Diagnosing 7.3 Powerstroke Low Pressure Oil Pump Failure: Troubleshooting Guide

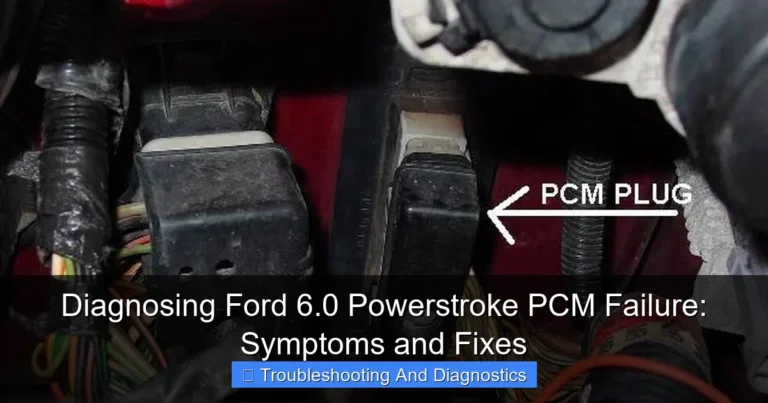

Featured image for this comprehensive guide about Diagnosing 7.3 Powerstroke low pressure oil pump failure

Image source: takeuroil.com

Diagnosing 7.3 Powerstroke Low Pressure Oil Pump Failure: Troubleshooting Guide

The 7.3L Powerstroke diesel engine holds a legendary status among truck enthusiasts and heavy-duty workers alike. Renowned for its durability, reliability, and impressive torque, this engine has powered countless Ford Super Duty trucks and vans for decades. However, even the toughest engines have their Achilles’ heel, and for the 7.3L Powerstroke, one critical component that demands attention is the low pressure oil pump (LPOP). A failing LPOP can quickly turn your trusty workhorse into a frustrating lawn ornament, or worse, lead to catastrophic engine damage.

Understanding the intricate dance of oil flow within your 7.3 Powerstroke engine is crucial, and the LPOP plays a starring role. Unlike gasoline engines, the 7.3 Powerstroke relies on a dual oil system to not only lubricate moving parts but also to actuate the fuel injectors – a system known as HEUI (Hydraulic Electronic Unit Injector). This means that proper oil pressure isn’t just about preventing wear; it’s fundamental to engine operation. When you suspect a 7.3 Powerstroke low pressure oil pump failure, it’s imperative to diagnose it accurately and promptly. This comprehensive guide will walk you through the symptoms, diagnostic steps, and preventative measures to keep your Powerstroke running strong.

Don’t let the thought of a failing oil pump intimidate you. With the right knowledge and tools, many common issues can be identified and addressed. This article is your ultimate resource for troubleshooting and understanding LPOP failure in your 7.3 Powerstroke, offering actionable insights and expert tips to ensure you’re well-equipped to tackle this challenge head-on. Let’s dive deep into the world of 7.3L oil pressure problems and arm you with the information you need.

Quick Answers to Common Questions

What are the common signs of a failing 7.3 Powerstroke low pressure oil pump?

You’ll often notice a ‘no-start’ condition, especially when warm, or a significant lack of power and rough running. Your dash oil pressure gauge might read unusually low or even zero.

Can I still drive my 7.3 Powerstroke if I suspect the low pressure oil pump is bad?

Absolutely not! Driving with a failing low pressure oil pump can lead to catastrophic engine damage due to lack of lubrication. It’s crucial to stop driving and diagnose the issue immediately.

What’s the quickest way to check if my 7.3 Powerstroke low pressure oil pump is the culprit?

While the dash gauge isn’t always precise, a quick check is to see if it shows extremely low or no oil pressure during cranking. For a more definitive test, you’ll need to hook up a mechanical oil pressure gauge to the engine.

How do I differentiate a bad 7.3 Powerstroke low pressure oil pump from a High Pressure Oil Pump (HPOP) issue?

A low pressure oil pump failure usually causes extremely low or no oil pressure on the dash gauge, preventing the engine from starting or running poorly. HPOP issues might cause starting problems or rough running, but often with some oil pressure present, just not enough to fire the injectors effectively.

