Ford 7.3 Powerstroke Oil Pump Specifications: Key Details

Featured image for this comprehensive guide about Ford 7.3 Powerstroke oil pump specifications

Image source: mascdn.militaryautosource.com

The roar of a Ford 7.3 Powerstroke engine isn’t just a sound; it’s a testament to raw power, reliability, and a legendary status that has captivated truck enthusiasts for decades. These iconic diesel workhorses, produced from 1994.5 to 2003, are renowned for their incredible durability and a reputation for piling on hundreds of thousands of miles with proper care. But what truly makes these engines tick? Beyond the robust block and heavy-duty internals lies a sophisticated, albeit ingenious, injection system that relies heavily on a component often overlooked until it causes trouble: the oil pump.

Far from just lubricating engine components, the Ford 7.3 Powerstroke oil pump specifications are central to how this diesel engine generates its immense power. Unlike many conventional diesel engines, the 7.3 Powerstroke utilizes a unique Hydraulically Actuated Electronic Unit Injector (HEUI) system. This means that highly pressurized engine oil is the driving force behind fuel injection, making the oil pumps not just vital for lubrication, but absolutely critical for the engine to run at all. Understanding the intricacies of these pumps – their roles, specifications, common issues, and maintenance – is paramount for any 7.3 Powerstroke owner looking to maximize their engine’s longevity and performance.

In this comprehensive guide, we’ll dive deep into the world of the 7.3 Powerstroke oil pump. We’ll explore both the Low-Pressure Oil Pump (LPOP) and the High-Pressure Oil Pump (HPOP), dissecting their specific functions, critical specifications, common failure points, and the best practices for maintenance and upgrades. Whether you’re a seasoned mechanic, a DIY enthusiast, or simply a proud 7.3 owner, this article will equip you with the knowledge needed to keep your beloved Powerstroke running strong for years to come.

Quick Answers to Common Questions

What kind of oil pump does the Ford 7.3 Powerstroke actually use?

The Ford 7.3 Powerstroke engine actually utilizes two critical oil pumps: a Low-Pressure Oil Pump (LPOP) for general lubrication, and a High-Pressure Oil Pump (HPOP) specifically for actuating the fuel injectors. Understanding both is key to its unique oil pump specifications.

How do I know if my Ford 7.3 Powerstroke oil pump is failing?

Common signs of a failing Ford 7.3 Powerstroke oil pump include rough idling, stalling, a “check engine” light, or a noticeable loss of power, especially under load. You might also hear unusual engine noises indicating an issue with oil pressure or volume.

What are the general Ford 7.3 Powerstroke oil pump specifications for pressure?

The Low-Pressure Oil Pump (LPOP) typically maintains around 50-70 PSI for lubrication purposes, while the High-Pressure Oil Pump (HPOP) can generate anywhere from 500 to over 3,000 PSI to fire the injectors. These specific pressure ranges are crucial for the Ford 7.3 Powerstroke oil pump’s operation.

Is there a difference in Ford 7.3 Powerstroke oil pump specifications across model years?

Yes, there can be subtle differences, particularly with the High-Pressure Oil Pump (HPOP). Early 7.3L engines (94-97) used a single-shot HPOP, while later models (99-03) often feature a more efficient “17-degree” HPOP, which impacts fuel delivery and engine performance characteristics.

How critical is the oil pump for the 7.3 Powerstroke’s overall health?

The Ford 7.3 Powerstroke oil pump, encompassing both the LPOP and HPOP, is absolutely vital for the engine’s operation and longevity. Without proper oil pressure from either, the engine will either fail to start, run poorly, or suffer severe damage, making its specifications paramount.

📋 Table of Contents

- The Heart of the Beast: Understanding the 7.3 Powerstroke’s Oil System

- Low-Pressure Oil Pump (LPOP) Specifications and Role

- High-Pressure Oil Pump (HPOP) Specifications and Critical Function

- Decoding Common 7.3 Powerstroke Oil Pump Problems and Symptoms

- Maintenance, Replacement, and Upgrade Options for Your 7.3 Powerstroke Oil Pumps

- Maximizing Your 7.3 Powerstroke’s Longevity: Expert Tips for Oil System Health

- Key 7.3 Powerstroke Oil Pump Specifications & Quick Reference

- Conclusion

The Heart of the Beast: Understanding the 7.3 Powerstroke’s Oil System

Before delving into specific pump details, it’s crucial to grasp the ingenious design of the 7.3 Powerstroke’s oil system. As mentioned, the 7.3 employs a HEUI (Hydraulically Actuated Electronic Unit Injector) fuel injection system. This system is a marvel of engineering, using engine oil at extremely high pressures to actuate the fuel injectors, which then precisely spray fuel into the combustion chambers.

