7.3 Powerstroke Fuel Leak on Top of Engine

Featured image for this comprehensive guide about 7.3 powerstroke fuel leak on top of engine

Image source: imgv2-2-f.scribdassets.com

Ah, the legendary 7.3 Powerstroke fuel leak on top of engine – a phrase that sends shivers down the spine of many a Ford truck owner. This robust diesel engine, renowned for its incredible durability and pulling power, isn’t entirely immune to the ravages of time and countless miles. One of the most frustrating, and potentially dangerous, issues that can arise is a fuel leak, particularly when it manifests right there, staring at you from the top of the engine.

If you’ve popped your hood to find that tell-tale sheen of diesel, perhaps accompanied by a distinct odor, you’re not alone. The 7.3 Powerstroke fuel leak is a common adversary, but it’s one that can be effectively diagnosed and repaired with the right knowledge and tools. Ignoring it isn’t an option; a persistent fuel leak on top of engine not only creates a mess but also poses a serious fire hazard, can impact engine performance, and is certainly not good for the environment.

This comprehensive guide is designed to empower you with everything you need to know about tackling a 7.3 Powerstroke fuel leak. We’ll delve into the common culprits, equip you with diagnostic techniques, walk you through potential fixes, and offer advice on preventative measures. Get ready to transform that frustrating drip into a distant memory and keep your beloved 7.3 Powerstroke roaring strong!

Quick Answers to Common Questions

What are the tell-tale signs of a 7.3 Powerstroke fuel leak on top of the engine?

You’ll likely notice a strong diesel smell, visible fuel pooling or wet spots on top of the engine, or even a decrease in engine performance. Don’t ignore these clues – they’re your truck trying to tell you something!

Where are the most common spots for a 7.3 Powerstroke fuel leak on top of the engine?

Often, the culprit is the fuel bowl’s drain valve or O-rings, the flexible fuel lines connecting to the cylinder heads, or sometimes even the injector O-rings themselves. These areas are under pressure and prone to wear.

Is a 7.3 Powerstroke fuel leak on top of the engine dangerous, and can I still drive my truck?

Absolutely, it’s serious! Fuel on a hot engine is a major fire hazard, and driving it risks further damage or a dangerous situation. It’s best to address a 7.3 Powerstroke fuel leak on top of the engine as soon as possible.

How can I quickly tell if it’s a 7.3 Powerstroke fuel leak on top of the engine versus an oil leak?

Fuel evaporates much faster than oil and has a very distinct, sharp diesel smell. You can dab a small amount with a paper towel; if it disappears quickly and smells like diesel, you’ve likely got a fuel leak.

What should I do immediately if I discover a 7.3 Powerstroke fuel leak on top of the engine?

First, safely shut down your engine and avoid starting it again until you’ve investigated. Then, carefully inspect the top of the engine to try and pinpoint the source of the 7.3 Powerstroke fuel leak so you can plan your repair.

📋 Table of Contents

- The Heart of the Matter: Why 7.3 Powerstroke Fuel Leaks Emerge on Top of the Engine

- Pinpointing the Problem: Common Sources of 7.3 Powerstroke Fuel Leaks

- Decoding the Signs: Diagnosing Your 7.3 Powerstroke Fuel Leak on Top

- Tools, Techniques, and Triumphs: Repairing Your 7.3 Fuel Leak

- Proactive Measures: Preventing Future 7.3 Powerstroke Fuel Leaks

- The Financial & Functional Fallout: Don’t Ignore a 7.3 Powerstroke Fuel Leak

The Heart of the Matter: Why 7.3 Powerstroke Fuel Leaks Emerge on Top of the Engine

Before we dive into specific leak points, it’s crucial to understand the fundamental design of the 7.3 Powerstroke fuel system, especially the High-Pressure Oil Injection (HEUI) system, and why the top of the engine becomes such a common battleground for fuel leaks. Unlike many diesel engines, the 7.3 Powerstroke uses highly pressurized engine oil to actuate its fuel injectors. This complex dance of oil and fuel, while incredibly efficient, introduces numerous seals and connections that can degrade over time.

