Ford 7.3 Powerstroke Turbo Boost Pressure: What’s the Optimal Level?

Featured image for this comprehensive guide about Ford 7.3 Powerstroke turbo boost pressure

Image source: rasekhoon.net

Ford 7.3 Powerstroke Turbo Boost Pressure: What’s the Optimal Level?

Ah, the legendary Ford 7.3 Powerstroke. For many truck enthusiasts, it’s not just an engine; it’s a way of life. Known for its rugged durability, impressive torque, and an exhaust note that sends shivers down your spine, the 7.3 Powerstroke has earned its reputation as one of the greatest diesel engines ever built. But even legends need a little attention to perform at their peak, and when it comes to unleashing the full potential of your 7.3, understanding turbo boost pressure is absolutely critical.

Your truck’s turbocharger is essentially its lungs, force-feeding more air into the engine to create more power and efficiency. The amount of pressure this turbo creates – its boost pressure – directly impacts how well your 7.3 breathes, performs, and even lasts. Too little boost, and your truck feels sluggish; too much without proper support, and you risk damage. So, what’s the sweet spot? What’s the optimal Ford 7.3 Powerstroke turbo boost pressure, and how can you ensure your workhorse is hitting it consistently?

In this comprehensive guide, we’re diving deep into the world of 7.3 Powerstroke turbo pressure. We’ll explore how boost works, what ideal levels look like for stock and modified trucks, common issues that can plague your turbo system, and actionable steps to diagnose, troubleshoot, and even upgrade your setup for maximum performance and longevity. Whether you’re a seasoned diesel mechanic or a proud new owner of a 7.3 Powerstroke, get ready to unlock the secrets to optimal boost and keep your rig running strong for years to come.

Quick Answers to Common Questions

What’s a normal Ford 7.3 Powerstroke turbo boost pressure range?

For a stock Ford 7.3 Powerstroke, you’ll typically see **turbo boost pressure** ranging from 15-20 PSI under heavy acceleration. This is a healthy indication that your turbocharger is working efficiently.

How do I check my Ford 7.3 Powerstroke turbo boost pressure?

The easiest way to monitor your **Ford 7.3 Powerstroke turbo boost pressure** is by installing an aftermarket boost gauge. While some OBD-II scanners can display it, a dedicated mechanical or electronic gauge offers real-time, accurate readings.

Is low Ford 7.3 Powerstroke turbo boost pressure always a bad sign?

Consistently low **Ford 7.3 Powerstroke turbo boost pressure** during acceleration can indicate issues like boost leaks, a faulty wastegate, or a struggling turbo. It’s definitely something to investigate if you notice a drop!

What’s considered “too much” Ford 7.3 Powerstroke turbo boost pressure?

While modified 7.3s can handle more, exceeding 25-30 PSI without proper engine modifications can put excessive strain on your engine components. Sustained high **Ford 7.3 Powerstroke turbo boost pressure** above stock levels should be approached with caution.

Can I increase my Ford 7.3 Powerstroke turbo boost pressure for more power?

Yes, many owners modify their 7.3L Powerstrokes to increase boost for improved performance, often through tuning or turbo upgrades. However, always ensure your engine is properly prepared to handle the added **Ford 7.3 Powerstroke turbo boost pressure** to prevent damage.

📋 Table of Contents

- Understanding Turbo Boost in Your 7.3 Powerstroke

- What’s the Optimal Ford 7.3 Powerstroke Turbo Boost Pressure?

- Common Causes of Low 7.3 Powerstroke Boost

- Diagnosing and Troubleshooting 7.3 Powerstroke Boost Issues

- Upgrading Your 7.3 Powerstroke Turbo System for More Boost

- Maintaining Optimal Boost: Proactive Tips for Your 7.3 Powerstroke

- Conclusion

Understanding Turbo Boost in Your 7.3 Powerstroke

Before we talk about optimal levels, let’s briefly demystify what turbo boost actually is and how it benefits your 7.3 Powerstroke. In simple terms, a turbocharger is an air compressor powered by exhaust gases. Instead of relying solely on atmospheric pressure, which is what naturally aspirated engines do, a turbo forces more air into the engine’s cylinders.

Learn more about Ford 7.3 Powerstroke turbo boost pressure – Ford 7.3 Powerstroke Turbo Boost Pressure: What’s the Optimal Level?

Image source: cdnmedia.baotintuc.vn

How a Turbocharger Works

- Exhaust Gases In: Hot exhaust gases leaving the engine spin a turbine wheel.