Learn more about Ford 7.3 Powerstroke oil pump specifications – Ford 7.3 Powerstroke Oil Pump Specifications: Key Details

Image source: otosaigon.com

This unique setup means your 7.3 Powerstroke has not one, but two primary oil pumps, each with a distinct and equally vital role:

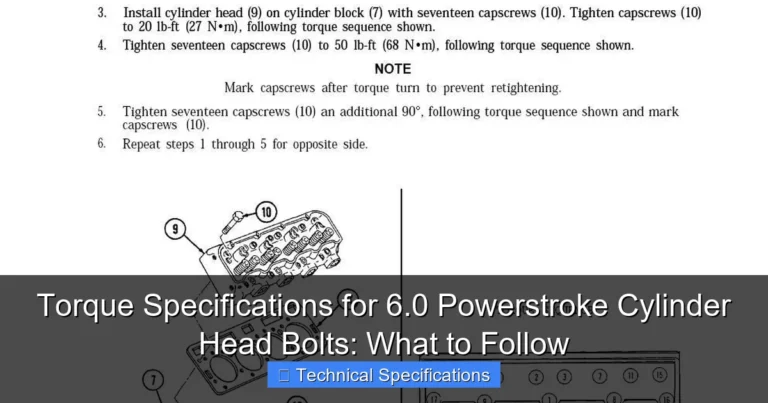

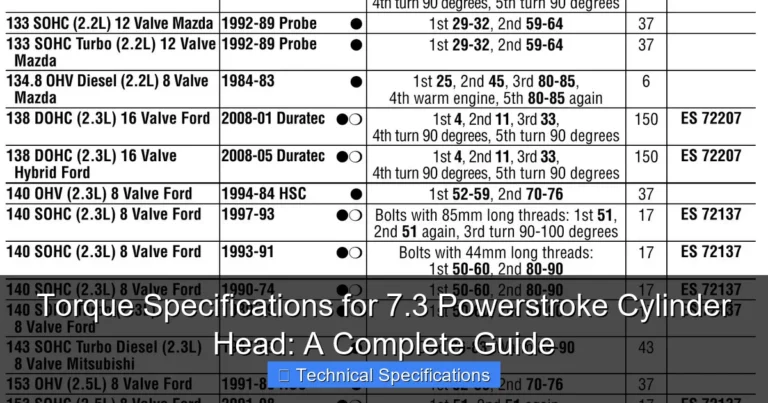

| Specification | Low-Pressure Oil Pump (LPOP) | High-Pressure Oil Pump (HPOP) |

|---|---|---|

| Pump Type | Gerotor Gear Pump | Axial Piston Pump |

| Primary Function | Engine Lubrication, Cooling, HPOP Supply | Actuate HEUI Fuel Injectors |

| Typical Operating Pressure | 50-80 PSI (Engine Oil Pressure) | 500-3000+ PSI (ICP – Injector Control Pressure) |

| Drive Mechanism | Crankshaft (via timing cover) | Camshaft (via gear drive) |

| Location | Front of engine, behind timing cover | Top-rear of engine in the valley |

- Low-Pressure Oil Pump (LPOP): This is your conventional oil pump, responsible for lubricating the engine’s internal components (bearings, camshaft, etc.) and, critically, for supplying a consistent flow of oil to the High-Pressure Oil Pump (HPOP) reservoir. Without a healthy LPOP, the HPOP simply starves.

- High-Pressure Oil Pump (HPOP): This is the workhorse of the HEUI system. It takes the oil supplied by the LPOP and dramatically increases its pressure – to thousands of PSI – to activate the fuel injectors. No high pressure from the HPOP means no fuel injection, and thus, no engine operation.

Both pumps are integral to the engine’s operation, and understanding their individual **Ford 7.3 Powerstroke oil pump specifications** is the first step toward effective diagnosis, maintenance, and potential upgrades. A healthy oil system is the bedrock of your 7.3 Powerstroke engine longevity.

