7.3 Powerstroke Fuel System Pressure Specifications: A Complete Breakdown

Featured image for this comprehensive guide about 7.3 Powerstroke fuel system pressure specs

Image source: i.ytimg.com

The roar of a 7.3 Powerstroke engine is a sound that resonates deeply with diesel enthusiasts and heavy-duty truck owners alike. Revered for its legendary durability, robust performance, and relatively simple mechanical design, the 7.3L Powerstroke has earned its place in the pantheon of iconic diesel engines. Whether you’re hauling heavy loads, navigating rugged terrain, or simply enjoying the open road, a well-maintained 7.3 is a powerhouse you can rely on. However, even the most legendary engines have their nuances, and understanding these can be the difference between years of trouble-free service and frustrating, costly repairs.

One of the most critical, yet often overlooked, aspects of maintaining optimal performance and longevity in your 7.3 Powerstroke is its fuel system. Specifically, paying close attention to the 7.3 Powerstroke fuel system pressure specs is paramount. Incorrect fuel pressure can lead to a cascade of problems, from diminished power and poor fuel economy to, in severe cases, premature wear of expensive components like injectors. This isn’t just about keeping the engine running; it’s about ensuring it runs efficiently, powerfully, and reliably for hundreds of thousands of miles, as it was designed to do.

In this comprehensive guide, we’ll dive deep into the world of 7.3 Powerstroke fuel pressure. We’ll explore the factory specifications, discuss optimal pressure ranges for enhanced performance and longevity, detail the symptoms of incorrect pressure, walk you through diagnostic steps, and outline maintenance and upgrade strategies. Our goal is to equip you with the knowledge needed to ensure your 7.3L Powerstroke’s fuel system is operating precisely as it should, helping you maximize its potential and extend its remarkable lifespan.

Quick Answers to Common Questions

What’s the ideal operating range for 7.3 Powerstroke fuel system pressure?

Ideally, you want your 7.3 Powerstroke’s fuel pressure to be consistently between 60-70 PSI at idle and under load. This range is crucial for optimal performance and injector longevity.

What happens if my 7.3 Powerstroke fuel system pressure is too low?

Low 7.3 Powerstroke fuel pressure is a big problem; it can starve your injectors, leading to poor performance, excessive smoke, and even costly injector damage. You might notice a lack of power or a rough idle.

How can I tell if my 7.3 Powerstroke fuel system pressure is off without a gauge?

While a gauge is best, signs of incorrect 7.3 Powerstroke fuel system pressure can include a rough idle, poor acceleration, excessive black smoke, or a “P1211” diagnostic trouble code. These indicate your engine isn’t getting enough fuel.

What’s the first thing I should check if my 7.3 Powerstroke fuel system pressure is low?

A clogged fuel filter is a very common culprit for low 7.3 Powerstroke fuel system pressure, so that’s always the first and easiest component to check and replace. A weak fuel pump is another possibility if the filter doesn’t fix it.

Is it possible for my 7.3 Powerstroke fuel system pressure to be too high?

While less common, excessive 7.3 Powerstroke fuel system pressure can potentially cause issues like premature wear on components or incorrect fueling. However, low pressure is generally a much more prevalent and damaging problem for these engines.

📋 Table of Contents

- The Heart of the Beast: Understanding the 7.3 Powerstroke Fuel System

- Decoding the 7.3 Powerstroke Fuel System Pressure Specs: The Numbers You Need

- Symptoms of Incorrect 7.3 Powerstroke Fuel Pressure

- Diagnosing 7.3 Powerstroke Fuel System Pressure Issues

- Maintaining and Upgrading Your 7.3 Powerstroke Fuel System for Optimal Pressure

