Diagnosing 7.3 Powerstroke Camshaft Position Sensor Failure: How to Fix

Featured image for this comprehensive guide about Diagnosing 7.3 Powerstroke camshaft position sensor failure

Image source: autotrends.org

Ah, the legendary 7.3 Powerstroke. A true workhorse, revered by truck enthusiasts and heavy-duty operators alike for its raw power, incredible durability, and relative simplicity. For many, it’s not just an engine; it’s a lifestyle. However, even legends have their Achilles’ heel, and for the mighty 7.3, one of the more common culprits behind frustrating performance issues is the camshaft position sensor (CPS). This unassuming little component plays a colossal role in your engine’s operation, and when it decides to call it quits, your beloved truck can go from a roaring beast to a stubborn lump of metal in the blink of an eye.

If you’re experiencing mysterious stalling, a relentless crank-no-start situation, or a peculiar loss of power, your mind might race through a litany of potential problems. But before you dive into complex diagnostics or costly repairs, understanding the symptoms and diagnosis of a failing 7.3 Powerstroke camshaft position sensor failure is absolutely crucial. This guide is designed to empower you with the knowledge and actionable steps needed to pinpoint if your CPS is the troublemaker, saving you time, money, and a significant amount of head-scratching. Let’s get your 7.3 roaring back to life!

Quick Answers to Common Questions

What are the first signs of a 7.3 Powerstroke camshaft position sensor failure?

If your truck suddenly stalls, has a long crank time, or won’t start at all, those are major red flags. You might also experience rough idling or unexpected engine shutdowns due to a failing 7.3 Powerstroke camshaft position sensor.

Will my Check Engine Light always come on for this problem?

Not always immediately, but it’s very common! A failing 7.3 Powerstroke camshaft position sensor usually triggers a P0340 or P0341 diagnostic trouble code, illuminating your Check Engine Light to alert you.

Can I still drive my 7.3 Powerstroke with a bad camshaft position sensor?

We strongly advise against it! A failing sensor can cause your engine to unexpectedly die at any time, which is dangerous and could leave you stranded, so address that 7.3 Powerstroke camshaft position sensor failure promptly.

Is diagnosing a 7.3 Powerstroke camshaft position sensor failure difficult for a DIYer?

While precise diagnosis often involves an oscilloscope, many owners simply replace the sensor as a first step due to its common failure rate and relatively low cost. It’s often an easy first step to addressing a potential 7.3 Powerstroke camshaft position sensor failure.

Where is the camshaft position sensor located on a 7.3 Powerstroke?

Good news, it’s fairly accessible! You’ll find the camshaft position sensor on the front of the engine, typically below the fan shroud on the timing cover, making replacement a manageable task.

📋 Table of Contents

- Understanding the 7.3 Powerstroke CPS: What It Does and Why It Fails

- Symptoms of a Failing 7.3 Powerstroke CPS: What to Look For

- Step-by-Step Diagnosis: Confirming a 7.3 Powerstroke CPS Failure

- Replacing Your 7.3 Powerstroke Camshaft Position Sensor: A DIY Guide

- Choosing the Right CPS: Black vs. Gray and Aftermarket Options

- Preventative Measures and Related Issues to Consider

- Conclusion: Empowering Your 7.3 Powerstroke Diagnostics

Understanding the 7.3 Powerstroke CPS: What It Does and Why It Fails

To effectively diagnose a problem, you first need to understand the component itself. The camshaft position sensor in your 7.3 Powerstroke is a vital electronic sensor that communicates directly with your engine’s computer, the Powertrain Control Module (PCM). This small but mighty sensor monitors the rotational speed and position of your camshaft, sending precise signals to the PCM. Why is this so important? Because the PCM uses this information, alongside data from the crankshaft position sensor (CKP), to accurately time critical engine functions like fuel injection and ignition. Without accurate CPS data, the PCM can’t properly synchronize the engine, leading to a cascade of performance problems.