Low-Pressure Oil Pump (LPOP) Specifications and Role

Often overshadowed by its high-pressure counterpart, the 7.3 Powerstroke LPOP is the unsung hero of the oil system. Its reliability is fundamental to the entire engine’s health and the successful operation of the HEUI system.

Learn more about Ford 7.3 Powerstroke oil pump specifications – Ford 7.3 Powerstroke Oil Pump Specifications: Key Details

Image source: elleman.vn

LPOP’s Core Function

The LPOP is located at the front of the engine, driven by the crankshaft. Its primary responsibilities include:

- Engine Lubrication: It circulates oil throughout the engine, providing a protective film to moving parts like crankshaft bearings, camshaft lobes, and piston walls, minimizing friction and heat.

- HPOP Supply: It continuously fills the High-Pressure Oil Pump reservoir, ensuring a steady supply of oil for the HPOP to pressurize and send to the injectors.

Think of the LPOP as the foundation. If it fails, the entire structure eventually crumbles, leading to both lubrication issues and fuel injection problems.

Key 7.3 Powerstroke LPOP Specifications

The LPOP is a robust, gear-driven pump designed for continuous operation. Here are some general specifications:

- Type: Gerotor (internal gear) pump. This design is known for its efficiency and durability.

- Location: Mounted in the engine’s front cover.

- Normal Operating Pressure: This is a critical specification. A healthy 7.3 Powerstroke oil pressure from the LPOP typically ranges from 45 to 75 PSI at idle and can go up to 80-100+ PSI at higher RPMs. The pump usually incorporates an internal relief valve to prevent excessive pressure.

- Flow Rate: While not a commonly published numerical spec, the LPOP must provide sufficient flow to maintain the specified pressure and adequately fill the HPOP reservoir.

- Construction: Made from durable cast iron or aluminum housings with hardened steel gears, designed to withstand the rigors of diesel engine operation.

Common LPOP Issues and Warning Signs

While generally reliable, the Low-Pressure Oil Pump 7.3 can experience issues, often due to wear or oil starvation. Key problems and their symptoms include:

- Low Oil Pressure: The most direct symptom. The dashboard oil pressure gauge (while often inaccurate) might drop, or a mechanical gauge will confirm low readings. This can lead to lack of lubrication and eventual engine damage.

- Front Cover Bore Wear: The LPOP rides in a bore within the engine’s front cover. Over time, this bore can wear, leading to oil pressure loss even with a new pump.

- Gear Wear/Breakage: Although rare with proper maintenance, extreme conditions or previous oil starvation can lead to wear or even catastrophic failure of the LPOP gears.

- HPOP Starvation: If the LPOP isn’t supplying enough oil to the HPOP reservoir, you’ll start experiencing symptoms typically associated with HPOP issues (hard starts, no starts), but the root cause is the LPOP.

- Engine Noise: Lack of proper lubrication can cause lifter noise, ticking, or even knocking as engine components wear excessively.

High-Pressure Oil Pump (HPOP) Specifications and Critical Function

The 7.3 Powerstroke HPOP is arguably the most fascinating and critical component within the HEUI system. It’s what differentiates the 7.3 from many other diesel engines and is the direct enabler of its powerful fuel injection.

HPOP’s Pivotal Role in HEUI

Positioned on top of the engine, under the turbocharger pedestal, the HPOP takes the oil supplied by the LPOP (from the HPOP reservoir) and transforms it into the immense pressure needed to actuate the fuel injectors. Here’s a simplified breakdown:

- The LPOP fills the HPOP reservoir with engine oil.

- The HPOP draws oil from this reservoir.

- Through internal plungers and a swashplate, the HPOP rapidly pressurizes this oil.

- This high-pressure oil is then directed to the fuel injectors via high-pressure lines and oil rails.

- Inside each injector, this high-pressure oil pushes down on an intensifier piston, which in turn pressurizes the fuel within the injector, causing it to spray into the cylinder.

Essentially, the HPOP is the muscle behind the 7.3 Powerstroke injection system.

7.3 Powerstroke HPOP Specifications and Generations

The HPOP is a precision-engineered component. Its specifications vary slightly depending on the engine’s year, mainly due to evolving injector designs (single-shot vs. split-shot).