Could something else be causing low oil pressure symptoms on my 7.3 Powerstroke, besides the low pressure oil pump?

Yes, definitely! A clogged oil filter, a faulty oil pressure sensor, or even incorrect oil viscosity can mimic low pressure oil pump failure symptoms. Always check these simpler items first during your diagnosis.

📋 Table of Contents

- Understanding the 7.3L Powerstroke Oil System and the LPOP’s Role

- Common Symptoms of 7.3 Powerstroke Low Pressure Oil Pump Failure

- Preliminary Checks: What to Do Before Diving Deep

- Advanced Diagnostic Procedures for LPOP Failure

- Differentiating LPOP Failure from Other Oil Pressure Issues

- Preventative Maintenance and LPOP Longevity

- Conclusion

Understanding the 7.3L Powerstroke Oil System and the LPOP’s Role

Before we can effectively diagnose a 7.3 Powerstroke low pressure oil pump failure, it’s essential to grasp how the entire oil system functions and where the LPOP fits into the grand scheme. The 7.3L Powerstroke utilizes a unique dual-oil pressure system, which can sometimes be a source of confusion.

Learn more about Diagnosing 7.3 Powerstroke low pressure oil pump failure – Diagnosing 7.3 Powerstroke Low Pressure Oil Pump Failure: Troubleshooting Guide

Image source: powerstroke.org

The Dual Oil System Explained: LPOP vs. HPOP

Your 7.3 Powerstroke engine actually has two distinct oil pumps: the Low Pressure Oil Pump (LPOP) and the High Pressure Oil Pump (HPOP).

| Symptom / Observation | Potential LPOP-Related Cause | Diagnostic Step / Expected Result (LPOP Failure) |

|---|---|---|

| Low/No Oil Pressure Gauge Reading on Dash | LPOP inability to build or maintain adequate base oil pressure in the system. | Verify with a mechanical oil pressure gauge at the filter housing. *Expected: <10 PSI at idle, <30 PSI at 2000 RPM (engine warm).* |

| Extended Crank / No Start (especially after sitting) | Insufficient LPOP output prevents the HPOP reservoir from filling, leading to low Injection Control Pressure (ICP). | Monitor ICP (Injection Control Pressure) during cranking with a scan tool. *Expected: ICP remains <500 PSI, engine will not start.* Check HPOP reservoir level; it may be low. |

| Excessive Engine Noise (e.g., valve clatter, lifter tick, turbo whine) | Low base oil pressure causes inadequate lubrication to critical engine components. | Confirm actual oil pressure with a mechanical gauge. *Expected: Persistently low pressure across the entire RPM range.* Inspect oil for metal shavings. |

| Check Engine Light (CEL) with ICP-related Codes | LPOP failure indirectly causes issues with Injection Control Pressure, triggering codes like P1211 (ICP too high/low). | Retrieve codes with a scan tool. Perform base oil pressure test and ICP test. *Expected: Low base oil pressure directly correlates with low ICP readings or failure to build ICP.* |

| HPOP Reservoir Low/Empty After Engine Off | LPOP is not effectively pushing oil up to fill and maintain the HPOP reservoir. | Remove the HPOP reservoir fill plug after the engine has been off for ~30 minutes. *Expected: Oil level is significantly below the fill hole, or reservoir appears mostly empty.* |

- Low Pressure Oil Pump (LPOP): This is the primary oil pump responsible for drawing oil from the oil pan and circulating it throughout the engine at a relatively low pressure (typically 15-70 PSI, depending on RPM and temperature). Its main functions are to lubricate all internal engine components (crankshaft, camshaft, connecting rods, cylinder walls, turbocharger, etc.) and to supply oil to the HPOP. Think of the LPOP as the engine’s foundational circulatory system.

- High Pressure Oil Pump (HPOP): This pump takes the low-pressure oil supplied by the LPOP and pressurizes it to incredibly high levels (up to 3,000 PSI or more). This super-pressurized oil is then directed to the injectors, which use it to directly actuate fuel delivery into the cylinders. This is the heart of the HEUI system.

It’s crucial to understand that the HPOP cannot function without adequate oil supply from the LPOP. If the LPOP isn’t doing its job, the HPOP will starve for oil, leading to both lubrication issues and fuel injection problems. This is why a 7.3 Powerstroke low pressure oil pump failure can manifest in a wide range of symptoms.

