6.0 Powerstroke Timing Specifications: Perfecting Your Engine’s Performance

Featured image for this comprehensive guide about 6.0 Powerstroke timing specs

The Ford 6.0 Powerstroke diesel engine, despite its initial controversies, has earned a reputation for formidable power and torque when properly maintained. At the heart of its performance lies a sophisticated system of engine timing – not just a simple mechanical setting, but a complex, dynamic dance orchestrated by the engine's control module. Understanding the intricacies of 6.0 Powerstroke timing specifications is not merely academic; it's crucial for diagnosing issues, optimizing performance, and ensuring the longevity of your investment.

Many diesel enthusiasts and mechanics often grapple with the nuances of how these powerful engines operate. Unlike older, mechanically timed diesels, the 6.0 Powerstroke relies heavily on electronic sensors, high-pressure oil, and precise fuel delivery to achieve its combustion cycle. When any component within this intricate system falters, the ripple effect can lead to decreased power, poor fuel economy, hard starting, or even catastrophic engine damage. This comprehensive guide will pull back the curtain on the world of 6.0 Powerstroke timing, offering a deep dive into its components, operational parameters, and essential diagnostic insights.

Whether you're a seasoned Powerstroke owner looking to fine-tune your rig, a DIY mechanic tackling a new challenge, or simply curious about what makes these engines tick, this post will provide you with the knowledge needed to approach 6.0 Powerstroke timing specifications with confidence. We'll explore the critical components, discuss common issues, and arm you with actionable tips to keep your Powerstroke running at its peak, perfectly synchronized and powerfully efficient.

Quick Answers to Common Questions

Why are 6.0 Powerstroke timing specs so important?

Proper 6.0 Powerstroke timing specs are crucial for optimal engine performance, fuel efficiency, and to prevent serious engine damage. It ensures the fuel injectors fire at precisely the right moment for efficient combustion.

What happens if my 6.0 Powerstroke timing is off?

If your 6.0 Powerstroke timing is incorrect, you might experience reduced power, poor fuel economy, rough idling, increased emissions, and even engine damage over time. It can severely impact your engine's health and longevity.

Can I adjust the 6.0 Powerstroke timing specs myself?

While some basic checks can be done, adjusting the precise 6.0 Powerstroke timing specs often requires specialized tools and expertise. It's generally best left to experienced technicians to ensure accuracy and prevent costly mistakes.

What's the biggest challenge with 6.0 Powerstroke timing specs?

The primary challenge often lies in the intricate interplay of the camshaft and crankshaft sensors, along with the precise nature of the high-pressure oil and fuel injection system. Getting the 6.0 Powerstroke timing specs exactly right is critical for this engine.

How can I tell if my 6.0 Powerstroke timing needs attention?

Look out for symptoms like a noticeable loss of power, excessive smoke from the exhaust (especially white or blue), unusually loud engine knocking or clicking, or a significant drop in fuel economy. These can all be signs that your 6.0 Powerstroke timing specs might be off.

📋 Table of Contents

- Understanding the Heartbeat: What is Engine Timing?

- The Complex Dance: Key Components of 6.0 Powerstroke Timing

- Deciphering the 6.0 Powerstroke Timing Specifications

- Common Timing-Related Issues in the 6.0 Powerstroke

- Diagnosing Timing Problems: Tools and Techniques

- Maintaining Optimal Timing: Proactive Steps and Best Practices

- Conclusion

Understanding the Heartbeat: What is Engine Timing?

At its core, engine timing refers to the precise synchronization of several key events within an internal combustion engine to ensure optimal performance. For a diesel engine like the 6.0 Powerstroke, this primarily involves two critical aspects:

- Valve Timing: The opening and closing of the intake and exhaust valves relative to the piston's position in the cylinder. This controls the flow of air into and exhaust gases out of the combustion chamber.

- Fuel Injection Timing: The exact moment fuel is injected into the combustion chamber relative to the piston's compression stroke. In a diesel engine, this is paramount, as ignition is achieved through compression, not a spark plug. Injecting fuel at the wrong time can lead to incomplete combustion, wasted fuel, reduced power, and excessive exhaust temperatures.

