Ford 6.0 Powerstroke Injection Timing: How It Affects Your Engine

Featured image for this comprehensive guide about Ford 6.0 Powerstroke injection timing

Image source: xecong.vn

The Ford 6.0 Powerstroke diesel engine, a powerhouse known for its impressive torque and capability, has a reputation that precedes it. While often lauded for its performance potential, it’s also a complex machine that demands precise calibration and understanding to run optimally. At the heart of its efficient operation lies a critical parameter: Ford 6.0 Powerstroke injection timing. This isn’t just a technical specification; it’s the heartbeat of your engine, dictating how smoothly, powerfully, and economically your truck performs.

For any owner of a Ford truck equipped with the legendary 6.0L Powerstroke, grasping the nuances of injection timing is not just beneficial, it’s essential. Improper timing can lead to a cascade of issues, ranging from decreased fuel efficiency and noticeable power loss to severe engine damage over time. Understanding how this system works, what can go wrong, and how to diagnose and correct problems can save you significant headaches and repair costs, ensuring your trusty Powerstroke continues to serve you reliably for years to come.

In this comprehensive guide, we’ll dive deep into the world of Ford 6.0 Powerstroke injection timing. We’ll explore the fundamental principles that govern this system, examine the complex interplay of components, identify the tell-tale signs of timing issues, and equip you with actionable insights for diagnosis and resolution. Whether you’re a seasoned mechanic or a curious truck owner, preparing to arm yourself with knowledge about your 6.0 Powerstroke engine, this article is designed to illuminate one of its most vital operational aspects.

Quick Answers to Common Questions

What is Ford 6.0 Powerstroke injection timing?

Ford 6.0 Powerstroke injection timing refers to the precise moment fuel is sprayed into your engine’s cylinders relative to the piston’s position. It’s a critical factor that dictates how efficiently and powerfully your engine runs.

Why is injection timing important for my 6.0 Powerstroke?

Proper Ford 6.0 Powerstroke injection timing is essential for maximizing horsepower, optimizing fuel economy, reducing harmful emissions, and ensuring the overall longevity of your engine. Getting it right makes a huge difference!

What are the signs of incorrect Ford 6.0 Powerstroke injection timing?

If your Ford 6.0 Powerstroke injection timing is off, you might notice reduced power, poor fuel economy, excessive black or white smoke, a rough idle, or increased engine noise. These are all signs something needs attention.

Can I adjust my Ford 6.0 Powerstroke injection timing myself?

While advanced tuning software allows for Ford 6.0 Powerstroke injection timing adjustments, it’s a complex process that requires specific tools and expert knowledge. It’s generally best left to professional technicians to avoid engine damage.

How does the engine’s computer control Ford 6.0 Powerstroke injection timing?

Your Ford 6.0 Powerstroke’s Powertrain Control Module (PCM) continuously adjusts injection timing in real-time based on sensor inputs like engine load, RPM, and temperature. This dynamic control ensures optimal performance and efficiency under varying conditions.

📋 Table of Contents

- Understanding the Basics of Ford 6.0 Powerstroke Injection Timing

- How the 6.0 Powerstroke’s HEUI System Manages Injection Timing

- Symptoms of Incorrect 6.0 Powerstroke Injection Timing

- Factors Affecting Ford 6.0 Powerstroke Injection Timing

- Diagnosing and Correcting 6.0 Powerstroke Injection Timing Problems

- Optimizing Your Ford 6.0 Powerstroke Injection Timing for Performance and Longevity

- Conclusion

Understanding the Basics of Ford 6.0 Powerstroke Injection Timing

At its core, injection timing in any diesel engine refers to the precise moment fuel is injected into the combustion chamber relative to the piston’s position. For the Ford 6.0 Powerstroke engine, this timing is meticulously controlled to ensure optimal combustion. Unlike gasoline engines where a spark ignites a pre-mixed fuel-air charge, diesel engines rely on the heat generated by compressing air to ignite the fuel. This makes the timing of fuel delivery paramount.