Learn more about 7.3 powerstroke fuel leak on top of engine – 7.3 Powerstroke Fuel Leak on Top of Engine

Image source: dieselworldmag.com

The top of your 7.3 Powerstroke diesel engine is a busy place. It houses the fuel filter housing, critical fuel lines, the fuel pressure regulator, and, crucially, the fuel injectors themselves, nestled under the valve covers. Over two decades of operation for many of these trucks means countless heat cycles, vibrations, and exposure to varying fuel qualities. These factors conspire to degrade rubber seals, plastic components, and metal lines, eventually leading to a fuel leak on top of engine.

| Common Leak Location | Primary Symptom(s) | Estimated Repair Complexity & Cost |

|---|---|---|

| Fuel Bowl Drain Valve (O-rings/Body) | Visible fuel puddle in the engine valley, strong diesel odor, potential rough idle or hard start due to air intrusion. | Low complexity (DIY friendly), Part Cost: $10-$30, Labor: 0.5-1 hour. |

| Fuel Filter Housing Base O-rings | Fuel pooling around the fuel filter housing, wetness on the pedestal, persistent strong fuel odor, extended cranking to start. | Medium complexity (DIY with care), Part Kit: $20-$50, Labor: 1-2 hours. |

| Fuel Line Fittings (to bowl/filter base) | Wetness/drips around specific line connections, typically metal lines connecting to the fuel bowl or filter housing, fuel odor. | Low to Medium complexity, Part Cost: $10-$50 (O-rings/fittings), Labor: 0.5-2 hours. |

| Fuel Injector O-rings (Upper) | Fuel accumulating in the engine valley, often accompanied by oil dilution (fuel in oil), hard start when hot, rough running. | High complexity (requires special tools), Part Kit: $200-$500, Labor: 6-10 hours (DIY) / $800-$1500+ (Shop). |

The relentless stress on these components, combined with the inherent properties of diesel fuel which can be corrosive to certain types of rubber and plastic, makes a leak almost inevitable at some point in the truck’s life. Think of it as wear and tear on an intricate system that’s constantly under pressure. Understanding this underlying vulnerability is the first step in effectively tackling your 7.3 fuel leak.

Pinpointing the Problem: Common Sources of 7.3 Powerstroke Fuel Leaks

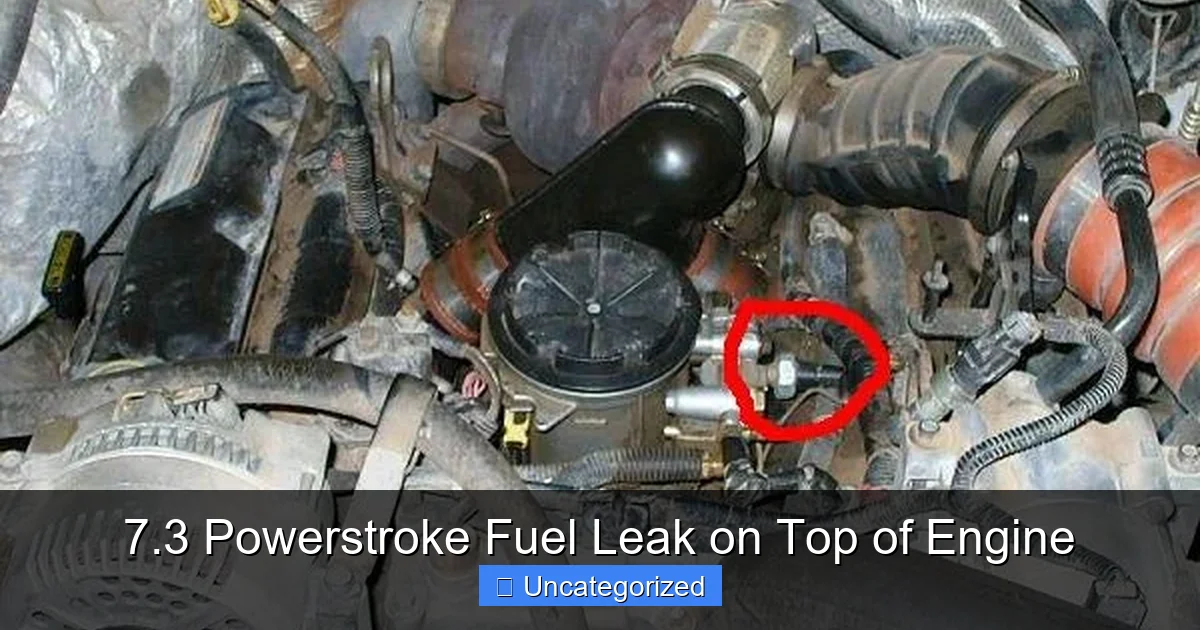

When you’re faced with a 7.3 Powerstroke fuel leak on top of engine, the biggest challenge can be identifying the exact source. Many components are clustered together, and a leak from one can easily drip down, making it appear as though the fuel is coming from somewhere else. Here are the most common culprits:

