7.3 Powerstroke High Pressure Oil Pump Specifications Explained

Featured image for this comprehensive guide about 7.3 Powerstroke high pressure oil pump specs

Welcome, fellow Powerstroke enthusiasts! If you own a legendary 7.3L Ford Powerstroke diesel, you know you’ve got a robust and reliable workhorse. But even the toughest engines have a “heart” that requires attention and understanding to keep performing at its peak. For the 7.3L, that heart is undoubtedly the High Pressure Oil Pump, or HPOP.

This ingenious component is the driving force behind your injectors, supplying the immense oil pressure needed for precise fuel delivery. Whether you’re chasing more horsepower, ensuring peak towing performance, or simply aiming for maximum longevity, a deep dive into the 7.3 Powerstroke high pressure oil pump specs is essential. Understanding how this vital part works, what its original specifications are, and how aftermarket upgrades can transform your truck will empower you to make informed decisions and keep your “old iron” running strong.

In this comprehensive guide, we’ll strip down the intricacies of the 7.3 Powerstroke HPOP system, explore its OEM specifications, discuss common failure symptoms, and reveal the best upgrade paths to unleash your engine’s true potential. Get ready to elevate your knowledge and become an expert on one of the most critical components of your beloved 7.3L Powerstroke!

Quick Answers to Common Questions

What is the HPOP and why is it so important for my 7.3 Powerstroke?

The High Pressure Oil Pump (HPOP) is the heart of your 7.3 Powerstroke’s HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, creating the immense oil pressure needed to fire your injectors. Understanding its 7.3 Powerstroke HPOP specs is crucial because without it, your engine literally can’t run!

What kind of pressure should my 7.3 Powerstroke HPOP be making?

Typically, you’re looking for idle pressures around 500-700 PSI and wide-open throttle (WOT) pressures reaching 2500-3000 PSI, depending on load and tune. Monitoring these 7.3 Powerstroke HPOP specs helps confirm your pump is healthy.

How do I know if my 7.3 Powerstroke HPOP is going bad?

Common signs include hard starts (especially when hot), rough idle, lack of power, or stalling. Consistently low ICP (Injector Control Pressure) readings are a strong indicator that your 7.3 Powerstroke HPOP specs are no longer being met.

Are there different types of 7.3 Powerstroke HPOP units, and do they have different specs?

Yes, absolutely! There are factory units (15-degree, 17-degree swash plate angles) and various aftermarket upgrades (like Adrenaline, Gen3), each with different flow capabilities. These variations directly impact the 7.3 Powerstroke HPOP specs like maximum flow and sustained pressure.

Can I upgrade my 7.3 Powerstroke HPOP for more power?

You bet! Upgrading to a higher-flow 7.3 Powerstroke HPOP (e.g., a 17-degree or an aftermarket option) is a very common modification to support larger injectors and achieve higher horsepower goals. Matching your 7.3 Powerstroke HPOP specs to your injector size is key for optimal performance.

📋 Table of Contents

- The Heart of the Beast: Understanding the 7.3L Powerstroke’s HPOP System

- Diving Deep into Original 7.3 Powerstroke High Pressure Oil Pump Specs

- Recognizing HPOP Failure: Symptoms and Diagnostics

- Upgrading Your HPOP: Enhancing 7.3 Powerstroke Performance

- Installation, Maintenance, and Longevity Tips for Your HPOP

- Data Table: Comparing HPOP Specifications

- Conclusion

The Heart of the Beast: Understanding the 7.3L Powerstroke’s HPOP System

The 7.3L Powerstroke engine is unique in its fuel injection strategy. Unlike many diesels that use a direct mechanical high-pressure fuel pump, the 7.3L employs an “Hydraulically Actuated Electronically Controlled Unit Injector” (HEUI) system. This means your engine oil isn’t just for lubrication; it’s also the medium used to pressurize and inject fuel into the cylinders. At the core of this system, converting low-pressure oil into the incredibly high pressures needed, is the 7.3 Powerstroke high pressure oil pump.