How the LPOP Works and Why it’s Critical

The 7.3L Powerstroke LPOP is typically a gerotor-style pump, located at the front of the engine behind the timing cover, driven directly by the crankshaft. It consists of an inner and outer rotor that spin, creating a vacuum to draw oil from the pan through the pickup tube and then pushing it through the oil filter and into the engine’s main oil galleries. From these galleries, oil branches off to lubricate components, cool the turbo, and feed the HPOP reservoir.

The criticality of the LPOP cannot be overstated:

- Engine Lubrication: Without sufficient oil pressure from the LPOP, friction increases dramatically between moving parts, leading to rapid wear of bearings, camshafts, lifters, and cylinder walls. This is the fastest route to a seized or destroyed engine.

- HPOP Supply: As mentioned, the HPOP requires a constant, steady supply of low-pressure oil to generate its high-pressure output. An inadequate supply will cause the HPOP to cavitate (draw air instead of oil), leading to intermittent or complete loss of injector actuation, and eventually, engine no-start or stalling.

- Turbocharger Health: The turbocharger relies heavily on a continuous supply of oil for both lubrication and cooling. A failing LPOP can starve the turbo, causing premature bearing failure and excessive wear.

Any disruption to the LPOP’s function can have widespread, detrimental effects on your 7.3 Powerstroke’s health and performance.

Common Symptoms of 7.3 Powerstroke Low Pressure Oil Pump Failure

Recognizing the early warning signs of a failing 7.3 Powerstroke low pressure oil pump is paramount to preventing extensive engine damage. These symptoms can range from subtle to severe, but all point to a critical issue with your engine’s oil system.

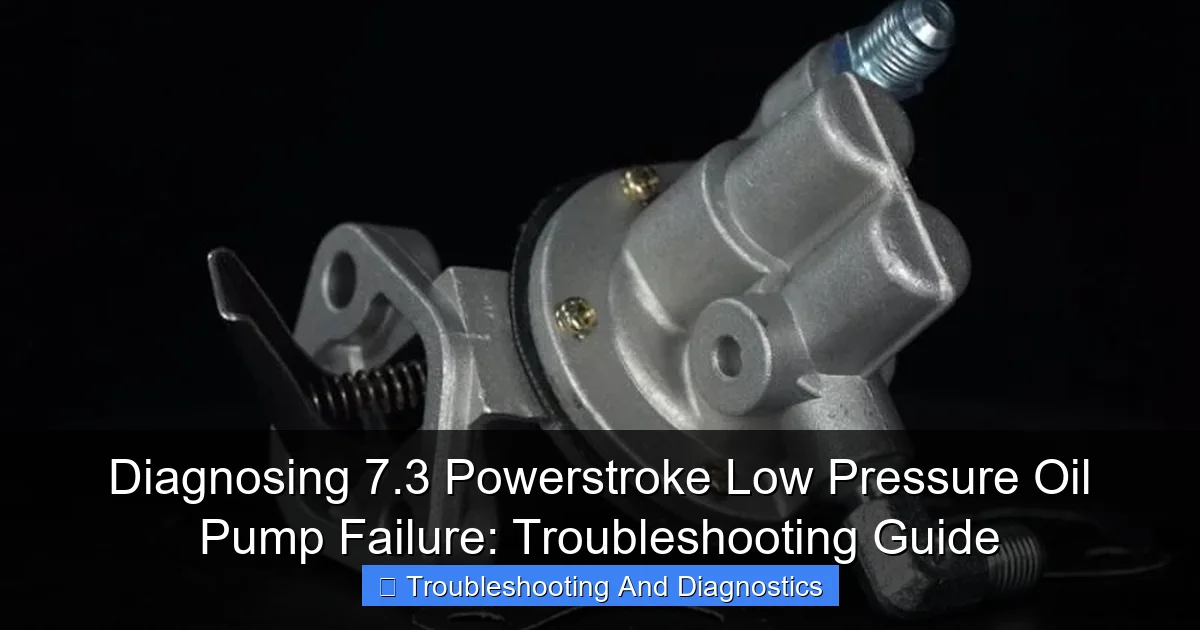

Learn more about Diagnosing 7.3 Powerstroke low pressure oil pump failure – Diagnosing 7.3 Powerstroke Low Pressure Oil Pump Failure: Troubleshooting Guide

Image source: i2.wp.com

Visible & Audible Cues

- Low Oil Pressure Gauge Reading: This is often the most direct indicator. Your dash gauge might consistently read low, fluctuate wildly, or drop to zero, especially at idle or low RPMs. While dash gauges aren’t always perfectly accurate, a consistent low reading is a red flag for engine oil pressure problems.