Learn more about Ford 6.0 Powerstroke injection timing – Ford 6.0 Powerstroke Injection Timing: How It Affects Your Engine

Image source: 2.bp.blogspot.com

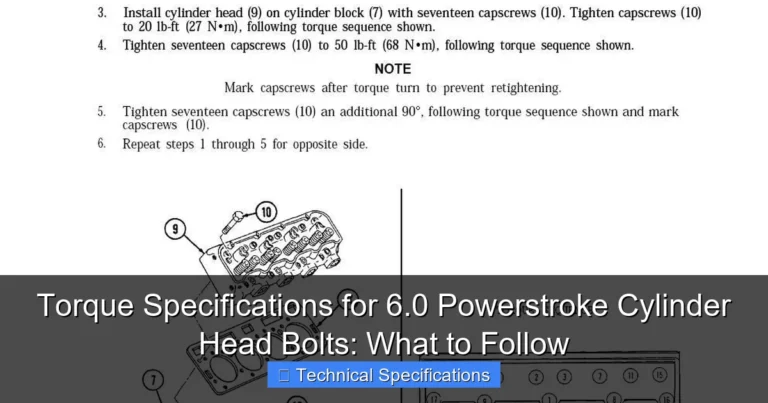

What is Injection Timing? The Degrees of Precision

In technical terms, injection timing is measured in degrees of crankshaft rotation. The key reference point is Top Dead Center (TDC), the highest point the piston reaches in the cylinder. Fuel injection typically begins before TDC (BTDC) when the piston is still on its compression stroke. The goal is to introduce fuel at precisely the right moment so that maximum pressure and temperature are achieved shortly after TDC, maximizing the force exerted on the piston as it begins its power stroke. If fuel is injected too early (advanced timing) or too late (retarded timing), combustion efficiency plummets.

| Parameter | Typical Value / Range | Relevance / Impact on Timing |

|---|---|---|

| Base Idle Injection Timing | 4-8° Before Top Dead Center (BTDC) | Optimized for smooth idle, reduced noise, and emissions. |

| Maximum Injection Timing (Under Load) | 20-30° BTDC (Varies with RPM & Load) | Advances for improved power, fuel efficiency, and combustion at higher RPMs/loads. |

| Injection Control Pressure (ICP) | 500-750 PSI (Idle) / 3000-4000 PSI (WOT) | Critical for injector function; low ICP causes misfires, reduced power, and affects the precision of injection timing. |

| FICM Main Power Voltage | 48.0-48.5 Volts (Key On Engine Running) | Essential for firing injectors accurately and timely. Low voltage impacts injection quality and timing. |

| Desired vs. Actual Timing Variance | Typically < 0.5-1.0° (Deviation) | Large deviation indicates issues with cam/crank sensors, high-pressure oil system, or injector problems, impacting engine performance. |

Why is Timing So Crucial for Diesel Engines?

The importance of accurate diesel engine timing cannot be overstated. It directly impacts:

- Combustion Efficiency: Correct timing ensures a complete and efficient burn of the fuel, extracting maximum energy.

- Power and Torque: Optimal timing delivers the peak pressure at the ideal point, leading to maximum horsepower and torque output.

- Fuel Economy: Efficient combustion means less wasted fuel, translating to better miles per gallon.

- Emissions: Proper timing helps reduce harmful exhaust emissions by ensuring a cleaner burn.

- Engine Longevity: Incorrect timing can lead to excessive heat, stress on internal components, and premature wear.

- Engine Noise and Smoothness: An engine with correctly set Powerstroke injection timing will run quieter and smoother.

Key Components Involved in 6.0 Powerstroke Timing

The Ford 6.0 Powerstroke utilizes a sophisticated Hydraulic Electronic Unit Injector (HEUI) system, meaning high-pressure engine oil is used to actuate the fuel injectors. Several critical components work in concert to manage injection timing:

- Powertrain Control Module (PCM): The “brain” of the engine, receiving sensor data and commanding the FICM.

- Fuel Injection Control Module (FICM): Provides the high voltage (48V) needed to fire the solenoid-actuated HEUI injectors. It works under PCM command.

- Camshaft Position (CMP) Sensor & Crankshaft Position (CKP) Sensor: These sensors provide vital rotational position data to the PCM, allowing it to determine engine speed and piston position. This is fundamental for accurate timing.

