6.7 Powerstroke Turbocharger Specifications: Maximize Your Engine’s Potential

Featured image for this comprehensive guide about 6.7 Powerstroke turbocharger specifications

Image source: f150forum.com

6.7 Powerstroke Turbocharger Specifications: Maximize Your Engine’s Potential

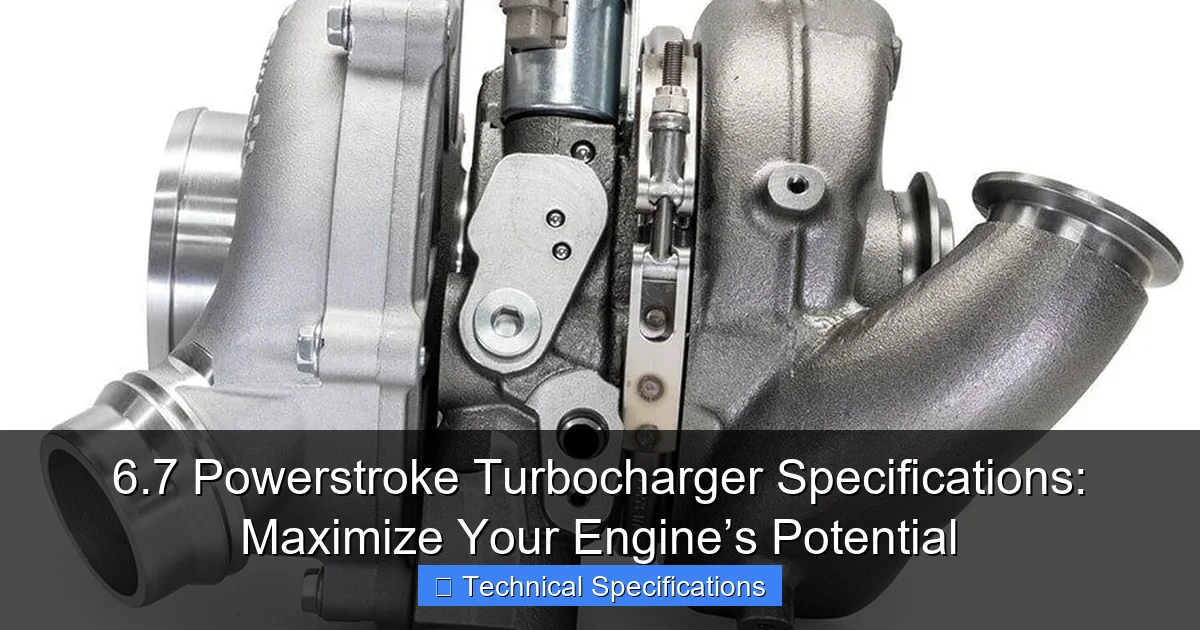

The roar of a diesel engine, the immense torque, and the sheer capability of a Ford F-Series Super Duty are legendary. At the heart of this power, especially in the modern era, lies the sophisticated turbocharger system, and for owners of the formidable 6.7 Powerstroke engine, understanding its turbocharger is paramount. This isn’t just about boosting horsepower; it’s about optimizing efficiency, ensuring longevity, and unlocking the full potential of your truck.

From hauling heavy loads up steep inclines to cruising effortlessly on the open highway, your 6.7 Powerstroke turbocharger plays a critical role. It’s the unsung hero, forcing more air into the engine to create a bigger, more powerful combustion cycle. But what exactly makes these turbos tick? What are the precise 6.7 Powerstroke turbocharger specifications that define their performance and reliability? Delving into these details empowers you as an owner, whether you’re performing routine maintenance, diagnosing an issue, or contemplating an upgrade.

In this comprehensive guide, we’ll peel back the layers of the 6.7 Powerstroke turbo, exploring its evolution, core components, intricate specifications, and crucial maintenance tips. We’ll also discuss upgrade paths for those seeking even more power and efficiency. Get ready to gain a deeper understanding of the technology that drives your truck, transforming it from a mere workhorse into a marvel of modern engineering.

Quick Answers to Common Questions

What type of turbocharger does the 6.7 Powerstroke typically use?

The 6.7 Powerstroke primarily uses a Variable Geometry Turbocharger (VGT), which precisely controls exhaust flow to optimize performance across the RPM range. Understanding this design is key to its unique **6.7 Powerstroke turbocharger specifications**.

What are some core 6.7 Powerstroke turbocharger specifications I should know about?