Learn more about 7.3 powerstroke fuel leak on top of engine – 7.3 Powerstroke Fuel Leak on Top of Engine

Image source: powerstroke.org

Injector O-Rings and Copper Washers

This is arguably the most notorious source of a 7.3 Powerstroke fuel leak. Each of your eight fuel injectors has a set of O-rings (typically three per injector) and a copper washer at the tip. These O-rings seal the injector against the fuel rail and the cylinder head, preventing fuel from escaping. With time, mileage, and heat cycles, these O-rings become brittle and lose their sealing capability. A failing O-ring can cause fuel to seep into the valve cover area, which then drains down the side of the engine.

- Symptoms: Fuel smell, visible fuel in the valley of the engine, sometimes misfires or rough idle, especially when cold.

- Why they fail: Degradation from heat and fuel exposure, improper installation, age.

Fuel Filter Housing (Fuel Bowl)

The fuel filter housing, often called the “fuel bowl,” sits prominently in the valley of the engine. It’s a complex assembly containing the fuel filter, a heating element, and a drain valve. There are several potential leak points here:

- Bowl Seal/Gasket: The main gasket between the two halves of the bowl can fail.

- Drain Valve: The yellow drain valve at the front of the bowl is a common leak source, especially if it’s plastic and has become brittle.

- Fuel Heater O-Rings: The O-rings for the fuel heater element, located inside the bowl, can leak.

- Fuel Lines: The hard lines connecting to and from the bowl can develop leaks where they connect, or even pinholes in the lines themselves.

A leak here is often highly visible in the valley of the engine, making it a prime suspect for a fuel leak on top of engine.

Fuel Pressure Regulator (FPR)

Located on the back side of the fuel filter housing, the fuel pressure regulator maintains consistent fuel pressure. It has an O-ring and a diaphragm that can fail, leading to fuel seepage. While less common than the bowl or injector O-rings, it’s definitely a candidate for a subtle but persistent 7.3 fuel leak.

- Symptoms: Visible fuel around the rear of the fuel bowl, fuel smell.

- Why it fails: O-ring degradation, internal diaphragm failure due to age and fuel exposure.

Fuel Hoses and Lines

Various rubber fuel hoses and hard lines run across the top of the engine. Over time, rubber hoses can crack, chafe, or degrade where they connect to fittings. Hard lines can develop corrosion or small stress cracks, especially near bends or connections. Pay close attention to the small return fuel lines, often made of plastic, which can become brittle.

- Symptoms: Visible wet spots along the lines, especially at connection points.

- Why they fail: Age, vibration, material degradation, improper clamping.

Check Valve (Early 7.3s)

Some early model 7.3 Powerstrokes had a check valve on the fuel return line near the driver’s side valve cover. This small valve is another potential leak point due to O-ring failure or the valve body cracking.

Thorough inspection of each of these areas is paramount in diagnosing your Powerstroke fuel leak.

Decoding the Signs: Diagnosing Your 7.3 Powerstroke Fuel Leak on Top

Identifying that you have a 7.3 Powerstroke fuel leak is often the easy part; pinpointing its origin requires a methodical approach. Here’s how to effectively diagnose the source of your fuel leak on top of engine:

Step 1: Visual Inspection (The Obvious Clues)

- Clean the Engine: Start with a clean engine. Use a degreaser and a pressure washer (carefully, avoiding electrical components) to remove all existing fuel and oil residue. This makes fresh leaks much easier to spot.

- Start Cold: With the engine clean and cold, start your truck. Fuel leaks are often more pronounced when the engine is cold and components haven’t expanded yet.

- Look, Smell, Listen:

- Look: Carefully inspect the entire top of the engine, especially the valley, around the fuel filter housing, the fuel lines, and both valve covers. Look for drips, wet spots, or a sheen of fuel. A small mirror and a flashlight can be invaluable for hard-to-reach areas.

- Smell: The distinct odor of diesel fuel is a strong indicator.

- Listen: While rare for fuel, sometimes a hiss can indicate a pressure leak.

- Check Fuel Bowl Drain: Ensure the yellow drain valve on the fuel bowl is fully closed. Many leaks here are simply due to the valve not being seated properly.

Step 2: The Paper Towel Test

For small, slow leaks that are hard to see, a paper towel can be your best friend. Wad up clean paper towels and place them strategically under suspected leak points (e.g., around fuel line connections, under the fuel pressure regulator, etc.). Run the engine and check the towels after a few minutes for any absorbed fuel.