How the 7.3L Injector System Works

Imagine your injectors as tiny, precision hydraulic cylinders. The HPOP delivers highly pressurized engine oil to these injectors. Inside each injector, this high-pressure oil acts on an intensifier piston, which in turn amplifies the pressure even further to atomize and inject diesel fuel into the combustion chamber. This sophisticated system allows for precise control over injection timing and duration, which is crucial for emissions, fuel economy, and power output.

| Specification | Value | Unit / Description | Notes / Application |

|---|---|---|---|

| Pump Design Type | Piston (Swash Plate) / Gerotor | N/A | Early (94-95) / Late (96-03) Models |

| Drive Mechanism | Gear-driven | Off Camshaft | All 7.3L Powerstroke Engines |

| Max Stock Injection Control Pressure (ICP) | 2800-3000 | psi | Factory Calibration Target |

| Common Volumetric Displacement (OEM) | 15-degree / 17-degree | Swash Plate Angle | Earlier (lower flow) / Later (higher flow) |

| Normal Operating ICP Range | 500 – 3000 | psi | Varies with engine RPM and load |

- Low Pressure Oil Pump (LPOP): Before the HPOP can do its job, the LPOP (located in the front cover) supplies engine oil from the pan to the HPOP reservoir and for general engine lubrication. Maintaining adequate oil levels and pressure from the LPOP is foundational for the HPOP’s operation.

- Injection Control Pressure (ICP) Sensor: This sensor measures the actual oil pressure in the high-pressure oil rails, providing critical feedback to the Powertrain Control Module (PCM).

- Injection Pressure Regulator (IPR) Valve: The IPR valve, controlled by the PCM, regulates the output pressure of the HPOP by diverting excess oil back to the crankcase. Its duty cycle dictates how much pressure the HPOP generates and maintains.

Why the HPOP is So Crucial

The HPOP is not just a pump; it’s the lynchpin of the 7.3L’s direct injection system. Without sufficient high-pressure oil, the injectors simply cannot fire correctly, or at all. This means a perfectly functioning HPOP is synonymous with a powerful, reliable, and smooth-running 7.3L. Any degradation in its performance directly translates to:

- Hard starting conditions, especially when hot

- Loss of power and poor acceleration

- Rough idling or stumbling

- Potentially catastrophic engine damage if left unaddressed.

Understanding the intricacies of the 7.3 Powerstroke high pressure oil pump specs is therefore not just for mechanics; it’s for any owner who wants to maximize their truck’s potential and ensure its longevity.

Diving Deep into Original 7.3 Powerstroke High Pressure Oil Pump Specs

When you’re talking about the “original” 7.3 Powerstroke HPOP specifications, it’s important to note that Ford made some revisions during the production run of the 7.3L engine. Primarily, there were two distinct HPOP designs: the early ’94-’95 single-shot style and the ’96-’03 split-shot style. While both are critical, their capabilities and the injectors they supported were different.

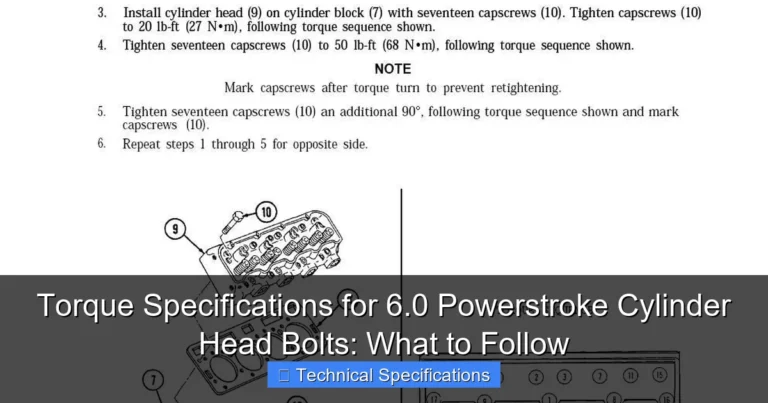

OEM HPOP Specifications

The original HPOP in your 7.3L Powerstroke is a fixed-displacement, piston-style swashplate pump. It’s a remarkably robust design, capable of generating significant pressure. Here’s a breakdown of the key specifications for the most common variants:

Early 7.3L HPOP (1994-1995 – 18-degree swashplate):

- Displacement: Approximately 3.65 cc/revolution.