Key specifications include its ability to generate significant boost pressure (up to 30-40 PSI stock) and its rapid spool-up, thanks to that VGT technology. These specs highlight why it’s so efficient and powerful.

Can I upgrade my 6.7 Powerstroke turbocharger for more power?

Absolutely! Many owners upgrade their **6.7 Powerstroke turbocharger specifications** with larger aftermarket units to achieve higher horsepower and torque, especially for towing or performance applications. This is a popular modification to maximize potential.

What are common signs that my 6.7 Powerstroke turbocharger might be failing?

Watch out for excessive black or white smoke, a distinct whining or siren-like noise, or a noticeable loss of power and boost. These are clear indicators that your **6.7 Powerstroke turbocharger specifications** might not be performing as they should.

Are there different 6.7 Powerstroke turbocharger specifications depending on the model year?

Yes, there are notable differences, primarily between the 2011-2014 and 2015+ models, with later trucks featuring a slightly redesigned, single sequential turbo. Always verify the specific **6.7 Powerstroke turbocharger specifications** for your truck’s year.

📋 Table of Contents

- The Evolution of Power: A Brief History of 6.7 Powerstroke Turbochargers

- Dissecting the Beast: Core Turbocharger Components and Their Role

- Diving Deep into Specifications: Numbers That Matter

- Common Turbocharger Issues and Maintenance Tips

- Upgrading Your 6.7 Powerstroke Turbo: Options and Considerations

- The Future of Forced Induction for the 6.7 Powerstroke

- Conclusion: Mastering Your 6.7 Powerstroke Turbo

The Evolution of Power: A Brief History of 6.7 Powerstroke Turbochargers

The 6.7 Powerstroke engine, introduced in 2011, marked a significant departure from its predecessors, and its turbocharging strategy was a key differentiator. Ford opted for an innovative, proprietary design, evolving it over the years to meet increasingly stringent emissions standards and consumer demands for more power and better fuel economy.

Learn more about 6.7 Powerstroke turbocharger specifications – 6.7 Powerstroke Turbocharger Specifications: Maximize Your Engine’s Potential

Image source: i.pinimg.com

Early Years: The GT32 SST (2011-2014)

The initial iteration of the 6.7 Powerstroke turbocharger was a unique BorgWarner design known as the GT32 SST (Sequential Series Turbo). Don’t let the “sequential” fool you; it was actually a single-sequential turbo. This meant it used a single turbine housing with two volutes (entry passages) and two wastegates. One volute was smaller for faster spooling at low RPMs, and the other was larger, opening up for high RPM flow. This design aimed to combine the responsiveness of a small turbo with the top-end power of a large turbo.

| Powerstroke Year Range | Turbocharger Model / Type | Compressor Wheel Inducer (mm) | Turbine Wheel Exducer (mm) |

|---|---|---|---|

| 2011-2014 | Garrett GT32 SST (Dual Entry) | 64.0 | 68.0 |

| 2015-2016 | Garrett GT37 VGT (Gen 1) | 64.0 | 72.5 |

| 2017-2019 | Garrett GT37 VGT (Gen 2) | 67.0 | 76.0 |

| 2020-Present | Garrett GT37 VGT (Gen 3) | 68.0 | 76.5 |

- Design: Single-sequential, variable geometry turbo (VGT).

- Unique Feature: Dual compressor wheels (one on each side of the turbine wheel) – a “reverse spin” design.

- Pros: Excellent low-end response, strong mid-range power, good for emissions.

- Cons: Known for failures related to the ceramic ball bearings and variable geometry components, especially when subjected to high heat or aggressive tuning. The exhaust-side location also contributed to higher operating temperatures.

The Next Generation: GT37 VGT (2015-2019)

Recognizing the limitations and reliability concerns of the GT32 SST, Ford completely revamped the 6.7 Powerstroke turbocharger for the 2015 model year. They introduced a conventional single-stage, BorgWarner GT37 VGT unit. This was a significant shift, moving to a larger compressor and turbine and relocating the turbo to the traditional position between the engine’s cylinder banks (the “hot V” design). This change improved cooling and simplified the exhaust system.

- Design: Single-stage, variable geometry turbo (VGT).

- Improvements: Larger compressor and turbine wheels, robust conventional ball bearings, improved oiling and cooling, simplified exhaust flow.

- Performance: Significantly increased horsepower and torque (from 400hp/800lb-ft to 440hp/860lb-ft).

- Reliability: Much improved over its predecessor, becoming a staple for the platform.