- Engine Knocking or Ticking Noises: As oil pressure drops, parts that should be cushioned by oil (like lifters, pushrods, and rod/main bearings) begin to make metal-on-metal contact. This can result in a distinct knocking, ticking, or clattering sound, particularly noticeable after a cold start or when the engine is hot and oil viscosity is lower. These noises are a serious indication of insufficient lubrication.

- Turbo Whine or Squeal: If the turbocharger is being starved of oil, its bearings will wear rapidly, leading to a loud, distinctive whine or squealing sound. This often precedes complete turbo failure.

Performance-Related Issues

- Rough Idle or Stalling: A struggling LPOP means the HPOP isn’t getting enough oil. This directly impacts the HEUI system’s ability to fire injectors correctly, leading to a rough, erratic idle, misfires, or even complete stalling, particularly after the engine warms up. The engine might start fine cold but then die once hot.

- Lack of Power or Hesitation: Insufficient oil pressure for the HPOP will result in weak injector actuation, reducing the engine’s ability to develop full power. You’ll notice a significant loss of acceleration, a general feeling of sluggishness, and poor throttle response. This is a classic symptom of the HEUI system struggling due to low oil supply.

- Extended Crank Times or No-Start Condition: If the LPOP isn’t building enough pressure quickly during cranking, the HPOP won’t be able to generate the necessary pressure to fire the injectors. This can lead to very long crank times or a complete no-start situation, especially when the engine is hot, as hot oil is thinner and harder for a weak pump to pressurize.

Warning Lights

- Illuminated “Check Engine Light” (CEL): While not specific to oil pressure, a CEL can be triggered by various issues stemming from low oil pressure impacting the HEUI system. Diagnostic trouble codes (DTCs) related to injector performance (e.g., P1211 – Injector Control Pressure (ICP) higher/lower than desired) or oil pressure sensor faults might appear.

- Oil Pressure Warning Light: Many vehicles have a dedicated oil pressure warning light on the dashboard. This light typically illuminates when pressure drops below a critically low threshold. While basic, it’s an undeniable sign that immediate attention is required.

If you experience any combination of these symptoms, especially the engine noises or performance issues, you should immediately suspect a 7.3 Powerstroke low pressure oil pump failure and begin diagnostic procedures.

Preliminary Checks: What to Do Before Diving Deep

Before you jump into complex diagnostics or start disassembling your engine, there are several simple, yet crucial, preliminary checks you should perform. These steps can help rule out common, less severe issues and often save you significant time and money by avoiding unnecessary repairs for a suspected LPOP failure.

1. Checking Oil Level and Condition

This might seem obvious, but a surprisingly high percentage of “low oil pressure” complaints are simply due to low engine oil.

- Check Oil Level: Park your truck on a level surface, allow the engine to cool for at least 15-20 minutes, then pull the dipstick. The oil level should be between the “Add” and “Full” marks. If it’s low, add the correct type and amount of oil.

- Inspect Oil Condition: While checking the level, also look at the oil’s condition. Is it extremely dirty, black, or does it smell burnt? Is it thin and watery, or does it have a milky appearance (indicating coolant contamination)? Extremely dirty or thinned oil can struggle to maintain adequate pressure, even with a healthy LPOP.

2. Verifying the Oil Pressure Sender/Gauge

The dashboard oil pressure gauge in a 7.3L Powerstroke, like many vehicles, is often less of an accurate instrument and more of an “idiot light” disguised as a gauge. It typically shows “normal” as long as there’s any pressure above a very low threshold. A faulty oil pressure sender unit is a very common cause of false low oil pressure readings.