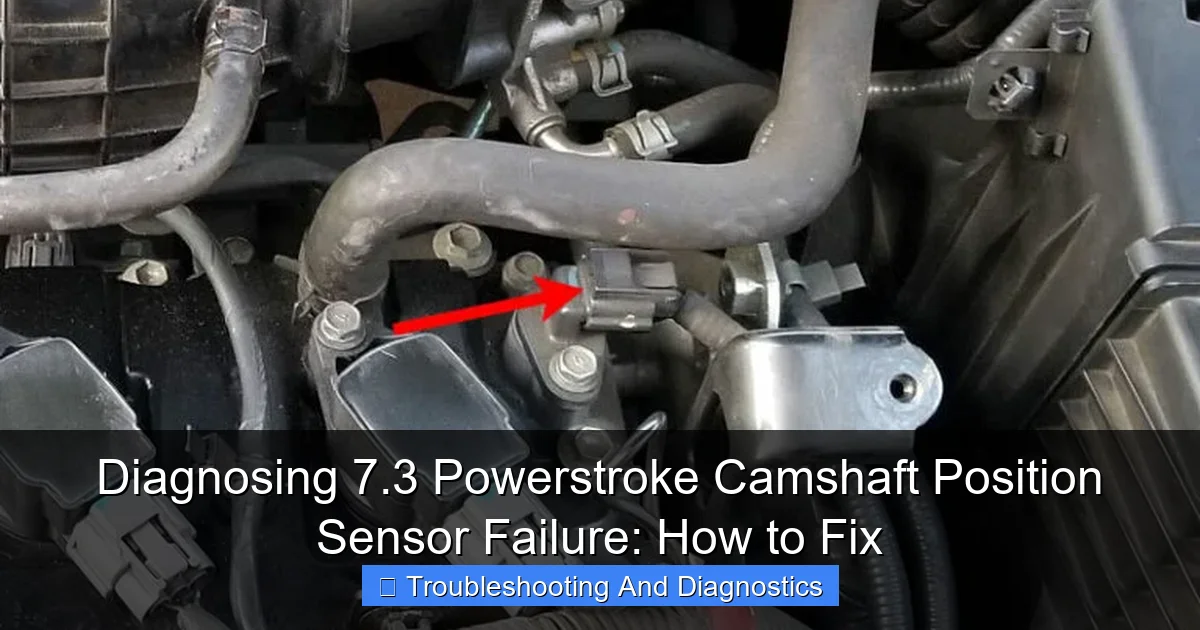

Learn more about Diagnosing 7.3 Powerstroke camshaft position sensor failure – Diagnosing 7.3 Powerstroke Camshaft Position Sensor Failure: How to Fix

Image source: themotorguy.com

The Vital Role of the CPS in Your 7.3 Powerstroke

Think of the CPS as the conductor of an orchestra, ensuring every instrument (fuel injector) plays its note at the exact right moment. Specifically, for a diesel engine like the 7.3 Powerstroke, the CPS provides the crucial data needed for:

- Injection Timing: The PCM uses CPS signals to determine when to fire the injectors, ensuring optimal combustion and power output.

- Engine Synchronization: It helps the PCM understand which cylinder is at top dead center (TDC) for precise fuel delivery.

- Engine Speed Monitoring: It contributes to the PCM’s overall understanding of engine RPM.

A perfectly functioning CPS ensures smooth operation, optimal fuel efficiency, and consistent power delivery. When this signal is weak, intermittent, or absent, the PCM struggles to control the engine, resulting in the notorious symptoms associated with 7.3 Powerstroke CPS failure.

| Symptom / Indication | Likely Cause (CPS Related) | Diagnostic Action / Result |

|---|---|---|

| Engine Cranks, No Start | Complete loss or erratic CPS signal preventing PCM from synchronizing injection. | Monitor live data for RPM during cranking; if 0 or unstable (e.g., 0-50 RPM), CPS is primary suspect. Check ICP sensor for adequate pressure (~500 PSI). |

| Sudden Engine Stalling While Driving | Intermittent CPS failure, often triggered by engine heat, causing sudden loss of injection timing. | Attempt immediate restart; if it restarts after cooling or multiple tries, strongly suggests CPS. Check for P0340/P0341 codes. |

| Rough Idle, Misfire, or Erratic Running | Weak or noisy CPS signal providing inaccurate engine speed/position data to the PCM. | Observe tachometer for erratic behavior. Use a scanner to monitor RPM stability. Replace CPS with a known good, high-quality “gray” or “black” sensor. |