Modern Marvels: GT37 VGT & Beyond (2020-Present)

For the 2020 model year and beyond, Ford continued to refine the 6.7 Powerstroke turbocharger, building on the success of the GT37 VGT. While the fundamental design remained similar, engineers made subtle but impactful changes to further enhance performance, efficiency, and durability. These revisions often involved updated compressor and turbine wheel aero, improved VGT actuation, and material enhancements to cope with the engine’s ever-increasing power output.

- Refinements: Optimized compressor and turbine wheel designs, improved VGT control for faster response, stronger materials.

- Power Gains: Contributed to further horsepower and torque increases (e.g., 475hp/1050lb-ft for 2020+ models).

- Focus: Enhanced low-end torque, better transient response, and sustained power under heavy loads, while meeting stricter emissions.

Dissecting the Beast: Core Turbocharger Components and Their Role

Understanding the internal workings of your 6.7 Powerstroke turbo helps in appreciating its engineering marvel and diagnosing potential issues. Each component plays a vital role in its overall function.

Compressor Wheel: Boosting Airflow

The compressor wheel is located on the intake side of the turbocharger. Its primary function is to draw in ambient air, compress it, and force it into the engine’s intake manifold. Made from lightweight yet durable aluminum, it spins at incredibly high RPMs (up to 150,000+). A larger compressor wheel generally means more air can be moved, translating to higher potential horsepower, but it can also increase turbo lag if not properly matched.

- Material: Typically billet aluminum for strength and light weight.

- Function: Draws in ambient air, compresses it, and delivers it to the engine.

- Impact: Directly influences the amount of boost pressure and overall airflow.

Turbine Wheel: Harvesting Exhaust Energy

On the exhaust side, the turbine wheel is driven by the hot, expanding exhaust gases exiting the engine. These gases spin the turbine, which in turn is connected by a shaft to the compressor wheel, making them spin together. The design of the turbine wheel and its housing are critical for efficient energy recovery and controlling exhaust backpressure. It must withstand extreme temperatures and corrosive exhaust gases.

- Material: High-nickel alloy (e.g., Inconel) for extreme heat resistance.

- Function: Converts exhaust gas energy into rotational force to drive the compressor.

- Impact: Affects spool time, exhaust backpressure, and overall turbo efficiency.

Center Housing Rotating Assembly (CHRA): The Heartbeat

The CHRA is the core of the turbocharger, containing the shaft that connects the compressor and turbine wheels, along with the bearings that allow them to spin freely at high speeds. These bearings are typically either journal bearings (hydrodynamic, relying on a film of oil) or more advanced ball bearings (less friction, faster spool). The 6.7 Powerstroke turbos rely on robust journal bearings in later models, while the early GT32 SST famously used ceramic ball bearings.

- Components: Shaft, bearings (journal or ball), oiling passages.

- Function: Supports the rotating assembly, provides lubrication and cooling.

- Maintenance: Crucial to maintain proper oil pressure and quality to prevent premature bearing failure.

Variable Geometry Turbocharger (VGT) Actuator: Precision Control

A defining feature of the 6.7 Powerstroke turbochargers is their Variable Geometry Turbocharger (VGT) system. Instead of a traditional wastegate, the VGT uses a series of movable vanes within the turbine housing. These vanes change the angle at which exhaust gases hit the turbine wheel. At low RPMs, the vanes close to restrict exhaust flow, making the turbo spool faster. At high RPMs, they open up for maximum flow and reduced backpressure. The VGT actuator, typically electronically controlled, precisely adjusts these vanes based on engine demands.

- Function: Optimizes turbo performance across the entire RPM range, reducing lag and enhancing efficiency.

- Control: Electronically controlled by the engine’s PCM (Powertrain Control Module).

- Common Issues: Carbon buildup can cause vanes to stick, leading to over-boosting or under-boosting.

Diving Deep into Specifications: Numbers That Matter

Understanding the specific measurements and characteristics of your 6.7 Powerstroke turbocharger is key to appreciating its design and comparing it with aftermarket options. While exact measurements can vary slightly by model year and manufacturing tolerances, here are typical specifications for the post-2015 GT37 VGT which is the most common and reliable unit.

Compressor Wheel Inducer/Exducer Diameters

The inducer is the smaller diameter of the compressor wheel where air enters, and the exducer is the larger diameter where air exits after compression. A larger exducer generally means more flow potential.