Step 3: UV Dye (The Definitive Method)

If the leak remains elusive, a UV dye kit is the most effective way to find a stubborn 7.3 fuel leak. This method is highly recommended for pinpointing exactly where your Powerstroke fuel leak originates.

- Purchase a Diesel Fuel UV Dye Kit: These kits typically include a bottle of dye, a syringe for injection, and a UV flashlight with special glasses.

- Add Dye to Fuel Tank: Follow the kit’s instructions for the correct amount of dye to add to your fuel tank.

- Drive the Truck: Drive the truck for a day or two to allow the dye to circulate through the fuel system and leak out.

- Inspect with UV Light: In a dark environment (at night or in a dimly lit garage), use the UV flashlight and glasses to meticulously inspect the top of the engine. The dye will glow brightly at the exact source of the leak, making it undeniable.

Once you’ve identified the exact location, you’re ready to move on to the repair phase for your 7.3 Powerstroke fuel leak.

Tools, Techniques, and Triumphs: Repairing Your 7.3 Fuel Leak

Once you’ve diagnosed the source of your 7.3 Powerstroke fuel leak on top of engine, it’s time to roll up your sleeves and get to work. While some repairs are relatively straightforward, others can be more involved. Always prioritize safety: disconnect the battery, relieve fuel pressure if necessary, and have appropriate spill containment ready.

General Tools You’ll Likely Need:

- Socket set (metric and standard)

- Wrenches (open-end and ratcheting)

- Torx bits (for valve covers, etc.)

- Screwdrivers

- Pliers (needle-nose, hose clamp)

- Fuel line disconnect tools (if applicable)

- Razor blade or gasket scraper

- Rags and shop towels

- Degreaser and brake cleaner

- Torque wrench

- Eye protection and gloves

- Drain pan for fuel

Repairing Common 7.3 Powerstroke Fuel Leaks:

H3: Fixing Injector O-Rings

This is a more involved repair as it requires removing the valve covers. While not technically “on top” of the engine, the leaking fuel often collects in the valley. If your 7.3 fuel leak is from injector O-rings, here’s a general overview:

- Drain Coolant (if removing intercooler pipes): Some guides recommend removing the intake manifold for better access.

- Remove Valve Covers: Disconnect all electrical connectors and remove the bolts securing the valve covers. Be gentle to avoid damaging the gaskets.

- Remove Rocker Arms & Pushrods: To get to the injectors, you’ll need to remove the rocker arms and pushrods for each cylinder you’re working on. Keep them organized!

- Remove Injectors: Use an injector puller tool. Be careful not to damage the injector body or bore.

- Replace O-Rings and Copper Washers: Thoroughly clean the injector and the injector bore. Install new O-rings (top, middle, and bottom) and a new copper washer. Use a thin coat of clean engine oil or petroleum jelly to aid installation and prevent damage to the new O-rings.

- Reassemble: Reinstall injectors, rocker arms, pushrods, and valve covers (with new gaskets if needed). Torque all bolts to factory specifications.

Pro Tip: When replacing injector O-rings, it’s often wise to replace all of them at once, even if only one is leaking. They’re all the same age and likely to fail soon.

H3: Repairing the Fuel Filter Housing (Fuel Bowl)

This is a much more accessible and common repair for a Powerstroke fuel leak.

- Depressurize Fuel System: Disconnect the fuel bowl heater, then crank the engine for a few seconds to relieve pressure.

- Drain Fuel Bowl: Use the yellow drain valve to empty the fuel into a suitable container.

- Disconnect Fuel Lines and Electrical: Carefully disconnect all fuel lines (supply, return, crossover) and the electrical connector for the fuel heater. Be mindful of residual fuel.

- Remove Fuel Bowl: Unbolt the fuel filter housing from the engine.

- Identify and Replace Leaking Seals/Components:

- If the bowl seal, replace the large gasket.

- If the drain valve, replace the entire drain valve assembly.

- If the fuel heater O-rings, remove the heater element and replace its O-rings.

- If fuel lines, replace the problematic section of the line or fitting.

- Clean and Reassemble: Thoroughly clean all mating surfaces. Install new components, ensuring O-rings are lubricated. Reconnect all lines and electrical, and bolt the bowl back in place.

- Prime Fuel System: Cycle the key several times (without starting the engine) to allow the fuel pump to prime the system and fill the bowl. Check for new leaks before starting.