- 7.3 Powerstroke Fuel System Quick Reference Data

- Conclusion: The Undeniable Importance of Fuel Pressure in Your 7.3 Powerstroke

The Heart of the Beast: Understanding the 7.3 Powerstroke Fuel System

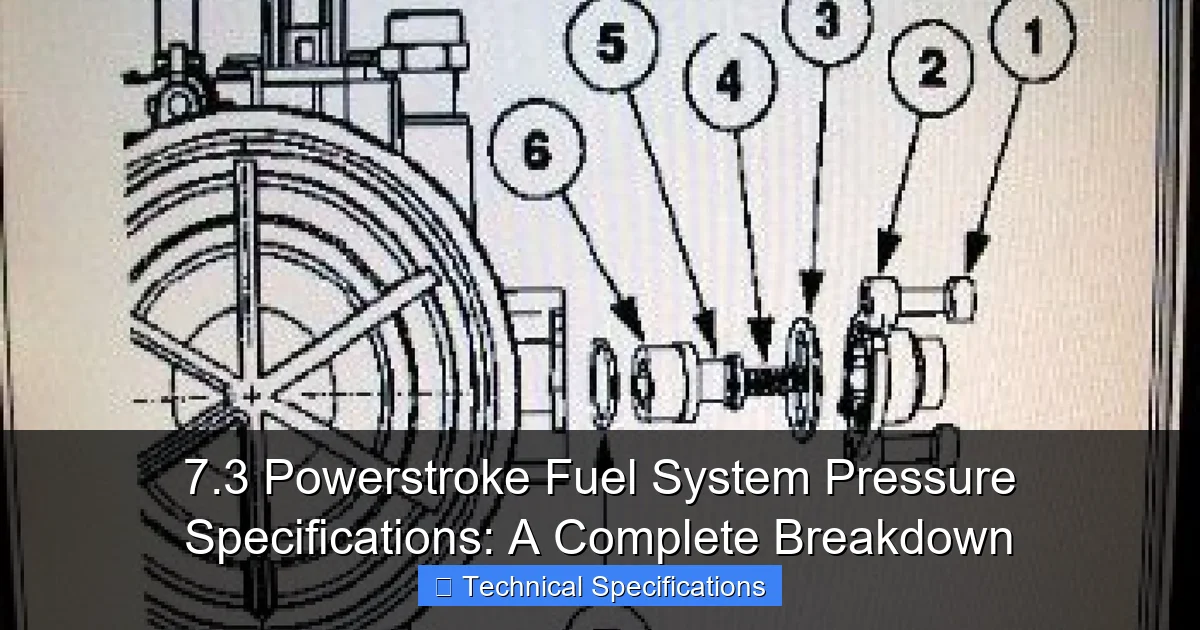

Before we delve into the numbers, it’s essential to grasp the fundamental workings of the 7.3 Powerstroke fuel system. Unlike modern common-rail diesel engines, the 7.3 operates with a two-stage injection process. First, the low-pressure fuel system delivers fuel from the tank to the cylinder heads. Second, the High-Pressure Oil Pump (HPOP) system creates the immense pressure needed to actuate the fuel injectors. Our focus today is primarily on the low-pressure side, as this is where 7.3 Powerstroke fuel system pressure specs are most directly relevant to engine health and performance.

Learn more about 7.3 Powerstroke fuel system pressure specs – 7.3 Powerstroke Fuel System Pressure Specifications: A Complete Breakdown

Image source: diagraminfo.com

The journey of fuel in your 7.3 begins in the fuel tank, where it’s drawn by the lift pump. Early 7.3 models used a mechanical lift pump mounted on the engine block, while later models (typically 1999.5 and up) featured an electric lift pump located on the frame rail. From there, the fuel travels through fuel lines to the fuel filter housing, often referred to as the “fuel bowl.” This housing not only filters the fuel but also contains the 7.3 Powerstroke fuel pressure regulator (FPR). The FPR is a critical component that maintains consistent fuel pressure to the injectors by bypassing excess fuel back to the tank.

| Measurement Point | Pressure (PSI) | Pressure (kPa) | Notes/Condition |

|---|---|---|---|

| Key On, Engine Off (KOEO) Prime | 50 – 65 PSI | 345 – 448 kPa | Brief initial pump cycle to pressurize system. |

| Engine Idle (Warm) | 55 – 70 PSI | 379 – 483 kPa | Healthy operating range, engine at normal operating temp. |

| Wide Open Throttle (WOT) / Under Load | 45 – 65 PSI | 310 – 448 kPa | Should remain stable and not drop below minimum. |

| Minimum Acceptable Pressure (Under Load) | 40 PSI | 276 kPa | Below this indicates a weak pump or system issue. |

| Maximum Regulated Pressure | ~ 70 PSI | ~ 483 kPa | Typically limited by the fuel pressure regulator. |

Finally, the regulated and filtered fuel is delivered to the cylinder heads, where it feeds directly into the fuel galleries that supply each of the eight hydraulically actuated electronic unit injectors (HEUI). These injectors use high-pressure engine oil, supplied by the HPOP, to pressurize and atomize the diesel fuel for combustion. A healthy low-pressure fuel system is vital because the injectors require a consistent supply of fuel at the correct pressure to function efficiently and avoid cavitation, which can rapidly wear them out. Without proper 7.3 Powerstroke fuel pump pressure, your injectors are essentially trying to draw fuel from a straw in an empty glass, leading to misfires, reduced power, and expensive damage.

