have a good set of pliers and a wire brush on hand for cleaning and tightening.

Using a torque wrench can help you avoid over or under-tightening bolts, which could lead to costly and even dangerous problems down the road. With the right tools and a bit of practice, you’ll be able to tackle any job with confidence and precision.

Steps to Follow

Aligning the starter with the flywheel is an essential task to perform to ensure your vehicle starts smoothly every time. Here are the steps to follow to align starter with the flywheel correctly. First, ensure the battery is disconnected, and the vehicle is jacked up and supported safely.

Then, locate the starter and remove any wires attached to it, followed by removing the starter from the vehicle. Next, find the starter’s pinion gear and align it with the flywheel’s teeth. You can use a screwdriver or pry bar to maneuver the pinion gear into the correct position.

Once aligned, reattach the starter wires and secure the starter to the vehicle. Finally, reconnect the battery and test the vehicle to ensure it starts correctly. Taking the time to align the starter with the flywheel correctly will save you time and hassle in the long run.

Step 1: Disconnect the Battery

If you’re planning to work on your car’s electrical system, the first step is to disconnect the battery. This is a critical step that should not be overlooked. It’s essential to disconnect the battery to prevent any electrical shock, short circuits, or damage to the electrical system.

Make sure you have the correct tools and safety equipment before starting. Depending on the car model, the battery’s location may vary, but it’s usually found under the hood or in the trunk. Begin by locating the battery and identifying the positive and negative terminals.

The positive terminal is usually labeled with a “+” sign, while the negative terminal is labeled with a “-” sign. Once you’ve identified the terminals, use a wrench to loosen the negative terminal’s nut or bolt. Remove the negative cable from the terminal and place it away from the battery to prevent it from accidentally touching the terminal.

After disconnecting the negative terminal, move on to the positive terminal. Use the same steps to loosen the positive terminal’s nut or bolt and remove the cable from the terminal. Once both cables are disconnected, double-check to ensure they are not touching any metal parts, especially the other terminal.

You can also cover the ends of the cables with electrical tape for added security. In conclusion, disconnecting the battery is a crucial step in working on your car’s electrical system. It’s a simple process that can prevent significant damage or electrical shock.

Remember to take your time and use the proper tools and safety equipment. Develop a habit of disconnecting the battery before working on your car’s electrical system to ensure your safety, and avoiding any potential damage.

Step 2: Locate the Starter and Flywheel

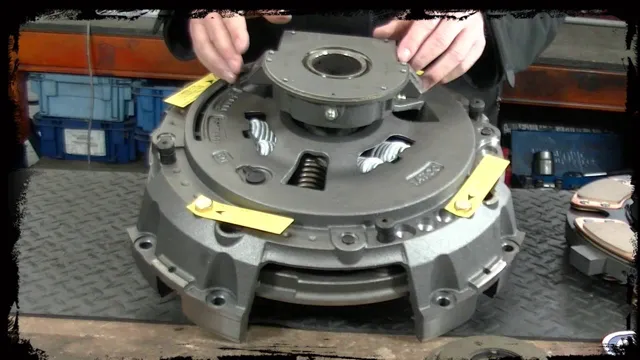

Once you have your vehicle lifted and secured, the next step in installing a new starter is to locate the starter and flywheel. The starter motor is typically located at the back of the engine, near the transmission. You’ll need to identify the starter, which looks like a small cylinder with wires attached to it, and also locate the flywheel.

The flywheel is a large round metal disk located at the rear of the engine. It engages with the starter to turn the engine over when you turn the key in the ignition. To locate the flywheel, you’ll need to look at the back of the engine and follow the transmission to find the large circular object.

It’s essential to identify these two parts before attempting to replace the starter. Once you have located both the starter and flywheel, you are ready to move on to the next step of the installation process. Remember to take your time and be careful when working around the engine and transmission to avoid injury.

Step 3: Loosen Starter Bolts

When it comes to replacing a starter on your car, there are several crucial steps to follow. One of these is to loosen the starter bolts. These bolts are what keep the starter attached to the engine, so it’s important to proceed with care.

Typically, the starter bolts will be located towards the bottom of the starter and will require a socket wrench to loosen. Be sure to consult your car’s manual to determine the exact location of the bolts and the appropriate size wrench to use. Once you have the right tools on hand, proceed to carefully loosen each bolt.

It’s important not to remove them completely at first, as this could cause the starter to drop or become misaligned. Instead, loosen them just enough to allow you to remove the starter when the time comes. By taking this step cautiously, you’ll help ensure a smooth and safe replacement process.

Step 4: Adjust Starter Alignment

When it comes to installing a starter, adjusting its alignment is a crucial step. This ensures that the starter’s gear meshes properly with the flywheel teeth and helps prevent damage to both components. To adjust the starter alignment, loosen the two mounting bolts and wiggle the starter into the desired position.

Use a pry bar if necessary to align it with the flywheel teeth. Once properly aligned, tighten the mounting bolts to secure the starter in place. It’s important to note that over-tightening the bolts can cause damage to the starter or the engine block, so make sure to follow the manufacturer’s recommended torque specifications.

By properly adjusting the starter alignment, you can ensure that your engine will start smoothly and efficiently every time.