H3: Addressing Fuel Line Leaks

For rubber hoses, simply cut out the damaged section and replace it with a new piece of diesel-rated fuel hose and new hose clamps. For hard lines, you might be able to use a compression fitting for a small repair, but often the best solution is to replace the entire line section, especially if corrosion is extensive. Ensure all fittings are tight but not overtightened.

When to Call a Professional:

While many 7.3 Powerstroke fuel leak repairs are DIY-friendly, some situations warrant professional help:

- Lack of Experience/Tools: If you’re uncomfortable with complex engine work or don’t have the necessary specialized tools (like an injector puller).

- Persistent Leaks: If you’ve attempted a repair and the leak persists, there might be a more subtle or multiple issues at play.

- Time Constraints: If you rely on your truck daily and cannot afford downtime.

- Secondary Issues: If the leak is accompanied by severe engine performance problems, it could indicate a deeper issue.

Proactive Measures: Preventing Future 7.3 Powerstroke Fuel Leaks

An ounce of prevention is worth a pound of cure, especially when it comes to a potential 7.3 Powerstroke fuel leak on top of engine. Implementing a robust preventative maintenance schedule can significantly extend the life of your fuel system components and save you headaches down the road.

- Regular Visual Inspections: Make it a habit to pop the hood regularly (e.g., during oil changes or before long trips) and visually inspect the top of the engine. Look for any signs of wetness, discoloration, or the faint smell of diesel fuel. Early detection is key.

- Use Quality Fuel and Fuel Additives: The quality of your diesel fuel can impact the longevity of your fuel system components. Inferior fuel can contain contaminants that accelerate O-ring degradation. Consider using a reputable diesel fuel additive, especially one designed to lubricate seals and clean injectors.

- Replace Fuel Filter Regularly: A clogged fuel filter can put undue stress on your fuel pump and other components. Follow the manufacturer’s recommended service intervals, or replace it more frequently if you notice reduced performance or operate in dusty conditions.

- Proactive O-Ring Replacement: If you’re already going into the fuel bowl for a filter change or other maintenance, consider replacing the drain valve and its O-rings as a preventative measure. They are inexpensive and a common failure point.

- Inspect Fuel Lines and Hoses: Periodically check all rubber fuel hoses for cracking, hardening, or chafing. Inspect hard lines for any signs of corrosion or damage. Replace any suspicious sections before they turn into a full-blown 7.3 fuel leak.

- Use OEM or High-Quality Aftermarket Parts: When replacing seals, O-rings, or fuel system components, resist the temptation to buy the cheapest parts available. High-quality materials are more resistant to heat, fuel, and time, offering a longer lifespan and better sealing capabilities.

- Address Other Leaks Promptly: An oil leak in the valley can mask a fuel leak, and vice-versa. Keeping your engine clean and addressing any fluid leaks promptly helps you identify new issues quickly.

- Avoid Over-Tightening Fittings: When performing any work on the fuel system, be mindful of torque specifications. Over-tightening can strip threads or crack plastic/metal components, leading to a new Powerstroke fuel leak.

By staying vigilant and adhering to these preventative strategies, you can significantly reduce the chances of encountering a frustrating 7.3 Powerstroke fuel leak and ensure your truck remains a reliable workhorse for years to come.

The Financial & Functional Fallout: Don’t Ignore a 7.3 Powerstroke Fuel Leak

Ignoring a 7.3 Powerstroke fuel leak on top of engine isn’t just an inconvenience; it can lead to a cascade of problems, ranging from minor annoyances to catastrophic failures. Understanding the potential consequences underscores the importance of prompt diagnosis and repair.

Immediate Risks:

- Fire Hazard: This is the most serious risk. Diesel fuel is flammable, and a leak on a hot engine, especially near electrical components or exhaust, is an extreme fire hazard. This risk alone should be enough motivation to address any 7.3 fuel leak immediately.

- Environmental Damage: Leaking fuel contaminates soil and water, harming the environment. You could also face fines for environmental violations.

- Reduced Fuel Economy: Even a small leak means you’re literally watching your money drip away. Over time, this adds up significantly.

- Poor Engine Performance: A leak can lead to a loss of fuel pressure, causing hard starting, rough idle, misfires, or a general lack of power, making your 7.3 Powerstroke less reliable.

Long-Term Consequences:

- Damage to Other Components: Diesel fuel can degrade rubber and plastic components it comes into contact with, potentially damaging wiring harnesses, sensor connectors, and other seals on the engine.

