Engine Hoists for Ford 6.0 Powerstroke Engine Removal: Lifting Made Easy

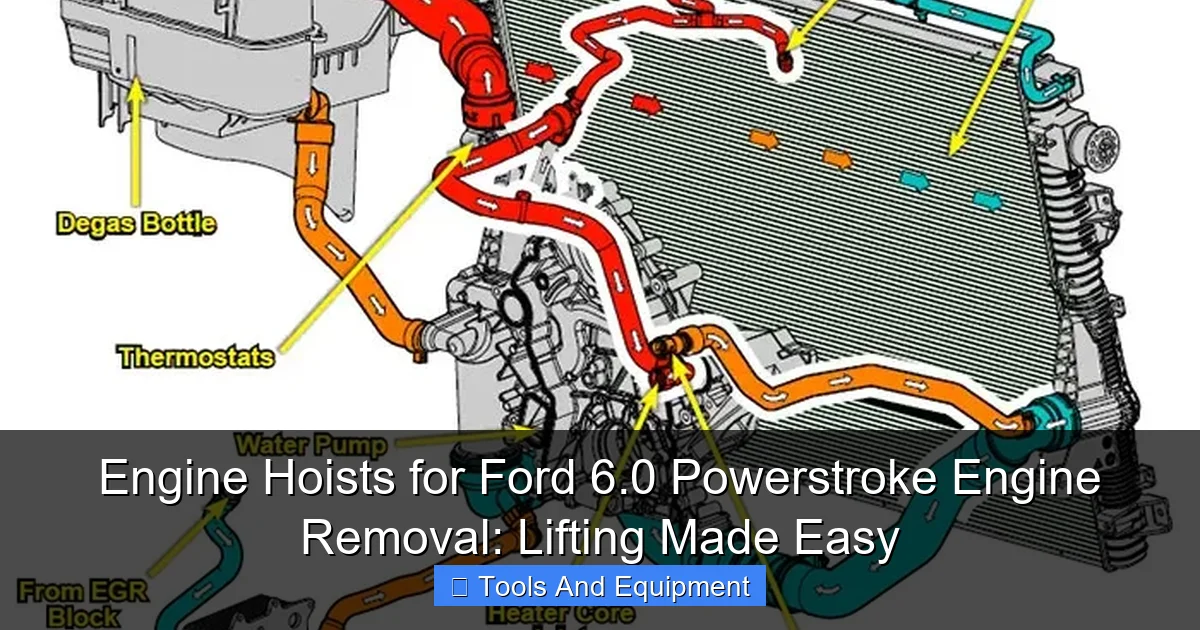

Featured image for this comprehensive guide about Engine hoists for Ford 6.0 Powerstroke engine removal

Image source: freedomracing.com

Engine Hoists for Ford 6.0 Powerstroke Engine Removal: Lifting Made Easy

The Ford 6.0 Powerstroke diesel engine is a magnificent beast, known for its raw power and the incredible capabilities it lends to Ford Super Duty trucks. However, like any complex piece of machinery, it occasionally requires significant maintenance or even complete removal for rebuilding or replacement. If you’ve ever contemplated or attempted this task, you know one thing for sure: the 6.0 Powerstroke is incredibly heavy.

Attempting to remove such a formidable engine without the proper tools isn’t just inefficient; it’s downright dangerous. This is where the mighty engine hoist, often referred to as a cherry picker or shop crane, becomes an indispensable asset. It’s not merely a convenience; it’s a critical piece of equipment that ensures safety, protects your valuable engine, and saves your back. Whether you’re a seasoned mechanic or a determined DIY enthusiast, understanding the nuances of choosing and using an engine hoist for Ford 6.0 Powerstroke engine removal is paramount to a successful operation.

In this comprehensive guide, we’ll delve deep into everything you need to know about lifting that formidable Powerstroke engine out of its bay. We’ll explore different types of hoists, essential features to look for, a step-by-step overview of the removal process, crucial safety protocols, and tips for maintaining your equipment. Get ready to lift with confidence and conquer your next 6.0 Powerstroke engine removal project!

Quick Answers to Common Questions

What kind of engine hoist do I need for a Ford 6.0 Powerstroke?

You’ll definitely want a robust engine hoist with at least a 2-ton (4,000 lb) capacity to safely lift the heavy Ford 6.0 Powerstroke engine. A folding hydraulic shop crane is a popular choice for its power and ease of storage.