- Locate the Sender: The oil pressure sender (or switch) for the dash gauge on a 7.3L is usually located near the oil filter housing or on the back of the engine block.

- Disconnect and Test: Disconnecting the sender wire and grounding it should make the dash gauge read high (full pressure). If it does, the gauge and wiring are likely fine.

- Replace Sender (if suspected): If your gauge reads consistently low but you have no other severe symptoms (like engine noise or performance issues), replacing the relatively inexpensive oil pressure sender unit is a good first step.

3. Inspecting for External Leaks

Significant external oil leaks can directly contribute to low oil levels, which in turn leads to low pressure. A visual inspection can reveal obvious leaks.

- Check around the oil pan gasket, valve covers, oil filter housing, front crankshaft seal, and HPOP reservoir.

- A very common leak point for 7.3 Powerstrokes can be the HPOP lines or even the HPOP itself, which won’t directly lower LPOP pressure but will deplete oil quickly.

4. Fuel Filter/Oil Filter Check

While seemingly unrelated, a severely clogged oil filter can restrict oil flow, causing a drop in pressure downstream. Similarly, while not directly related to LPOP, issues with the fuel filter can sometimes indirectly affect performance symptoms that might be confused with oil pressure issues.

- Ensure you are using a quality oil filter and that it has been changed regularly according to your maintenance schedule. A cheap or incorrect filter can bypass oil prematurely or restrict flow.

- A clogged fuel filter can cause similar symptoms to low HPOP pressure (rough idle, lack of power) but won’t typically cause a low LPOP gauge reading.

Once these preliminary checks are done and haven’t resolved your issue, or if you’re experiencing severe symptoms, it’s time to move on to more advanced diagnostic procedures for a potential 7.3 Powerstroke low pressure oil pump failure.

Advanced Diagnostic Procedures for LPOP Failure

When preliminary checks don’t pinpoint the problem, or when symptoms strongly suggest a 7.3 Powerstroke low pressure oil pump failure, it’s time to employ more precise diagnostic methods. These steps will help you definitively determine if your LPOP is the culprit.

1. Mechanical Oil Pressure Test: The Gold Standard

This is the most accurate way to verify actual engine oil pressure. Do not rely solely on the dashboard gauge when diagnosing a critical issue like an LPOP failure.

- Gather Tools: You will need a reliable mechanical oil pressure gauge with the correct adapter fitting (usually 1/8″ NPT) for your 7.3L Powerstroke.

- Locate Test Port: The most common and accurate place to test LPOP pressure on a 7.3L is by removing the oil pressure sender unit near the oil filter housing or on the back of the engine block and screwing in your mechanical gauge.

- Perform the Test:

- Cold Start: Start the engine cold. You should see higher pressure initially.

- Warm Up: Allow the engine to reach operating temperature.

- Idle Test: At a warm idle (approximately 600-800 RPM), a healthy 7.3 Powerstroke LPOP should produce at least 15-20 PSI. Many will show 25-35 PSI.

- Operating RPM Test: At 2000-2500 RPM, the pressure should rise significantly, typically to 45-70 PSI.

- Compare to Specs: Refer to the table below for typical 7.3L Powerstroke oil pressure specifications. If your readings are consistently below these figures, especially when warm, it’s a strong indicator of a failing LPOP or other internal oil system issue.

7.3L Powerstroke Oil Pressure Specifications

These values are approximate and can vary slightly based on engine condition, oil type, and temperature. Always consult your vehicle’s service manual for precise specifications.

| Condition | Minimum Oil Pressure (PSI) | Typical Oil Pressure (PSI) |

|---|---|---|

| Warm Idle (approx. 600-800 RPM) | 15 PSI | 25-35 PSI |

| Warm @ 2000-2500 RPM | 45 PSI | 50-70 PSI |

| Cold Start (briefly, before warm-up) | 60 PSI + | 70-90 PSI |

| Oil Pressure Warning Light Threshold | < 7 PSI (approx.) | N/A |

2. Scan Tool Diagnostics (Monitoring PIDs)

While the LPOP doesn’t have a direct sensor that reports its pressure, its performance heavily influences the High Pressure Oil Pump (HPOP) system, which does have sensors. A good scan tool (like FORScan or a professional diagnostic tool) can monitor several crucial PIDs (Parameter Identifiers):

- ICP (Injector Control Pressure): This is the pressure generated by the HPOP. If the LPOP isn’t supplying enough oil, the ICP will struggle to reach desired values, especially during cranking or under load. Look for ICP actual vs. ICP desired discrepancies.