- Inducer Diameter: Typically around 61-63 mm

- Exducer Diameter: Typically around 83-85 mm

Turbine Wheel Inducer/Exducer Diameters

For the turbine wheel, the inducer is the larger diameter where exhaust gases enter, and the exducer is the smaller diameter where they exit.

- Inducer Diameter: Typically around 70-72 mm

- Exducer Diameter: Typically around 63-65 mm

A/R Ratios and Housing

The A/R (Area/Radius) ratio describes the geometric relationship of the turbocharger turbine housing and is critical for matching the turbo to the engine’s flow characteristics. A higher A/R generally results in less backpressure but slower spooling, while a lower A/R spools faster but can create more backpressure. VGT turbos effectively have a variable A/R, which is why they are so responsive.

- Turbine Housing: Integrated with the VGT mechanism, effectively providing a variable A/R ratio.

- Compressor Housing: Typically a cast aluminum housing, optimized for airflow.

Boost Pressure Ranges (Stock vs. Tuned)

The boost pressure generated by the turbocharger is a direct measure of its effectiveness.

- Stock Boost Pressure: Generally ranges from 28-35 psi under full load, depending on load, altitude, and year.

- Tuned Boost Pressure: With appropriate engine tuning and supporting modifications, boost can be safely increased to 40-45 psi, and even higher with upgraded turbos and extensive modifications (50+ psi). However, exceeding stock limits without proper tuning can lead to engine damage.

Flow Rates (Cubic Feet per Minute – CFM)

While precise CFM numbers for stock turbos are not always widely published by manufacturers, the 6.7 Powerstroke turbochargers are designed to move a substantial volume of air. The 2015+ GT37 VGT can support upwards of 500-600+ horsepower effectively in stock form, indicating a significant airflow capacity.

- Estimated Flow: Capable of moving enough air for the stock 440-475hp range, with some headroom for mild tuning.

Material Composition

The materials used are crucial for durability, especially given the extreme temperatures and pressures involved.

- Compressor Wheel: Billet aluminum for strength, light weight, and precise manufacturing.

- Turbine Wheel: High-nickel alloy (e.g., Inconel) for exceptional heat resistance (exhaust gases can reach 1500°F+).

- Housing: Cast iron for the turbine housing (heat resistance) and cast aluminum for the compressor housing (light weight).

Here’s a simplified table summarizing key approximate specifications for the more common post-2015 6.7 Powerstroke turbocharger:

| Component/Specification | Approximate Value | Notes |

|---|---|---|

| Compressor Inducer Diameter | ~61-63 mm | Air entry diameter |

| Compressor Exducer Diameter | ~83-85 mm | Air exit diameter |

| Turbine Inducer Diameter | ~70-72 mm | Exhaust entry diameter |

| Turbine Exducer Diameter | ~63-65 mm | Exhaust exit diameter |

| Stock Boost Pressure | 28-35 psi | Under full load, depends on year and conditions |

| VGT Type | Electronic Actuator | Variable Geometry Turbine |

| Bearing Type | Journal Bearings | For 2015+ models |

| Supported HP (Stock Turbo) | Up to ~600 HP (with tuning) | Varies with tuning and supporting mods |

Common Turbocharger Issues and Maintenance Tips

Even with robust designs, turbochargers are high-stress components. Recognizing signs of trouble and performing proactive maintenance can save you significant time and money.

Turbo Lag and Sluggish Performance

A noticeable delay between hitting the throttle and feeling the boost, or a general lack of power, can indicate a turbo problem. This might be due to a faulty VGT actuator, sticky VGT vanes (due to carbon buildup), a boost leak, or a failing turbo itself. For 6.7 Powerstroke engines, VGT issues are a common culprit for lag.

Excessive Smoke (Black, White, Blue)

- Black Smoke: Often indicates too much fuel for the amount of air, potentially due to insufficient boost from the turbo or clogged air filter.

- White Smoke: Can be unburnt fuel or coolant. If it smells sweet, it’s coolant; if it smells like raw fuel, it’s a fueling issue. Turbo problems can sometimes cause white smoke if the engine isn’t getting enough air.

- Blue Smoke: A tell-tale sign of burning oil. This is a critical indicator of a failing turbocharger seal (either compressor or turbine side) or internal engine wear. Address immediately.

Whining, Screeching, or Grinding Noises

Any abnormal noise from the turbocharger area is a red flag.

- Whining: Can indicate worn bearings or compressor wheel rub.

- Screeching/Grinding: Often signals significant internal damage, such as compressor or turbine wheels making contact with their housings, usually due to bearing failure.