Decoding the 7.3 Powerstroke Fuel System Pressure Specs: The Numbers You Need

Understanding the exact 7.3 Powerstroke fuel system pressure specs is the cornerstone of effective diagnosis and maintenance. These numbers provide the benchmark against which you can measure your engine’s health. While there’s a stock specification, many enthusiasts and experts recommend a slightly higher “optimal” range for improved longevity and performance, especially with any modifications.

Learn more about 7.3 Powerstroke fuel system pressure specs – 7.3 Powerstroke Fuel System Pressure Specifications: A Complete Breakdown

Image source: i.etsystatic.com

Stock 7.3 Powerstroke Fuel Pressure Specifications

From the factory, Ford specified the following pressure ranges for the 7.3L Powerstroke:

- Idle Fuel Pressure: When your engine is idling, you should typically see pressure between 45-60 PSI (Pounds per Square Inch).

- Wide Open Throttle (WOT) Fuel Pressure: Under full load, at Wide Open Throttle, the pressure should ideally not drop below 40-45 PSI. A significant drop below this threshold indicates a problem with the fuel delivery system’s ability to keep up with demand.

These figures represent the minimum acceptable operating parameters. Deviations from these ranges, particularly on the lower end, are strong indicators of potential issues that need attention. Remember, consistent pressure is key. Fluctuations, especially drops under load, are just as concerning as a consistently low reading.

Optimal 7.3 Powerstroke Fuel Pressure Range

While the stock specifications are functional, many 7.3 Powerstroke owners and experts advocate for a slightly higher operating pressure to maximize injector lifespan and improve overall engine efficiency. This is often referred to as the “optimal” range:

- Optimal Fuel Pressure: Maintaining pressure between 60-75 PSI throughout the entire RPM range (idle to WOT) is generally considered ideal.

Why aim higher? Running your injectors with consistent pressure in this optimal range provides several benefits. It ensures that the injectors always have enough fuel readily available, preventing cavitation (the formation of vacuum bubbles) which can erode injector components over time. This higher pressure also helps with better fuel atomization, leading to more efficient combustion, potentially better fuel economy, and a reduction in the notorious “7.3 injector cackle.” Achieving this optimal range often involves minor modifications, which we’ll discuss later, but the investment often pays for itself in extended injector life and improved engine performance.

Symptoms of Incorrect 7.3 Powerstroke Fuel Pressure

Your 7.3 Powerstroke is an incredibly communicative engine, and it will often display clear symptoms when its fuel system pressure is not within optimal ranges. Recognizing these signs early can save you from more severe, costly damage down the line, especially to your precious injectors.

Low Fuel Pressure Symptoms

Low 7.3 Powerstroke fuel pressure is by far the more common issue and can manifest in a variety of ways:

- Loss of Power & Poor Acceleration: This is one of the most immediate and noticeable symptoms. If your truck feels sluggish, struggles to accelerate, or loses power climbing hills, insufficient fuel delivery is a prime suspect. The injectors aren’t getting enough fuel to generate full combustion.

- Rough Idle & Stumbling: An inconsistent supply of fuel can cause the engine to idle roughly, stumble, or even misfire, especially when cold.

- Hard Starting / Extended Crank Times: If the fuel system isn’t maintaining residual pressure, the engine will require more cranking to build up adequate fuel pressure to fire the injectors.

- Excessive Black Smoke: While some black smoke can be normal for a diesel under heavy acceleration, excessive black smoke, especially at partial throttle or idle, can indicate poor fuel atomization due to low pressure. The fuel isn’t burning completely.

- Poor Fuel Economy: An inefficient combustion process, often caused by low fuel pressure, directly translates to more fuel consumed for less work.

- Loud “Injector Cackle”: While 7.3s are known for their characteristic diesel noise, an abnormally loud or harsh “cackle” from the injectors can be a sign that they are running dry or are starved of fuel, leading to cavitation and wear. This is a critical warning sign for premature injector failure.

- Check Engine Light (CEL): While a stock 7.3 won’t directly monitor fuel pressure, low fuel pressure can indirectly trigger codes related to injector performance or engine misfires.