- Type: Radial Piston Pump. It typically consists of two plungers that move in and out, driven by an internal cam plate (swashplate) that rotates as the engine runs.

- Location: Mounted in the valley of the engine, driven by a gear from the camshaft.

- Output Pressure: This is where the HPOP truly shines.

- Idle: Typically 500-750 PSI (pounds per square inch).

- Wide Open Throttle (WOT): Can reach anywhere from 2,800 PSI to 3,600 PSI or even 4,000 PSI on later models or with performance upgrades. This incredibly high pressure is what gives the HEUI system its precise control over fuel delivery.

- Reservoir: The HPOP sits in an oil reservoir, continuously refilled by the LPOP, ensuring it always has oil to draw from.

- Generations/Displacement:

- Early HPOP (1994.5-1997): These pumps were designed to work with “single-shot” injectors and typically had a lower displacement, sufficient for their original application. Often referred to by their casting number suffixes (e.g., AD, AB).

- Later HPOP (1999-2003): With the introduction of “split-shot” injectors and a desire for cleaner emissions and more power, Ford increased the HPOP’s displacement. These are often colloquially referred to as “17-degree” pumps (a reference to the swashplate angle, though actual displacement is the key factor), providing higher flow for the larger and more demanding later injectors.

Common HPOP Failures and Symptoms

Given the extreme pressures it generates, the High-Pressure Oil Pump 7.3 is susceptible to wear and leaks. Common issues and their tell-tale signs include:

- Internal Wear: Over time, the plungers, barrels, and swashplate can wear, leading to a loss of efficiency and reduced output pressure. This is a common cause of hard starts and loss of power.

- Oil Leaks: Leaks can occur from the HPOP housing itself, the seals on the Injection Pressure Regulator (IPR) valve, or the high-pressure oil lines (often called “standpipes” or “branches”). External leaks are visible, but internal leaks (e.g., a crack in the HPOP housing) can be devastating.

- HPOP Starvation: As mentioned, if the LPOP fails or the oil level is critically low, the HPOP will be starved of oil, leading to cavitation and rapid wear.

- Symptoms of HPOP Failure:

- No Start / Hard Start: Especially when the engine is hot, as worn components allow oil to bleed off more easily.

- Rough Idle / Misfires: Inconsistent high-pressure oil supply can lead to erratic injector firing.

- Loss of Power: The engine feels sluggish, struggles to accelerate, or won’t reach full RPMs.

- Stalling: The engine might suddenly die, especially under load.

- “Cackle” or “Knock”: A distinct noise from the engine valley area due to inconsistent injection.

- DTCs (Diagnostic Trouble Codes): P1211 (ICP Actual vs. Desired), P1280 (ICP sensor circuit high), P1282 (Excessive ICP), P1283 (IPR circuit fault).

Decoding Common 7.3 Powerstroke Oil Pump Problems and Symptoms

Diagnosing an oil pump issue in a 7.3 Powerstroke requires understanding the interplay between the LPOP and HPOP. Symptoms can often overlap, making a precise diagnosis crucial. The ultimate goal is to maintain optimal 7.3 Powerstroke oil pressure.

LPOP-Related Symptoms

When the LPOP is failing, you might observe:

- Consistently Low Oil Pressure Gauge Readings: Even if the stock gauge is slow, a persistent low reading, especially after warming up, is a red flag.

- Engine Ticking or Knocking: Lack of lubrication can lead to excessive wear on engine bearings and lifters, creating audible mechanical noise.

- Hard Cold Starts: If the LPOP isn’t quickly building pressure, the HPOP reservoir might not fill fast enough, leading to extended cranking.

- Visible Oil Leaks from Front Cover: Though less common, front cover gasket leaks can be mistaken for LPOP issues.

HPOP-Related Symptoms

HPOP issues are generally more dramatic due to its direct role in injection:

- No Start / Extended Crank: The most common symptom. If the HPOP can’t build sufficient pressure (typically >500 PSI) to fire the injectors, the engine simply won’t start. This is often worse when hot because thin oil leaks out of worn components more easily.

- Rough Running / Misfires: Inconsistent pressure delivery to injectors causes uneven combustion.

- Loss of Power / Turbo Lag: Insufficient pressure prevents the injectors from delivering enough fuel, leading to a noticeable lack of power and responsiveness.

