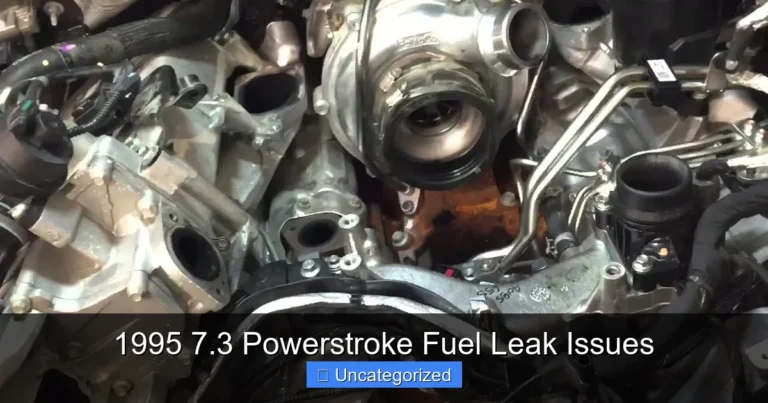

7.3 Powerstroke Engine Fuel System Diagram Explained

Featured image for this comprehensive guide about 7.3 powerstroke engine fuel system diagram

Image source: 1.bp.blogspot.com

Quick Answers to Common Questions

What’s the most unique feature on the 7.3 Powerstroke engine fuel system diagram?

The most distinctive feature is the HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, where high-pressure engine oil, not just fuel, is used to fire the injectors.

How does fuel actually flow through the 7.3 Powerstroke engine fuel system diagram?

Fuel starts its journey from the tank, travels through an electric fuel pump and filter, then moves to the cylinder heads where it’s ready for the injectors.

Why is the fuel filter so critical when understanding the 7.3 Powerstroke engine fuel system diagram?

It’s absolutely vital! The fuel filter protects your expensive HEUI injectors from harmful contaminants, ensuring clean fuel delivery and optimal engine performance, which is key to the 7.3 Powerstroke engine fuel system diagram’s function.

What’s the relationship between oil and fuel in the 7.3 Powerstroke engine fuel system diagram?

This is where it gets interesting! The 7.3 Powerstroke uses engine oil under high pressure to actuate the fuel injectors, making the fuel system unique and interdependent with the engine’s oil system.

If I’m troubleshooting, what’s the first component I should locate on the 7.3 Powerstroke engine fuel system diagram?

Start by locating the electric fuel pump, typically mounted on the frame rail, as it’s responsible for drawing fuel from the tank and starting the entire fuel delivery process.

📋 Table of Contents

- 7.3 Powerstroke Engine Fuel System Diagram Explained

- Understanding the 7.3 Powerstroke: A Brief Overview

- The Core Components of the 7.3 Powerstroke Fuel System

- Tracing the Fuel’s Journey: A Step-by-Step 7.3 Powerstroke Fuel System Diagram Explanation

- Common 7.3 Powerstroke Fuel System Issues and Troubleshooting Tips

- Maintenance Matters: Keeping Your 7.3 Powerstroke Fuel System Pristine

- Upgrades and Enhancements for Your 7.3 Powerstroke Fuel System

- Conclusion

7.3 Powerstroke Engine Fuel System Diagram Explained

The 7.3 Powerstroke engine. Just uttering its name conjures images of raw power, unwavering reliability, and a legacy that has cemented its place in diesel history. For decades, this iconic powerplant has been the heart of countless Ford Super Duty trucks and vans, hauling heavy loads, conquering rugged terrains, and delivering consistent performance. But beneath its legendary reputation lies a sophisticated, albeit robust, fuel system that is absolutely critical to its operation. Understanding this system isn’t just for mechanics; it’s for every owner who wants to maximize their truck’s lifespan and performance.