- High-Pressure Oil Pump (HPOP) and Injector Pressure Regulator (IPR) Valve: The HPOP generates the high oil pressure, and the IPR regulates it, which is then sent to the injectors to actuate them.

- Fuel Injectors: These are the final delivery system, spraying atomized fuel directly into the cylinders. Their internal components (spool valve, intensifier piston) are critical to precise injection.

How the 6.0 Powerstroke’s HEUI System Manages Injection Timing

The HEUI system is a marvel of engineering, known for its ability to deliver precise fuel control. The 6.0 Powerstroke injection timing is not fixed; it’s dynamically adjusted by the PCM based on numerous factors like engine load, speed, temperature, and atmospheric pressure. This allows for optimal performance across a wide range of operating conditions.

Learn more about Ford 6.0 Powerstroke injection timing – Ford 6.0 Powerstroke Injection Timing: How It Affects Your Engine

Image source: haiquanonline.com.vn

The Role of the FICM in Fuel Delivery

The Fuel Injection Control Module (FICM) is arguably one of the most unique and vital components in the 6.0 Powerstroke engine‘s fuel system. It takes the 12-volt supply from the vehicle and boosts it to 48 volts, which is then used to energize the solenoids in each fuel injector. This high voltage allows for rapid and precise opening and closing of the injector, enabling the PCM to command extremely accurate injection events. Any drop in FICM voltage below acceptable levels (typically below 45-48V) can severely impact injector performance and thus, injection timing.

High-Pressure Oil System and Injector Operation

The HPOP, driven by the engine, generates oil pressure upwards of 3,600 PSI (later models even higher). This high-pressure oil is directed through oil rails to each injector. When the FICM commands an injector to fire, its solenoid opens a spool valve, allowing this high-pressure oil to enter the injector. This oil then acts on an intensifier piston, which in turn dramatically increases the pressure of the fuel inside the injector (up to 26,000 PSI) and forces it through the nozzle into the cylinder. The speed and duration of the spool valve’s opening, controlled by the FICM, directly affect the start and end of the injection event, thus controlling the injection timing and fuel quantity.

Sensors Guiding the PCM for Precise Timing

The PCM relies on a sophisticated network of sensors to determine the optimal injection timing:

- Camshaft Position (CMP) Sensor & Crankshaft Position (CKP) Sensor: These are the primary inputs for engine speed and piston position. The PCM uses these signals to synchronize all fuel injection events.

- Engine Oil Temperature (EOT) Sensor: Affects timing due to oil viscosity changes.

- Engine Coolant Temperature (ECT) Sensor: Colder engines often require more advanced timing for easier starting and better combustion.

- Intake Air Temperature (IAT) Sensor: Air density changes require timing adjustments.

- Manifold Absolute Pressure (MAP) Sensor & Barometric Pressure (BARO) Sensor: Provide information on engine load and atmospheric conditions.

- Exhaust Back Pressure (EBP) Sensor: Crucial for EGR operation and can influence timing in some calibrations.

- Fuel Rail Pressure (FRP) Sensor: Monitors fuel pressure in the primary fuel system.

The 6.0 Powerstroke also employs a “split shot” injection strategy. This involves a small pilot injection of fuel followed by the main injection. The pilot shot helps to pre-heat the combustion chamber and reduce combustion noise (diesel knock) while improving emissions. The timing and duration of both the pilot and main injections are precisely managed by the PCM and FICM.

Symptoms of Incorrect 6.0 Powerstroke Injection Timing

When the delicate balance of Ford 6.0 Powerstroke injection timing is disturbed, your truck will almost certainly let you know. Recognizing these symptoms early can prevent further complications and aid in faster diagnosis. Ignoring them can lead to costly repairs down the line.

Performance Issues: Loss of Power and Poor Acceleration

One of the most immediate and frustrating symptoms of incorrect injection timing is a noticeable drop in engine performance. If the fuel is injected too late, the combustion event occurs past its optimal point, meaning less energy is transferred to the pistons. This results in:

- Reduced horsepower and torque.

- Sluggish acceleration, especially when pulling a load.