High Fuel Pressure Symptoms

While less common, excessively high 7.3 Powerstroke fuel system pressure can also lead to problems:

- Rich Running Conditions: The engine may run too rich, indicated by excessive exhaust smoke (sometimes white or bluish, but can also be black if combustion is very poor) and a strong diesel smell.

- Potential for Fuel Leaks: Higher than designed pressure can stress fuel lines, O-rings, and connections, leading to leaks.

- Difficult Starting (Flooding): If the pressure is too high, it might effectively “flood” the injectors, making starting difficult.

- Stress on Fuel System Components: Constant high pressure can prematurely wear out components designed for lower operating pressures.

Diagnosing 7.3 Powerstroke Fuel System Pressure Issues

Diagnosing fuel pressure problems on a 7.3 Powerstroke requires a methodical approach and the right tools. Unlike many newer vehicles, the stock 7.3 Powerstroke doesn’t have a factory fuel pressure sensor that feeds data to the PCM, so you’ll need to manually measure the pressure.

Essential Diagnostic Tools

- Mechanical Fuel Pressure Gauge: This is your most critical tool. You’ll need a gauge that can read up to 100 PSI or more, equipped with the correct fitting (usually a Schrader valve adapter) to connect to the fuel bowl.

- Basic Hand Tools: For accessing the fuel bowl and other components.

- OBD-II Scanner (Optional, but Recommended): While it won’t directly read fuel pressure, an OBD-II scanner can help you check for other diagnostic trouble codes (DTCs) that might be related to engine performance issues caused by incorrect fuel pressure.

How to Test 7.3 Powerstroke Fuel Pressure

The most accurate way to check your 7.3 Powerstroke fuel pressure is to connect a mechanical gauge directly to the fuel system, specifically at the Schrader valve on the fuel filter housing (fuel bowl).

- Locate the Schrader Valve: It’s typically on the driver’s side of the fuel filter housing. It looks like a tire valve stem.

- Connect the Gauge: Carefully thread your mechanical fuel pressure gauge onto the Schrader valve. Ensure a tight seal to prevent leaks.

- Test at Idle: Start the engine and observe the pressure reading at idle. Note the PSI.

- Test Under Load (Simulated or Actual): This is crucial.

- Static Test: While stationary, briefly rev the engine to various RPMs (e.g., 2000-3000 RPM) and watch for significant pressure drops.

- Dynamic Test (Preferred): If safe and possible, take the truck for a drive. Observe the pressure gauge during acceleration, especially at Wide Open Throttle (WOT). This is where weaknesses in the fuel system often become apparent. A healthy system should maintain steady pressure, ideally above 45 PSI (stock minimum) or 60 PSI (optimal) even under heavy load.

- Check for Residual Pressure: After shutting off the engine, observe if the fuel pressure holds for an extended period (e.g., 10-15 minutes). A rapid drop could indicate a leaking injector or a faulty check valve in the fuel system.

Compare your readings against the 7.3 Powerstroke fuel system pressure specs we discussed earlier (45-60 PSI idle, >40-45 PSI WOT for stock; 60-75 PSI optimal).

Common Causes of Incorrect Fuel Pressure

Causes of Low Fuel Pressure:

- Weak or Failing Lift Pump: The lift pump is responsible for drawing fuel from the tank. If it’s weak, it can’t supply enough fuel to maintain pressure, especially under load. This is a very common failure point for both mechanical and electric pumps.

- Clogged Fuel Filter: A dirty or restricted fuel filter is a significant impediment to fuel flow and will directly cause low pressure. This is why regular filter changes are paramount.

- Faulty Fuel Pressure Regulator (FPR): The diaphragm in the FPR can weaken or tear, or the spring can lose tension, causing it to bypass too much fuel back to the tank, leading to low pressure.

- Fuel Leaks: Leaks in fuel lines, O-rings on the fuel bowl, or even in the injector cups can cause a loss of pressure.

- Fuel Tank Pickup Issues (Hutch/Harpoon Mods): The factory fuel tank pickup in the 7.3 is prone to clogging and can cause aeration (air in the fuel), leading to pressure drops. The “Hutch Mod” and “Harpoon Mod” are popular solutions to address these design flaws.

Causes of High Fuel Pressure:

- Stuck or Incorrect Fuel Pressure Regulator: If the FPR’s bypass valve is stuck closed, or if an aftermarket spring is too stiff, it can prevent excess fuel from returning to the tank, leading to excessively high pressure.