Learn more about 7.3 powerstroke engine fuel system diagram – 7.3 Powerstroke Engine Fuel System Diagram Explained

Image source: junglewood.xyz

Many diesel engines can seem like a mysterious tangle of pipes and wires, and the 7.3 Powerstroke engine fuel system diagram can initially appear daunting. However, breaking it down into its core components and tracing the fuel’s journey demystifies the process. This comprehensive guide will pull back the curtain, explaining each crucial part, how they work together, and providing you with the knowledge to maintain, troubleshoot, and even upgrade your 7.3’s fuel delivery. Whether you’re a seasoned enthusiast or a new 7.3 owner, this post is your definitive resource for mastering the heart of your diesel’s operation.

| Component | Primary Function | Typical Specification/Value | Common Issue/Note |

|---|---|---|---|

| Electric Fuel Pump (Lift Pump) | Draws fuel from the tank and supplies it to the engine. | 45-65 PSI (stock operating pressure) | Weak output leads to hard starts, power loss, injector issues. |

| Fuel Filter/Water Separator | Filters contaminants and separates water from diesel fuel. | 10-micron filtration (typical) | Clogging reduces fuel flow and pressure; replace every 15,000 miles. |

| Fuel Pressure Regulator (FPR) | Maintains consistent fuel pressure to the injectors. | ~60-65 PSI (regulated pressure) | Spring fatigue can cause low fuel pressure, affecting performance. |

| HEUI Injectors | Utilize high-pressure oil to actuate and inject fuel into cylinders. | ~2000-3000 PSI (injection pressure via HPOP) | Stiction, O-ring leaks, and poor atomization are common failures. |

| High-Pressure Oil Pump (HPOP) | Supplies high-pressure oil to actuate the HEUI fuel injectors. | Up to 3000+ PSI (oil pressure) | Swash plate wear, IPR valve issues, and cavitation can lead to no-start conditions. |

Join us as we dive deep into the veins of this beast, illustrating how fuel travels from the tank to the combustion chamber, ensuring your beloved Powerstroke continues to thunder down the road with the reliability it’s famous for. Getting familiar with your 7.3 Powerstroke fuel system is a significant step towards becoming a more informed and empowered owner.

Understanding the 7.3 Powerstroke: A Brief Overview

Before we dissect its fuel system, let’s briefly acknowledge what makes the 7.3 Powerstroke so revered. Produced by International Navistar and sold by Ford from 1994.5 to 2003, this direct-injected V8 diesel engine is celebrated for its remarkable durability, simplicity (compared to modern diesels), and impressive longevity. Many 7.3 Powerstrokes routinely exceed 300,000 to 500,000 miles, with some even pushing past the million-mile mark with proper maintenance. Its robust cast-iron block, gear-driven camshaft, and relatively low-stress design contribute to its legendary bulletproof nature.

Learn more about 7.3 powerstroke engine fuel system diagram – 7.3 Powerstroke Engine Fuel System Diagram Explained

Image source: img.freepik.com

The 7.3 Powerstroke utilizes a unique fuel injection system known as HEUI (Hydraulically Actuated Electronically Controlled Unit Injector). Unlike common rail systems, the HEUI system uses high-pressure engine oil to actuate the fuel injectors, which then directly inject fuel into the combustion chamber. This interplay between the high-pressure oil system and the low-pressure fuel system is a cornerstone of the 7.3 Powerstroke engine fuel system diagram, making it distinct and highly effective for its time.

The Core Components of the 7.3 Powerstroke Fuel System

The 7.3 Powerstroke fuel system is a marvel of engineering, designed for reliability and efficiency. Understanding each component is key to visualizing the complete 7.3 Powerstroke engine fuel system diagram. Here’s a breakdown of the critical parts:

Fuel Tank & Sender Unit

This is where it all begins. The fuel tank stores the diesel, and the sender unit within the tank measures the fuel level, sending electrical signals to your dashboard gauge. Ensuring your tank is free of contaminants and rust is vital for the longevity of your entire fuel system.

Electric Fuel Pump (Lift Pump)

Typically mounted on the frame rail (post-1999 models) or within the fuel valley (early models), the electric fuel pump, often called the lift pump, is responsible for drawing fuel from the tank and pushing it towards the engine. It maintains a relatively low pressure, generally between 40-70 PSI, which is crucial for the subsequent components. A failing lift pump is a common cause of poor performance and starting issues in a 7.3 Powerstroke.

Fuel Filter & Water Separator

Located in the engine valley, this integrated unit is one of the most vital components. The fuel filter removes contaminants, dirt, and debris from the diesel, preventing them from reaching sensitive components like the injectors. The water separator does exactly what its name suggests: it separates water from the fuel, collecting it at the bottom. Water is highly detrimental to diesel engines, causing corrosion and significant damage to injectors and pumps. Regular draining and replacement of this unit are non-negotiable for a healthy 7.3 Powerstroke fuel system.