| Check Engine Light (CEL) & DTCs | PCM detects an open circuit, short, or implausible signal from the CPS. | Scan for codes: P0340 (Camshaft Position Sensor Circuit Malfunction), P0341 (Circuit Range/Performance), P0344 (Intermittent Circuit). These are direct indicators. |

| Tachometer Inoperative or Erratic | The tachometer receives its signal directly from the PCM, which relies on the CPS for engine speed. | If other symptoms (no-start, stalling) are present, a dead or jumping tachometer significantly increases the likelihood of a CPS failure. |

Common Causes of CPS Failure in the 7.3 Powerstroke

Given its critical role, it’s unfortunate that the 7.3 Powerstroke CPS has a bit of a reputation for failing. But why? Several factors contribute to its eventual demise:

- Heat and Vibration: Located on the front of the engine, the CPS is constantly exposed to extreme engine heat and vibrations. Over time, this can degrade the internal electronics and wiring.

- Electrical Interference: The 7.3 Powerstroke engine bay is a bustling place with many electrical components. Poor shielding or a faulty CPS can be susceptible to electromagnetic interference.

- Age and Wear: Like any electronic component, the CPS has a finite lifespan. The internal magnets or Hall effect sensor can simply wear out or lose their effectiveness.

- Contamination: Oil or debris can sometimes penetrate the sensor housing, affecting its readings.

- Manufacturing Defects: While less common today with improved designs, early versions of the CPS (and even some aftermarket ones) have been known to have inherent defects.

Understanding these root causes helps explain why diagnosing 7.3 Powerstroke camshaft position sensor failure is a common topic in the diesel community.

Symptoms of a Failing 7.3 Powerstroke CPS: What to Look For

When your 7.3 Powerstroke camshaft position sensor starts to go bad, your truck will almost certainly let you know. The symptoms can range from mild annoyances to outright immobilizing issues. Recognizing these early warning signs can help you prevent further frustration and potential damage to other components from prolonged misfire or improper operation.

Learn more about Diagnosing 7.3 Powerstroke camshaft position sensor failure – Diagnosing 7.3 Powerstroke Camshaft Position Sensor Failure: How to Fix

Image source: sensormass.com

Intermittent or No Start Conditions

One of the most common and frustrating symptoms of a failing CPS is an intermittent or complete no-start condition. You might find your truck cranks over strong, but the engine simply won’t catch. This happens because the PCM isn’t receiving the necessary timing signals from the CPS to tell the injectors when to fire. Without this crucial data, the PCM prevents fuel injection as a protective measure. Many 7.3 owners have experienced this; they’ll crank, crank, and crank, only for the engine to sputter weakly or not fire at all. Sometimes, it will start after several attempts, especially when cold, but then refuse to start again once warm.

Engine Stalling and Rough Idle

Another classic sign of a problematic CPS is engine stalling, particularly after the engine has warmed up, or during low-speed maneuvers. You could be driving along, and suddenly, your engine just dies, leaving you coasting to the side of the road. This intermittent loss of signal from the CPS can cause the PCM to lose its timing reference, leading to an immediate shutdown. Additionally, you might notice a very rough, erratic idle. The engine may surge, stumble, or even sound like it’s missing, especially when cold, as the PCM struggles to maintain consistent timing information.

Reduced Power and Fuel Economy

A failing 7.3 Powerstroke camshaft position sensor doesn’t always result in an immediate no-start. Sometimes, the sensor signal can become weak or inconsistent before completely failing. When this happens, the PCM receives faulty data, leading to incorrect fuel injection timing. The result? A noticeable reduction in engine power, poor throttle response, and a significant drop in fuel economy. Your truck might feel sluggish, struggle to accelerate, and you’ll find yourself visiting the fuel pump more often than usual. These are subtle but important indicators that something isn’t quite right under the hood.

Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs)

Perhaps the most definitive sign of a problem, especially for electronic components, is the illumination of your Check Engine Light (CEL). When the PCM detects an anomaly or a complete absence of signal from the CPS, it will log a Diagnostic Trouble Code (DTC) and light up your dashboard. The most common codes associated with 7.3 Powerstroke CPS failure include:

- P0340: Camshaft Position Sensor Circuit Malfunction (General)

- P0341: Camshaft Position Sensor Circuit Range/Performance

- P0342: Camshaft Position Sensor Circuit Low Input

- P0343: Camshaft Position Sensor Circuit High Input

- P0344: Camshaft Position Sensor Circuit Intermittent

If you have access to an OBD-II scanner, pulling these codes is often the quickest way to confirm your suspicions. However, remember that sometimes a failing CPS won’t immediately throw a code, especially if the signal is only intermittently weak, which can make diagnosing 7.3 Powerstroke camshaft position sensor failure a bit more challenging without additional testing.

Step-by-Step Diagnosis: Confirming a 7.3 Powerstroke CPS Failure

Once you’ve observed the symptoms, the next critical step is to accurately diagnose the problem. Rushing to replace parts without proper diagnosis can lead to wasted time and money, especially when other components can mimic CPS symptoms. Here’s a systematic approach to confirm if your 7.3 Powerstroke camshaft position sensor is indeed the culprit.

Initial Visual Inspection

Before grabbing any tools, a quick visual inspection can sometimes reveal obvious issues.

- Locate the CPS: The CPS on a 7.3 Powerstroke is located on the front of the engine block, near the crankshaft damper/harmonic balancer. It’s usually identifiable by a single wire connector and is bolted into the timing cover.

- Check Wiring and Connector: Inspect the wiring harness leading to the sensor for any signs of damage, fraying, exposed wires, or corrosion. Ensure the connector is securely seated and not loose. Sometimes, simply cleaning the connector or ensuring a tight fit can resolve intermittent issues.

- Look for Physical Damage: While rare, check the sensor itself for any visible cracks or signs of impact.

This simple step can sometimes prevent more involved diagnostics.

OBD-II Scanner Diagnostics (P0340, P0341, etc.)

As mentioned, the Check Engine Light and associated DTCs are strong indicators.

- Connect Your Scanner: Plug your OBD-II scanner into the diagnostic port (usually under the dashboard on the driver’s side).

- Read Codes: Retrieve any stored or pending Diagnostic Trouble Codes. Look specifically for P0340, P0341, P0342, P0343, or P0344.

- Clear Codes and Re-test: If you find CPS-related codes, clear them, then try to start the truck or drive it briefly (if possible) to see if the codes reappear. This helps confirm the issue is current and not a historical fault.

- Monitor Live Data: A more advanced scanner can show live data. Look for engine RPM readings. If the engine is cranking but showing 0 RPM, or highly erratic RPM readings, it’s a very strong indicator of a faulty CPS or a complete lack of signal. Note that some scanners may not display RPM until the engine is actually running, so this test might be limited to crank-no-start scenarios where a faulty signal is causing the problem.

The presence of persistent CPS-specific codes after clearing is a nearly definitive sign of a 7.3 Powerstroke camshaft position sensor failure.

The “Known Good Part” Swap (The Most Common DIY Test)

For the 7.3 Powerstroke, perhaps the most common and often quickest DIY diagnostic method for a suspected CPS issue is to simply swap it out with a known good sensor. This is particularly effective for intermittent no-start or stalling issues.

- Acquire a New CPS: Keep a spare, high-quality CPS in your toolbox. Many 7.3 owners consider this essential “truck insurance.” We’ll discuss choosing the right one later.

- Perform the Swap: The replacement process is relatively simple (detailed below). It typically takes 10-15 minutes.

- Test the Truck: After installing the new sensor, attempt to start the truck. If it fires right up and runs smoothly, congratulations – you’ve likely found your problem!

While not a diagnostic “test” in the traditional sense, the low cost and ease of replacement make this a highly practical approach for confirming a 7.3 Powerstroke camshaft position sensor failure, especially when you’re stranded.

Advanced Testing (Less Common for DIY CPS, More for Wiring)

While a multimeter can be used to test the CPS signal, it’s often complex for the average DIYer due to the Hall effect nature of the sensor and the need to backprobe a live circuit. More commonly, a multimeter is used to test the wiring harness *to* the CPS for proper voltage supply (typically 5V reference) and ground, and for continuity of the signal wire back to the PCM. If you’ve replaced the CPS and still have issues, this is the next logical step to rule out a wiring problem instead of the sensor itself.