Maintaining and Upgrading Your 7.3 Powerstroke Fuel System for Optimal Pressure

Once you understand the 7.3 Powerstroke fuel system pressure specs and how to diagnose issues, the next step is ensuring your system is maintained correctly or upgraded to meet optimal standards. Proactive maintenance and strategic upgrades can significantly enhance your truck’s performance and extend its life.

Essential Maintenance for Fuel Pressure Health

- Regular Fuel Filter Changes: This cannot be stressed enough. Replace your fuel filter every 10,000 to 15,000 miles, or more frequently if you use questionable fuel or drive in dusty conditions. A new filter is cheap insurance against significant problems.

- Inspect Fuel Lines and Connections: Periodically check for any signs of leaks, cracks, or damage in the fuel lines, especially around the fuel bowl and connections to the injectors.

- Listen to Your Lift Pump: If you have an electric lift pump (1999.5+), listen for unusual noises or lack of sound. A failing pump will often become noisy or completely silent when it gives up.

- Consider a Fuel Additive: High-quality fuel additives can help keep your fuel system clean, lubricate components, and prevent gelling in cold weather, contributing to consistent fuel flow.

Upgrading Your 7.3 Powerstroke Fuel System

For those looking to move beyond stock specifications and achieve the optimal 60-75 PSI range, especially if you have performance modifications (like larger injectors or tuning), several popular upgrades are available:

1. Fuel Pressure Regulator (FPR) Spring Mod

This is one of the simplest and most cost-effective ways to increase your 7.3 Powerstroke fuel pressure. By replacing the stock spring in your fuel pressure regulator with a stiffer aftermarket spring, you increase the pressure required to open the bypass valve, thus raising the minimum fuel pressure. This often brings the pressure into the 60-75 PSI range. It’s a great first step for any 7.3 owner.

2. Aftermarket Lift Pump (FASS, AirDog, etc.)

Upgrading to a high-performance aftermarket lift pump system is a significant step, offering several advantages:

- Consistent, Higher Pressure: These systems are designed to deliver a steady stream of fuel at higher, more consistent pressures, regardless of engine demand.

- Superior Filtration: Many aftermarket systems include advanced filtration, often finer than stock, which is excellent for protecting injectors.

- Air/Water Separation: They often incorporate fuel/water separators and air separation, ensuring that only clean, air-free fuel reaches your injectors, preventing cavitation and cackle.

- Support for Modifications: Absolutely essential for trucks running larger injectors or aggressive tuning.

3. Big Fuel Lines / Fuel Bowl Delete

The stock fuel lines and the fuel bowl itself can present some restriction to fuel flow. Upgrading to larger diameter fuel lines (e.g., 1/2-inch) and removing the restrictive stock fuel bowl (replacing it with an external filter system, often part of an aftermarket lift pump setup) can significantly reduce resistance and improve fuel delivery volume and pressure, especially at WOT. This ensures less pressure drop under heavy load.

4. Hutch Mod / Harpoon Mod

These popular modifications address the inherent design flaws in the factory fuel tank pickup system. The “Hutch Mod” typically involves replacing the in-tank pickup and feed lines with larger, less restrictive components, often incorporating a pre-filter. The “Harpoon Mod” involves modifying the in-tank fuel return line to prevent “sloshing” and air entrapment. Both aim to ensure a constant supply of air-free fuel to the lift pump, preventing fuel starvation and aeration, which can mimic low fuel pressure symptoms.

Benefits of an Optimized Fuel System

Investing in your 7.3 Powerstroke fuel system pressure specs by maintaining or upgrading it yields substantial returns:

- Extended Injector Lifespan: This is arguably the biggest benefit. Proper fuel pressure prevents cavitation, which is a leading cause of premature injector wear, saving you thousands in repair costs.

- Improved Performance: Consistent fuel delivery at optimal pressure ensures your engine receives the precise amount of fuel it needs for efficient combustion, leading to better throttle response, increased horsepower, and torque.

- Better Fuel Economy: More efficient combustion means less wasted fuel.

- Reduced “Cackle”: Proper fuel pressure helps quiet down noisy injectors, leading to a smoother, quieter running engine.

- Reliability: A well-maintained and optimized fuel system is a reliable system, reducing the chances of roadside breakdowns.