- IPR (Injector Pressure Regulator) Duty Cycle: This PID tells you how hard the HPOP’s regulator is working to maintain ICP. If the LPOP is weak, the IPR duty cycle will be excessively high (often above 60-70%) just trying to maintain minimal ICP, especially at idle.

- Engine Oil Temperature (EOT): High oil temperature can thin the oil, exacerbating LPOP issues. Monitor this to ensure it’s within spec (typically 180-220°F).

Consistent low ICP and high IPR duty cycle, particularly when combined with low mechanical LPOP pressure readings, strongly indicate an issue originating from the LPOP’s inability to supply sufficient oil to the HPOP.

3. Inspecting the Oil Cooler and Filter Housing

Occasionally, problems within the oil cooler or its bypass valve can lead to low pressure symptoms, mimicking a 7.3 Powerstroke LPOP failure.

- Oil Cooler Bypass Valve: If this valve sticks open, some oil can bypass the cooler entirely or return to the pan without adequate pressure. This is less common but worth considering if LPOP pressure is low but the pump itself appears fine.

- Clogged Oil Cooler: While rare, a severely clogged oil cooler can restrict flow, though this usually manifests as high oil temperature more than low pressure.

4. LPOP Bypass Valve Check (Internal to the pump)

Most oil pumps have an internal bypass valve that opens at high RPMs to prevent over-pressurization. If this valve sticks open due to debris or a weak spring, it can continuously dump oil back into the pan, resulting in low pressure. This usually requires LPOP removal to properly inspect or replace the pump, as the valve is integral.

By systematically performing these diagnostic steps, you can confidently determine if a 7.3 Powerstroke low pressure oil pump failure is indeed the root cause of your engine’s woes.

Differentiating LPOP Failure from Other Oil Pressure Issues

While this guide focuses on LPOP failure, it’s crucial to understand that low oil pressure symptoms can also stem from other sources within your 7.3 Powerstroke engine. Misdiagnosis can lead to costly and unnecessary repairs. Here’s how to differentiate a failing LPOP from other common causes of low oil pressure or related performance issues.

High Pressure Oil Pump (HPOP) vs. LPOP

This is arguably the most common diagnostic confusion point for 7.3L Powerstroke owners because both pumps are critical to engine operation and a failure in either can lead to similar performance symptoms (rough idle, no-start). However, their direct symptoms and diagnostic pathways differ:

- LPOP Failure Symptoms: Directly affects the mechanical oil pressure gauge. Will show low pressure on a mechanical test. Leads to poor lubrication and eventually HPOP starvation. Often accompanied by mechanical engine noise (knocking, ticking).

- HPOP Failure Symptoms: Typically, the mechanical LPOP pressure will read normal (30-70 PSI depending on RPM), but the engine will still suffer from poor performance, extended crank, or a no-start condition. Scan tool data will show low ICP (Injector Control Pressure) even with a healthy IPR duty cycle, as the HPOP itself cannot generate pressure. There might not be traditional engine knocking due to lubrication unless the LPOP also failed.

- Key Diagnostic Tool: Mechanical oil pressure gauge for LPOP, and a scan tool monitoring ICP/IPR for HPOP. If your mechanical gauge reads good LPOP pressure but you have HEUI-related performance issues, look to the HPOP, IPR valve, ICP sensor, or even internal injector o-rings.

Oil Cooler Issues

A severely clogged oil cooler or a stuck-open oil cooler bypass valve can restrict oil flow and potentially contribute to lower engine oil pressure, although their primary manifestation is usually high oil temperature. If your mechanical oil pressure test shows acceptable readings, but your oil temperature is consistently high, investigate the oil cooler. An external cooler bypass valve (not to be confused with the internal LPOP bypass) sticking open could also lead to slight pressure drops by diverting oil prematurely.

