The Ultimate Guide to Adjusting Clutch Brake on Semi-Trucks: Step-by-Step Instructions for a Smooth Ride

Are you a truck driver dealing with an annoying clutch brake issue on your semi-truck? Don’t worry, adjusting the clutch brake is an easy fix that doesn’t require expensive tools or a mechanic’s expertise. A clutch brake helps slow down the rotation of the transmission input shaft when shifting gears, preventing damage to the gears and synchronizing the speed between the two shafts. However, when the clutch brake is not adjusted correctly, it can lead to various problems, such as grinding gears, difficulty shifting, and even transmission damage.

In this blog post, we will guide you through adjusting the clutch brake on your semi-truck in simple steps, saving you time and money in the process. So, tighten your seatbelt, and let’s get started!

Understanding the Clutch Brake

If you’re driving a semi-truck, you might already know what a clutch brake is, but do you know how to adjust it? The clutch brake is a mechanism that helps to slow down the transmission when shifting gears and ultimately reduces wear on the clutch. To adjust the clutch brake on a semi, start by locating the adjustment bolt on the clutch brake rod. You may need to remove a cover or access panel to find it.

Loosen the locknut and turn the adjustment bolt until you feel tension on the clutch pedal, but it doesn’t engage the clutch. Then, tighten the locknut and test the clutch brake by shifting gears. If the clutch pedal now engages smoothly, you’ve successfully adjusted the clutch brake.

Remember to test it on flat ground first before driving on uneven terrain. Regularly maintaining and adjusting your clutch brake can help prolong the life of your clutch and ensure a smoother driving experience.

What is a Clutch Brake?

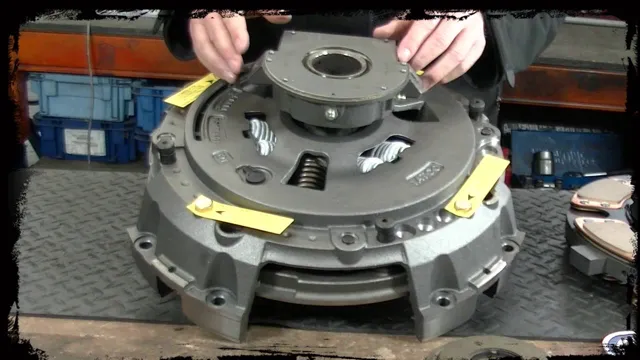

A clutch brake is a component that is often present in machines that require quick, precise, and safe stops. It is a mechanical device located between the engine and the transmission system and is responsible for stopping the rotation of the engine and the connected machinery. The clutch brake is activated when the operator of the machinery depresses the brake pedal, causing a metal plate to enter into the clutch assembly and create friction, thereby stopping the movement of the machinery.

Clutch brakes are often used in heavy machinery, such as cranes, forklifts, and bulldozers, to ensure safety during operation. By using a clutch brake, the operator can quickly stop the machine from moving forward or backward, ensuring minimal damage in case of accidents. These devices are essential for the smooth and safe operation of heavy machinery and should be inspected frequently to ensure their proper function.

Why Adjust it?

If you’re wondering why you need to adjust the clutch brake, let’s start by understanding what it is and why it’s important. A clutch brake is typically found in manual transmission vehicles and helps prevent gear damage while shifting gears. The brake applies pressure to the clutch disc, temporarily stopping the transmission from rotating, allowing for smoother shifting.

Over time, the brake can become worn down, causing a delay in gear shifting. That’s where adjustment comes in. By adjusting the brake, you can ensure smoother gear shifting, prevent gear damage, and prolong the lifespan of your transmission.

It’s important to have the clutch brake adjusted regularly, especially if you use your vehicle for heavy-duty purposes. As with any mechanical issue, it’s best to have a professional mechanic inspect and adjust it to ensure proper functioning of your vehicle.

Adjusting the Clutch Brake

Adjusting the clutch brake on a semi-truck is a crucial maintenance task that ensures the smooth functioning of the vehicle’s transmission and gear shifting. A clutch brake is a feature located between the clutch pedal and the transmission system which helps to slow down the gears and reduce the wear on the clutch plate during gear changes. To adjust the clutch brake, first, locate the brake adjustment bolt on the clutch pedal and loosen it with the help of a wrench.

Then, press the clutch pedal down to disengage the clutch, and while holding it down, tighten the brake adjustment bolt until the clutch brake starts to touch the clutch release fork on the transmission. Finally, release the clutch pedal and check if the clutch brake is now engaging smoothly and there is no slippage during gear changes. Regularly adjusting the clutch brake can extend the life of the clutch plate and ensure the safe operation of the semi-truck on the road.

Step-by-step Guide

Adjusting the clutch brake is a crucial step in ensuring the smooth functioning of your vehicle’s transmission. If you notice that your clutch is slipping or is engaged even when the pedal is fully depressed, it might be time to adjust the clutch brake. The process is relatively simple but requires some care and attention.

First, locate the clutch brake adjustment bolt, which is usually located on the side of the clutch housing. Loosen the bolt and adjust the clutch brake nut until you feel resistance. Tighten the adjustment bolt and try out the clutch to see if the slipping has stopped.

Repeat the process until you achieve the desired results. By adjusting the clutch brake, you’ll be able to run your vehicle more efficiently and reduce the risk of damage to your transmission. Remember to take your time and be patient when making adjustments, and always refer to your owner’s manual if you need any further guidance.

Tools Required

When it comes to adjusting the clutch brake, the tools required aren’t too complicated. In fact, you only need a few basic items to get started. First, a wrench to adjust the clutch brake’s nut is a must-have.