- Compressor Spins: This turbine is connected by a shaft to a compressor wheel. As the turbine spins, the compressor also spins rapidly.

- Air Compression: The spinning compressor draws in fresh air from the air filter and compresses it, increasing its density and pressure.

- Boost to the Engine: This compressed, pressurized air (known as “boost”) is then pushed into the intake manifold and, subsequently, into the engine’s combustion chambers.

More air means more oxygen, which allows for more fuel to be burned efficiently, resulting in a significant increase in horsepower and torque – especially at higher RPMs. For your Ford 7.3 Powerstroke, the turbocharger is a non-negotiable component for its power output and characteristic feel.

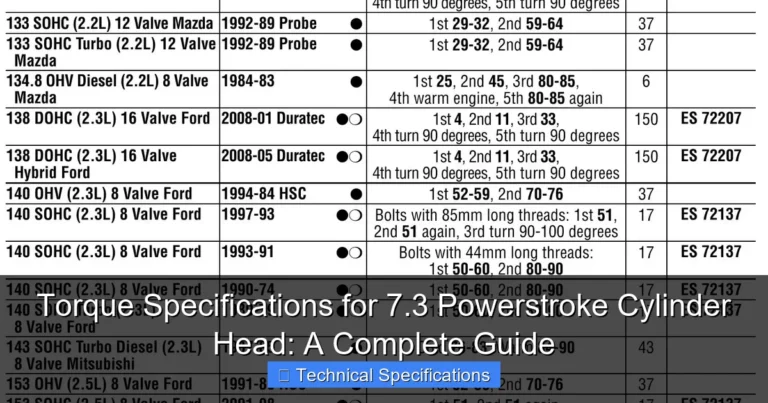

| Condition / Specification | Boost Pressure (psi) | Notes / Context |

|---|---|---|

| Stock (OEM) Max Boost | 18 – 22 | Typical maximum boost under Wide Open Throttle (WOT) from the factory. |

| Performance Tuned (Typical) | 24 – 28 | Common boost range with a performance chip or programmer. |

| Max Safe Boost (Stock Turbo/Engine) | 30 – 32 | Exceeding this consistently can lead to premature turbo wear or engine damage on stock components. |

| Cruising Speed (65 mph) | 2 – 5 | Low boost under light load conditions for fuel efficiency. |

| Overboost Fuel Cutoff (OEM) | ~24 | Factory protection feature to prevent engine damage; fuel delivery is temporarily cut. |

Key Components Affecting Boost

Several components work in harmony to create and manage 7.3 Powerstroke boost:

- Turbocharger (Garrett TP38 / GTP38): The heart of the system, responsible for compressing air.

- Intercooler: Located between the turbo and the intake manifold, the intercooler cools the compressed air. Cooler air is denser, leading to even more oxygen per volume and reducing engine temperatures.

- Intake and Exhaust Systems: These must be free-flowing to allow the turbo to spool up efficiently and expel gases effectively.

- MAP Sensor (Manifold Absolute Pressure): Measures the pressure inside the intake manifold (your boost pressure) and sends this data to the PCM (Powertrain Control Module).

- EBP Sensor (Exhaust Back Pressure): Measures pressure in the exhaust manifold. While not directly measuring boost, its data is used by the PCM to control the Exhaust Back Pressure Valve (EBPV) on earlier models, which can impact turbo spool and overall exhaust flow. A clogged EBP sensor tube is a common issue that can cause low boost.

What’s the Optimal Ford 7.3 Powerstroke Turbo Boost Pressure?

Defining “optimal” boost pressure isn’t a one-size-fits-all answer for the 7.3 Powerstroke. It largely depends on whether your truck is stock or has undergone modifications, particularly performance tuning.

Learn more about Ford 7.3 Powerstroke turbo boost pressure – Ford 7.3 Powerstroke Turbo Boost Pressure: What’s the Optimal Level?

Image source: chochotte.org

Stock 7.3 Powerstroke Boost Levels

For a factory-original Ford 7.3 Powerstroke, you can expect the turbo boost pressure to fall within a specific range. It’s important to note that boost can vary slightly depending on the year of your truck (early vs. late models), ambient conditions, and even specific driving situations (e.g., heavy load vs. empty). The PCM is designed to limit boost to protect the engine and turbo.

- Early 7.3s (1994.5-1997): Typically see peak boost in the range of 18-22 PSI under heavy acceleration or load. These models often had the Garrett TP38 turbo.

