6.7 Powerstroke Reduced Engine Power and Low Fuel Pressure Fix

Featured image for this comprehensive guide about 6.7 powerstroke reduced engine power low fuel pressure

Image source: drivepurepower.com

The open road, a heavy load, or just the daily grind – your Ford 6.7 Powerstroke is built to handle it all. It’s a workhorse, renowned for its incredible torque and reliability. But what happens when that mighty engine starts to stumble? What if you suddenly experience a dramatic decrease in performance, accompanied by the dreaded “Reduced Engine Power” message, and suspect low fuel pressure is the culprit? It’s a frustrating scenario that can leave any truck owner scratching their head, or worse, stranded.

You’re not alone. Issues related to 6.7 Powerstroke reduced engine power due to fuel delivery problems are more common than many owners realize. The complex high-pressure common rail fuel system, while incredibly efficient, can be susceptible to a range of issues that manifest as insufficient fuel pressure. This isn’t just about a drop in performance; it can lead to costly damage if left unaddressed. Understanding the intricacies of your truck’s fuel system and knowing how to diagnose and fix these problems is crucial for keeping your Powerstroke running strong.

This comprehensive guide is designed to empower you with the knowledge and actionable steps needed to tackle 6.7 Powerstroke low fuel pressure and restore your truck’s full potential. We’ll delve into the common causes, effective diagnostic techniques, and practical fixes, along with essential preventative maintenance tips. Get ready to understand your Powerstroke like never before and put an end to those power-robbing fuel system woes.

Quick Answers to Common Questions

What does it mean when my 6.7 Powerstroke shows “reduced engine power”?

This warning indicates your truck’s computer has detected an issue, often related to low fuel pressure, and is limiting engine performance to prevent potential damage. It’s your truck telling you something needs attention!

Why is my 6.7 Powerstroke suddenly experiencing low fuel pressure?

Low fuel pressure in your 6.7 Powerstroke often stems from common culprits like clogged fuel filters, a failing fuel pump, or issues with the fuel pressure regulator. These components are vital for maintaining proper fuel delivery.

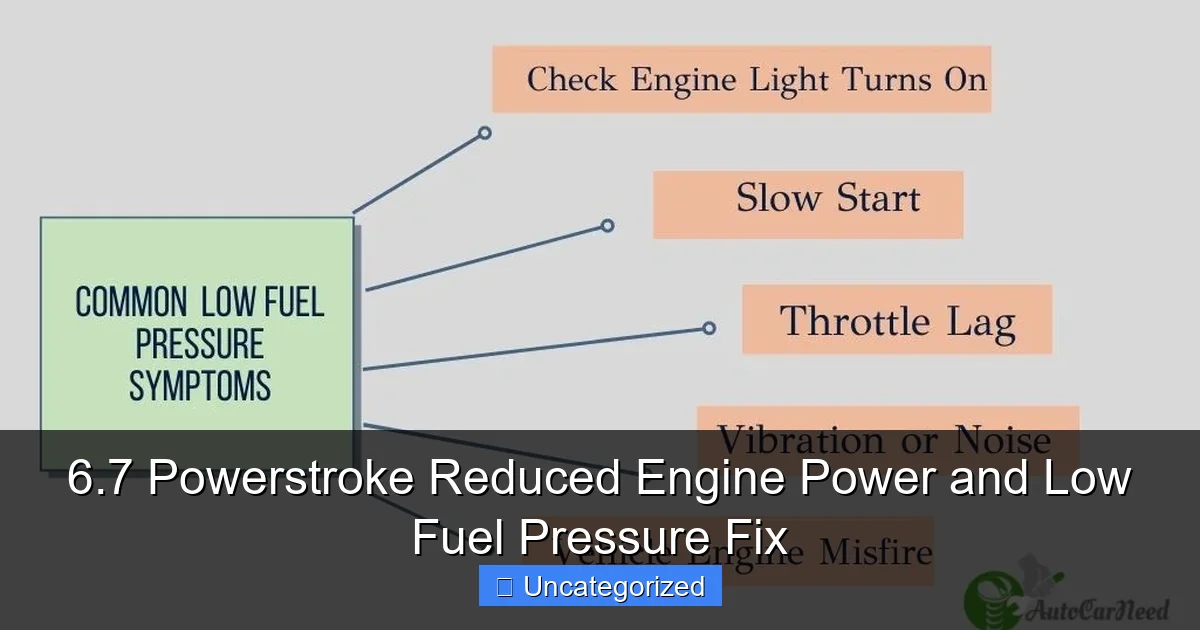

What are the common symptoms of low fuel pressure in a 6.7 Powerstroke besides the dash warning?