- Corrosion: Fuel spills can strip paint and coatings, leading to rust and corrosion on engine components and the chassis.

- Contamination: A persistent fuel leak can mix with dirt and debris, forming a gritty sludge that further exacerbates wear on components and makes future diagnosis more difficult.

Estimated Repair Costs (General Averages):

The cost to fix a Powerstroke fuel leak varies widely depending on the source of the leak, whether you do it yourself (DIY), and labor rates if you take it to a professional shop. Here’s a rough breakdown:

| Leak Source | Typical Symptoms | DIY Difficulty | Estimated DIY Parts Cost | Estimated Professional Repair Cost |

|---|---|---|---|---|

| Fuel Filter Housing (Bowl) Seals/Drain Valve | Fuel pooling in engine valley, strong diesel smell. | Easy to Moderate | $30 – $100 | $150 – $400 |

| Fuel Pressure Regulator (FPR) | Fuel around rear of fuel bowl. | Moderate | $50 – $150 | $200 – $500 |

| Fuel Hoses/Lines | Visible wet spots on lines/fittings. | Easy to Moderate | $20 – $100 (per section) | $100 – $300 (per section) |

| Injector O-Rings | Rough idle, fuel in valley, misfires (more complex). | Moderate to Difficult | $100 – $250 (for a full set) | $800 – $2000+ (labor intensive) |

*These are estimates only and can vary significantly based on parts brand, location, labor rates, and any additional components needed.

As you can see, addressing a small 7.3 fuel leak early is almost always less expensive than letting it fester and potentially cause more extensive damage or, worse, a fire. Don’t procrastinate; your truck, your wallet, and your safety depend on it.

Conquering a 7.3 Powerstroke fuel leak on top of engine might seem daunting at first, but with the right approach, it’s a manageable and necessary repair. By understanding the common leak points, employing effective diagnostic techniques, and choosing the appropriate repair method, you can restore your truck’s integrity and performance. Remember, vigilance through regular inspection and proactive maintenance are your best allies in keeping your beloved 7.3 Powerstroke running reliably and leak-free. Tackle that drip, enjoy the peace of mind, and keep that iconic diesel engine purring for many more miles to come!

Frequently Asked Questions

How do I know I have a fuel leak on top of my 7.3 Powerstroke engine?

You might notice a strong diesel smell inside or outside the cab, especially after driving or during a cold start. Visual inspection will often reveal wetness or puddles of diesel fuel in the valley of the engine, typically around the fuel filter housing or under the intake manifold.

What are the most common sources of a 7.3 Powerstroke fuel leak on top of the engine?

The most frequent culprits for a 7.3 Powerstroke fuel leak on top of the engine include worn O-rings on fuel lines, especially at the fuel filter housing, and injector cup seals. Leaks can also originate from the fuel pressure regulator (FPR) or from the fuel filter housing itself due to cracked plastic or failed seals.

Is a fuel leak on top of the engine for a 7.3 Powerstroke a serious problem?

Yes, a fuel leak on top of your 7.3 Powerstroke engine can be quite serious and should be addressed promptly. Besides the strong diesel smell and environmental hazard, it poses a significant fire risk if fuel comes into contact with hot engine components. It can also lead to reduced fuel economy, hard starting, or engine damage if left unchecked.

How can I pinpoint the exact location of a 7.3 Powerstroke fuel leak on top of the engine?

Start by thoroughly cleaning the engine valley to remove any existing fuel or debris. Then, run the engine and carefully observe with a bright flashlight for fresh leaks around the fuel filter housing, fuel lines, injector areas, and the fuel pressure regulator. Sometimes, the leak is more visible during a cold start due to higher fuel pressure.

How difficult is it to fix a 7.3 Powerstroke fuel leak on top of the engine, and what’s the typical cost?

The difficulty of fixing a 7.3 Powerstroke fuel leak on top of the engine varies depending on the source; some O-ring replacements are moderate DIY tasks, while injector cup seals are more involved. Parts for common leaks are relatively inexpensive, often under $100, but labor costs at a shop can range from $200 to $800 or more, depending on the complexity of the specific repair.

What maintenance can I perform to prevent a 7.3 Powerstroke fuel leak on top of the engine?

Regular inspection of fuel lines, O-rings, and seals around the fuel filter housing and injectors can help catch potential issues early. Using quality diesel fuel and changing your fuel filter at recommended intervals also helps maintain the integrity of the fuel system components, reducing wear and tear that can lead to a 7.3 Powerstroke fuel leak on top.