- Max Pressure Output: Designed to operate up to 2,100 PSI (pounds per square inch) to support the ‘single-shot’ injectors.

- Flow Rate: Adequate for the stock single-shot injectors, which required less oil volume compared to the later split-shot design.

Late 7.3L HPOP (1996-2003 – 17-degree swashplate):

- Displacement: Approximately 4.1 cc/revolution. This increased displacement was crucial to support the higher volume demands of the ‘split-shot’ injectors.

- Max Pressure Output: Capable of producing up to 3,000 PSI, though typical operating pressures rarely exceed 2,800 PSI under heavy load with stock tuning.

- Flow Rate: Increased significantly over the early model to meet the demands of split-shot injection, which fires a small “pilot” injection before the main injection event.

It’s important to differentiate between the ‘94-‘95 and ‘96-‘03 pumps because they are not directly interchangeable without other modifications. The larger displacement of the later pump is often referred to as a “17-degree” pump, referencing the angle of its internal swashplate, while the earlier is a “18-degree” pump.

Key Performance Metrics

Beyond the pump’s physical specifications, understanding how it interacts with other sensors provides critical insight into its health and performance:

- ICP (Injection Control Pressure) Targets: The PCM commands a specific ICP based on engine load, RPM, and other factors. A healthy HPOP should be able to maintain the commanded ICP within a tight tolerance (usually +/- 100-200 PSI). At idle, ICP typically sits around 500-600 PSI. Under full load, it can reach 2,500-3,000 PSI.

- IPR (Injection Pressure Regulator) Duty Cycle: This is the percentage of time the IPR valve is open. A low duty cycle (e.g., 8-15% at idle) indicates the HPOP is easily meeting pressure demands. As engine load increases, the IPR duty cycle will rise to maintain pressure. If the duty cycle consistently approaches 60-65% or higher under load, it’s a strong indicator that the HPOP is struggling to keep up, or there’s a leak in the high-pressure oil system.

- Role of the LPOP: The 7.3 Powerstroke oil pump refers to both the low-pressure (LPOP) and high-pressure (HPOP) pumps. The LPOP is responsible for feeding the HPOP with a consistent supply of engine oil, typically at 40-70 PSI. If the LPOP fails or has low output, the HPOP will be starved, leading to a host of problems.

Monitoring these parameters with a diagnostic scanner is the single most effective way to assess the health of your 7.3 Powerstroke HPOP without disassembling the engine.

Recognizing HPOP Failure: Symptoms and Diagnostics

A failing HPOP can manifest in various ways, from subtle performance drops to complete no-start conditions. Recognizing these symptoms early can save you from more extensive damage or being stranded on the side of the road. Understanding how to diagnose issues with your 7.3 Powerstroke high pressure oil pump is crucial for any owner.

Common Symptoms of a Failing HPOP

The symptoms often stem from insufficient oil pressure reaching the injectors. Keep an eye (or ear) out for these indicators:

- Hard Starting/No Start (especially when hot): This is the most classic symptom. When the oil is hot and thinner, a weak HPOP struggles even more to build and maintain the required 500 PSI for the injectors to fire. Cold starts might be fine, but once the engine reaches operating temperature, it becomes difficult or impossible to restart.

- Loss of Power, Rough Idle, Poor Acceleration: If the HPOP can’t consistently supply enough pressure, the injectors won’t atomize fuel effectively, leading to a noticeable drop in power, sluggish acceleration, and an uneven idle. You might feel the engine “fall on its face” during acceleration.

- Stalling: In severe cases, particularly under load, the HPOP might fail to maintain pressure, causing the engine to stall.