- A general feeling that the engine is “losing its pep.”

Fuel Economy Decline

Inefficient combustion directly translates to wasted fuel. If your 6.0 Powerstroke timing is off, the engine will consume more fuel to produce the same amount of power, leading to a significant decrease in your miles per gallon. This is often one of the first subtle signs many truck owners notice.

Rough Idling and Stalling

An engine with improper timing may struggle to maintain a consistent idle. You might experience:

- A “lumpy” or erratic idle.

- Shaking or vibrations felt through the cabin.

- Sudden stalling, particularly at low speeds or when coming to a stop.

Increased Smoke Production

The color of your exhaust smoke can be a strong indicator of combustion issues related to timing:

- Black Smoke: Often indicates unburned fuel, usually due to retarded timing or insufficient air for combustion.

- White Smoke: Can be caused by partially burned fuel, especially in cold conditions, suggesting very late timing or water in the fuel.

- Blue Smoke: Typically points to burning oil, but can sometimes be exacerbated by timing issues if it leads to poor ring sealing or injector problems.

Hard Starting, Especially When Cold

When injection timing is not correct, especially if it’s too retarded, the engine will have difficulty igniting the fuel, particularly in colder temperatures. This results in prolonged cranking times and a reluctant start.

Engine Noise: Knocking or Excessive Clatter

An advanced injection timing can lead to an early, rapid combustion event, creating a distinct, harsh metallic knocking sound, often referred to as “diesel knock” or “clatter.” While a certain degree of clatter is normal for a diesel, excessive or unusually loud knocking can signal an issue. Retarded timing can also cause a duller, heavier knock.

Diagnostic Trouble Codes (DTCs)

The PCM is constantly monitoring engine parameters. If it detects a fault related to the components influencing Powerstroke injection timing, it will store a Diagnostic Trouble Code (DTC) and illuminate the Check Engine Light (CEL). Common DTCs related to timing issues include:

- P0340, P0341, P0344: Camshaft Position Sensor (CMP) circuit malfunctions.

- P0611: FICM performance error.

- P0261-P0284: Injector circuit low/high or contribution/balance faults for individual cylinders, often pointing to injector electrical issues or internal failures.

- P0335: Crankshaft Position Sensor (CKP) circuit malfunction.

Here’s a quick reference table for some common DTCs and their potential implications for 6.0 Powerstroke timing:

| DTC | Description | Potential Timing Impact | Action |

|---|---|---|---|

| P0340/P0341 | CMP Sensor Circuit Malfunction | Directly affects PCM’s ability to determine engine position and synchronize injection. | Inspect/replace CMP sensor and wiring. |

| P0335 | CKP Sensor Circuit Malfunction | Loss of primary engine speed/position signal; severe timing disruption or no-start. | Inspect/replace CKP sensor and wiring. |

| P0611 | FICM Performance | Low FICM voltage or internal fault, leading to weak injector firing and improper timing. | Test FICM voltage, repair/replace FICM. |

| P0261-P0284 | Cylinder Injector Circuit Low/High | Individual injector electrical fault, preventing proper firing and affecting timing of that cylinder. | Perform buzz test, inspect injector harness, replace faulty injector. |

| P1316 | Injector Circuit/IDM Fault | Broader issue with the FICM (previously IDM) or injector harness, impacts multiple injectors. | Diagnose FICM, harness, or multiple injectors. |

Factors Affecting Ford 6.0 Powerstroke Injection Timing

Given the complexity of the HEUI system, several components and conditions can throw off your 6.0 Powerstroke injection timing. Understanding these potential culprits is key to effective diagnosis and repair.

Sensor Malfunctions: The Eyes and Ears of the PCM

The PCM relies heavily on accurate data from its array of sensors. If any of these sensors provide incorrect readings, the PCM will make poor decisions regarding injection timing:

- Camshaft Position (CMP) Sensor & Crankshaft Position (CKP) Sensor: These are paramount. A faulty CMP or CKP sensor can cause erratic timing, hard starting, or even a no-start condition. They can also cause incorrect RPM readings, throwing off the entire timing strategy.

