How to Detect a Weak Fuel Pump on a 6.0 Powerstroke Engine?

If you own a vehicle with a 6.0 Powerstroke engine, you likely understand the importance of a properly functioning fuel system. The fuel pump plays a crucial role in delivering fuel to the engine, ensuring smooth and efficient operation. However, over time, a fuel pump can weaken, leading to a range of performance issues and potential breakdowns.

In this blog post, we will guide you through the process of detecting a weak fuel pump on your 6.0 Powerstroke engine. Recognizing the early signs of a failing fuel pump can save you from costly repairs and prevent potential engine damage. We will discuss common symptoms, such as decreased fuel efficiency, loss of power, rough idle, and difficulties starting the vehicle. Additionally, we will explore the underlying causes of a weak fuel pump, including wear and tear, clogged filters, and electrical problems.

By learning how to identify the warning signs of a weak fuel pump, you can take proactive measures to address the issue before it escalates, ensuring optimal performance and reliability for your 6.0 Powerstroke engine.

How do I know if my 6.0 fuel pump is bad?

Identifying a failing fuel pump on your 6.0 Powerstroke can involve a combination of observing symptoms, using diagnostic tools (if available), and potentially seeking a professional mechanic’s expertise.

5 Symptoms To Detect A Weak Fuel Pump On 6.0 Powerstroke:

1. Decreased Fuel Efficiency

One of the first indicators of a weak fuel pump on a 6.0 Powerstroke engine is a noticeable decrease in fuel efficiency. If you find yourself visiting the gas station more frequently or experiencing a significant drop in miles per gallon, it could be a sign that your fuel pump is struggling to supply an adequate amount of fuel to the engine.

2. Loss of Power

A weak fuel pump may cause a noticeable loss of power, especially during acceleration or when climbing hills. You might experience a lack of responsiveness or a sluggish feeling when pressing the accelerator pedal. This reduced power output can be frustrating and potentially dangerous, particularly in situations that require quick acceleration, such as merging onto a highway.

3. Rough Idle

An irregular or rough idle can also be an indication of a weak fuel pump. If you notice that your 6.0 Powerstroke engine is running unevenly, with fluctuations in RPMs or a shaking sensation at idle, it could be due to insufficient fuel delivery caused by a struggling fuel pump.

4. Difficulties Starting the Vehicle

A weak fuel pump can make starting your vehicle a challenge. You may experience prolonged cranking or multiple attempts before the engine finally starts. This can be especially apparent when the vehicle has been sitting for an extended period or when it’s cold outside. If you notice these difficulties consistently, it’s worth investigating the condition of your fuel pump.

5. Engine Stalling

A failing fuel pump can cause intermittent engine stalling while driving. The engine may suddenly shut off, leaving you stranded on the road. If you experience frequent stalling episodes that seem to occur randomly, it’s crucial to have your fuel pump checked as it may not be supplying the required fuel pressure consistently.

Additional Signs Specific to 6.0 Powerstroke:

- Blue engine oil: This can be a sign of diesel fuel leaking into the engine oil due to low pressure and worn injector seals, which can be caused by a failing fuel pump.

- Turbocharger issues: The 6.0 Powerstroke relies on proper fuel pressure to spool the turbocharger efficiently. Low fuel pressure from a bad pump can hinder turbo performance and reduce power output.

Using Diagnostic Tools (if available):

- Scan Tool with Live Data: If you have a scan tool that displays live data streams from various sensors, monitor the fuel pressure readings. Look for a parameter labeled “fuel pressure” or “FRP” (Fuel Rail Pressure). The specific values will vary depending on engine RPM and load, but generally, you should see fuel pressure within the range specified by the manufacturer (consult your repair manual for exact values). Low and inconsistent readings can indicate a failing fuel pump.

Professional Diagnosis:

For a definitive diagnosis, consulting with a qualified mechanic is recommended. They can perform a comprehensive inspection that might include:

- Physical Inspection: The mechanic will look for leaks or external signs of damage around the fuel pump assembly.

- Fuel Pressure Testing: They will use a fuel pressure gauge to measure the pressure at different points in the fuel system to assess the pump’s functionality.

- Fuel Volume Test: In some cases, a test might be conducted to measure the volume of fuel delivered by the pump within a specific time frame to determine if it meets the required specifications.

Important Notes:

- While these methods can provide valuable clues, a failing fuel pump might not always throw a specific diagnostic trouble code (DTC). So, a combination of symptoms, tool readings, and a mechanic’s expertise is often the best approach for an accurate diagnosis.