Beyond the “reduced engine power” alert, you might notice your 6.7 Powerstroke running rough, experiencing misfires, having difficulty starting, or a noticeable lack of acceleration and overall power. These are all signs your engine isn’t getting enough fuel.

Is it safe to drive my 6.7 Powerstroke if I have reduced engine power and low fuel pressure?

It’s generally not recommended to drive your 6.7 Powerstroke extensively with reduced engine power and low fuel pressure. Continued operation can lead to further, more expensive damage to critical components like the fuel injectors or high-pressure fuel pump.

What’s the very first thing I should check if my 6.7 Powerstroke has reduced engine power and low fuel pressure?

Your immediate priority should be to check and likely replace your fuel filters. They are a very common and relatively inexpensive point of failure that can cause significant low fuel pressure issues in your 6.7 Powerstroke.

📋 Table of Contents

- Understanding the 6.7 Powerstroke Fuel System: A High-Pressure World

- Common Causes of Low Fuel Pressure and Reduced Engine Power in Your 6.7 Powerstroke

- Diagnosing Low Fuel Pressure: What to Look For (and How to Test)

- Step-by-Step Fixes for 6.7 Powerstroke Low Fuel Pressure Issues

- Preventative Maintenance: Keeping Your 6.7 Powerstroke Running Strong

- Fuel Pressure Specifications & Component Cost Estimates (Data Table)

- Conclusion: Restore Your Powerstroke’s Roar

Understanding the 6.7 Powerstroke Fuel System: A High-Pressure World

To truly grasp why your 6.7 Powerstroke reduced engine power low fuel pressure issue occurs, you need a basic understanding of its sophisticated fuel system. Unlike older diesel engines, the 6.7L Powerstroke utilizes a high-pressure common rail (HPCR) system. This system delivers fuel to the injectors at extremely high pressures, allowing for precise fuel atomization and efficient combustion. It’s a marvel of engineering, but also a system with several critical components that must work in perfect harmony.

Learn more about 6.7 powerstroke reduced engine power low fuel pressure – 6.7 Powerstroke Reduced Engine Power and Low Fuel Pressure Fix

Image source: autocarneed.com

At the heart of the system are two main fuel pumps: the lift pump and the high-pressure fuel pump (HPFP). The lift pump, typically located in or near the fuel tank, draws fuel from the tank, filters it, and delivers it to the HPFP at a relatively low pressure (usually around 50-70 PSI). From there, the HPFP – the infamous Bosch CP4.2 pump – takes over, pressurizing the fuel to immense levels (up to 30,000 PSI or more) before sending it to the fuel rails. The fuel rails act as accumulators, distributing this high-pressure fuel to each individual fuel injector. Fuel pressure sensors monitor the pressure at various points, feeding data back to the Powertrain Control Module (PCM), which then precisely controls fuel delivery.

| Observed Symptom | Typical Fuel Pressure Reading (PSI) | Likely Root Cause | Recommended Diagnostic/Action |

|---|---|---|---|

| Reduced Engine Power (Limp Mode) | Below 45 PSI (under load) | Clogged Fuel Filters / Weak Lift Pump | Replace Fuel Filters, Test Lift Pump Output |

| Hard Starting / Extended Cranking | Fluctuating 45-60 PSI at crank | Failing Fuel Pressure Regulator / Small Leak | Inspect FPRV, Perform Air-in-Fuel Test |

| Engine Stalling / Rough Idle | Drops significantly below 40 PSI (intermittent) | Compromised Fuel Pump (Lift or HPFP) | Perform Fuel Volume/Pressure Test, Scan for HPFP Deviation |

| Diagnostic Trouble Code (P0087, P0088) | Actual vs. Desired Pressure Mismatch (ECM reports low) | HPFP Failure / Injector Leak / Pressure Sensor Fault | Check for External Leaks, Conduct Injector Return Flow Test |