- Check Engine Light (CEL) and Diagnostic Trouble Codes (DTCs): Your PCM is smart. It monitors ICP and IPR. If the HPOP can’t meet commanded pressure, or if the IPR duty cycle is excessively high (indicating it’s working overtime), you’ll likely get codes such as P1211 (ICP Actual vs. Desired Difference) or P1280 (ICP Sensor Circuit Out of Range Low).

- Excessive IPR Duty Cycle: As mentioned, monitoring the IPR duty cycle (with a scanner) at idle and under load can show if your HPOP is struggling. If it’s consistently at 40-60%+ even at idle, or spikes high immediately under light throttle, it’s a red flag.

Diagnostic Steps and Tools

Before you condemn your HPOP, it’s vital to perform proper diagnostics. Many other issues can mimic HPOP failure (e.g., weak LPOP, high-pressure oil leaks, faulty ICP/IPR sensors). Here’s a systematic approach:

- Scan Tool Data Monitoring: This is your best friend. Use a diagnostic scanner (like ForScan, AutoEnginuity, or a higher-end professional tool) to monitor these key PIDs (Parameter IDs) while cranking and running:

- ICP (Injection Control Pressure): Must reach at least 500 PSI during cranking for the injectors to fire. Monitor its stability at idle and under load.

- IPR (Injection Pressure Regulator) Duty Cycle: Should be low at idle (8-15%) and increase steadily with load. Excessive values suggest a problem.

- RPM (Revolutions Per Minute): Ensure the engine is cranking fast enough (at least 150 RPM) – a weak battery can prevent starting even with a healthy HPOP.

- FIPW (Fuel Injection Pulse Width): Should show values (e.g., 2-4 ms) during cranking if the PCM is commanding injection.

- High-Pressure Oil System Air Test: This is a definitive test for high-pressure oil leaks. You remove the ICP sensor and screw in an air fitting, then apply compressed shop air (around 100-120 PSI) into the high-pressure oil rail. Listen for air leaks from:

- Under the valve covers (injector O-rings, standpipes).

- The IPR valve (if it’s stuck open or leaky).

- The HPOP itself (internal seal failure).

- The oil filter housing (oil cooler seals).

If you hear significant air leaks, that’s your problem, not necessarily the HPOP itself.

- Visual Inspection: Look for any obvious external oil leaks around the HPOP, its lines, or the valve covers. While external leaks are less common for HPOP failure, they can indicate other issues affecting the high-pressure oil system.

- Oil Condition and Level: Always ensure your engine has the correct amount of clean engine oil. Dirty or low oil will severely impact HPOP performance and longevity. The 7.3L relies heavily on its oil for operation!

By systematically performing these checks, you can accurately pinpoint if your 7.3 Powerstroke HPOP is indeed the culprit or if another component is to blame.

Upgrading Your HPOP: Enhancing 7.3 Powerstroke Performance

For many 7.3L owners, the journey doesn’t stop at maintaining stock performance. The allure of more power, better throttle response, and superior towing capability often leads to modifications. One of the most critical upgrades for any performance-tuned or modified 7.3L – especially those with larger injectors – is an aftermarket HPOP. Understanding these 7.3 Powerstroke HPOP upgrades is key to unlocking your engine’s full potential.

Why Upgrade Your HPOP?

The stock HPOP, while adequate for OEM applications, simply cannot keep up with the demands of modified injectors or aggressive tuning. Here’s why an upgrade becomes necessary:

- Supporting Larger Injectors: The biggest reason for an HPOP upgrade. Larger injectors require significantly more oil volume and pressure to operate efficiently. A stock HPOP will “defuel” (fail to maintain commanded ICP) when paired with injectors it can’t support, leading to power loss and excessive IPR duty cycle.

- Increased Horsepower and Torque: By ensuring sufficient high-pressure oil, a performance HPOP allows your larger injectors and custom tunes to deliver their full power potential.

- Improved Throttle Response: A strong HPOP can more quickly build and maintain target ICP, leading to snappier throttle response and less lag.