The 6.0 Powerstroke takes this concept to another level with its "Hydraulic Electronic Unit Injector" (HEUI) system, where high-pressure engine oil is used to actuate the fuel injectors. This means that maintaining optimal oil pressure and flow is directly linked to precise fuel injection timing and, consequently, overall engine timing. The engine's computer (PCM – Powertrain Control Module) continuously monitors various sensors and makes real-time adjustments to injection timing, injection duration, and turbocharger VGT (Variable Geometry Turbocharger) position to optimize power, emissions, and fuel efficiency across all operating conditions. This dynamic control means there isn't a single static "6.0 Powerstroke timing spec" in the way older engines had a fixed distributor timing mark.

| Parameter | Typical Value / Range | Notes / Condition |

|---|---|---|

| CKP/CMP Synchronization Status | Synchronized | Essential for PCM to determine engine position and enable injection. |

| ICP (Injection Control Pressure) at Idle | 500 - 600 PSI | Hot idle, in gear (automatic). Directly influences injector firing pressure. |

| IPR (Injection Pressure Regulator) Duty Cycle at Idle | 23 - 35% | Hot idle, in gear (automatic). Higher values can indicate HPOP/oil leak issues. |

| FICM (Fuel Injection Control Module) Voltage (KOEO) | 47.5 - 48.5 V | Key On, Engine Off. Critical for injector solenoid activation timing and strength. |

| Cylinder Contribution Test (CCT) Status | All Cylinders "PASS" | Indicates balanced power delivery and correct individual injector timing/fueling. |

The Complex Dance: Key Components of 6.0 Powerstroke Timing

Achieving precise engine timing in the 6.0 Powerstroke is a collaborative effort involving numerous components. A malfunction in any one of these can throw the entire system out of sync, leading to noticeable performance degradation.

High-Pressure Oil Pump (HPOP) System

The HEUI system relies on high-pressure oil, generated by the HPOP, to actuate the fuel injectors. The HPOP takes oil from the crankcase and pressurizes it, sending it to the oil rails. This pressurized oil then travels to each injector, where it's used to push the fuel into the combustion chamber at pressures exceeding 20,000 PSI.

- Importance: Without adequate HPOP pressure, the injectors cannot fire correctly, directly impacting fuel injection timing and duration.

- Common Issue: HPOP failures, STC (Standpipe and Dummy Plug) issues, or leaks in the high-pressure oil system can lead to no-starts or severe power loss.

Injector Pressure Regulator (IPR) Valve

The IPR valve is a crucial component that controls the amount of oil pressure the HPOP delivers to the injectors. It's an electronically controlled solenoid that the PCM commands to regulate the oil pressure in the high-pressure oil system.

- Role in Timing: By precisely controlling oil pressure, the IPR directly influences the timing and force of fuel injection. A sticking or failing IPR can cause erratic injection timing, leading to rough idle, hard starting, or stalling.

Injector Control Pressure (ICP) Sensor

The ICP sensor measures the actual oil pressure in the high-pressure oil system and sends this data back to the PCM. The PCM uses this feedback to adjust the IPR valve, maintaining the desired injection pressure.

- Feedback Loop: This sensor is vital for the PCM to accurately command and confirm the correct injection pressure, thereby ensuring consistent and accurate fuel injection timing.

- Common Issue: A faulty ICP sensor can send incorrect readings, leading the PCM to mismanage injection pressure, resulting in various drivability issues.

Camshaft Position (CMP) and Crankshaft Position (CKP) Sensors

These two sensors are the eyes and ears of the PCM, providing critical information about the engine's rotational position and speed. The CMP sensor tracks the camshaft, while the CKP sensor tracks the crankshaft.

- Synchronization: The PCM uses signals from both the CMP and CKP sensors to determine the exact position of each piston and the engine's overall speed. This information is absolutely critical for calculating and commanding precise fuel injection timing and duration, as well as valve operation.

- Failure Impact: A failing CMP or CKP sensor can cause a no-start condition, rough running, or erratic engine behavior because the PCM loses its ability to synchronize the engine's operations.

Variable Geometry Turbocharger (VGT) System

The 6.0 Powerstroke features a VGT, which uses movable vanes to alter exhaust gas flow through the turbine. This allows the turbocharger to spool up quickly at low RPMs (reducing lag) and maintain efficiency at high RPMs.

- Indirect Timing Influence: While not directly controlling fuel injection, the VGT system significantly impacts engine breathing and exhaust back pressure. Proper VGT operation is essential for efficient combustion, which in turn affects how the PCM fine-tunes injection timing for optimal performance and emissions.

- Common Issue: Sticking VGT vanes or a faulty VGT solenoid can lead to over-boosting, under-boosting, or sluggish throttle response.