This intricate dance of pumps, filters, sensors, and injectors means there are many potential points of failure that can lead to low fuel pressure. Whether it’s a minor sensor glitch or a catastrophic pump failure, any disruption in this finely tuned process can trigger reduced engine power, engine codes, and leave you in “limp mode.” Knowing these components is the first step in effective 6.7 Powerstroke troubleshooting.

Common Causes of Low Fuel Pressure and Reduced Engine Power in Your 6.7 Powerstroke

When your 6.7 Powerstroke reduced engine power low fuel pressure alert lights up, it’s a symptom, not the root cause. Pinpointing the actual culprit requires a systematic approach. Several common issues can lead to insufficient fuel pressure, and understanding these will guide your diagnostic process.

Learn more about 6.7 powerstroke reduced engine power low fuel pressure – 6.7 Powerstroke Reduced Engine Power and Low Fuel Pressure Fix

Image source: backyardmechanic.org

Clogged Fuel Filters

This is by far one of the most common and easily overlooked causes. The 6.7 Powerstroke has two fuel filters: a primary filter located on the frame rail and a secondary filter located on top of the engine. Both are critical for protecting the sensitive high-pressure components from contaminants. A clogged filter restricts fuel flow, starving the HPFP and causing a significant drop in pressure. Symptoms often include a gradual loss of power, hesitation, and eventually, reduced engine power notifications. This is often the first thing to check when experiencing 6.7 Powerstroke low fuel pressure.

Failing Lift Pump (Fuel Pump Module)

The lift pump (or fuel pump module, which integrates the pump and sender) is responsible for supplying the HPFP with a steady stream of fuel at adequate pressure. If this pump weakens or fails, it won’t be able to keep up with the demands of the HPFP, resulting in low fuel pressure throughout the system. Symptoms can include hard starting, especially after sitting, poor acceleration, and of course, reduced engine power messages.

High-Pressure Fuel Pump (HPFP) Issues (The CP4.2 Story)

The Bosch CP4.2 HPFP has gained notoriety among 6.7 Powerstroke owners. While it’s an efficient pump, it can be prone to premature failure, particularly when subjected to contaminated fuel or insufficient lubrication from low-sulfur diesel. When a CP4.2 begins to fail, it can shed metallic debris throughout the entire fuel system, leading to widespread damage including injectors, fuel rails, and other components. This is a catastrophic failure that results in very severe low fuel pressure and often prevents the engine from starting at all. The resulting repair can be extremely costly, often requiring a complete fuel system replacement.

Malfunctioning Fuel Pressure Sensors

The 6.7 Powerstroke has several fuel pressure sensors, including the fuel rail pressure (FRP) sensor. These sensors provide vital feedback to the PCM. If a sensor fails or provides inaccurate readings, the PCM might incorrectly interpret the fuel pressure, leading it to command incorrect fuel delivery, or trigger a reduced engine power mode even if actual pressure isn’t critically low. Sometimes, the issue isn’t truly low pressure, but a bad signal.

Fuel Injector Problems

While not a direct cause of low supply pressure, leaking or malfunctioning fuel injectors can cause a drop in fuel rail pressure. If an injector is stuck open or leaking excessively, it can bleed off pressure from the common rail, leading to insufficient pressure for other cylinders, resulting in engine misfires, poor performance, and potentially reduced engine power warnings.

Fuel Contamination or Air Intrusion

Water or other contaminants in your fuel can severely damage fuel system components, especially the HPFP and injectors. Air in the fuel system, perhaps from running out of fuel or a leaking fuel line, can also disrupt fuel flow and cause erratic pressure readings and performance issues.