- Better Towing Performance: Maintaining high ICP under heavy load is crucial for towing. An upgraded HPOP prevents defueling and keeps your truck pulling strong up hills.

Popular Aftermarket 7.3 Powerstroke HPOP Upgrades

The aftermarket for 7.3 Powerstroke HPOP solutions is robust, offering several highly regarded options that deliver increased flow and pressure capabilities. These pumps are typically designed with larger displacement swashplates, stronger internal components, and often feature billet construction for enhanced durability.

Key Players in the Aftermarket:

- Adrenaline HPOP (DieselSite): One of the most popular and well-regarded upgrades. The Adrenaline pump is a direct bolt-in replacement that offers significantly increased flow compared to the stock unit. It’s an excellent choice for trucks running mid-sized injectors (e.g., 160/30s, 180/30s, 205/30s). DieselSite also offers the “Stealth” pump, a lower-cost option for stock to mild applications.

- Terminator HPOP (Terminator Engineering): Known for offering pumps with serious flow capabilities, Terminator HPOPs come in various “stages” (e.g., T500, T500 Stealth, T500 Pro) designed to support increasingly larger injectors. A T500 pump, for instance, is designed to support 200cc+ injectors, making it a favorite for high-performance builds. They achieve this with larger displacement pistons and specialized internal designs.

- Pulsar HPOP (Swamps Diesel): Another reputable name in the 7.3L world, Swamps Diesel offers their Pulsar series of HPOPs, which are also high-performance units designed to flow more oil than stock, supporting various injector sizes.

When choosing an aftermarket 7.3 Powerstroke HPOP, it’s crucial to consider the reputation of the manufacturer and the warranty offered. Quality components are paramount for reliability.

Matching HPOP to Injector Size

This is perhaps the most critical aspect of upgrading your HPOP. An undersized HPOP will starve even moderately larger injectors, leading to poor performance, high EGTs (Exhaust Gas Temperatures), and potentially injector damage. Conversely, an oversized HPOP won’t hurt, but it might be overkill for mild upgrades, adding unnecessary cost. Here’s a general guideline:

- Stock Injectors (120cc-140cc): Stock HPOP (late 99-03 – 17-degree) is usually sufficient, though an upgraded stock replacement (like a new OEM Ford unit or a remanufactured one with strict quality control) is always a good idea for reliability.

- Mild Injectors (160cc-180cc, up to 30% nozzle): A stock HPOP might barely keep up with excellent tuning, but it will be at its limit. This is the sweet spot for an Adrenaline HPOP or a similar “Stage 1” upgrade.

- Moderate Injectors (200cc-238cc, up to 80% nozzle): A high-flow HPOP like the Terminator T500 or a high-stage Pulsar pump is highly recommended. These injectors demand substantial oil volume.

- Large/Extreme Injectors (250cc+, 100%+ nozzle): These setups often require twin HPOP configurations (two pumps working in tandem) or highly specialized single pumps with massive displacement.

Always consult with your tuner and the HPOP/injector manufacturer for precise recommendations. Overlooking the importance of matching your 7.3 Powerstroke high pressure oil pump specs to your injectors is a common mistake that can severely hinder performance and cause frustration.

Installation, Maintenance, and Longevity Tips for Your HPOP

Whether you’re replacing a failed HPOP or upgrading to a performance unit, proper installation and ongoing maintenance are crucial for maximizing its lifespan and ensuring optimal performance. The HPOP is not a “set it and forget it” component, especially given its vital role in your 7.3L Powerstroke.

Proper Installation Practices

Replacing the 7.3 Powerstroke HPOP can be a challenging job, often requiring removal of the turbocharger and intake plenum. If you’re tackling this yourself, precision and attention to detail are key:

- Cleanliness is Paramount: Any dirt or debris introduced into the high-pressure oil system can quickly damage the new HPOP or clog injectors. Work in a clean environment and ensure all mating surfaces, lines, and fittings are spotless before assembly.