Replacing Your 7.3 Powerstroke Camshaft Position Sensor: A DIY Guide

Good news! Replacing the 7.3 Powerstroke camshaft position sensor is one of the easier DIY repairs you can undertake on your truck. Even with basic mechanical skills, you can typically complete this job in under 30 minutes. Having the right tools and knowing the exact location are key to a smooth process.

Tools and Supplies You’ll Need

Gathering your tools beforehand will make the job much quicker and less frustrating:

- New 7.3 Powerstroke camshaft position sensor (preferably a high-quality OEM or trusted aftermarket unit).

- 10mm socket or wrench (for the sensor retaining bolt).

- Ratchet with an extension (makes reaching the bolt easier).

- Flathead screwdriver (optional, for prying if the sensor is stuck).

- Small pry bar (optional, for stubborn sensors).

- Clean shop rag.

- Dielectric grease (optional, but recommended for the electrical connector).

- Safety glasses.

Having these items ready will ensure a seamless replacement of your 7.3 Powerstroke CPS.

Locating the CPS on Your 7.3 Powerstroke

The CPS is positioned in a relatively accessible spot on the front of the engine:

- Open the Hood: Ensure the engine is cool to the touch.

- Identify the Front of the Engine: Look directly at the front of the engine block, below the water pump and above the crankshaft balancer (the large pulley at the very bottom).

- Spot the Sensor: The CPS is typically a small, cylindrical sensor, often black or gray, secured by a single 10mm bolt. It will have a 3-wire electrical connector attached to it. It’s usually located slightly to the passenger side of the centerline of the engine.

Once you’ve visually identified it, you’re ready to proceed with the removal.

The Replacement Process (Step-by-Step)

Follow these steps for a straightforward replacement:

- Disconnect Battery (Optional but Recommended): For any electrical work, disconnecting the negative terminal of your battery is a good safety practice to prevent accidental shorts.

- Disconnect the Electrical Connector: Carefully press the tab on the electrical connector and pull it straight off the old sensor. Inspect the connector for any corrosion or damage.

- Remove the Retaining Bolt: Use your 10mm socket or wrench with an extension to loosen and remove the single bolt that holds the CPS in place.

- Remove the Old Sensor: Gently wiggle the sensor while pulling it straight out. It might be a bit snug due to the O-ring seal. If it’s stubborn, you can use a flathead screwdriver or small pry bar to carefully leverage it out, being careful not to damage the housing or surrounding components.

- Clean the Mounting Area: Use a clean shop rag to wipe away any oil or debris from the sensor’s mounting hole and the surrounding area.

- Install the New Sensor: Apply a thin coat of clean engine oil or dielectric grease to the O-ring of the new 7.3 Powerstroke camshaft position sensor. This helps with installation and ensures a good seal. Carefully push the new sensor straight into the mounting hole until it’s fully seated.

- Install the Retaining Bolt: Reinstall the 10mm retaining bolt and tighten it snugly. Do not overtighten, as this can damage the sensor or the housing.

- Reconnect the Electrical Connector: Push the electrical connector firmly onto the new sensor until you hear or feel it click into place.

- Reconnect Battery (If Disconnected): Reattach the negative battery cable.

- Test the Truck: Start your 7.3 Powerstroke. It should fire right up and run smoothly. If the Check Engine Light was on, it might turn off on its own after a few drive cycles, or you can clear it with your OBD-II scanner.

You’ve successfully addressed the 7.3 Powerstroke CPS failure!

Post-Replacement Checks

After installing the new sensor, it’s wise to perform a few checks:

- Monitor Engine Performance: Drive the truck to ensure symptoms like stalling, rough idle, or lack of power are gone.

- Check for Leaks: Briefly check around the new sensor for any oil leaks, although this is uncommon.

- Scan for Codes Again: Even if the CEL is off, a quick scan can confirm no new or pending codes have appeared.