- Addressing a failing fuel pump promptly is crucial to prevent further damage to your 6.0 Powerstroke engine.

What To Do When You Detect A 6.0 Powerstroke Weak Fuel Pump?

When you detect a weak fuel pump on your 6.0 Powerstroke engine, it’s essential to take prompt action to address the issue and prevent further damage. Here are the steps you can follow:

Confirm the Diagnosis

If you experience symptoms indicative of a weak fuel pump, such as decreased fuel efficiency, loss of power, rough idle, difficulties starting, or engine stalling, it’s crucial to have a qualified mechanic confirm the diagnosis. They will use diagnostic tools to assess the fuel pump’s performance and determine if it needs replacement or repair.

Replace the Fuel Pump

In most cases, a weak fuel pump will require replacement to restore proper fuel delivery. It is recommended to have a professional mechanic handle this task as it involves accessing the fuel tank and dealing with potentially hazardous substances. They will ensure the correct fuel pump is installed and perform any necessary adjustments to ensure optimal performance.

Check and Replace Fuel Filters

Weak fuel pump performance can be exacerbated by clogged fuel filters. Therefore, it is advisable to inspect and replace the fuel filters if necessary during the fuel pump replacement process. This helps ensure that clean fuel reaches the engine, improving its overall performance.

Consider Upgrades

The 6.0 Powerstroke engine has had a history of fuel system issues, including weak fuel pumps. As part of addressing the weak fuel pump, you may want to consider upgrading certain components, such as the fuel pressure regulator or adding auxiliary fuel filtration systems, to enhance fuel system reliability and prevent future problems.

Regular Maintenance

To prevent recurring fuel pump issues, it is vital to prioritize regular maintenance for your 6.0 Powerstroke engine. Follow the manufacturer’s recommended maintenance schedule, including fuel filter replacements, fuel system cleanings, and inspections. Routine maintenance will help identify and address potential problems early on, ensuring the longevity and optimal performance of your fuel pump and engine.

6.0 Powerstroke Fuel Pump Replacement Cost

The cost of replacing a fuel pump on a 6.0 Powerstroke engine can vary depending on several factors, including the location, the mechanic or dealership you choose, and the quality of the replacement part. Additionally, prices can fluctuate over time. However, as of my knowledge cutoff in September 2021, I can provide you with a rough estimate of the fuel pump replacement cost for a 6.0 Powerstroke engine.

On average, you can expect to pay between $400 and $800 for the fuel pump itself. Keep in mind that this cost can vary based on whether you opt for an OEM (Original Equipment Manufacturer) fuel pump or an aftermarket option.

Labor costs for the replacement can range from $200 to $500, depending on the shop’s hourly rate and the complexity of the job. Since replacing a fuel pump on a 6.0 Powerstroke requires accessing the fuel tank, it can be a time-consuming process.

Additionally, you may need to account for any additional parts or components that may need replacement during the fuel pump replacement, such as fuel filters or gaskets.

How Often Should You Inspect Or Service A Fuel Pump?

The frequency of fuel pump inspections or servicing can vary depending on several factors, including the vehicle’s make and model, driving conditions, and the manufacturer’s recommendations. However, there are some general guidelines to keep in mind:

Consult the Owner’s Manual

The best place to start is by referring to your vehicle’s owner’s manual. It will provide specific recommendations from the manufacturer regarding fuel pump inspections and servicing intervals. The manual may also include information on fuel filter replacements, which are often interconnected with the fuel pump.

Regular Maintenance Schedule

As a general rule, it is a good practice to have your fuel pump inspected during your regular maintenance appointments. Depending on the vehicle, this could be every 30,000 to 60,000 miles or every couple of years. During these inspections, the fuel pump can be checked for signs of wear, leaks, or reduced performance.

Pay Attention to Symptoms

If you notice any symptoms of a weak fuel pump, such as decreased fuel efficiency, loss of power, rough idle, difficulties starting, or engine stalling, it is important to have the fuel pump inspected promptly, regardless of the scheduled maintenance. Ignoring these symptoms can lead to further damage and more expensive repairs.

Consider Driving Conditions

If you frequently drive in harsh conditions that can put additional strain on the fuel system, such as dusty or off-road environments, it may be wise to have the fuel pump inspected more frequently. These conditions can lead to increased debris and contaminants that can impact the fuel pump’s performance.

Remember, regular inspections and maintenance are key to catching any potential fuel pump issues early on. By following the manufacturer’s recommendations and staying vigilant for symptoms, you can help ensure the optimal performance and longevity of your fuel pump and the overall fuel system.