- Use New Gaskets and O-rings: Never reuse old gaskets or O-rings. They are designed for a single compression. Always use high-quality replacement seals. Pay particular attention to the HPOP gasket, IPR valve O-rings, and the snap-to-connect fittings on the HPOP lines.

- Lubricate O-rings: Prior to installation, lightly lubricate all O-rings with clean engine oil. This prevents tearing and helps them seat properly.

- Correct Torque Specs: Follow the manufacturer’s torque specifications for all bolts, especially those securing the HPOP and its lines. Overtightening can strip threads or damage components, while undertightening can lead to leaks.

- Prime the System: After installation, it’s critical to prime the high-pressure oil system. This usually involves cranking the engine for several short bursts (e.g., 10-15 seconds) without allowing it to start (e.g., by unplugging the ICP sensor or GPR). This allows the HPOP to fill its reservoir and lines with oil before the injectors are commanded to fire, preventing dry-start damage.

Maintenance for Peak Performance

The health of your HPOP is directly tied to the health of your engine oil. It’s literally pumping the lifeblood of your engine!

- Regular Oil Changes with Correct Spec Oil: This cannot be stressed enough. Follow your Ford owner’s manual recommendations for oil change intervals, or even shorten them if you do heavy towing or demanding work. Always use diesel-specific engine oil (CJ-4 or CK-4 rated) with the correct viscosity (typically 15W-40 or 5W-40 synthetic in colder climates). Dirty, degraded oil is the enemy of your HPOP.

- Monitor Oil Level and Condition: Check your oil level regularly. Low oil levels can starve the HPOP and lead to premature failure. If your oil appears extremely dark, gritty, or smells strongly of fuel, it’s time for a change and potentially further diagnostics.

- Address Leaks Promptly: Any leaks in the low-pressure oil system (even seemingly minor ones) can lead to insufficient oil supply for the HPOP. High-pressure oil leaks, even tiny ones, can cause the HPOP to work overtime, leading to premature wear.

- Maintain the LPOP: Remember, the LPOP feeds the HPOP. While less common to fail, ensure your LPOP is functioning correctly by monitoring engine oil pressure at the cluster or with a mechanical gauge.

Extending HPOP Life

A few proactive measures can significantly extend the life of your 7.3 Powerstroke high pressure oil pump:

- Avoid Excessive Engine Abuse: While the 7.3L is tough, consistently running at high RPMs under heavy load with insufficient HPOP capacity (e.g., trying to fuel oversized injectors with a stock pump) will stress the HPOP and shorten its life.

- Proper Tuning: If you have performance modifications, ensure your engine is professionally tuned. A good tune optimizes HPOP control (IPR duty cycle) to match injector demands, reducing unnecessary strain.

- Quality Replacement Parts: When it’s time for a new HPOP, whether stock replacement or upgrade, invest in a quality unit from a reputable manufacturer. Cheap, no-name pumps are a false economy and often lead to repeat failures.

By adhering to these installation and maintenance guidelines, you’ll ensure that your 7.3 Powerstroke HPOP – be it stock or upgraded – provides reliable service for years to come.

Data Table: Comparing HPOP Specifications

To help visualize the differences between OEM and common aftermarket 7.3 Powerstroke HPOP specifications, the table below provides a concise comparison. Keep in mind that “cc/rev” (cubic centimeters per revolution) is a primary indicator of a pump’s potential flow capability.

| HPOP Model / Type | Approx. Displacement (cc/rev) | Max Operating Pressure (PSI) | Recommended Injector Support (cc / Nozzle %) | Typical Application |

|---|---|---|---|---|

| OEM ’94-’95 (18°) | 3.65 | ~2,100 | Stock Single Shot (~120cc) | Stock Power |

| OEM ’96-’03 (17°) | 4.1 | ~3,000 | Stock Split Shot (~140cc) | Stock Power, Mild Tuning |

| DieselSite Adrenaline | 4.3 – 4.6 (varies by model) | ~3,000+ | 160/30 up to 205/30 | Moderate Performance, Towing |

| Terminator T500 / T500 Stealth | 5.0+ (T500) | ~3,000+ | 200/30 up to 250/100 | High Performance, Larger Injectors |

| Swamps Pulsar | 4.3 – 5.0+ (varies by stage) | ~3,000+ | 180/30 up to 250/100 | Performance Builds |

| Twin HPOP System | Combined Displacement | ~3,000+ | 250/100+ and beyond | Extreme Performance, Drag Racing |

Note: “Recommended Injector Support” is a general guideline. Actual performance depends heavily on tuning, engine health, and desired power output. Always consult with specific manufacturers and tuners for precise recommendations.