- Late 7.3s (1999-2003, especially ‘99.5+): Equipped with the larger Garrett GTP38 turbo, these trucks generally run a bit higher, seeing peak boost between 20-25 PSI in stock form. Some might occasionally kiss 26-27 PSI under very specific conditions.

Any reading significantly below these ranges in a stock truck under load could indicate an issue. Readings slightly above, if consistent, are usually not a concern for a healthy engine, but extreme highs (e.g., 30 PSI+) without tuning are highly unlikely and would suggest a faulty sensor reading.

Optimal Boost for Tuned and Modified 7.3s

This is where things get exciting for performance enthusiasts. With custom tuning and supporting modifications, the optimal boost for a 7.3 Powerstroke can safely increase significantly.

- Common Tuned Boost: Many well-tuned 7.3 Powerstrokes with minor modifications (e.g., larger injectors, intercooler upgrade) can safely run peak boost levels between 28-35 PSI.

- Aggressive Builds: More aggressive setups with larger turbochargers, upgraded HPOPs, and substantial fuel system modifications can push boost into the 35-40 PSI range. Some drag racing or extreme pulling setups might even exceed 40 PSI, but this requires a heavily built engine and highly specialized components.

Important Considerations for Modified Boost:

- EGTs (Exhaust Gas Temperatures): As boost and fuel increase, EGTs rise. Excessive EGTs are the primary killer of diesel engines. You must monitor EGTs with a gauge and ensure they remain within safe limits (typically below 1250-1300°F sustained).

- Fueling: More boost requires more fuel to maintain a safe air-fuel ratio. Upgraded injectors and a robust high-pressure oil pump (HPOP) are often necessary.

- Airflow: A high-flow intake and exhaust system are crucial to prevent restrictions.

- Tuning: Custom tuning is absolutely essential. A good tune will manage fuel, timing, and boost parameters to extract power safely. Running high boost without proper tuning is an recipe for disaster.

- Supporting Mods: Intercooler upgrades, stronger transmission components, and head studs are common recommendations when significantly increasing boost and power.

Never chase high boost numbers blindly. The goal is efficient power, and that means balancing boost, fuel, and exhaust temperatures.

Common Causes of Low 7.3 Powerstroke Boost

If your 7.3 Powerstroke feels sluggish, lacks power under acceleration, or your boost gauge isn’t hitting the numbers you expect, you likely have a low boost issue. Diagnosing it requires a systematic approach. Here are the most common culprits:

1. Boost Leaks

This is arguably the #1 cause of low 7.3 Powerstroke boost. Any compromise in the pressurized air path from the turbo to the intake manifold will result in a loss of boost.

- Intercooler Boots: The silicone boots connecting the intercooler pipes are prone to tearing, cracking, or slipping off due to age, heat, and high pressure.

- Intercooler: The intercooler itself can develop cracks, often due to age, debris, or excessive pressure.

- Spider/Intake Manifold: Gaskets or seals around the intake spider or manifold can leak.

- EBPV O-rings (if applicable): On early models, leaks around the Exhaust Back Pressure Valve can cause problems.

2. Exhaust Leaks

Just as a leak after the turbo causes boost loss, a leak before the turbo prevents it from spooling efficiently.

- Up-Pipes: The exhaust up-pipes (connecting exhaust manifolds to the turbo) are notorious for developing leaks at the bellows or flange connections. These leaks allow exhaust gases to escape before they can spin the turbo turbine, severely impacting spool and peak boost.

- Exhaust Manifolds: Cracks or loose bolts on the exhaust manifolds can also cause pre-turbo exhaust leaks.

3. Turbocharger Issues

The turbo itself can be the source of the problem.

- Worn Bearings: A worn shaft or bearing allows the compressor and turbine wheels to rub against their housings, causing friction and limiting spool. You might hear a “whining” or “screaming” sound.

- Damaged Wheels: Bent or chipped compressor/turbine fins (often caused by foreign object ingestion) reduce the turbo’s efficiency.

- EBPV Stuck Closed (Early Models): If the Exhaust Back Pressure Valve (EBPV) on early 7.3s (often controlled by the EBP sensor) gets stuck partially or fully closed, it can restrict exhaust flow and prevent the turbo from spooling.

4. Sensor Malfunctions

Faulty sensors can provide incorrect data to the PCM, leading to improper boost control or misleading readings.