Choosing the Right CPS: Black vs. Gray and Aftermarket Options

When it comes to replacing your 7.3 Powerstroke camshaft position sensor, you’ll quickly encounter discussions about different types and brands. Making the right choice can significantly impact reliability and performance.

The “Black” CPS vs. “Gray” CPS Debate

For years, a common debate among 7.3 Powerstroke owners revolved around the “black” versus “gray” CPS. This distinction refers to the color of the sensor’s body and is indicative of different revisions and, in some cases, manufacturers:

- Original Black CPS: These were the factory-installed sensors in many early 7.3 Powerstrokes. They were notorious for intermittent failures, especially when hot.

- Updated Gray CPS (Ford/International): Ford/International later released an updated gray-bodied CPS, which was designed to be more robust and less prone to the heat-related failures of the black units. For a long time, the gray sensor was considered the gold standard for reliability. It’s often referred to as the “correct” replacement for improved performance and longevity.

- Newer Black CPS (International): More recently, International (who manufactured the 7.3 for Ford) has produced new black-bodied CPS units that are engineered with the latest technology and are considered reliable. These should not be confused with the problematic original black sensors.

Key takeaway: If you’re buying a new sensor, the color alone isn’t the sole indicator of quality anymore. Focus on the manufacturer and part number. Always opt for the most current revision recommended by Ford/International.

OEM vs. Aftermarket: What’s Best for Your 7.3 Powerstroke CPS?

When shopping for a replacement 7.3 Powerstroke camshaft position sensor, you’ll have options from Original Equipment Manufacturer (OEM) or various aftermarket brands.

- OEM (Ford/International): Generally, the safest bet for critical sensors like the CPS is to go with an OEM part. These are designed to meet exact factory specifications and often come with a warranty. The current International/Navistar part numbers are often the most reliable. While they might cost a bit more upfront, their reliability often pays off in the long run, preventing recurring 7.3 Powerstroke CPS failure.

- Trusted Aftermarket Brands: Some aftermarket companies produce high-quality CPS sensors that perform comparably to OEM. Look for reputable brands with positive reviews within the 7.3 Powerstroke community. Brands like Alliant Power, Dorman (ensure it’s a newer revision), or specific performance-oriented companies might offer good alternatives. Be wary of extremely cheap, generic sensors, as these are often the source of recurring issues or even new problems.

It’s highly recommended to invest in a quality sensor. Saving a few dollars on a cheap CPS could leave you stranded or facing another 7.3 Powerstroke camshaft position sensor failure very soon.

Performance CPS Options (For Modified Engines)

For enthusiasts running highly modified 7.3 Powerstrokes (e.g., with large injectors, custom tuning, or high-revving setups), there are also “performance” camshaft position sensors available. These are designed to offer a more stable and accurate signal at higher RPMs, which can be beneficial for precision tuning and maximizing power. However, for a stock or mildly modified truck, a quality OEM-spec sensor is more than adequate and typically the most reliable choice.

Preventative Measures and Related Issues to Consider

While the 7.3 Powerstroke camshaft position sensor failure is a known weak point, there are steps you can take to potentially extend its life and ensure you’re looking at the whole picture if your truck still isn’t running right after a CPS replacement.

General Maintenance Tips for Your CPS

While you can’t prevent all failures, some practices can help:

- Keep a Spare: As discussed, carrying a known good, high-quality spare CPS is perhaps the best preventative measure against being stranded.

- Inspect Wiring Regularly: During routine oil changes or under-hood checks, quickly inspect the CPS wiring and connector for any signs of wear, fraying, or corrosion.

- Address Engine Vibrations: Excessive engine vibrations can contribute to sensor failure. Ensure engine mounts are in good condition.

- Use Quality Parts: When it’s time for replacement, don’t skimp on quality. An OEM or reputable aftermarket sensor is worth the investment.

Other Components to Inspect if You Suspect CPS Issues

The symptoms of a failing CPS can sometimes mimic other problems. If replacing the 7.3 Powerstroke camshaft position sensor doesn’t resolve your issue, consider these other common culprits:

- Crankshaft Position Sensor (CKP): Located near the crankshaft, this sensor works in tandem with the CPS. A faulty CKP can also cause no-start conditions, stalling, and rough running.