- Stalling: The engine might suddenly die, particularly under load, if the HPOP pressure drops too low.

- Oil Leaks in Engine Valley: Look for puddles of oil under the turbo pedestal or around the HPOP itself. The “dollar bill” leak test (placing a dollar bill in the valley to see if it gets oily) is a classic for identifying HPOP leaks.

- Diagnostic Codes: P1211 (ICP Actual vs. Desired), P1280, P1282, P1283 are strong indicators of HPOP or related sensor/circuit issues.

The “Dollar Bill” Test and Other Diagnostic Steps

To pinpoint the problem, a systematic approach is needed:

- Check Oil Level and Condition: This is basic, but critical. Low oil starves both pumps.

- Monitor OEM Oil Pressure Gauge: While not precise, a sudden drop is a sign.

- Use a Scan Tool: A capable scan tool can read live data, specifically:

- ICP (Injection Control Pressure): Shows the actual pressure the HPOP is generating.

- IPR (Injection Pressure Regulator) Duty Cycle: Shows how hard the IPR valve is working to maintain pressure.

- EOT (Engine Oil Temperature): Affects oil viscosity and can impact HPOP performance when hot.

- Air Test (HPOP Leaks): A common diagnostic is to remove the IPR valve and inject shop air into the HPOP system. Listening for air hissing from the oil fill tube (internal HPOP leak or high-pressure oil rail leaks) or injector cups (injector O-rings) can help locate leaks.

- External Visual Inspection: Look for any visible oil leaks around the pumps, lines, or reservoir.

Addressing these 7.3 Powerstroke common oil pump problems swiftly is crucial to prevent further engine damage and ensure the longevity of your truck.

Maintenance, Replacement, and Upgrade Options for Your 7.3 Powerstroke Oil Pumps

Proactive maintenance and informed decisions about replacement and upgrades can significantly extend the life of your 7.3 Powerstroke. Understanding Ford 7.3 Powerstroke oil pump specifications is key here.

Proactive Maintenance for Oil Pump Longevity

The best defense against oil pump failure is diligent maintenance:

- Regular Oil Changes: This is paramount. Use high-quality engine oil (CJ-4 or CK-4 rated, typically 15W-40 or 5W-40 synthetic for colder climates) at manufacturer-recommended intervals. Clean oil prevents wear on internal pump components.

- Use Correct Oil Filters: Don’t skimp on oil filters. A good filter traps contaminants that can damage pump internals.

- Monitor Oil Level: Check your oil level religiously, especially before long trips. The 7.3 Powerstroke uses a lot of oil for injection, and running low can quickly starve the HPOP and LPOP.

- Address Leaks Promptly: Even small oil leaks reduce the available oil and can lead to starvation. Fix them as soon as they appear.

- Allow Proper Warm-Up: Give your engine time to warm up, especially in cold weather. This allows the oil to reach optimal operating temperature and viscosity before putting the engine under heavy load.

When to Consider Replacement

A failed oil pump typically requires replacement. Here’s when to consider a new 7.3 Powerstroke oil pump replacement:

- Confirmed Failure: If diagnostic tests conclusively point to an internal failure of either the LPOP or HPOP (e.g., severe internal wear, cracks).

- Preventative Maintenance for High Mileage: For very high-mileage engines (e.g., 250,000+ miles), especially if you’re undertaking other major engine work (like injector replacement), consider replacing the HPOP as a preventative measure. A worn HPOP might not be “failed” but could be operating at reduced efficiency.

- LPOP During Front Cover Work: If you’re removing the front cover for any reason (e.g., water pump, timing gears), it’s often wise to replace the LPOP, especially if the engine has high mileage.

7.3 Powerstroke Oil Pump Upgrade Options

For those looking for enhanced performance or simply a more robust replacement, several 7.3 Powerstroke oil pump upgrade options are available:

- LPOP Upgrades:

- Melling M229: A popular aftermarket LPOP known for its slightly improved design and relief valve, offering a marginal but noticeable increase in idle oil pressure for some applications.

- Complete Front Cover: If the LPOP bore in your front cover is worn, simply replacing the pump won’t fix the issue. A new or remanufactured front cover with a new LPOP is the proper solution.

- HPOP Upgrades: This is where performance enthusiasts spend more attention, as it directly impacts injector performance and horsepower potential.