- Engine Oil Temperature (EOT) Sensor: An incorrect EOT reading might cause the PCM to use the wrong oil viscosity compensation, impacting injector operation.

- Exhaust Back Pressure (EBP) Sensor: A clogged EBP sensor tube or a faulty sensor can lead to incorrect EGR valve operation and subsequent timing adjustments that hurt performance.

FICM Issues: The Power Behind the Punch

The FICM’s role in providing 48V to the injectors is non-negotiable. Any compromise in its output can directly affect injection timing:

- Low FICM Voltage: If the FICM output drops below 45 volts, the injectors may not fire quickly or forcefully enough, leading to retarded timing, rough idle, misfires, and hard starting. This is one of the most common 6.0 Powerstroke engine issues.

- Internal FICM Failure: Component failure within the FICM itself can lead to intermittent or complete loss of injector control for one or more cylinders.

Injector Problems: The Fuel Deliverers

The fuel injectors themselves are mechanical and electrical components prone to wear and failure:

- Sticking Injectors: Debris or wear can cause the internal spool valve or intensifier piston to stick, delaying or altering injection.

- Worn Injectors: Over time, the internal components wear, leading to poor spray patterns, reduced fuel delivery, and inefficient combustion, which is functionally similar to incorrect timing.

- Electrical Issues: Open or short circuits in the injector’s solenoid or wiring harness will prevent it from firing correctly, if at all.

HPOP or IPR Valve Failure: The Oil Pressure Source

The high-pressure oil system is integral to HEUI injector operation. Problems here directly affect how quickly and forcefully injectors fire:

- HPOP Failure: If the HPOP cannot generate sufficient pressure, the injectors will not operate correctly, causing a no-start or rough-running condition.

- IPR Valve Malfunction: A faulty IPR valve (which regulates HPOP pressure) can lead to either excessively high or low oil pressure, both detrimental to proper injection timing. A common issue is a screen on the IPR valve becoming clogged.

PCM Calibration or Software Glitches

The PCM’s programming dictates the entire injection timing strategy. Corrupted software or an outdated calibration can lead to incorrect timing commands.

Aftermarket Tuning Implications

While custom tunes can unlock significant power and efficiency, they must be reputable and properly designed. A poorly written tune can aggressively advance or retard injection timing beyond safe limits, leading to:

- Excessive cylinder pressure (damaging to head gaskets, pistons, rods).

- Increased EGTs (Exhaust Gas Temperatures).

- Reduced engine longevity.

- Increased turbocharger lag.

Diagnosing and Correcting 6.0 Powerstroke Injection Timing Problems

Diagnosing Ford 6.0 Powerstroke injection timing issues requires a systematic approach and the right tools. While some basic checks can be done at home, professional diagnostic equipment is often necessary for pinpoint accuracy.

Essential Diagnostic Tools

- OBD-II Scan Tool: A must-have for reading DTCs, monitoring live data (FICM voltage, ICP pressure, IPR duty cycle, CKP/CMP sync), and performing diagnostic tests (like injector buzz test). Ford-specific tools (like IDS) offer the most in-depth diagnostics.

- Multimeter: For checking voltage, resistance, and continuity in wiring and components like the FICM, sensors, and injector harness.

- Fuel Pressure Gauge: To verify adequate low-pressure fuel delivery to the injectors.

- Oil Pressure Gauge: While ICP sensor monitors high-pressure oil, a manual gauge can verify the HPOP’s mechanical health if suspect.

Checking FICM Voltage

This is a crucial first step for many 6.0 Powerstroke engine issues. Use a multimeter or a capable scan tool to check FICM voltage in three scenarios:

- Key On, Engine Off (KOEO): Should be around 48.0-49.0 volts.

- During Cranking: Should remain above 45.0 volts, ideally staying close to 47.0-48.0 volts.

- Engine Running (KOER): Should maintain a steady 48.0-49.0 volts.

Any readings consistently below 45 volts, especially during cranking or running, indicate a failing FICM that needs repair or replacement. This will directly impact injection timing.

Sensor Testing

- CMP/CKP Sensors: While difficult to test directly without an oscilloscope, you can check for continuity in their circuits and ensure the PCM is receiving a consistent RPM signal via a scan tool. Ensure both sensors show a “sync” status.