Step 5: Tighten Starter Bolts

After installing your starter motor, it’s important to properly tighten the bolts to ensure it stays in place and functions efficiently. This final step is crucial for preventing the starter from loosening over time and causing further issues down the road. Firstly, use a torque wrench to set the proper torque specifications for your specific vehicle.

Then, proceed to tighten all the bolts in a criss-cross pattern to ensure even distribution of pressure. Applying a small amount of thread locker on the bolts before tightening can also help to prevent them from loosening due to vibrations. With the starter bolts finally tightened, your vehicle should be ready to start up smoothly without any issues.

Always refer to your manufacturer’s instructions for specifications on tightening the bolts, and never hesitate to ask for professional help if needed.

Step 6: Reconnect Battery

Now that you’ve successfully installed your new car battery, it’s time to reconnect the battery cables. Before doing so, it’s important to make sure that all the systems in your car are turned off, including the headlights, interior lights, and radio. This will prevent any sudden surges of electricity that could damage the new battery.

Begin by connecting the positive cable to the positive terminal of the battery and then connect the negative cable to the negative terminal. Tighten the bolts using a wrench and make sure that the cables are securely attached. Once all the cables are connected, it’s time to start your car and ensure that it starts up smoothly.

If there are any issues, double-check the cables and connections to make sure everything is secure. By following these simple steps, you can save yourself time and money by replacing your own car battery.

Benefits of Proper Alignment

Proper alignment is crucial when working with starter motors and flywheels. If they are not correctly aligned, it can cause a host of problems, including damage to both components and the engine itself. To align a starter motor with the flywheel, you need to make sure that the starter’s gear teeth mesh correctly with the flywheel’s teeth.

If the starter and flywheel are not lined up accurately, the gear teeth will not mesh correctly, causing excessive wear and eventual failure. In addition, an incorrectly aligned starter motor can result in abnormal noise during the starting process, improper starter engagement, and electrical overload of the starter motor. Therefore, it is essential to ensure proper alignment to prevent these issues.

By following simple tips and techniques, such as checking for proper shim thickness and ensuring that the starter and flywheel are mounted correctly, you can align your starter motor with the flywheel effectively. Proper alignment of the starter motor with the flywheel is critical to ensure reliable and efficient engine performance and prolong its lifespan.

Eliminates Grinding Noises

Proper alignment of your vehicle’s wheels can bring a wealth of benefits, including eliminating those annoying grinding noises that can occur when you’re driving. But beyond just preventing wear on your tires and suspension, there are a number of ways that having your wheels aligned can improve your driving experience. For one, it can help improve your vehicle’s handling, making it easier to control and maneuver.

Proper alignment can also help extend the lifespan of your tires, reducing the need for costly replacements and preventing unexpected blowouts on the road. So if you haven’t had your wheels aligned recently, it might be worth considering a trip to the mechanic to reap all the benefits that proper alignment can offer.

Prevents Starter Damage

Proper wheel alignment has many benefits, one of which is preventing starter damage. When your wheels are misaligned, they can cause undue stress on your vehicle’s starter, causing it to wear out prematurely. This leads to costly repairs that could have been avoided.

By ensuring your wheels are properly aligned, you can reduce the strain on your car’s starter and extend its lifespan. Plus, with a properly aligned vehicle, you’ll notice improved handling and steering, providing a safer driving experience overall. Don’t wait until it’s too late; schedule an alignment check with your mechanic today and reap the benefits of a properly aligned vehicle.

Increases Engine Performance

Proper alignment is vital to the overall performance of your engine. It may seem like a minor issue, but misalignment can lead to various problems that can affect the power and efficiency of your engine. For instance, when the wheels are not aligned correctly, your engine has to work harder, which can lead to increased fuel consumption and cause it to wear out faster.

Additionally, misalignment can cause your tires to wear unevenly, reducing their lifespan and affecting your overall safety on the road. On the other hand, when your vehicle is correctly aligned, your engine will run smoothly, making your ride enjoyable and efficient. Your engine will require less effort, reducing fuel consumption and increasing its lifespan.

Therefore, it’s vital to make sure your vehicle is appropriately aligned to keep your engine running smoothly.

Conclusion

In conclusion, aligning the starter with the flywheel may seem like a daunting task, but with a little patience and finesse, anyone can become a pro at it. Think of it like a game of darts – you want to aim for the bullseye, but it takes practice and precision to hit your mark. So, get your tools ready, take a deep breath, and aim for that sweet spot.

Your engine (and your ego) will thank you for it!”

FAQs

What tools do I need to align the starter with the flywheel?

Generally, you will need a socket wrench and possibly a pry bar or crowbar to properly align the starter with the flywheel.

Is it necessary to disconnect the battery before aligning the starter with the flywheel?

Yes, it is always necessary to disconnect the battery before working on any electrical components, including the starter. This is for safety reasons to avoid potential electric shock.

How do I know if the starter is misaligned with the flywheel?

If you hear a grinding or clicking noise when starting your engine, this may indicate that the starter is not properly aligned with the flywheel.

Can I align the starter with the flywheel myself or do I need a professional mechanic?

It is possible to align the starter with the flywheel yourself, but if you are not comfortable working with mechanical components, it is best to consult a professional mechanic to avoid potentially damaging your engine.