- “17-Degree” HPOP Upgrade: If you have an early (94.5-97) 7.3 Powerstroke with a smaller HPOP, upgrading to a later model “17-degree” HPOP (which has more displacement) is a common and effective upgrade, especially if you plan to install larger or upgraded injectors.

- Adrenaline HPOP: A popular aftermarket performance HPOP designed to provide more volume and pressure than a stock unit, ideal for trucks with mild to moderate injector upgrades and tuning.

- Terminator HPOP: These pumps are built for serious performance, offering significantly increased flow and pressure to support very large injectors and aggressive tuning. They come in various stages (e.g., T500, T580) indicating their output.

- Dual HPOP Systems: For extreme performance builds with very large injectors, a dual HPOP setup (two high-pressure pumps working in tandem) is often necessary to provide sufficient oil volume.

Important Note on HPOP Upgrades: Always match your HPOP upgrade to your injector size and engine tuning. An oversized HPOP with stock injectors might not yield significant benefits, and an undersized HPOP will limit the performance of larger injectors.

Maximizing Your 7.3 Powerstroke’s Longevity: Expert Tips for Oil System Health

Beyond the technical specifications and individual pump functions, a holistic approach to your 7.3 Powerstroke’s oil system health will ensure you get the maximum life and performance out of this legendary engine. Keeping a close eye on your Ford Super Duty oil pump systems is paramount.

- Invest in an Aftermarket Oil Pressure Gauge: The factory dashboard gauge for oil pressure is notoriously inaccurate and merely an “on/off” switch indicating *some* pressure. A dedicated mechanical or electronic aftermarket oil pressure gauge provides real-time, accurate readings of your LPOP pressure, giving you early warning of potential issues.

- Monitor Other Vital Signs: While not directly oil pump related, monitoring Engine Oil Temperature (EOT) and Exhaust Gas Temperature (EGT) can give insights into how hard your engine is working and if oil is becoming excessively hot, which can accelerate wear.

- Use the Right Oil, Always: We cannot stress this enough. The 7.3 Powerstroke’s HEUI system is incredibly sensitive to oil quality and viscosity. Stick to heavy-duty diesel engine oils (CJ-4 or CK-4 rated) with the correct viscosity (e.g., 15W-40, or 5W-40 synthetic in colder climates). Avoid passenger car oils or oils not rated for diesel use.

- Check for Leaks Regularly: Perform visual inspections under the hood and under the truck. The engine valley is a common spot for HPOP and injector-related oil leaks. Early detection saves money and prevents potential pump starvation.

- Avoid Extended Idling: While a diesel can idle for long periods, prolonged idling can lead to lower oil pressure and increased carbon buildup. If you must idle, ensure the engine is fully warmed up.

- Listen to Your Engine: Become familiar with your truck’s normal sounds. Any new ticking, knocking, or changes in engine behavior should prompt investigation. Often, early oil pump issues manifest as subtle changes in engine noise or starting characteristics.

- Professional Diagnostics: Don’t hesitate to take your truck to a qualified diesel mechanic if you suspect an oil pump issue or are getting diagnostic trouble codes. They have specialized tools and expertise to accurately diagnose complex HEUI system problems.

By following these tips and understanding the critical role of both the LPOP and HPOP, you’re not just maintaining a vehicle; you’re preserving a piece of automotive history. Your 7.3 Powerstroke oil pump specifications are more than just numbers – they’re the blueprint for a long-lasting, powerful engine.

Key 7.3 Powerstroke Oil Pump Specifications & Quick Reference

To summarize the critical aspects of the 7.3 Powerstroke’s oil pump system, here’s a quick reference table:

| Component | Type | Normal Operating Pressure (PSI) | Key Function | Common Issues |

|---|---|---|---|---|

| Low-Pressure Oil Pump (LPOP) | Gerotor Gear Driven | 45-75 PSI (idle) 80-100+ PSI (WOT) |

Engine Lubrication, Feeds HPOP Reservoir | Gear wear, relief valve issues, front cover bore wear, low oil pressure |

| High-Pressure Oil Pump (HPOP) – Early (94.5-97) | Radial Piston Pump | 500-750 PSI (idle) Up to ~3,000 PSI (WOT) |