Diagnosing Low Fuel Pressure: What to Look For (and How to Test)

Effective 6.7 Powerstroke troubleshooting for low fuel pressure begins with careful observation and proper diagnostic tools. Don’t just guess; systematically narrow down the possibilities to avoid costly and unnecessary repairs.

Initial Observations and Symptoms

- Reduced Engine Power / Limp Mode: The most obvious symptom, often accompanied by a dashboard warning light.

- Hard Starting or No Start: Especially if the problem is severe, the engine may crank but fail to fire.

- Poor Acceleration / Lack of Power: The truck feels sluggish, struggles to accelerate, especially under load.

- Engine Misfire / Rough Idle: Irregular engine operation can indicate inconsistent fuel delivery to cylinders.

- Excessive Smoke: White or blue smoke can indicate unburnt fuel due to insufficient pressure or injector issues.

- Check Engine Light (CEL): The PCM will often trigger a CEL with associated diagnostic trouble codes (DTCs) related to fuel pressure.

Key Diagnostic Steps and Tools

- Check for Diagnostic Trouble Codes (DTCs):

- Use an OBD-II scanner to read codes. Look for codes like P0087 (Fuel Rail/System Pressure – Too Low), P0088 (Fuel Rail/System Pressure – Too High), or other fuel pressure-related codes. These codes are your first major clue for fuel system diagnostics.

- Monitor Live Data (Fuel Pressure Readings):

- A capable scanner allows you to monitor live data, specifically fuel rail pressure (FRP) and low-pressure fuel pump (LPFP) pressure.

- Observe these values during cranking, idle, and under load.

- A healthy lift pump should provide around 50-70 PSI to the HPFP.

- Fuel rail pressure should build quickly during cranking (typically 3,000-5,000 PSI to start) and maintain high pressure (e.g., 25,000+ PSI under heavy acceleration). Significant deviations from expected values are a clear sign of 6.7 Powerstroke low fuel pressure.

- Visual Inspection of Fuel Filters:

- Remove and inspect both primary and secondary fuel filters. They should be replaced regularly (every 15,000-20,000 miles or as per Ford’s recommendations).

- Look for signs of heavy contamination, rust, or water in the fuel filter housing. This could indicate fuel contamination issues.

- Low-Pressure Fuel System Test (External Gauge):

- If your scanner doesn’t read low-side pressure, you can physically tap into the low-pressure fuel line (before the HPFP) with a mechanical fuel pressure gauge. This directly tests the health of the lift pump.

- Fuel Return Flow Test (Advanced):

- A high amount of fuel returning to the tank at idle can indicate leaking injectors or a pressure relief valve issue, which would cause a drop in rail pressure. This is a more advanced test usually performed by a qualified diesel technician.

Step-by-Step Fixes for 6.7 Powerstroke Low Fuel Pressure Issues

Once you’ve diagnosed the problem, it’s time for the fix. The approach to a 6.7 Powerstroke fuel pressure fix will depend entirely on your diagnosis. Always prioritize the easiest and most common fixes first.

1. Replace Fuel Filters (The First and Easiest Step)

If you haven’t replaced your fuel filters recently, this is your starting point. It’s inexpensive, relatively easy, and resolves many low fuel pressure issues.

- Purchase genuine Ford or high-quality aftermarket fuel filters (primary and secondary).

- Follow the manufacturer’s instructions for draining the water separator and replacing both filters. Be meticulous to avoid introducing air into the system.

- Prime the fuel system after replacement (usually by cycling the key several times without starting) to remove any air.

This simple fuel filter replacement can often restore full power.

2. Address Lift Pump (Fuel Pump Module) Failure

If diagnostics point to a failing lift pump:

- Replace the Fuel Pump Module: This typically involves dropping the fuel tank or accessing the top of the tank on certain models. This is a more involved repair and might require professional assistance.

- Consider Aftermarket Fuel Systems (FASS/AirDog): Many 6.7 Powerstroke owners upgrade to an aftermarket fuel system like FASS (Fuel Air Separation System) or AirDog. These systems provide superior filtration, remove air and water, and often deliver more consistent fuel pressure than the factory lift pump. They can significantly enhance fuel system longevity and performance, acting as a preventative measure against future low fuel pressure issues and even providing better protection for the HPFP.