- ICP Sensor: Monitor ICP pressure and IPR duty cycle with a scan tool. Low ICP pressure during cranking or running, especially with high IPR duty cycle, points to an HPOP or IPR issue.

Injector Buzz Test and Contribution Test

These are invaluable diagnostic tools performed with a scan tool:

- Buzz Test: The PCM commands each injector to “buzz” (actuate its solenoid). You listen for consistent buzzing from all 8 injectors. A quiet or absent buzz indicates an electrical issue (FICM, harness, or injector solenoid) for that specific injector, directly impacting its injection timing.

- Contribution/Balance Test: While the engine is running, the PCM temporarily disables each injector one by one and measures the RPM drop. A smaller-than-expected RPM drop for a cylinder indicates that injector wasn’t contributing much, pointing to an injector issue or a compression problem. This test helps identify weak or failing injectors that are not delivering fuel with the correct timing or quantity.

HPOP and IPR System Checks

Using a scan tool, monitor ICP pressure (actual vs. desired) and IPR duty cycle. During cranking, you should see ICP pressure build rapidly (e.g., to 500 PSI or more for starting) with the IPR duty cycle fluctuating. If pressure is low despite high IPR duty cycle, investigate the HPOP, standpipes, dummy plugs, or IPR valve itself (check for debris on the screen).

PCM Re-flash or Updates

Sometimes, simply updating the PCM’s software to the latest Ford calibration can resolve timing-related issues, especially if they are software-based glitches or if performance improvements have been released. This should be done by a Ford dealer or a reputable shop with Ford diagnostic capabilities.

Professional Assistance: When to Call the Pros

If you’ve performed basic checks and are still stumped, or if the diagnosis points to complex internal engine work (like injector replacement or HPOP service), it’s always best to consult a qualified diesel mechanic with experience in Ford 6.0 Powerstroke engines. They have specialized tools, training, and experience to handle these intricate repairs safely and effectively.

Optimizing Your Ford 6.0 Powerstroke Injection Timing for Performance and Longevity

Beyond fixing problems, there are proactive steps you can take to ensure your 6.0 Powerstroke engine maintains optimal injection timing, leading to better performance, efficiency, and a longer life span.

The Role of Quality Fuel and Filters

This cannot be stressed enough. The HEUI fuel system is extremely sensitive to fuel quality:

- Clean Fuel: Always use high-quality, reputable diesel fuel. Water and contaminants are the enemies of injectors and the HEUI system.

- Regular Filter Changes: Adhere strictly to or even exceed the recommended intervals for changing both your primary and secondary fuel filters. Clogged filters restrict fuel flow, stressing the fuel pump and potentially affecting injector performance.

- Fuel Additives: Consider using a quality fuel additive, especially those that boost cetane, lubricate the fuel system, and disperse water. This can help keep injectors clean and functioning precisely.

Regular Maintenance Schedule

A well-maintained engine is a happy engine:

- Oil Changes: Since the 6.0L Powerstroke uses engine oil to actuate its injectors, regular oil changes with the correct viscosity (e.g., 15W-40 or 5W-40 synthetic for colder climates) and a quality oil filter are critical. Dirty or incorrect oil can lead to injector sticking and HPOP wear.

- Air Filter: A clean air filter ensures proper airflow for combustion, which indirectly supports efficient fuel burning and timing.

- Cooling System: Maintaining a healthy cooling system prevents overheating, which can stress all engine components and impact sensor readings.

Monitoring Key Parameters

Investing in a dedicated monitoring tool (like an Edge Insight, SCT Livewire, or a compatible OBD-II app) allows you to constantly keep an eye on vital 6.0 Powerstroke engine parameters. Regularly monitoring values like:

- FICM voltage

- ICP pressure (actual and desired)

- IPR duty cycle

- Engine Oil Temperature (EOT) vs. Engine Coolant Temperature (ECT) (delta)

can provide early warnings of impending issues before they escalate into major problems affecting injection timing.