Conclusion

The 7.3L Powerstroke is revered for its durability and capability, and a significant portion of that legend is owed to its unique HEUI fuel system, with the High-Pressure Oil Pump at its core. As we’ve explored, understanding the intricate 7.3 Powerstroke high pressure oil pump specs is not merely academic; it’s fundamental to maintaining, diagnosing, and enhancing your truck’s performance.

From the original OEM ‘94-‘95 and ‘96-‘03 pumps with their distinct displacement figures to the powerful aftermarket units like the Adrenaline and Terminator HPOPs, each pump has a role to play in the 7.3L ecosystem. Knowing the telltale signs of failure, from hard starting to a struggling IPR duty cycle, empowers you to troubleshoot effectively. And when it comes time to push beyond stock limits, carefully matching your HPOP upgrade to your chosen injectors is the secret to unlocking true power and reliability.

Ultimately, a well-maintained and correctly specified 7.3 Powerstroke HPOP is not just a component – it’s an investment in your engine’s longevity and your truck’s legendary performance. Keep that oil clean, keep those pressures optimal, and your 7.3L Powerstroke will continue to serve you faithfully for countless miles to come!

Frequently Asked Questions

What is the primary function of the 7.3 Powerstroke high pressure oil pump (HPOP)?

The 7.3 Powerstroke high pressure oil pump is a critical component responsible for generating the intense oil pressure required to actuate the fuel injectors. It’s the heart of the “HEUI” (Hydraulically actuated Electronic Unit Injector) system, ensuring precise fuel delivery to the engine’s cylinders.

What are the typical operating pressure specifications for a 7.3 Powerstroke HPOP?

A healthy 7.3 Powerstroke high pressure oil pump typically operates between 500 PSI at idle and up to 3000-3600 PSI under full load or heavy acceleration. These pressure specifications are crucial for proper injector function and overall engine performance.

Are there different versions or generations of the 7.3 Powerstroke high pressure oil pump?

Yes, there are distinct versions of the 7.3 Powerstroke HPOP. Early engines (1994-1997) commonly featured a 15/17-degree swash plate pump, while later models (1999-2003) typically utilize a 17/17-degree design. The latter generally offers improved performance due to higher flow capacity.

How does the 17-degree HPOP differ in specifications from earlier 7.3 Powerstroke models?

The “17-degree” in the 7.3 Powerstroke high pressure oil pump specification refers to the angle of the swash plate, which dictates the pump’s displacement and maximum output volume. A 17-degree pump provides a greater volume of oil per revolution compared to earlier 15-degree units, allowing for higher sustained pressure and better support for performance modifications.

What flow rate should I expect from my 7.3 Powerstroke high pressure oil pump?

While exact flow rates (gallons per minute) are less commonly cited than pressure, the internal design of the 7.3 Powerstroke HPOP, particularly the swash plate angle, directly determines its volumetric efficiency. A 17-degree pump moves more oil per engine revolution than a 15-degree unit, which is vital for maintaining injector control pressure under heavy demand.

What are common symptoms of a failing or weak 7.3 Powerstroke high pressure oil pump?

Symptoms of a failing 7.3 Powerstroke high pressure oil pump often include hard starting (especially when the engine is hot), rough idle, lack of power, and stalling. Diagnosing HPOP issues usually involves monitoring ICP (Injector Control Pressure) and IPR (Injector Pressure Regulator) duty cycle values using a diagnostic scan tool.