- Injection Pressure Regulator (IPR) Valve: The IPR controls oil pressure to the fuel injectors. A failing IPR can cause similar symptoms, including stalling, no-start, and rough idle. It’s located at the rear of the HPOP (High-Pressure Oil Pump).

- Injector Control Pressure (ICP) Sensor: This sensor measures the oil pressure in the high-pressure oil system. A bad ICP can also lead to no-start or poor running conditions. It’s typically located on the passenger side cylinder head, towards the front.

- Fuel Supply Issues: Clogged fuel filters, a weak fuel pump, or a faulty fuel pressure regulator can also cause a lack of fuel, mimicking a stalling or no-start condition.

- Wiring Harness Problems: As mentioned, a damaged or corroded wiring harness to the CPS, IPR, or ICP can cause sensor readings to be incorrect, leading to similar symptoms.

- Relays and Fuses: Check the engine-related fuses and relays, especially the PCM relay and fuel pump relay.

Remember, accurate diagnosis is paramount. Don’t just throw parts at the problem; use your scanner, visual inspections, and logical elimination to narrow down the actual fault.

Conclusion: Empowering Your 7.3 Powerstroke Diagnostics

The 7.3 Powerstroke is an engine renowned for its longevity, but like any mechanical marvel, it has its quirks. The camshaft position sensor failure is undoubtedly one of the most common and frustrating issues owners face, often leaving them scratching their heads or stranded on the side of the road. However, by understanding the symptoms, following a systematic diagnostic approach, and knowing how to properly replace the sensor, you can tackle this problem with confidence and precision.

We’ve covered everything from identifying the subtle signs of a failing sensor to the hands-on steps of replacement and the critical decision of choosing the right part. Armed with this comprehensive guide, you’re now better equipped to diagnose, address, and even prevent 7.3 Powerstroke camshaft position sensor failure. Keep a quality spare on hand, stay vigilant for the tell-tale symptoms, and remember that a little knowledge goes a long way in keeping your legendary 7.3 Powerstroke running strong for years to come. Happy wrenching!

🎥 Related Video: Ford 7.3L Powerstroke Camshaft Position Sensor Installation

📺 FordTechMakuloco

You can get the updated Cam Sensor Here- …

Frequently Asked Questions

What are the common signs of a failing 7.3 Powerstroke camshaft position sensor?

A failing camshaft position sensor (CPS) can cause various issues like sudden engine stalling, rough idling, prolonged cranking before starting, or even complete no-start conditions. You might also notice the tachometer dropping to zero while driving, even if the engine is still running.

Where is the 7.3 Powerstroke camshaft position sensor located on the engine?

The 7.3 Powerstroke camshaft position sensor is typically found on the front of the engine, usually mounted low on the passenger side. It is often bolted into the timing cover near the crankshaft damper.

How can I test my 7.3 Powerstroke’s camshaft position sensor to confirm failure?

You can test a 7.3 Powerstroke CPS by checking for diagnostic trouble codes (DTCs) with an OBD-II scanner, such as P0340, which directly indicates a camshaft position sensor circuit malfunction. For more advanced diagnostics, a multimeter can be used to check for proper voltage signals and resistance, or you can monitor live data while cranking.

Is 7.3 Powerstroke camshaft position sensor failure a common problem, and why do they fail?

Yes, camshaft position sensor failure is a very common issue on 7.3 Powerstroke engines; many owners even carry a spare. These sensors often fail due to exposure to heat, vibrations, and general wear and tear over time, especially the older, original equipment units.

Can I still drive my 7.3 Powerstroke if the camshaft position sensor is failing?

While your 7.3 Powerstroke might still run erratically or intermittently with a failing CPS, it’s not recommended to drive it for long. A completely failed sensor will cause a no-start condition or sudden, unpredictable engine stalling, which can be dangerous and leave you stranded.

Is replacing the 7.3 Powerstroke camshaft position sensor a difficult DIY job?

For most mechanically inclined individuals, replacing the 7.3 Powerstroke camshaft position sensor is a relatively straightforward DIY task. It typically involves removing one bolt and unplugging a connector, though access to the sensor can be a bit tight depending on the vehicle’s configuration.