Fuel Lines & Hoses

A network of high-quality lines and hoses transports fuel throughout the system. These include lines from the tank to the pump, from the pump to the filter, and from the filter to the cylinder heads. Over time, these can degrade, crack, or leak, leading to air intrusion or fuel leaks, both of which can significantly impair engine performance.

Fuel Pressure Regulator (FPR)

Integrated into the fuel filter housing on later models (or a separate component on earlier ones), the Fuel Pressure Regulator (FPR) is crucial. It ensures that a consistent, steady fuel pressure is delivered to the fuel galleries in the cylinder heads. It bleeds off excess pressure by returning unused fuel back to the fuel tank via the return line. A malfunctioning FPR can lead to erratic fuel pressure, affecting injector performance and overall engine smoothness.

Fuel Heater

In colder climates, diesel fuel can “gel” or become too thick, impeding flow. The fuel heater, typically located in the fuel filter housing, warms the fuel to prevent gelling, ensuring smooth operation even in freezing temperatures.

Cylinder Head Fuel Galleries

Once the fuel passes through the filter and FPR, it enters the fuel galleries within the cylinder heads. These passages distribute the pressurized fuel to each individual injector, ensuring they have a constant supply ready for injection.

High-Pressure Oil Pump (HPOP)

While not strictly a fuel system component, the HPOP is inseparable from the 7.3 Powerstroke fuel system diagram because it provides the immense oil pressure (up to 3000 PSI or more) required to actuate the HEUI injectors. Without adequate HPOP pressure, the injectors cannot fire, regardless of how much fuel is present. This interplay is unique to the 7.3.

HEUI Injectors (Hydraulically Actuated Electronically Controlled Unit Injectors)

These are the heart of the 7.3 Powerstroke’s injection system. Each injector is a complex unit that receives low-pressure fuel from the cylinder head gallery and high-pressure oil from the HPOP. When the Powertrain Control Module (PCM) commands an injection event, a solenoid within the injector opens, allowing high-pressure oil to act on an intensifier piston. This piston, in turn, pressurizes the fuel within the injector barrel to extreme levels (up to 21,000 PSI) before it’s sprayed into the combustion chamber. The precise timing and duration of this injection are critical for optimal engine performance, emissions, and fuel economy.

Fuel Return System

Any fuel not injected into the cylinders, primarily excess fuel from the FPR, is returned to the fuel tank via a dedicated return line. This helps to cool the fuel and prevents excessive pressure buildup in the system.

Tracing the Fuel’s Journey: A Step-by-Step 7.3 Powerstroke Fuel System Diagram Explanation

Let’s visualize the fuel’s complete journey through the 7.3 Powerstroke engine fuel system diagram, from the tank to the engine’s combustion chambers:

- Fuel Pickup in Tank: Diesel fuel is drawn from the fuel tank through a pickup tube, typically equipped with a screen to prevent large debris from entering the system.

- To the Electric Fuel Pump: The fuel then travels through fuel lines to the electric fuel pump (lift pump), which provides the initial push.

- Pressurized Flow to Filter: The lift pump pressurizes the fuel to approximately 40-70 PSI and sends it forward towards the engine.

- Through the Fuel Filter & Water Separator: The pressurized fuel enters the fuel filter housing. Here, it is meticulously cleaned of particulate matter by the filter element and any entrained water is separated and collected. In cold weather, it may pass through the fuel heater.

- Regulated Pressure at the FPR: After filtration, the fuel reaches the Fuel Pressure Regulator (FPR). The FPR ensures a consistent fuel pressure is maintained for the injectors, typically around 45-60 PSI. Excess fuel is routed back to the tank via the fuel return line.

- Into the Cylinder Head Fuel Galleries: The precisely regulated fuel then flows into internal passages within the cylinder heads, known as fuel galleries. These galleries provide a reservoir of fuel for each injector.

- Injector Actuation (HEUI System): This is where the magic happens. Simultaneously, the High-Pressure Oil Pump (HPOP) delivers high-pressure engine oil (up to 3000+ PSI) to the injectors.

- Fuel Injection: When the PCM signals an injector to fire, a solenoid opens, allowing high-pressure oil to enter the injector. This oil pushes down on an intensifier piston, which in turn pressurizes the fuel inside the injector barrel to an incredible ~21,000 PSI. This ultra-high-pressure fuel is then sprayed directly into the combustion chamber in a finely atomized mist for efficient burning.

- Combustion & Exhaust: The injected fuel ignites with compressed air, driving the piston, and the resulting exhaust gases are expelled.