3. Repair or Replace Fuel Pressure Sensors

If sensor readings are erratic or consistently out of spec, but other components seem fine:

- Verify Wiring: Check the sensor’s electrical connector and wiring for any signs of damage or corrosion.

- Replace the Sensor: If the sensor is indeed faulty, replacing the specific fuel pressure sensor (e.g., FRP sensor on the fuel rail) is usually a straightforward task, though accessing it may require some engine bay dexterity. Always use OEM or high-quality aftermarket sensors.

4. Dealing with Fuel Injector Issues

If you’ve identified a leaking or faulty injector:

- Injector Replacement: Depending on the severity and number of faulty injectors, this can range from replacing a single injector to an entire set. Injector replacement is a precise job that requires special tools and careful attention to detail to avoid damaging other components or introducing contaminants.

- Injector Testing: Professional shops can perform “balance rates” or “contribution tests” to identify specific underperforming injectors.

5. The Dreaded HPFP (CP4.2) Failure

If your diagnostics confirm a catastrophic HPFP failure (especially if you see metal in the fuel filter):

- Complete Fuel System Replacement: This is a major, costly repair. A CP4.2 failure typically sheds metal throughout the entire fuel system, meaning the HPFP, fuel rails, fuel lines, injectors, and often the lift pump and fuel tank need to be replaced and thoroughly flushed to prevent immediate re-contamination. This is why prevention is paramount.

- Consider CP4.2 Bypass Kit: Some aftermarket solutions offer a “Disaster Prevention Kit” or “CP4 Bypass Kit” designed to isolate the HPFP from the rest of the fuel system in the event of a failure, preventing metal debris from contaminating the entire system. While it won’t prevent the pump from failing, it can significantly reduce the repair cost if it does.

Preventative Maintenance: Keeping Your 6.7 Powerstroke Running Strong

Prevention is always better (and cheaper) than repair, especially when it comes to the complex 6.7 Powerstroke fuel system. Proactive maintenance is key to avoiding 6.7 Powerstroke reduced engine power low fuel pressure issues.

- Regular Fuel Filter Replacement: This cannot be stressed enough. Follow Ford’s recommended service intervals (typically 15,000-20,000 miles or annually) religiously, or even more frequently if you tow heavy loads, use questionable fuel sources, or drive in dusty conditions. Always use high-quality filters.

- Use Quality Diesel Fuel: Source your fuel from reputable stations. Avoid “bargain” diesel. The lubrication properties of modern diesel fuel are critical for the longevity of your HPFP and injectors.

- Add a Quality Fuel Additive: Many diesel owners swear by fuel additives that provide additional lubrication (especially for the HPFP) and cetane boost. Look for additives that specifically address lubricity and moisture removal.

- Avoid Running Your Tank Dry: Repeatedly running your fuel tank to empty increases the chances of picking up sediment from the bottom of the tank and potentially sucking air into the fuel system, both of which are detrimental.

- Consider Aftermarket Fuel Filtration/Lift Pump Systems: Investing in a FASS or AirDog system can significantly upgrade your fuel filtration, improve fuel delivery, and extend the life of your factory components, providing peace of mind against HPFP failure and low fuel pressure problems.

- Regularly Drain Water Separator: The primary fuel filter assembly includes a water separator. Drain it regularly (e.g., with every oil change or every few thousand miles) to remove any accumulated water, which can be highly damaging to the fuel system.