What other equipment is essential for Ford 6.0 Powerstroke engine removal?

Besides the engine hoist, a quality engine load leveler is crucial for balancing the Ford 6.0 Powerstroke during removal and installation, ensuring a smooth, controlled lift. You’ll also need sturdy chains or lifting slings.

Is removing a 6.0 Powerstroke with an engine hoist difficult for a DIYer?

While the actual lifting with an engine hoist is straightforward, preparing a Ford 6.0 Powerstroke for removal is a complex task requiring mechanical knowledge. Take your time, follow a detailed guide, and always prioritize safety.

Can I rent an engine hoist for my Ford 6.0 Powerstroke project?

Absolutely! Many equipment rental stores and even some auto parts stores offer engine hoists for rent, which is a great option if you don’t plan on frequent engine removals. Just ensure it meets the capacity requirements for your Ford 6.0 Powerstroke.

Where should I attach the engine hoist chains to the 6.0 Powerstroke?

For a Ford 6.0 Powerstroke, you’ll typically attach the chains to strong, secure points on the engine like exhaust manifold bolts, cylinder head bolts, or dedicated lifting eyes if present. Using an engine load leveler will help you find the perfect balance point for a stable lift.

📋 Table of Contents

- Why an Engine Hoist is Non-Negotiable for Your 6.0 Powerstroke

- Understanding Different Types of Engine Hoists: Which One for Your Powerstroke?

- Key Features and Specifications to Look for in a 6.0 Powerstroke Engine Hoist

- The Engine Removal Process: Step-by-Step with Your Hoist

- Safety First: Essential Precautions When Using an Engine Hoist

- Maintaining Your Engine Hoist: Ensuring Longevity and Reliability

- Comparative Overview of Engine Hoists for Powerstroke Engines

- Conclusion: Lift with Confidence, Work with Ease

Why an Engine Hoist is Non-Negotiable for Your 6.0 Powerstroke

Let’s not mince words: attempting to remove a Ford 6.0 Powerstroke engine without a purpose-built engine hoist is a recipe for disaster. This isn’t just about making the job easier; it’s about making it possible and, most importantly, safe. The sheer mass of this diesel powerhouse demands a robust, reliable lifting solution.

Learn more about Engine hoists for Ford 6.0 Powerstroke engine removal – Engine Hoists for Ford 6.0 Powerstroke Engine Removal: Lifting Made Easy

Image source: dieselhub.com

The Sheer Weight of the 6.0 Powerstroke

A bare 6.0 Powerstroke engine (long block) can weigh in the ballpark of 900 to 1,000 pounds. Add accessories like the turbocharger, intake manifold, injectors, and exhaust manifolds, and that weight can easily climb to over 1,200 pounds or more. That’s half a ton of steel and cast iron! For perspective, that’s equivalent to lifting a small horse or a grand piano. Human strength alone is utterly inadequate for such a task, and even a team of strong individuals would be putting themselves at extreme risk of injury.

| Hoist Type / Description | Typical Capacity (lbs) | Approx. Max Lift Height (in) | Key Considerations for 6.0L Powerstroke |

|---|---|---|---|

| Standard 2-Ton Folding Engine Hoist | 4,000 lbs | 78 – 85 inches | Sufficient capacity for ~950lb engine. May struggle with reach over tall Super Duty fenders; often requires removing front clip/grille. |

| Heavy-Duty 2-Ton Long-Reach Hoist | 4,000 lbs | 85 – 95 inches | Improved reach and lift height compared to standard. Highly recommended for Super Duty trucks to clear fenders and firewall. |

| 3-Ton Shop Crane / Heavy-Duty | 6,000 lbs | 90 – 100 inches | Excellent stability, capacity, and reach. Often found in professional shops. Makes the job significantly easier due to robust build. |

| Gantry Crane System (Fixed or Portable) | 4,000 – 8,000 lbs | 90 – 120+ inches (adjustable) | Ultimate in stability and lifting power. Ideal for shops with dedicated space. Offers superior control for precise engine placement. |

Using improper lifting techniques or inadequate equipment could lead to:

- Severe personal injury, including crushed limbs, back injuries, or even fatalities.

- Extensive damage to the engine itself, potentially bending crucial components or causing cracks.

- Damage to the vehicle’s bodywork or frame.

- Financial losses from medical bills, repair costs, and project delays.