- MAP Sensor: A dirty or faulty MAP sensor can report lower than actual boost, causing the PCM to fuel incorrectly or give a false low boost reading on a diagnostic tool.

- EBP Sensor & Tube: The EBP sensor and its tube are highly prone to clogging with soot. A clogged tube or faulty sensor can lead to the PCM believing exhaust back pressure is too high or too low, potentially affecting engine operation and turbo spool.

5. Fueling Issues

The turbocharger makes boost based on exhaust energy, which comes from burning fuel. If your engine isn’t getting enough fuel, it won’t produce enough exhaust energy to spool the turbo effectively.

- Weak HPOP (High-Pressure Oil Pump): The HPOP provides the oil pressure necessary to fire the injectors. A weak HPOP can lead to insufficient fuel delivery.

- Injector Problems: Worn, dirty, or faulty injectors can result in poor combustion and reduced exhaust energy.

- Fuel Filter/Pump Issues: A restricted fuel filter or a failing lift pump can starve the engine of fuel.

6. Air Filter Restriction

A severely clogged air filter will restrict the amount of air the compressor can draw in, limiting boost production. This is often an overlooked but easy-to-check item.

Diagnosing and Troubleshooting 7.3 Powerstroke Boost Issues

When you suspect a 7.3 Powerstroke turbo boost pressure problem, a systematic approach to diagnosis will save you time and money. Here’s how to go about it:

Step 1: Get a Reliable Boost Gauge

This is non-negotiable. If you don’t have one, install a mechanical or electronic boost gauge immediately. The factory gauge cluster does NOT show actual boost pressure. A dedicated boost gauge allows you to accurately monitor real-time boost levels under various loads and identify if you’re hitting your target numbers.

Step 2: Visual Inspection (The “Look and Listen” Test)

Start with the basics – a thorough visual inspection and listening for tell-tale signs.

- Inspect Intercooler Boots and Pipes: Look for cracks, tears, bulges, or signs of oil residue around the boots and clamps. Wiggle them to check for looseness. Ensure clamps are tight.

- Exhaust Up-Pipes: Look for black soot stains around the bellows or flanges of the up-pipes, indicating an exhaust leak. Listen for a loud “hissing” or “ticking” sound from the engine bay, especially when cold.

- Air Filter: Check if it’s dirty or clogged.

- Turbocharger: Remove the intake pipe leading to the turbo and inspect the compressor wheel. It should be clean and free of damage (bent or missing fins). Check for excessive shaft play (up-and-down or side-to-side movement). A slight bit of in-and-out play is normal.

- EBP Sensor & Tube: Locate the EBP sensor (usually on the front of the driver’s side exhaust manifold) and its metal tube. Check for soot buildup blocking the tube or a damaged sensor wiring.

Step 3: Perform a Boost Leak Test

This is the most effective way to find leaks in the charged air system.

- Obtain or build a boost leak tester (a PVC cap with an air fitting).

- Remove the air filter box and install the boost leak tester on the turbo intake.

- Apply shop air (typically 15-30 PSI) to the system.

- Listen for hissing sounds. Use a spray bottle with soapy water on all boots, clamps, the intercooler, and intake manifold gaskets. Bubbles will indicate a leak.

Step 4: Scan for Diagnostic Trouble Codes (DTCs) and Live Data

A good scan tool (like Forscan, AE, or a higher-end professional scanner) is invaluable for 7.3 Powerstroke diagnosis.

- Check for Codes: Any codes related to the MAP sensor, EBP sensor, or turbo performance should be investigated.

- Monitor Live Data:

- MAP Sensor Reading: Compare this to your boost gauge. If they differ significantly, one is likely faulty.

- EBP Sensor Reading: Monitor EBP vs. MAP. Under full load, EBP should generally be higher than MAP (e.g., MAP 25 PSI, EBP 30-35 PSI). If EBP is excessively high (e.g., 50+ PSI when MAP is low), it could indicate a plugged exhaust or a faulty EBP sensor/tube. If EBP is very close to MAP at WOT, it might indicate an exhaust leak before the turbo.

- ICP (Injection Control Pressure) & IPR (Injector Pressure Regulator) Duty Cycle: Low ICP or high IPR duty cycle can indicate a weak HPOP or injector issues, which indirectly affect boost.

Step 5: Test Actuators (Early Models with EBPV)

For early models, if the EBPV (Exhaust Back Pressure Valve) is suspected, you can often command it open or closed with a scan tool to verify its operation. A stuck closed EBPV can significantly reduce boost.