- Fuel Return: Any fuel that was not used by the injectors or was bled off by the FPR, along with any high-pressure oil that actuated the injectors, is routed back to the fuel tank (for fuel) or the oil pan (for oil) through their respective return lines. This continuous circulation helps cool the fuel and maintain system equilibrium.

This intricate dance of fuel and oil, precisely timed by the PCM, is what gives the 7.3 Powerstroke its characteristic rumble and enduring power.

Common 7.3 Powerstroke Fuel System Issues and Troubleshooting Tips

Even the most robust systems can encounter issues. Recognizing the symptoms of a failing 7.3 Powerstroke fuel system component can save you from costly repairs down the line. Here are some common problems and troubleshooting tips:

Low Fuel Pressure

Symptoms: Lack of power, poor acceleration, hard starts (especially when warm), rough idle, black smoke.

Causes: Failing electric fuel pump, clogged fuel filter, leaking fuel lines/fittings, faulty Fuel Pressure Regulator (FPR).

Troubleshooting: The first step is to check fuel pressure with a mechanical gauge. Connect it to the port on the fuel filter housing. You should see 40-70 PSI at idle. If it’s low, inspect the fuel filter (replace if old), check for leaks, and consider testing or replacing the fuel pump.

Air in Fuel System

Symptoms: Extended cranking, rough idle, stalling, “cavitation” noise from the fuel pump, white smoke.

Causes: Leaking fuel lines, loose fittings, cracked fuel pickup, aftermarket fuel bowls that don’t seal correctly, or simply running the tank too low.

Troubleshooting: Visually inspect all fuel lines and connections for wet spots or visible leaks. Listen for a sucking sound near the tank or fuel pump. Bleeding the fuel system (usually by cycling the key several times without starting) can help, but finding and fixing the source of the air is paramount.

Clogged Fuel Filter

Symptoms: Similar to low fuel pressure – reduced power, sluggish acceleration, hard starting. Can also manifest as surging under load.

Causes: Neglecting regular filter replacement, contaminated fuel.

Troubleshooting: This is an easy fix. Replace the fuel filter. If symptoms persist, then dig deeper. Always carry a spare fuel filter and the necessary tools.

Injector Problems

Symptoms: Rough idle, excessive smoke (blue/grey for O-ring issues, black for over-fueling), misfires, loss of power, increased fuel consumption, “contribution codes” (check engine light).

Causes: Worn internal components, failed O-rings (allowing fuel and oil to mix or high-pressure oil to leak), electrical issues.

Troubleshooting: While complex, some initial checks include listening for “cackle” from specific cylinders (can indicate O-ring leaks), and running a contribution test with a diagnostic scanner to identify weak cylinders. O-ring replacement is a common and often effective repair.

Fuel Leaks

Symptoms: Visible fuel puddles, strong diesel smell, potential for fire hazard.

Causes: Deteriorated fuel lines, loose fittings, cracked fuel bowl, leaking injector O-rings.

Troubleshooting: Visually inspect the entire 7.3 Powerstroke fuel system for wet spots, especially around the fuel filter housing, lines, and injector areas on top of the engine. Use a flashlight and look for signs of seepage.

Remember, a good fuel pressure gauge is your best friend when diagnosing 7.3 fuel system issues. Many problems can be traced back to insufficient or inconsistent fuel pressure.

Maintenance Matters: Keeping Your 7.3 Powerstroke Fuel System Pristine

The 7.3 Powerstroke is known for its longevity, but that longevity is directly proportional to the quality of its maintenance. A well-maintained 7.3 Powerstroke fuel system is critical for peak performance, fuel economy, and avoiding costly repairs. Here are actionable tips:

Regular Fuel Filter Replacement

This is arguably the most important maintenance item for your fuel system. A clogged filter starves the engine of fuel, strains the fuel pump, and can lead to damage.

Tip: Replace your fuel filter every 10,000 to 15,000 miles or annually, whichever comes first. If you use questionable fuel sources, consider more frequent changes.

Monitoring Fuel Pressure

An inexpensive fuel pressure gauge permanently mounted in your cab can provide invaluable real-time feedback.

Tip: Install an aftermarket fuel pressure gauge. Monitor it regularly, especially during driving. A sudden drop or consistent low pressure indicates a problem that needs immediate attention.

Using Quality Fuel

The saying “you are what you eat” applies to your diesel engine too. Substandard fuel can contain more contaminants and water, leading to faster filter clogging and potential damage.