7.3 Powerstroke Fuel System Quick Reference Data

For a quick overview, here’s a table summarizing the key 7.3 Powerstroke fuel system pressure specs and related information:

| Parameter | Stock Specification | Optimal/Upgraded Target | Common Problem Indication | Recommended Solution |

|---|---|---|---|---|

| Idle Fuel Pressure | 45-60 PSI | 60-75 PSI | Below 45 PSI | FPR spring mod, new lift pump, fuel filter |

| WOT Fuel Pressure (Minimum) | 40-45 PSI | 55-70 PSI | Drops below 40 PSI | Upgraded lift pump, FPR, larger fuel lines |

| Fuel Filter Replacement Interval | Every 15,000 miles | Every 10,000-15,000 miles | Pressure drop, poor flow | Regular, timely replacement |

| Fuel Pressure Regulator (FPR) | Spring-operated diaphragm | Adjustable/Performance FPR | Sticking, weak spring | Regulator spring mod, aftermarket FPR |

| Lift Pump Type (Stock) | Mechanical (early) / Electric (later) | Electric (later) / Aftermarket pump | Weak, failing pump | Aftermarket lift pump (e.g., FASS, AirDog) |

Conclusion: The Undeniable Importance of Fuel Pressure in Your 7.3 Powerstroke

The legendary 7.3 Powerstroke is an engineering marvel, a testament to robust design and enduring power. Yet, like any finely tuned machine, its longevity and performance are intrinsically linked to meticulous care and understanding. As we’ve thoroughly explored, among the most critical aspects of this care is maintaining proper 7.3 Powerstroke fuel system pressure specs.

From the subtle hum of a healthy lift pump to the steady flow of fuel through the injectors, every component plays a vital role. Ignoring the signs of inadequate fuel pressure can lead to a cascade of problems, from irritating performance issues like a rough idle or loss of power, to far more severe and costly damage such as premature injector failure. By understanding the factory specifications, aiming for optimal pressure ranges, learning to diagnose common issues, and implementing smart maintenance and upgrade strategies, you are not just fixing problems; you are proactively safeguarding your investment.

So, take the actionable advice provided in this guide. Invest in a mechanical fuel pressure gauge, regularly check your fuel pressure, keep your fuel filters fresh, and consider the benefits of strategic upgrades. Your 7.3 Powerstroke has earned its reputation for durability, and by ensuring its fuel system is operating precisely within or above the recommended 7.3 Powerstroke fuel pressure parameters, you’ll ensure it continues to live up to that legend for many more miles and years to come. Drive smart, maintain well, and enjoy the unparalleled power of your 7.3 Powerstroke.

🎥 Related Video: 7.3 Powerstroke Low Fuel Pressure Repair

📺 Technician Red

Frequently Asked Questions

What is the ideal fuel system pressure for a 7.3 Powerstroke?

The recommended operating fuel system pressure for a stock 7.3 Powerstroke is typically between 45-70 PSI at idle, with a minimum of 45 PSI under load. Maintaining pressure within this range ensures proper injector function and optimal engine performance.

What are the symptoms of low 7.3 Powerstroke fuel system pressure?

Low fuel pressure can manifest as symptoms like sluggish acceleration, reduced power, rough idle, extended cranking times, and even misfires. If left unaddressed, consistently low pressure can lead to injector damage and other fuel system issues.

How can I accurately check my 7.3 Powerstroke’s fuel pressure?

You can check the fuel pressure by installing a mechanical fuel pressure gauge onto the fuel bowl test port, located on the top of the engine near the fuel filter. For ongoing monitoring, many owners opt for an in-cab electric gauge to keep an eye on the fuel system pressure specs.

Is it beneficial to upgrade my 7.3 Powerstroke fuel system for better pressure?

Yes, especially for modified trucks or those experiencing pressure drops under load. Upgrading components like the fuel pump, fuel lines, or adding a regulated return system can help maintain consistent pressure, improve fuel delivery, and extend injector life.

Can high fuel system pressure be a problem for a 7.3 Powerstroke, and what causes it?

While less common than low pressure, excessively high fuel pressure (above 70-75 PSI) can also be detrimental, potentially leading to hard starting, fuel leaks, or accelerated wear on fuel system components. This is often caused by a faulty fuel pressure regulator or a restriction in the return line.

Are the 7.3 Powerstroke fuel system pressure specs different under load compared to idle?

Yes, the fuel pressure should ideally remain stable or drop only slightly under load. While 45-70 PSI is a good idle range, it’s crucial that the pressure does not drop below 45 PSI when the engine is under full acceleration, as this indicates a deficiency in the fuel supply.