7.3 Powerstroke Boost Pressure Troubleshooting Quick Reference

| Symptom | Typical Boost Range (PSI) | Potential Issues | Diagnostic Action |

|---|---|---|---|

| Stock, heavy load | 18-25 PSI | Normal operation | Monitor with gauge |

| Tuned, heavy load | 28-35+ PSI | Normal operation (with mods) | Monitor EGTs, boost, fuel pressure |

| Low Boost (e.g., <15 PSI under load) | Too Low | Boost leaks, exhaust leaks, clogged EBP tube, faulty MAP sensor, turbo damage, fueling issues. | Boost leak test, inspect exhaust, check EBP/MAP sensors, inspect turbo. |

| Unusually High Boost (no tune) | >30 PSI | Faulty MAP sensor (reading low), EBPV stuck closed (early models), exhaust restriction. | Compare MAP to mechanical gauge, check EBPV operation, inspect exhaust. |

| Excessive Black Smoke / High EGTs | Varies | Insufficient air (low boost), overfueling. | Diagnose low boost, check injectors/HPOP, review tuning. |

Upgrading Your 7.3 Powerstroke Turbo System for More Boost

If you’ve tackled all the common issues and are now craving more power, upgrading your 7.3 Powerstroke turbo system is the next logical step. Remember, simply installing a bigger turbo isn’t enough; it’s a system that needs to be balanced.

1. Aftermarket Turbochargers

The stock Garrett GTP38 is a good turbo, but it has its limits. Upgrading to a larger, more efficient aftermarket turbo is the foundation for significant boost increases.

- GTP38R: A popular drop-in replacement that offers quicker spool and more top-end power than the stock GTP38. It’s essentially an upgraded version of the factory turbo.

- Stage 1/2/3 Turbos: Many manufacturers offer turbos with larger compressor wheels (e.g., 66mm, 70mm) and optimized turbine housings. These can dramatically increase airflow.

- Non-VGT Turbos (e.g., BorgWarner SXE line): These turbos are highly efficient and capable of very high boost and flow numbers, but often require custom pedestal and plumbing.

2. Intercooler Upgrades

More boost means hotter air. A larger, more efficient intercooler is crucial for cooling that compressed air, increasing its density, and keeping EGTs down. This allows you to safely run higher 7.3 Powerstroke turbo boost pressure.

- Look for full-aluminum, bar-and-plate designs that offer significantly more cooling surface area than the stock unit.

3. Injector and Fuel System Upgrades

You can’t make more power without more fuel. Larger injectors are necessary to match the increased airflow from an upgraded turbo. You may also need:

- High-Pressure Oil Pump (HPOP): Upgraded HPOPs (e.g., “Adrenaline” or “Terminator” pumps) ensure you have enough high-pressure oil to fire larger injectors at high RPMs.

- Electric Fuel System: Upgrading from the stock mechanical fuel pump to a high-flow electric fuel pump ensures consistent and sufficient low-pressure fuel delivery.

4. Custom Performance Tuning

This is non-negotiable for any significant turbo upgrade. A reputable custom tuner will write specific software that optimizes fuel delivery, timing, and boost control for your exact combination of modifications. Generic tunes will not cut it and can lead to poor performance or engine damage.

5. Supporting Modifications

To safely handle increased power and boost, consider:

- Head Studs: Stock head bolts can stretch under extreme cylinder pressures, leading to blown head gaskets. Head studs provide superior clamping force.

- Transmission Upgrades: The 4R100 transmission will likely need upgrades (e.g., heavy-duty torque converter, larger input shaft, stronger clutches) to handle significantly more torque.

- Performance Intake and Exhaust: Ensure your entire airflow path is as unrestricted as possible.

Maintaining Optimal Boost: Proactive Tips for Your 7.3 Powerstroke

Preventative maintenance is key to ensuring your 7.3 Powerstroke continues to deliver optimal turbo boost pressure and lasts for hundreds of thousands of miles. Here are some actionable tips:

- Regular Oil Changes with Quality Oil: The turbocharger relies on engine oil for lubrication and cooling. Dirty or low-quality oil can lead to premature turbo bearing wear. Follow Ford’s recommendations or slightly shorter intervals for severe duty.

- Inspect Intercooler Boots and Clamps Regularly: Make it a habit to visually inspect these components every oil change. Look for cracks, tears, or signs of oil. Tighten clamps as needed. Consider upgrading to quality aftermarket silicone boots with T-bolt clamps.