Safety and Efficiency Benefits

A proper heavy-duty engine hoist eliminates these risks by providing a controlled, stable lifting mechanism. It allows a single person (or two for optimal safety and control) to precisely maneuver the engine, guiding it out of the tight confines of the engine bay and safely onto an engine stand or workbench. This precision not only prevents accidents but also streamlines the entire process, making a daunting task manageable and significantly more efficient.

Think of the engine hoist as an investment. An investment in your safety, in the longevity of your valuable tools and equipment, and ultimately, in the success of your automotive projects. For any serious work involving a diesel engine removal, especially one as substantial as the 6.0 Powerstroke, an engine crane is not an option – it’s a necessity.

Understanding Different Types of Engine Hoists: Which One for Your Powerstroke?

When it comes to selecting the right engine hoist, you’ll encounter a few primary types, each with its own advantages and ideal applications. For a beast like the Ford 6.0 Powerstroke, your choice will largely depend on your available space, budget, and the frequency of use.

Learn more about Engine hoists for Ford 6.0 Powerstroke engine removal – Engine Hoists for Ford 6.0 Powerstroke Engine Removal: Lifting Made Easy

Image source: ashevilleengine.com

Foldable Hydraulic Engine Hoists (Cherry Pickers)

This is arguably the most common and popular type of engine hoist for home garages and small to medium-sized shops. These hoists feature a hydraulic ram that provides the lifting power, a boom that extends over the engine, and foldable legs that allow for compact storage when not in use. They typically come with capacities ranging from 1 to 2 tons (2,000 to 4,000 pounds), making them perfectly suited for 6.0 Powerstroke engine removal.

- Pros: Affordable, relatively portable (on wheels), excellent for space-conscious users, sufficient capacity for the 6.0 Powerstroke engine weight.

- Cons: Can be cumbersome to maneuver in very tight spaces, requires manual pumping of the hydraulic ram, maximum reach can sometimes be a limiting factor for taller trucks.

Shop Cranes / Fixed-Base Engine Hoists

Less common for the average DIYer, these hoists are often found in professional garages where space isn’t as much of a concern. They typically have a fixed, non-foldable base, which provides enhanced stability. While they share the hydraulic lifting mechanism, their larger footprint means they are not designed for portability but for constant, heavy-duty use in a dedicated workspace.

- Pros: Superior stability, often higher lifting capacities, built for frequent commercial use.

- Cons: Not portable, require significant dedicated floor space, generally more expensive.

Gantry Cranes

For truly heavy-duty applications or environments with very high ceilings and large work areas, a gantry crane might be considered. These are large, overhead systems that run on tracks or are mobile on large casters, allowing for movement across a wide area. While overkill for most home users tackling a single 6.0 Powerstroke engine removal, they are ideal for industrial settings or shops that regularly handle massive diesel engines or equipment.

- Pros: Highest lifting capacities, excellent reach and coverage, ideal for professional shops.

- Cons: Very expensive, require significant space and ceiling height, not practical for most home users.

For most individuals tackling a Ford 6.0 Powerstroke engine removal, a foldable hydraulic engine hoist with a 2-ton capacity is the sweet spot, offering the right balance of power, portability, and affordability.

Key Features and Specifications to Look for in a 6.0 Powerstroke Engine Hoist

Choosing the right engine hoist goes beyond just picking a type. You need to scrutinize specific features and specifications to ensure it can safely and effectively handle the demands of a 6.0 Powerstroke engine.

Lifting Capacity: Don’t Compromise

This is arguably the most critical specification. As discussed, the 6.0 Powerstroke engine weight can exceed 1,200 pounds with accessories. Therefore, you absolutely need an engine hoist with a rated lifting capacity of at least 1.5 tons (3,000 pounds). A 2-ton (4,000 pounds) capacity hoist offers a comfortable margin of safety, which is always recommended when dealing with such heavy loads. Never, under any circumstances, exceed the manufacturer’s stated lifting capacity.

Reach and Lift Height: Clear the Fender and Truck Frame

The Ford 6.0 Powerstroke sits fairly deep within the engine bay of a Super Duty truck. You need an engine crane with sufficient boom reach to get over the front of the truck and position the hook directly over the engine’s center of gravity. Equally important is the maximum lift height. The hoist must be able to lift the engine high enough to clear the frame rails, transmission, and any other obstacles during the removal process. Consider measuring the height from the ground to the top of your truck’s fender and ensuring your chosen hoist can easily clear it.