You’ll also need a screwdriver to make the necessary adjustments. A set of pliers or a wire cutter might also come in handy to make minor tweaks. When it comes to safety, make sure you have safety gloves and goggles to protect your hands and eyes.

With these tools on hand, you can easily adjust the clutch brake and keep your vehicle running smoothly. Just remember to follow the manufacturer’s instructions and seek professional help if needed. With a little bit of know-how and the right tools, you’ll have a clutch brake that’s perfectly adjusted and ready to go.

Common Issues to Watch For

One of the most common issues that arise with clutches is an improperly adjusted clutch brake. This can lead to a number of problems, including slipping or sticking clutches. To adjust the clutch brake, locate the brake lever and use a wrench to loosen the lock nut.

You can then turn the adjusting screw to bring the brake closer or further away from the clutch. Once you have made your adjustment, tighten the lock nut back up to secure the brake in place. It’s important to check the manufacturers guidelines for the correct adjustment of your clutch brake, as an adjustment that is too tight can cause a host of additional problems.

By taking the time to properly adjust your clutch brake, you can save yourself time, money, and frustration in the long run.

Testing the Clutch Brake

Adjusting the clutch brake on your semi truck is an important maintenance task to ensure smooth gear shifting and prevent damage to your transmission. Testing the clutch brake is the first step in the process. To do this, start your engine and put the transmission in gear.

Then, press down on the clutch pedal and release it quickly while giving your truck a bit of gas at the same time. If your truck lurches forward or makes a loud noise, your clutch brake may need to be adjusted. This is where the main keyword “how to adjust clutch brake on semi” comes in.

To adjust the clutch brake, locate the adjustment bolt on your clutch linkage and turn it clockwise to tighten the brake or counterclockwise to loosen it. Keep testing the clutch brake until you find the right adjustment that allows for smooth gear shifting. Remember that properly adjusted clutch brakes can save you time and money in the long run.

How to Test the Clutch Brake

Testing the clutch brake is a critical task that every vehicle owner should perform to ensure the proper functioning of their automobile. The clutch brake works in conjunction with the clutch to stop the engine from turning when the transmission is shifted into gear. To test the clutch brake, start by shifting the vehicle into first gear and gently releasing the clutch pedal.

The clutch should engage and move the vehicle forward slightly. Then, press the clutch pedal again and observe whether the engine stops abruptly or continues to rotate. If the engine continues to rotate, the clutch brake is not functioning correctly, and it’s time to take your vehicle to a mechanic.

In contrast, if the engine stops immediately, then your clutch brake is working as intended. Testing your clutch brake periodically will ensure that it is functioning correctly and will help avoid any potential accidents.

What to Do if Problems Persist?

If you’re still experiencing problems with your clutch brake, it’s important to take action to prevent further damage to your vehicle. One step you can take is to test the clutch brake to see if there are any issues with its operation. To do this, start by engaging the clutch, then apply the brake.

If the brake doesn’t stop the vehicle from moving, or if it jerks instead of smoothly slowing down, there may be a problem with the clutch brake. It’s important to address any issues with the clutch brake promptly, as continued use can cause unnecessary wear and tear on other parts of the vehicle, leading to more extensive and expensive repairs down the line. If you’re unsure of how to test the clutch brake yourself, it’s best to take your vehicle to a qualified mechanic or technician who can diagnose and fix the problem.

By taking care of issues with your clutch brake early on, you can keep your vehicle running smoothly and avoid costly breakdowns.

Conclusion

Adjusting the clutch brake on a semi is not rocket science, but it does take some know-how and patience. Like a well-placed punchline, getting the balance just right can make a world of difference. So if your clutch feels like a bad joke, it’s time to read the manual, roll up your sleeves, and get your hands dirty.

With a little finesse and some elbow grease, you’ll shift gears smoother than a smooth operator.”

FAQs

What is a clutch brake on a semi truck?

A clutch brake is a mechanism that is used to slow down or stop the rotation of the transmission input shaft when the clutch pedal is depressed.

Why do I need to adjust the clutch brake on my semi truck?

Over time, the clutch brake can wear out and lose its effectiveness. Adjusting the clutch brake ensures that it is working properly and helps to prolong its lifespan.

How do I know when my clutch brake needs adjustment?

Signs that your clutch brake may need adjustment include difficulty shifting gears, a grinding noise when shifting, or the transmission input shaft not stopping fast enough when the clutch pedal is depressed.

How do I adjust the clutch brake on my semi truck?

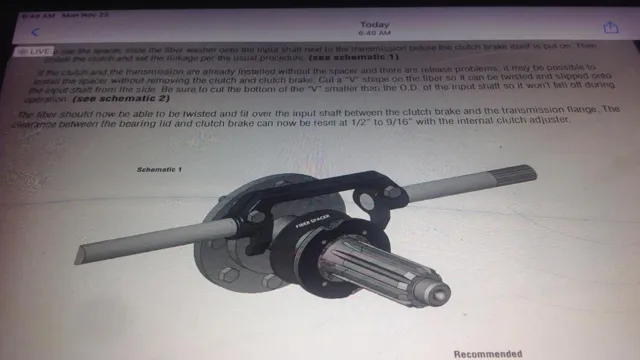

The process for adjusting the clutch brake can vary depending on the make and model of your semi truck. Generally, it involves adjusting the clearance between the brake and the transmission input shaft using a special tool. It is recommended that you refer to your truck’s owner’s manual or consult a professional mechanic for guidance.