Worn Engine Bearings

As a 7.3 Powerstroke engine accumulates high mileage, the clearances in the main and connecting rod bearings can gradually increase due to wear. These larger clearances allow oil to “escape” too easily, leading to a significant drop in oil pressure, especially when the oil is hot and thinner.

- Distinguishing Factor: A worn engine will often show lower-than-spec oil pressure across the board, even with a brand new, healthy LPOP. The pressure will be particularly low at hot idle and may not rise adequately with RPM. This is often accompanied by deep, internal knocking noises that are more pronounced than lifter tick.

- Diagnosis: This is harder to diagnose without internal inspection, but consistent low pressure after confirming LPOP health, using correct oil, and ruling out other issues, points to internal engine wear.

Incorrect Oil Viscosity

Using an oil that is too thin (e.g., 5W-30 instead of the recommended 15W-40) can result in lower measured oil pressure, particularly at operating temperature. Thinner oil simply flows more easily through clearances, resulting in less resistance for the pump to build pressure.

- Solution: Always use the manufacturer-recommended oil viscosity for your 7.3 Powerstroke (typically 15W-40 diesel-rated oil). If you’ve recently changed oil and noticed a pressure drop, verify the oil type.

Accurate diagnosis is key. Always use a mechanical oil pressure gauge as your primary diagnostic tool for LPOP failure, and complement it with scan tool data for HPOP-related issues. By systematically eliminating other possibilities, you can confidently identify the source of your 7.3L oil pressure problems.

Preventative Maintenance and LPOP Longevity

While no component lasts forever, proactive maintenance can significantly extend the life of your 7.3 Powerstroke low pressure oil pump and help prevent premature LPOP failure. Investing a little time and money now can save you thousands in engine repairs down the road.

1. Regular Oil Changes: The Most Critical Step

This cannot be stressed enough. Clean oil is the lifeblood of your 7.3L Powerstroke.

- Follow Schedule: Adhere strictly to the manufacturer’s recommended oil change intervals, typically every 5,000 to 7,500 miles or 6 months, whichever comes first. For vehicles subjected to heavy towing, frequent short trips, or extreme conditions, consider shorter intervals.

- Why it Matters: Old, degraded oil loses its lubricating properties and can become contaminated with soot, fuel, and moisture. These contaminants can cause wear on pump components (like the gerotor gears) and potentially clog the LPOP pickup screen, starving the pump.

2. Using the Correct Oil Type and Viscosity

The 7.3 Powerstroke is designed for specific oil properties.

- Recommended Viscosity: Always use a high-quality 15W-40 diesel-rated engine oil that meets or exceeds Ford’s specifications (e.g., Ford WSS-M2C171-D). In extremely cold climates, 10W-30 diesel oil might be acceptable for easier cold starting, but consult your owner’s manual.

- Why it Matters: Using oil that is too thin (e.g., 5W-30 gasoline engine oil) can result in lower oil pressure and reduced lubrication film strength, especially when hot. Oil that is too thick can make cold starting difficult and put excessive strain on the LPOP.

3. Quality Oil Filters: Don’t Skimp

The oil filter plays a vital role in keeping your engine’s oil clean.

- Use Reputable Brands: Always opt for high-quality oil filters from reputable brands (e.g., Motorcraft, Baldwin, Donaldson, Wix). Cheap filters may not filter effectively, can collapse, or may have bypass valves that open too easily, allowing unfiltered oil to circulate.

- Change with Oil: Always replace the oil filter every time you change your oil.

4. Monitoring Oil Pressure

While the dash gauge isn’t perfectly accurate, keeping an eye on it can alert you to significant changes.

- Pay Attention: If your dash gauge starts behaving erratically, reads consistently lower than usual, or drops dramatically, take it seriously. It might be a faulty sender, but it could also be an early warning of 7.3 Powerstroke low pressure oil pump failure.

- Consider an Aftermarket Gauge: For serious 7.3L Powerstroke owners, installing an accurate, mechanical aftermarket oil pressure gauge (or an electronic one with a good sender) provides far more precise information than the factory gauge, allowing you to catch minor pressure drops before they become catastrophic.

5. Addressing Small Leaks Promptly

Even minor oil leaks can, over time, lead to a low oil level and contribute to low pressure.