Construction Material and Durability

Look for hoists constructed from heavy-gauge steel. The frame, boom, and legs should feel robust and sturdy. Welds should be clean and consistent, indicating quality manufacturing. A well-built diesel engine hoist will have a durable powder-coat finish to resist rust and corrosion, extending its lifespan.

Portability and Storage

If your garage space is limited, a foldable engine hoist is an excellent choice. Check the dimensions when folded to ensure it will fit snugly against a wall or in a corner. Large, smooth-rolling swivel casters are essential for easy maneuverability, especially when loaded with a heavy engine.

Safety Features and Controls

- Hydraulic Release Valve: A smooth and controllable release valve is vital for precisely lowering the engine without sudden drops.

- Safety Latch Hook: The lifting hook should have a spring-loaded safety latch to prevent the engine chain or sling from slipping off.

- Locking Casters: While not all hoists have them, locking casters on the front wheels can add an extra layer of stability once the hoist is in position.

- Overload Protection: Some higher-end hydraulic rams include internal overload protection to prevent damage if you accidentally attempt to lift too much weight.

Investing in a quality Powerstroke engine hoist with these features will make your engine removal tool a reliable partner for many years to come.

The Engine Removal Process: Step-by-Step with Your Hoist

Removing a 6.0 Powerstroke engine is a complex task involving many steps before the hoist even comes into play. However, once all ancillary components are disconnected, the hoist becomes the star of the show. Here’s a simplified overview of the lifting phase:

Preparation is Key

Before you even think about lifting, ensure the engine is fully disconnected from the vehicle. This includes all wiring harnesses, fuel lines, coolant hoses, exhaust, and the transmission (which is usually separated and left in the truck). Drain all fluids to reduce weight and prevent spills. Remove the fan, shroud, and anything else that might interfere with the lift. A clean, well-lit, and level work area is paramount.

Connecting the Hoist

- Position the Truck: Ensure your truck is on a level surface, securely chocked, and ideally elevated on jack stands to provide ample clearance underneath if working on the transmission.

- Position the Hoist: Roll your engine hoist into position, extending its legs under the front of the truck as far as possible for maximum stability. The boom should be directly centered over the engine.

- Attach Chains/Slings: Using heavy-duty engine lifting chains or a nylon sling, attach the lifting points on the engine. The 6.0 Powerstroke typically has dedicated lifting eyes or strong points on the cylinder heads or intake manifold. Use a multi-point lifting spreader bar if necessary to maintain balance and prevent tilting. This is crucial for distributing the Powerstroke engine weight evenly.

- Hook Up: Connect the chains/sling to the hoist’s hook, ensuring the safety latch is engaged. Double-check all connections.

The Lift Itself

Begin slowly pumping the hydraulic ram. Watch the engine carefully as it just begins to take the weight. Make sure it lifts evenly. If it tilts excessively, lower it, re-adjust your lifting points, and try again. The goal is a perfectly balanced, stable lift. Once the engine is free of its mounts, raise it just enough to clear the transmission input shaft.

Maneuvering and Placement

With the engine disconnected and slightly raised, slowly and carefully pull the engine hoist backward, guiding the engine out of the engine bay. Have an assistant help guide the engine and watch for any snags or obstructions. Once clear of the truck, raise the engine to a comfortable working height and carefully maneuver it onto a sturdy engine stand. Securely bolt the engine to the stand before disconnecting the hoist.

This process requires patience, attention to detail, and a commitment to safety. Rushing or cutting corners can lead to costly mistakes and dangerous situations.

Safety First: Essential Precautions When Using an Engine Hoist

Working with heavy machinery like a Powerstroke engine and an engine hoist demands an unwavering commitment to safety. Neglecting precautions can lead to severe injuries or irreparable damage to equipment. Here are paramount safety tips for every lift:

Pre-Operation Checks

- Inspect the Hoist: Before every use, visually inspect the entire engine crane. Check for any signs of damage, cracks in welds, bent components, or leaks in the hydraulic system. Ensure all pins, bolts, and fasteners are present and secure.

- Check Hydraulic Fluid: Verify the hydraulic fluid level is adequate and that the ram operates smoothly without sticking or jerking.

- Test Operation: Perform a short, unloaded lift and lower cycle to ensure the hydraulic system and release valve are working correctly.