Actuates Fuel Injectors (Single-Shot) | Internal wear, oil leaks, IPR valve issues, starvation, hard hot starts |

| High-Pressure Oil Pump (HPOP) – Late (99-03) & Upgrade | Radial Piston Pump | 500-750 PSI (idle) Up to 3,600-4,000 PSI (WOT) |

Actuates Fuel Injectors (Split-Shot & Performance) | Internal wear, oil leaks, IPR valve issues, starvation, hard hot starts |

Conclusion

The Ford 7.3 Powerstroke is a legend, and its longevity is intrinsically linked to the health of its oil pumps. Far more than simple lubrication devices, the Low-Pressure Oil Pump (LPOP) and High-Pressure Oil Pump (HPOP) are the unsung heroes responsible for both engine lubrication and, uniquely, the precise actuation of its fuel injectors. Understanding the intricate Ford 7.3 Powerstroke oil pump specifications, their specific roles, and potential failure points is not just technical knowledge; it’s a commitment to preserving the lifeblood of your diesel icon.

From recognizing the subtle signs of a failing LPOP to diagnosing the more dramatic symptoms of an HPOP issue, being informed empowers you to make timely maintenance decisions. By prioritizing regular, high-quality oil changes, monitoring your engine’s vital signs, and considering appropriate upgrades when the time comes, you’re investing in years, if not decades, of reliable service from your 7.3 Powerstroke. Keep these critical components healthy, and your Ford will continue to roar with the power and dependability it’s famous for, truly maximizing your 7.3 Powerstroke engine longevity.

🎥 Related Video: 7.3 Powerstroke: Everything You Need to Know

📺 Dust Runners Automotive Journal

Article: https://dustrunnersauto.com/powerstroke-7-3l-everything-you-need-to-know-specs-and-more/ Things like the six head …

Frequently Asked Questions

What type of oil pump does the Ford 7.3 Powerstroke utilize?

The Ford 7.3 Powerstroke primarily utilizes a gerotor (gear rotor) style low-pressure oil pump (LPOP) for engine lubrication. This LPOP is crucial for drawing oil from the pan and delivering it to the engine’s internal components, as well as supplying the high-pressure oil pump (HPOP).

What are the key low-pressure oil pump (LPOP) specifications for the 7.3 Powerstroke?

The main LPOP specifications revolve around its flow rate and ability to maintain consistent oil pressure. A healthy LPOP should provide adequate pressure, typically 15-25 PSI at idle and 40-70 PSI at operating RPMs, which is vital for engine lubrication and feeding the HPOP. The pump is designed for high volume delivery rather than extremely high pressure itself.

How do the low-pressure and high-pressure oil pumps (LPOP & HPOP) work together in the 7.3 Powerstroke?

The LPOP draws oil from the pan and circulates it throughout the engine for lubrication, and critically, it also supplies the high-pressure oil pump (HPOP). The HPOP then pressurizes this oil significantly (up to 3000+ PSI) to actuate the HEUI (Hydraulically actuated Electronic Unit Injector) fuel injectors. This two-stage system is unique to the 7.3 Powerstroke.

What are the recommended oil pressure specifications for a healthy Ford 7.3 Powerstroke engine?

For the low-pressure oil system, a healthy 7.3 Powerstroke should show 15-25 PSI at idle and 40-70 PSI at 2,000 RPM when at operating temperature. High-pressure oil for the injectors will vary with demand but generally ranges from 500-3000+ PSI. These figures are key indicators of the health of both the LPOP and HPOP components.

Are there common upgrades or heavy-duty Ford 7.3 Powerstroke oil pump options available?

Yes, several aftermarket companies offer upgraded low-pressure oil pumps for the 7.3 Powerstroke. These often feature increased flow rates or more durable internal components to provide superior lubrication, especially for engines with performance modifications. Always ensure any upgraded Ford 7.3 Powerstroke oil pump meets or exceeds OEM specifications for proper fit and reliability.

How often should I consider inspecting or replacing my 7.3 Powerstroke’s low-pressure oil pump (LPOP)?

While there isn’t a strict replacement interval, the LPOP is typically inspected during major engine work or when diagnosing oil pressure issues. If you experience persistent low oil pressure, particularly at idle, or notice unusual noises from the front cover, it’s advisable to have your 7.3 Powerstroke oil pump assessed by a qualified technician.