What is the recommended fuel pressure for a 6.0 Powerstroke?

The recommended fuel pressure for a 6.0 Powerstroke engine varies depending on the RPM and driving conditions. Here’s a breakdown of the typical ranges:

- Idle (RPM below 600): 40-50 psi (2.76-3.45 bar)

- Low Speed (600-1400 RPM): 50-70 psi (3.45-4.83 bar)

- High Speed (Over 1400 RPM): 60-90 psi (4.14-6.21 bar)

It’s important to note that these are general guidelines. The specific fuel pressure readings for your 6.0 Powerstroke might differ slightly based on factors like:

- Year of manufacture: There could be minor variations in fuel pressure specifications between different model years of the 6.0 Powerstroke.

- Aftermarket modifications: If your engine has performance modifications like a tuner or aftermarket injectors, the recommended fuel pressure might be adjusted accordingly.

Here’s how you can check your fuel pressure:

- Using a scan tool (if available): Some advanced scan tools can display live data streams from various sensors, including the fuel pressure sensor. This allows you to monitor real-time fuel pressure readings.

- Fuel pressure gauge: A qualified mechanic can use a fuel pressure gauge connected to a specific test port on the fuel system to measure the pressure at different RPMs and engine loads.

Consulting a repair manual: Your vehicle’s repair manual should have specific fuel pressure specifications for your exact model year and engine configuration. Referring to the manual will provide the most accurate recommended fuel pressure range for your 6.0 Powerstroke.

Remember: Even slight variations from the recommended fuel pressure range can negatively impact engine performance and fuel efficiency. If you notice any concerning symptoms or suspect a fuel pressure issue, consulting with a qualified mechanic familiar with 6.0 Powerstroke engines is recommended for proper diagnosis and repair.

What happens if fuel pressure is low?

Low fuel pressure in a car engine can lead to a cascade of problems affecting performance, drivability, and even engine health. Here’s a breakdown of the potential consequences:

- Reduced Engine Power: This is a common symptom of low fuel pressure. The injectors won’t receive enough fuel to create a proper air-fuel mixture for efficient combustion. This leads to a lack of power, especially noticeable during acceleration when the engine demands more fuel.

- Rough Idle: Inconsistent or insufficient fuel pressure can cause the engine to run erratically at idle. You might experience vibrations or surging RPMs as the engine struggles to maintain a smooth idle.

- Hard Starts: If the fuel pressure is too low, the engine might struggle to start, particularly during cold starts when it needs more fuel for proper combustion.

- Increased Smoke from Exhaust: Black smoke coming out of the exhaust can be a sign of incomplete fuel combustion due to low fuel pressure. The engine isn’t able to properly atomize the fuel, leading to rich fuel mixture and black smoke.

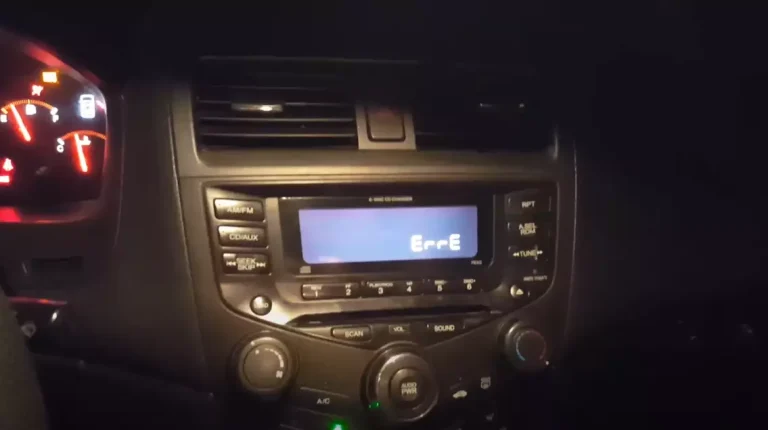

- Check Engine Light (CEL) illumination: The engine computer will likely detect the low fuel pressure and trigger the CEL to alert the driver of a potential problem.

- Long-term Engine Damage: In severe cases, persistently low fuel pressure can lead to long-term engine damage. Lean running conditions (due to insufficient fuel) can cause excessive heat and stress on engine components like pistons and valves. Additionally, poor lubrication can occur if the fuel system also carries lubricants for certain engine parts.

Additional Issues Depending on the Car:

- Modern cars with turbochargers: In these vehicles, low fuel pressure can disrupt the proper functioning of the turbocharger. The turbo relies on exhaust pressure created by efficient combustion to spool up and provide additional power. Low fuel pressure can hinder this process, reducing overall power output.