- Review Manual: Familiarize yourself with your specific hoist’s owner’s manual. It contains critical information about its operation, limitations, and maintenance.

Proper Weight Distribution and Balance

This is critical for preventing tipping and uncontrolled swings. Always aim to position the hoist hook directly over the engine’s center of gravity. Use a load leveler or spreader bar to adjust the balance as needed. If the engine is tilting significantly, lower it and readjust your lifting chains/slings until it hangs relatively level. An unbalanced load is an unstable load.

Clear Work Area

Ensure your workspace is free of clutter, tripping hazards, and anything that could obstruct the hoist’s movement or the engine’s path. Keep bystanders, especially children and pets, well away from the lifting area. The floor should be level and solid enough to support the combined weight of the hoist, engine, and truck.

Never Exceed Capacity

We’ve emphasized this before, but it bears repeating: know the exact 6.0 Powerstroke engine weight you’re lifting (including all attached accessories) and never, ever exceed the rated capacity of your engine hoist, chains, or slings. Overloading can lead to catastrophic failure of the equipment and severe consequences.

Personal Protective Equipment (PPE)

Always wear appropriate PPE:

- Safety Glasses: Protect your eyes from debris or hydraulic fluid.

- Work Gloves: Protect your hands from pinches, cuts, and grime.

- Steel-Toe Boots: Guard against dropped tools or components.

Remember, an engine hoist is a powerful tool designed to handle immense weights. Treat it with respect, follow all safety guidelines, and never take shortcuts. Your safety and the integrity of your equipment depend on it.

Maintaining Your Engine Hoist: Ensuring Longevity and Reliability

Just like any other valuable tool, your engine hoist requires regular maintenance to ensure its reliable operation and longevity. A well-maintained hoist is a safe hoist. Neglecting maintenance can lead to premature wear, performance degradation, or even dangerous failures.

Regular Inspections

Make a habit of performing a thorough visual inspection before and after each use, as well as periodically even if not in use. Look for:

- Frame and Boom: Check for any cracks, bends, or signs of stress, especially around welds and pivot points.

- Casters: Ensure wheels roll freely and smoothly. Check for worn bearings or flat spots.

- Pins and Fasteners: Verify that all locking pins, bolts, and nuts are tight and secure. Replace any missing or damaged components immediately.

- Hook and Latch: Inspect the hook for deformation or wear. Ensure the safety latch operates correctly.

Hydraulic Fluid Checks

The hydraulic system is the heart of your hydraulic engine hoist.

- Fluid Level: Consult your owner’s manual for instructions on checking and maintaining the hydraulic fluid level. Low fluid can lead to poor lifting performance or damage to the pump.

- Leaks: Look for any signs of hydraulic fluid leaks around the ram, pump, or hoses. Even minor leaks can indicate a problem that needs addressing.

- Fluid Replacement: Over time, hydraulic fluid can degrade. Follow the manufacturer’s recommendations for periodic fluid replacement to maintain optimal performance.

Cleaning and Lubrication

Keep your engine hoist clean. Wipe down any grease, dirt, or spills. Lubricate moving parts, such as pivot points, pins, and wheel axles, with appropriate grease or oil. This reduces friction, prevents rust, and ensures smooth operation.

Proper Storage

When not in use, store your engine hoist in a clean, dry environment. If you have a foldable engine hoist, fold it down to its compact size and store it upright to save space. Avoid leaving it exposed to the elements, as moisture can lead to rust and damage to the hydraulic components.

By following these simple maintenance steps, you can significantly extend the life of your Powerstroke engine hoist, ensuring it’s always ready and safe for your next 6.0 Powerstroke engine removal or installation project.

Comparative Overview of Engine Hoists for Powerstroke Engines

To help you visualize the choices, here’s a quick comparison of common hoist types for Powerstroke engine removal:

| Hoist Type | Typical Capacity (Tons) | Best Use Case for 6.0 Powerstroke | Pros | Cons |

|---|---|---|---|---|

| Foldable Hydraulic Engine Hoist | 1.5 – 2 Tons | Home garages, small to medium shops, occasional use. Ideal for most DIYers. | Affordable, space-saving (foldable), good maneuverability, ample capacity. | Manual pumping required, may have limited reach for very tall trucks. |

| Shop Crane / Fixed-Base Hoist | 2 – 3 Tons | Professional garages, frequent heavy lifting, dedicated workspace. | Superior stability, higher weight limits, built for commercial duty. | Requires significant floor space, not portable, generally more expensive. |

| Gantry Crane | 3+ Tons | Industrial settings, large commercial shops, very heavy equipment. | Highest capacity, extensive reach/coverage, versatile. | Very expensive, requires significant ceiling height and space, impractical for home use. |

As you can see, for the vast majority of individuals tackling a Ford 6.0 Powerstroke engine removal, the foldable hydraulic engine hoist stands out as the most practical and cost-effective solution, offering the necessary lifting power and flexibility.