Custom Tuning Considerations

For those looking to extract more power or optimize efficiency, custom tuning can adjust Ford 6.0 Powerstroke injection timing, fuel quantity, and pressure. However, choose wisely:

- Reputable Tuners: Only use tunes from well-regarded companies with a proven track record. Cheap or generic tunes can cause more harm than good.

- EGT Monitoring: If running custom tunes, an EGT (Exhaust Gas Temperature) gauge is highly recommended to ensure you’re not over-stressing the engine with excessive heat, often a byproduct of aggressive timing.

- Balance: Seek a balance between performance gains and engine longevity. Over-advancing timing for power can increase cylinder pressure and lead to head gasket failures.

Understanding EGR and its Impact

The Exhaust Gas Recirculation (EGR) system, while designed to reduce emissions, can be a source of problems for the 6.0L. A sticking or failed EGR valve can affect combustion efficiency and, indirectly, the PCM’s timing strategy. Keeping your EGR system clean and functional (or considering legal and proper aftermarket solutions for off-road use) can contribute to overall engine health and stable injection timing.

Conclusion

The Ford 6.0 Powerstroke injection timing is a complex yet fascinating aspect of this powerful diesel engine. It’s the silent conductor orchestrating the symphony of combustion, directly influencing everything from your truck’s raw power and fuel efficiency to its smooth operation and long-term durability. Far from a set-it-and-forget-it parameter, injection timing is a dynamic process constantly adjusted by the PCM, reliant on a multitude of sensors and robust components.

Understanding the intricacies of the HEUI system, recognizing the symptoms of incorrect timing, and knowing how to diagnose and address these issues are crucial skills for any 6.0 Powerstroke engine owner. From vigilant monitoring of FICM voltage and sensor data to adhering to a strict maintenance regimen with quality fluids and filters, proactive care is your best defense against timing-related woes.

Whether you’re battling a rough idle, chasing lost power, or simply striving for peak performance and longevity from your truck, remember that precise Ford 6.0 Powerstroke injection timing is fundamental. By investing your time in learning about and maintaining this vital system, you’re not just fixing a problem; you’re ensuring your 6.0L Powerstroke continues to be the reliable, hard-working machine it was designed to be, ready to tackle any challenge you throw its way.

🎥 Related Video: 6.7l powerstroke injection pump timing

📺 Friesen Automotive

Frequently Asked Questions

What is Ford 6.0 Powerstroke injection timing?

Ford 6.0 Powerstroke injection timing refers to the precise moment fuel is delivered into the combustion chamber relative to the piston’s position and engine cycle. It’s a critical parameter that dictates when combustion begins within the cylinder.

Why is correct injection timing crucial for my 6.0 Powerstroke engine?

Proper injection timing is vital for optimal engine performance, fuel efficiency, and reduced emissions. Incorrect timing can lead to incomplete combustion, resulting in reduced power, excessive exhaust smoke, and increased wear on engine components.

How does the 6.0 Powerstroke’s injection timing typically work?

The 6.0 Powerstroke’s injection timing is electronically controlled by the Powertrain Control Module (PCM) and the Fuel Injection Control Module (FICM). These modules use sensor inputs, such as crankshaft and camshaft position, to precisely command the high-pressure oil system to fire the injectors at the optimal moment.

What are the symptoms of incorrect Ford 6.0 Powerstroke injection timing?

Symptoms of incorrect Ford 6.0 Powerstroke injection timing can include hard starting, a rough idle, noticeable loss of power, poor fuel economy, and excessive black or white smoke from the exhaust. You might also experience increased engine noise or hesitation under acceleration.

Can the Ford 6.0 Powerstroke injection timing be adjusted or tuned?

While the base injection timing is set by the engine’s design and PCM programming, it can be influenced by aftermarket tuners or custom programming. These modifications can alter the timing strategy for improved performance or fuel economy, but should be done by knowledgeable professionals.

What common issues can affect injection timing on a 6.0 Powerstroke?

Several issues can negatively impact the 6.0 Powerstroke’s injection timing, including faulty crankshaft or camshaft position sensors, a failing FICM, or problems with the high-pressure oil system. Worn injectors or issues with the PCM itself can also lead to incorrect timing commands.