Tip: Always buy diesel from reputable stations with high turnover. If possible, opt for premium diesel that includes lubricity and cetane improvers.

Addressing Leaks Promptly

Even a small fuel leak can lead to air intrusion, poor performance, and is a fire hazard.

Tip: Periodically inspect fuel lines, fittings, and the fuel filter housing for any signs of wetness or drips. Address any leaks immediately. Keep an eye on your oil level as well; fuel in the oil could indicate injector O-ring leaks.

Water Separator Draining

The integrated fuel filter and water separator needs regular attention.

Tip: Drain the water separator every oil change (typically 5,000-7,500 miles) or more frequently if operating in humid climates or after refueling from a suspicious source. There’s a small valve at the bottom of the fuel bowl for this purpose.

Injector Cleaner (Use with Caution)

Some owners use fuel additives to help keep injectors clean.

Tip: If using additives, choose reputable brands specifically formulated for diesel engines. Be wary of over-reliance on additives as a substitute for proper maintenance or as a fix for existing problems.

By adhering to these maintenance practices, you’re not just preserving the 7.3 Powerstroke fuel system; you’re safeguarding the entire engine and ensuring its continued legendary performance. It’s an investment in your truck’s future.

Recommended Maintenance Schedule for 7.3 Powerstroke Fuel System Components

| Component | Recommended Interval | Notes |

|---|---|---|

| Fuel Filter | 10,000 – 15,000 miles | Or annually, whichever comes first. More often if fuel quality is poor. |

| Water Separator Drain | Every 5,000 – 7,500 miles | Or with every oil change. Essential for preventing water damage. |

| Fuel Pressure Check | Annually or if symptoms arise | Critical diagnostic step. Install an in-cab gauge for constant monitoring. |

| Fuel Line/Hose Inspection | Every 30,000 miles or annually | Check for cracks, chafing, and loose connections. |

| Injector O-Rings | As needed (usually with injector service) | Look for fuel in oil or oil in fuel, or external leaks. |

Upgrades and Enhancements for Your 7.3 Powerstroke Fuel System

While the stock 7.3 Powerstroke fuel system is robust, there’s always room for improvement, especially if you’re chasing more power, enhanced reliability, or simply want to future-proof your truck. Many popular upgrades address common weak points or limitations of the original design.

E-Fuel Conversion (Electric Fuel Pump Upgrade)

Many 7.3 owners opt to replace the original electric fuel pump (especially the early frame-mounted ones) or integrate a more robust, higher-flow electric fuel pump system.

Benefits:

- Consistent Pressure: Provides a steadier fuel pressure, particularly under load, which is beneficial for injector health and performance.

- Increased Flow: Essential for performance applications where higher horsepower injectors demand more fuel.

- Reduced Heat: Eliminates the fuel being routed through the fuel bowl, which can heat the fuel unnecessarily.

- Reliability: Often replaces older, potentially failing stock components with modern, more durable units.

Tip: Look for complete E-fuel kits that include a high-quality pump, filters, and all necessary lines and fittings for a seamless installation.

Regulated Return Fuel System

The stock 7.3 Powerstroke fuel system delivers fuel to the front of the heads, and any excess is regulated and returned at the back. This can lead to a slight pressure drop towards the rear cylinders. A regulated return system addresses this.

Benefits:

- Even Fuel Pressure: Ensures consistent fuel pressure across all eight injectors, leading to more balanced cylinder contribution and smoother operation.

- Improved Fuel Cooling: Better circulation of fuel can help keep it cooler, which is beneficial for performance.

- Eliminates the OEM Fuel Bowl: Many kits eliminate the often-problematic factory fuel bowl and its associated heater, improving reliability and reducing potential leak points.

Tip: This upgrade is highly recommended for anyone running larger injectors or seeking to maximize the efficiency and longevity of their 7.3 Powerstroke fuel system.

Upgraded Injectors

For those looking for significant horsepower gains, upgrading the injectors is a common path.

Benefits:

- More Fuel: Larger injectors deliver more fuel per injection event, leading to increased power potential.

- Better Atomization: Some aftermarket injectors can offer improved fuel atomization, potentially leading to better combustion and efficiency.

Considerations: Upgraded injectors often require supporting modifications like a larger High-Pressure Oil Pump (HPOP), custom tuning, and a robust E-fuel or regulated return system to supply the necessary fuel and oil. It’s a comprehensive modification.