Over-boosting or Under-boosting

The engine’s computer monitors boost pressure. If the turbo is consistently generating too much (over-boosting) or too little (under-boosting) boost, it will likely trigger a check engine light and put the truck into “limp mode.” This is almost always related to the VGT actuator or sticky VGT vanes.

Maintenance for Longevity: Oil Changes, Air Filters, EGT Monitoring

Proactive maintenance is the best defense against turbo failure.

- Regular Oil Changes: The turbocharger relies heavily on clean engine oil for lubrication and cooling. Use the manufacturer-recommended oil and adhere to strict change intervals. Dirty or degraded oil is a turbo killer.

- Quality Air Filters: A clean air filter ensures the turbo receives a steady supply of clean air, preventing foreign object damage (FOD) to the compressor wheel and maintaining optimal performance.

- Monitor EGTs (Exhaust Gas Temperatures): High EGTs are detrimental to the turbine wheel and internal turbo components. If you tow heavy or run performance tunes, an EGT gauge is a wise investment. Avoid shutting down the engine immediately after heavy loads; allow it to cool down to prevent “coking” of oil in the hot turbo.

- Check for Boost Leaks: Periodically inspect intercooler pipes and connections for cracks or loose clamps that can cause boost leaks, leading to under-performance.

- Inspect VGT Actuator: If you suspect VGT issues, a visual inspection of the actuator linkage can sometimes reveal problems, though diagnostic tools are usually required for proper assessment.

Upgrading Your 6.7 Powerstroke Turbo: Options and Considerations

For many 6.7 Powerstroke owners, the quest for more power and performance is unending. Upgrading your turbocharger can be one of the most impactful modifications, but it requires careful planning.

Why Upgrade? Performance Gains and Reliability

The primary reasons for a turbo upgrade include:

- Increased Horsepower & Torque: Unlock significantly more power for towing, racing, or daily driving.

- Improved Efficiency: A larger, more efficient turbo can sometimes improve fuel economy under certain driving conditions, especially when properly tuned.

- Enhanced Reliability: Replacing an older, failing stock turbo with a robust aftermarket unit can improve long-term reliability, particularly if you run aggressive tunes.

- Reduced EGTs: More efficient turbos can often lower exhaust gas temperatures, beneficial for engine longevity under load.

Drop-in Replacements vs. Compound Turbo Systems

- Drop-in Replacements: These turbos are designed to bolt directly into the stock location, often using larger compressor and turbine wheels within the stock-style housing. They offer a good balance of increased power with minimal installation fuss. Examples include “64mm” or “66mm” turbos that are larger than stock.

- Compound Turbo Systems: For extreme power, compound setups (two turbos, one small and one large, working in series) are popular. The smaller turbo spools quickly for low-end response, feeding the larger turbo for massive top-end power. These are complex, expensive, and require significant engine modifications.

Choosing the Right Turbo: Matching Your Goals

Selecting an upgrade requires understanding your specific needs:

- Daily Driver/Towing: Focus on quick spooling, broad powerband, and reasonable EGTs. A slightly larger drop-in turbo is often ideal.

- Performance/Racing: You might prioritize peak horsepower, even if it means some trade-off in low-end response. Larger single turbos or compound setups are considered here.

- Reliability Enhancement: If you’re running high power on a stock turbo, a more robust aftermarket unit designed for higher boost and flow might be a wise investment to prevent future failures.

Essential Supporting Modifications (Fueling, Tuning, Exhaust)

A turbo upgrade is rarely a standalone modification. To safely and effectively utilize a larger turbo, you’ll almost certainly need:

- Custom Tuning: Absolutely critical. Your engine’s computer must be reprogrammed to take advantage of the increased airflow, adjust fuel delivery, and manage boost. Without proper tuning, a new turbo can damage your engine.

- Fueling Upgrades: Higher horsepower requires more fuel. This might mean upgraded fuel injectors, a higher-pressure fuel pump, or a lift pump system to ensure consistent fuel supply.

- Exhaust System: A less restrictive exhaust (e.g., a 4-5 inch turbo-back exhaust) allows the turbo to breathe better, reducing backpressure and improving spool.

- Cold Air Intake (CAI): A high-flow air intake system helps the turbo ingest more cool, dense air.

- Intercooler Upgrades: More boost generates more heat. An upgraded intercooler efficiently cools the compressed air before it enters the engine, improving power and reducing EGTs.