- Keep Your Air Filter Clean: A restricted air filter makes the turbo work harder and reduces its efficiency, leading to lower boost. Replace it according to your owner’s manual or more frequently if driving in dusty conditions.

- Clean Your EBP Sensor and Tube: Soot buildup in the EBP sensor tube is very common. Periodically remove the tube (usually a 10mm bolt and a few wrench turns for the fittings) and clean it out with a wire brush or drill bit. Clean the sensor port if possible. This ensures accurate EBP readings.

- Monitor Your Gauges: If you’ve installed a boost gauge and an EGT gauge, use them! Pay attention to your normal operating ranges. Any sudden deviation can be an early indicator of a problem.

- Address Exhaust Leaks Promptly: Don’t ignore those tell-tale exhaust soot stains around the up-pipes or manifold. Repairing them quickly prevents a cascade of performance issues and potential damage to your turbo.

- Let the Turbo Cool Down: After heavy towing or sustained high-speed driving, allow your engine to idle for a few minutes before shutting it off. This allows oil to continue circulating through the turbo, cooling its bearings and preventing “coking” (burning of oil residue) which can shorten turbo life.

- Listen to Your Truck: Pay attention to any new or unusual noises coming from the engine bay, especially while accelerating. A sudden whistle, whine, or hiss can often point to a developing turbo or boost-related issue.

Conclusion

The Ford 7.3 Powerstroke is a powerhouse, and its heart beats with the rhythm of its turbocharger. Understanding and maintaining optimal 7.3 Powerstroke turbo boost pressure is not just about chasing big numbers; it’s about ensuring your truck performs reliably, efficiently, and with the robust power you’ve come to expect from this legendary diesel engine.

Whether your 7.3 is a stock workhorse or a heavily modified beast, knowing the ideal boost levels, being able to diagnose common issues, and implementing proactive maintenance will keep your truck in top shape. From spotting those pesky boost leaks to considering strategic upgrades, every step you take contributes to the longevity and exhilarating performance of your rig. So, arm yourself with a reliable boost gauge, stay vigilant with your maintenance, and enjoy every mile with your truly optimal 7.3 Powerstroke!

Frequently Asked Questions

What is the optimal or healthy range for Ford 7.3 Powerstroke turbo boost pressure?

For a stock Ford 7.3 Powerstroke, the optimal turbo boost pressure typically ranges from 18 to 22 PSI under heavy acceleration. However, this can vary slightly depending on the specific model year, altitude, and condition of your engine. Heavily modified engines may run higher boost levels.

What are the common symptoms of incorrect Ford 7.3 Powerstroke turbo boost pressure?

If your Ford 7.3 Powerstroke turbo boost pressure is too low, you’ll often experience a noticeable lack of power, slow acceleration, and potentially excessive black smoke from the exhaust. Conversely, extremely high boost can lead to a rough running engine, potential turbo damage, or even engine component failure if not properly managed.

Why might my Ford 7.3 Powerstroke turbo boost pressure be low?

Low Ford 7.3 Powerstroke turbo boost pressure is most frequently caused by boost leaks, such as cracked intercooler boots or pipes, or leaks in the exhaust system before the turbo. Other culprits can include a worn-out turbocharger, a faulty wastegate, or a clogged air filter restricting airflow.

What could cause my Ford 7.3 Powerstroke turbo boost pressure to be too high?

Excessively high Ford 7.3 Powerstroke turbo boost pressure often indicates a problem with the wastegate, which may be stuck closed, or a malfunction in the boost control system. Aftermarket tuners or chips that are too aggressive without proper safeguards can also significantly increase boost beyond safe limits.

How can I accurately monitor my Ford 7.3 Powerstroke’s turbo boost pressure?

To accurately monitor your Ford 7.3 Powerstroke turbo boost pressure, installing an aftermarket boost gauge is highly recommended. Many owners also utilize digital monitoring devices, such as an Edge Insight CTS3 or similar OBD-II scanners, which can display real-time boost pressure along with other vital engine parameters.

How do performance modifications affect Ford 7.3 Powerstroke turbo boost pressure?

Performance modifications like aftermarket tuners, larger injectors, or upgraded turbochargers almost always result in higher Ford 7.3 Powerstroke turbo boost pressure. While this can increase horsepower and torque, it’s crucial to ensure that other components, such as the exhaust and intercooler, can handle the increased pressure and heat for engine longevity.