Fuel Additives

While not a “hard part” upgrade, consistent use of quality fuel additives can significantly enhance your 7.3 Powerstroke fuel system‘s performance and longevity.

Benefits:

- Increased Lubricity: Modern ultra-low sulfur diesel (ULSD) lacks the natural lubricity of older diesel fuels. Additives restore this, protecting fuel pumps and injectors from wear.

- Cetane Boost: Improves combustion efficiency, leading to smoother running, easier cold starts, and potentially better fuel economy.

- Injector Cleaning: Helps keep injectors free of deposits, maintaining optimal spray patterns.

- Water Demulsifier: Aids in separating water from fuel, allowing the water separator to function more effectively.

Tip: Research and choose a reputable, all-in-one diesel additive to use with every fill-up. It’s a small investment with big returns for your engine’s health.

Implementing these upgrades can transform your 7.3 Powerstroke, pushing its performance boundaries and enhancing its legendary reliability even further. Always consult with knowledgeable professionals or reputable aftermarket suppliers before undertaking significant modifications.

Conclusion

The 7.3 Powerstroke’s reputation as a workhorse is well-earned, and at the core of its enduring performance lies its meticulously designed fuel system. Understanding the 7.3 Powerstroke engine fuel system diagram, from the humble fuel tank to the sophisticated HEUI injectors, empowers you as an owner. You’re no longer just driving a truck; you’re operating a finely tuned piece of machinery that responds to intelligent care.

By diligently adhering to maintenance schedules, proactively addressing potential issues, and considering strategic upgrades, you can ensure your 7.3 Powerstroke continues to perform at its peak for hundreds of thousands more miles. This comprehensive guide has aimed to demystify its operation, providing you with the knowledge to troubleshoot common problems, maintain critical components, and even enhance its capabilities. Embrace the journey of understanding your 7.3 Powerstroke fuel system, and your truck will reward you with years of faithful, powerful service.

Frequently Asked Questions

What are the main components of the 7.3 Powerstroke fuel system?

The 7.3 Powerstroke fuel system includes the fuel tank, an electric fuel pump (usually frame-mounted), fuel lines, the fuel filter housing (often called the “fuel bowl”), and the Hydraulically Actuated Electronically Controlled Unit Injectors (HEUI). High-pressure engine oil from the HPOP is used to actuate these injectors, which then atomize the fuel for combustion.

How does the 7.3 Powerstroke fuel system deliver fuel to the injectors?

The 7.3 Powerstroke fuel system utilizes a unique HEUI (Hydraulic Electric Unit Injector) design. Fuel is delivered from the tank to the fuel bowl at low pressure, but high-pressure engine oil, not fuel, is used by the HPOP (High-Pressure Oil Pump) to physically actuate the fuel injectors. This high oil pressure then causes the fuel within the injector to be pressurized and atomized into the cylinders.

What is the purpose of the fuel filter bowl in the 7.3 Powerstroke fuel system diagram?

The fuel filter bowl, prominently located on top of the 7.3 Powerstroke engine, serves as the primary housing for the fuel filter, ensuring clean fuel delivery to the injectors. It also typically integrates a fuel heater to prevent gelling in cold weather and a Water-In-Fuel (WIF) sensor to alert the driver about water contamination, which can be drained from the bottom.

What are common problems associated with the 7.3 Powerstroke fuel system?

Common issues with the 7.3 Powerstroke fuel system include fuel leaks from lines or the fuel bowl, clogged fuel filters leading to reduced performance or stalling, and failures of the electric fuel pump. Air intrusion into the fuel lines can also cause hard starting or rough running, often due to cracked O-rings or loose connections.

What regular maintenance is recommended for the 7.3 Powerstroke fuel system?

Regular maintenance for the 7.3 Powerstroke fuel system primarily involves timely replacement of the fuel filter, typically every 10,000 to 15,000 miles, and draining water from the fuel bowl periodically. It’s also crucial to inspect fuel lines and fittings for any signs of cracks, leaks, or wear to prevent air intrusion or fuel starvation.

Where is the fuel pump located in the 7.3 Powerstroke fuel system and what is its role?

In most 7.3 Powerstroke trucks, the electric fuel pump is frame-mounted, usually on the driver’s side near the fuel tank. Its role is to draw fuel from the tank and deliver it under consistent low pressure (typically 60-70 PSI) to the fuel filter bowl on top of the engine, ensuring a steady supply for the injectors.