Conclusion: Lift with Confidence, Work with Ease

Removing a Ford 6.0 Powerstroke engine is undoubtedly one of the most challenging tasks an automotive enthusiast or professional mechanic can undertake. It demands precision, patience, and, above all, the right tools. An engine hoist isn’t just another item in your toolbox; it’s the foundational piece of equipment that makes this daunting job not only possible but also safe and efficient.

By understanding the substantial Powerstroke engine weight, selecting a hoist with adequate lifting capacity and appropriate features, meticulously following a safe lifting procedure, and committing to regular maintenance, you transform a potentially hazardous endeavor into a controlled and successful operation. Whether you opt for a versatile foldable engine hoist or a more robust shop crane, prioritizing safety and quality will pay dividends in the long run.

So, as you prepare for your next 6.0 Powerstroke engine removal, remember that the right engine hoist is your best friend. It’s the tool that empowers you to tackle monumental tasks with confidence, ensuring that your valuable engine, and more importantly, your well-being, are protected every step of the way. Invest wisely, lift safely, and enjoy the satisfaction of a job well done!

🎥 Related Video: Happy 4th! Taking the k24 off the engine stand

📺 Sally McNulty

Frequently Asked Questions

What lifting capacity engine hoist is recommended for a Ford 6.0 Powerstroke engine removal?

The Ford 6.0 Powerstroke engine, without accessories, weighs roughly 900-1000 lbs. To ensure maximum safety and account for the transmission or other components that might be lifted simultaneously, a hoist with a minimum 1.5-ton (3,000 lbs) capacity is highly recommended. A 2-ton (4,000 lbs) hoist provides an even greater margin of safety and stability for your Ford 6.0 Powerstroke engine removal.

What type of engine hoist is best suited for a Ford 6.0 Powerstroke engine removal?

For a Ford 6.0 Powerstroke engine removal, a hydraulic “shop crane” or “cherry picker” is the most common and practical choice. These hoists offer a wide reach and an adjustable boom, allowing you to easily maneuver the heavy engine out of the tight engine bay. Look for models with sturdy construction and robust wheels for stability.

How much does a Ford 6.0 Powerstroke engine typically weigh, affecting my engine hoist choice?

A bare Ford 6.0 Powerstroke engine weighs approximately 900-1000 lbs. However, when considering an engine hoist for removal, you should account for additional components like the turbo, manifolds, and potentially even the transmission, which can push the total lifted weight closer to 1200-1500 lbs. Always select a hoist with a capacity well above this maximum estimated weight for safety during your Ford 6.0 Powerstroke engine removal.

Besides the engine hoist, what other essential tools or accessories do I need for a Ford 6.0 Powerstroke engine removal?

An engine leveler is crucial for safely performing a Ford 6.0 Powerstroke engine removal, allowing you to adjust the engine’s angle as it’s lifted. You’ll also need strong, appropriately rated engine lifting chains or slings, an engine stand for storage, and a sturdy engine dolly or palette for transport.

How much garage space is needed to safely perform a Ford 6.0 Powerstroke engine removal with a hoist?

You’ll need substantial clear space around the front of the truck and above the engine bay for a Ford 6.0 Powerstroke engine removal. Ensure enough room for the hoist’s legs to extend around the vehicle and for the engine to be lifted vertically without hitting overhead obstructions. A minimum of 10-12 feet of clear ceiling height and ample floor space to maneuver the hoist is generally advisable.

Is it better to rent or buy an engine hoist for a one-time Ford 6.0 Powerstroke engine removal?

If you’re only planning a single Ford 6.0 Powerstroke engine removal, renting an engine hoist can be a cost-effective option, as purchasing a high-capacity hoist can be a significant investment. However, if you anticipate future engine work or have other heavy lifting needs, buying a quality hoist might be more economical in the long run. Consider the rental costs versus the purchase price and your projected usage.