- Regular Inspections: Periodically inspect your engine for any signs of oil leaks. Address valve cover leaks, HPOP line leaks, or oil pan leaks as soon as they are identified. Maintaining proper oil levels is fundamental to maintaining proper pressure.

By diligently adhering to these preventative maintenance practices, you can significantly reduce your risk of encountering a 7.3 Powerstroke low pressure oil pump failure and ensure your legendary diesel engine continues to perform reliably for many more miles.

Conclusion

The 7.3L Powerstroke diesel engine is a marvel of engineering, but like any complex machine, it requires proper care and attention. Understanding the critical role of the low pressure oil pump (LPOP) and knowing how to effectively diagnose a 7.3 Powerstroke low pressure oil pump failure is paramount to the longevity and reliability of your truck. From recognizing the early warning signs like dashboard gauge fluctuations and engine noises, to performing precise mechanical oil pressure tests and differentiating LPOP issues from other problems, you now have a comprehensive guide at your fingertips.

Remember, a healthy engine oil pressure system is not just about lubrication; it’s the very foundation upon which your 7.3L Powerstroke’s HEUI fuel injection system operates. Ignoring symptoms of LPOP failure or delaying diagnosis can lead to irreversible engine damage, turning a potentially manageable repair into a costly engine overhaul. Always prioritize prompt action and accurate troubleshooting.

Equipped with this knowledge, you’re better prepared to keep your legendary 7.3 Powerstroke on the road, where it belongs. Whether you’re a seasoned DIY mechanic or seeking to better understand your truck before visiting a professional, this troubleshooting guide empowers you to make informed decisions. Drive safe, maintain well, and enjoy the enduring power of your 7.3 Powerstroke!

🎥 Related Video: How To Check HPOP Oil 7.3 Powerstroke!

📺 Joshua Overman

Frequently Asked Questions

What are the common symptoms of a failing 7.3 Powerstroke low pressure oil pump?

A failing 7.3 Powerstroke low pressure oil pump (LPOP) often manifests as a “no-start” or “hard-start” condition, especially when the engine is warm. You might also notice a loss of power, rough running, or a check engine light related to low oil pressure codes.

How do I test my 7.3 Powerstroke to confirm a low pressure oil pump failure?

The most direct way to confirm a low pressure oil pump (LPOP) failure is to perform a manual oil pressure test using a gauge at the sending unit port. You should also monitor ICP (Injector Control Pressure) during cranking with a diagnostic scanner, as insufficient low-pressure oil will prevent the HPOP from building adequate ICP.

Can I safely drive my 7.3 Powerstroke with a suspected low pressure oil pump failure?

It is strongly advised not to drive your 7.3 Powerstroke with a suspected low pressure oil pump (LPOP) failure. Insufficient oil pressure can lead to catastrophic damage to the high-pressure oil pump (HPOP), injectors, and even critical engine components like bearings. Address the issue immediately to prevent further harm.

What specialized tools are needed to diagnose a 7.3 Powerstroke low pressure oil pump problem?

To accurately diagnose a low pressure oil pump (LPOP) problem, you’ll primarily need a good quality mechanical oil pressure gauge to test the LPOP’s output directly. A diagnostic scanner capable of reading live data, especially Injector Control Pressure (ICP) and Engine Oil Temperature (EOT), is also essential for comprehensive troubleshooting.

How can I differentiate between a 7.3 Powerstroke low pressure oil pump (LPOP) failure and a High Pressure Oil Pump (HPOP) issue?

A key difference is that a failing LPOP will result in *no* or very low pressure at the ICP sensor during cranking, as it’s the HPOP’s supply. An HPOP failure, however, might still show some initial low pressure but will struggle to build the high pressure needed for injection, even if the LPOP is supplying it adequately. Checking the actual oil pressure output of the LPOP directly with a gauge is crucial.

What’s the very first step I should take when troubleshooting a potential 7.3 Powerstroke low pressure oil pump issue?

The absolute first step is to check your engine’s oil level and condition, as low or dirty oil can mimic LPOP failure symptoms. After confirming adequate oil, use a diagnostic scanner to check for any diagnostic trouble codes (DTCs) and monitor live data, particularly ICP, during cranking to see if the high-pressure system is receiving adequate supply.