Fuel Pressure Specifications & Component Cost Estimates (Data Table)

Understanding the expected fuel pressure values and having an idea of component costs can aid in both diagnosis and budgeting for repairs related to 6.7 Powerstroke low fuel pressure.

| Component/Parameter | Normal Operating Range (Approximate) | Estimated Replacement Cost (Parts Only, USD) |

|---|---|---|

| Low Pressure Fuel Pump (Lift Pump) Output | 50-70 PSI (at idle/WOT) | $300 – $700 |

| Fuel Rail Pressure (Idle) | ~3,000 – 6,000 PSI | N/A (system parameter) |

| Fuel Rail Pressure (WOT/Under Load) | ~20,000 – 30,000+ PSI | N/A (system parameter) |

| Primary & Secondary Fuel Filters (Set) | N/A (wear item) | $70 – $150 |

| Fuel Rail Pressure (FRP) Sensor | N/A (measures pressure) | $150 – $300 |

| Fuel Injector (Single) | N/A (fuel delivery) | $300 – $600+ (each) |

| High-Pressure Fuel Pump (HPFP – CP4.2) | N/A (generates pressure) | $1,000 – $2,500+ |

| Complete Fuel System (HPFP Failure) | N/A (entire system) | $7,000 – $12,000+ |

| Aftermarket Lift Pump/Filtration System (e.g., FASS/AirDog) | Improved filtration & pressure | $600 – $1,000+ |

Note: These costs are estimates for parts only and can vary significantly based on brand, retailer, region, and labor rates. A complete HPFP failure often necessitates a full system replacement due to metal contamination.

Conclusion: Restore Your Powerstroke’s Roar

Experiencing 6.7 Powerstroke reduced engine power low fuel pressure can be a daunting experience, signaling potentially serious issues within your truck’s sophisticated fuel system. From easily overlooked clogged filters to the catastrophic failure of the HPFP, the range of possible causes is wide. However, by understanding your fuel system’s components, diligently performing diagnostics, and committing to proactive maintenance, you can effectively address these challenges and ensure your Powerstroke remains the powerful, reliable truck it was designed to be.

Remember, don’t ignore the warning signs. A quick diagnosis and timely repair can save you significant time, money, and headaches down the road. Regular fuel filter replacement, using quality fuel, and considering aftermarket enhancements are your best defenses against low fuel pressure issues. If you’re unsure, don’t hesitate to consult with a qualified diesel mechanic. Take charge of your Powerstroke’s health, and you’ll be back to enjoying its full potential on every journey. Keep your fuel clean, your pressure high, and your 6.7 Powerstroke will keep delivering that legendary performance you depend on!

Frequently Asked Questions

What are the common causes of reduced engine power and low fuel pressure in a 6.7 Powerstroke?

This issue often stems from a failing fuel pump (like the lift pump or High-Pressure Fuel Pump – HPFP), severely clogged fuel filters, or a leaking fuel line/injector. Contaminated fuel can also contribute significantly to these problems, impacting the entire fuel delivery system.

What symptoms indicate my 6.7 Powerstroke has low fuel pressure and reduced engine power?

You might notice your truck entering “limp mode,” experiencing a significant loss of acceleration, or struggling to maintain speed. Other signs include the “Reduced Engine Power” message on your dash, rough idling, misfires, or even stalling.

Is it safe to drive my 6.7 Powerstroke with reduced engine power and low fuel pressure?

It is generally not safe to continue driving your 6.7 Powerstroke under these conditions. Low fuel pressure can starve critical components like the High-Pressure Fuel Pump (HPFP), potentially causing extensive and very expensive damage to the entire fuel system.

What are the first steps I should take to diagnose low fuel pressure in my 6.7 Powerstroke?

Begin by checking your fuel filter(s) for clogs and ensuring they’ve been replaced according to the manufacturer’s schedule. Next, consider checking actual fuel pressure with a diagnostic tool or gauge if possible, and inspect for any visible fuel leaks in the lines or at the injectors.

What is the typical fix for a 6.7 Powerstroke experiencing reduced engine power due to low fuel pressure?

The fix often involves replacing clogged fuel filters, diagnosing and replacing a failing lift pump or High-Pressure Fuel Pump (HPFP), or addressing fuel line leaks. In some severe cases, contaminated fuel might necessitate flushing the entire fuel system and replacing affected components.

How can I prevent future occurrences of low fuel pressure in my 6.7 Powerstroke?

Regular and timely replacement of fuel filters, using high-quality diesel fuel, and considering an aftermarket fuel-water separator system are crucial preventative measures. Additionally, avoid consistently running your fuel tank extremely low, as this can put added strain on the fuel pump.