- Diesel engines: For diesel engines, proper fuel pressure is crucial for precise injection control. Low pressure can lead to erratic injection timing and incomplete combustion, resulting in rough running, white smoke (due to unburned fuel), and reduced fuel efficiency.

Importance of Addressing Low Fuel Pressure:

If you suspect low fuel pressure in your car, it’s crucial to address the issue promptly. Ignoring it can lead to performance problems, increased emissions, and potential engine damage that might be expensive to repair. Consulting with a qualified mechanic can help diagnose the cause of the low fuel pressure and recommend the appropriate repairs to get your car running smoothly again.

How did the issue of air getting into the upper fuel bowl and causing a gurgling sound get resolved?

The issue of air getting into the upper fuel bowl and causing a gurgling sound was successfully resolved by replacing the dried out o-rings located on the cover that seals the water separator and separate chambers on the frame-mounted lift pump. An additional step taken to address the issue involved changing the o-ring on the drain plug of the water separator. By undertaking these measures, the problem of air ingress into the upper fuel bowl and the resulting gurgling sound was effectively rectified.

What could be the cause of low power and high boost in a customer’s truck?

The cause of low power and high boost in a customer’s truck could potentially be due to issues with dried-out o-rings on crucial components like the cover sealing the water separator and different chambers on the frame-mounted lift pump. Additionally, problems with the o-ring on the drain plug for the water separator could contribute to the entry of air into the upper fuel bowl, leading to symptoms such as reduced power, high boost, and abnormal shifting patterns, including delayed shifts until higher rpm levels are reached and pedal pressure is released. Addressing and replacing these worn-out or damaged o-rings could help resolve these performance issues in the truck effectively.

What were the recommendations provided to the user regarding checking the fuel suction line and the pickup foot screen in the tank?

the user was advised to inspect the fuel suction line leading back to the tank to rule out any possible damage, as critters may have caused issues like in a previous incident. Additionally, the user was recommended to check the pickup foot screen within the tank itself, which could potentially be obstructed by debris.

The importance of ensuring clear and unobstructed fuel flow from the upper filter bowl was stressed, with emphasis placed on the potential impact of low pressure in causing frequent injector replacements. The recommendation for the user to consider installing a fuel gauge, in addition to other essential gauges like oil pressure and exhaust gas temperature, was also made to potentially prevent similar issues in the future.

FAQ:

Q: How can I tell if my 6.0 Powerstroke fuel pump is weak?

A: There are several symptoms that may indicate a weak fuel pump on a 6.0 Powerstroke engine. Look out for decreased fuel efficiency, loss of power during acceleration, rough idle, difficulties starting the vehicle, and engine stalling. If you experience one or more of these symptoms consistently, it’s advisable to have your fuel pump inspected by a qualified mechanic.

Q: Can a weak fuel pump affect the engine’s performance?

A: Yes, a weak fuel pump can significantly impact the engine’s performance. It may result in decreased power output, reduced fuel efficiency, rough idling, and even engine stalling. The fuel pump is responsible for supplying an adequate amount of fuel to the engine, and any weakness in its performance can disrupt the fuel delivery process.

Q: What causes a weak fuel pump on a 6.0 Powerstroke engine?

A: A weak fuel pump on a 6.0 Powerstroke engine can be caused by various factors. Common causes include wear and tear over time, clogged fuel filters, electrical issues, or a failing fuel pressure regulator. Contaminated fuel or running the vehicle on low fuel levels for extended periods can also contribute to the deterioration of the fuel pump.

Q: Can I replace the fuel pump on my 6.0 Powerstroke engine myself?

A: While it is technically possible to replace the fuel pump on your 6.0 Powerstroke engine yourself, it is a complex task that requires specialized knowledge and tools. Accessing the fuel pump, located inside the fuel tank, can be challenging, and mishandling the process can lead to safety hazards or further damage. It is recommended to have a professional mechanic or technician with experience in fuel system repairs handle the replacement to ensure proper installation and safety.

Q: How much does it cost to replace a fuel pump on a 6.0 Powerstroke engine?

A: The cost of replacing a fuel pump on a 6.0 Powerstroke engine can vary depending on factors such as location, labor rates, and the quality of the replacement part. On average, you can expect to pay between $400 and $800 for the fuel pump itself. Additional costs may include labor fees, fuel filter replacements, and any other necessary components. It is advisable to consult with local mechanics or service centers for a detailed quote based on your specific circumstances.