- Transmission Upgrades: The stock 6R140 transmission is robust but can be overwhelmed by extreme power. For very high horsepower, transmission modifications might be necessary.

The Future of Forced Induction for the 6.7 Powerstroke

The innovation in diesel engine technology, particularly forced induction, continues at a rapid pace. For the 6.7 Powerstroke, the future likely holds even more refined and powerful turbocharger designs.

Advancements in Material Science

Expect to see lighter, stronger, and more heat-resistant materials for compressor and turbine wheels. This allows for higher rotational speeds, better efficiency, and increased durability under extreme conditions.

Electronic Wastegates and Precision Control

While current 6.7 Powerstroke turbos use electronically controlled VGTs, further integration of electronic wastegates and more sophisticated control algorithms will allow for even finer tuning of boost pressure and transient response, leading to instantaneous power delivery and improved fuel economy.

Hybrid Turbo Designs

Manufacturers and aftermarket companies are continuously experimenting with hybrid turbo designs, combining different features and technologies (e.g., combining journal bearings with a specialized ceramic ball bearing on one side, or electric assistance for ultra-fast spooling). Electric turbos, which use an electric motor to assist spooling at low RPMs before exhaust gases take over, are also an area of active development, promising to virtually eliminate turbo lag.

Conclusion: Mastering Your 6.7 Powerstroke Turbo

The 6.7 Powerstroke turbocharger is a marvel of modern engineering, directly responsible for the impressive power and efficiency of your truck. From its early GT32 SST iteration to the refined GT37 VGT of today, understanding its evolution, intricate specifications, and operational principles is crucial for any owner.

By delving into the core components, knowing the key 6.7 Powerstroke turbocharger specifications, and recognizing the signs of potential issues, you are better equipped to maintain your truck’s performance and ensure its longevity. Whether you’re committed to keeping your Powerstroke stock or planning an ambitious upgrade, treating your turbocharger with the respect it deserves—through diligent maintenance and informed decisions—will ensure your engine continues to deliver maximum power and reliability for years to come. Embrace the power, understand the tech, and keep your 6.7 Powerstroke roaring!

🎥 Related Video: Hidden Benefits Of The KC Turbos Warlock Retrofit Kit! – Saving Your 2011-2014 6.7 Powerstroke!

📺 KC TURBOS

Today we go over all of the fine details and benefits of the KC Turbos Warlock Retrofit Kit for your 2011-2014 6.7 Powerstroke!

Frequently Asked Questions

What type of turbocharger is standard on the 6.7 Powerstroke engine?

The 6.7 Powerstroke engine primarily utilizes a single sequential variable geometry turbocharger (VGT) from the factory. This sophisticated design allows for precise control over exhaust gas flow to the turbine, optimizing performance across a wide RPM range.

What are the main specifications of the 6.7 Powerstroke turbocharger?

Key specifications of the 6.7 Powerstroke turbocharger include its unique reverse-flow design, which integrates both the high-pressure and low-pressure sides into a single housing. It typically features a compressor wheel around 64mm, designed for quick spool-up and efficient boost delivery to support the engine’s impressive torque output.

What kind of boost pressure does the 6.7 Powerstroke turbocharger typically produce?

The 6.7 Powerstroke turbocharger can generate significant boost pressure, often reaching up to 30-35 PSI in stock applications, depending on engine load and RPM. This substantial boost is crucial for achieving the engine’s high horsepower and torque figures, especially in heavy-duty situations.

Can I upgrade the 6.7 Powerstroke turbocharger for more power?

Yes, many owners choose to upgrade their 6.7 Powerstroke turbocharger for increased horsepower and torque, particularly when running other engine modifications. Aftermarket turbochargers often feature larger compressor and turbine wheels or different designs to deliver higher boost and airflow, enhancing overall performance.

How does the variable geometry feature benefit the 6.7 Powerstroke turbocharger’s performance?

The variable geometry (VGT) technology in the 6.7 Powerstroke turbocharger significantly improves throttle response and reduces turbo lag. By precisely adjusting vanes to control exhaust flow, it effectively mimics having multiple turbo sizes, providing optimal boost at both low and high RPMs for a broader powerband.

What are common signs that my 6.7 Powerstroke turbocharger might be failing?

Common indicators of a failing 6.7 Powerstroke turbocharger include a noticeable loss of power, excessive blue or white smoke from the exhaust, and unusual whining or whistling noises from the engine bay. Increased oil consumption or a check engine light related to boost issues can also point to a problem.