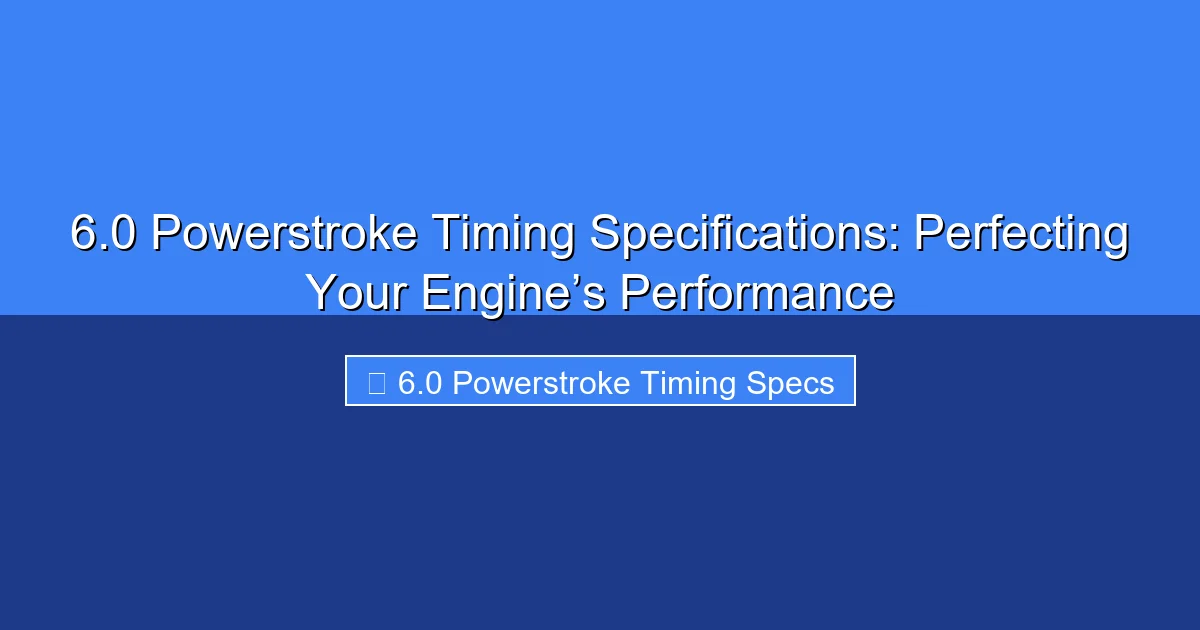

Deciphering the 6.0 Powerstroke Timing Specifications

As mentioned, the 6.0 Powerstroke timing specs aren't a fixed degree setting but rather a set of operational parameters and diagnostic values that indicate healthy operation. The PCM constantly adjusts fuel injection timing based on load, RPM, temperature, and other factors. Instead of a single "timing spec," we look at the dynamic ranges and relationships between various sensor readings.

Key Parameters and Their Normal Operating Ranges

When diagnosing 6.0 Powerstroke timing, technicians use a diagnostic scanner (like Ford IDS or FORScan) to monitor live data from the PCM. Here are some critical parameters and their typical normal ranges (these can vary slightly based on engine load, temperature, and specific calibration):

- ICP Pressure (psi):

- Idle (warm): 500-750 psi (approx.)

- WOT (Wide Open Throttle): 3,000-4,000+ psi

- Cranking: Minimum 500 psi required for starting.

Impact on Timing: Low ICP pressure directly prevents proper injector actuation, causing misfires or no-starts. High ICP can indicate IPR issues.

- IPR Duty Cycle (%):

- Idle (warm): 20-30%

- WOT: 60-85%

- Cranking: Can be higher (e.g., 35-50%) to build initial pressure.

Impact on Timing: The IPR duty cycle is the PCM's command for ICP. A high IPR duty cycle at idle (e.g., over 35%) might indicate an internal high-pressure oil leak or a failing HPOP, impacting pressure and therefore timing.

- Fuel Pulse Width (FPW) (ms):

- Idle (warm): 1.5-2.5 ms

- WOT: 3.0-5.0+ ms (depends heavily on load and RPM)

Impact on Timing: FPW is the duration the injector is open. While not "timing" in terms of ignition point, it's crucial for correct combustion and performance. Incorrect FPW can point to injector issues or PCM errors.

- VGT Duty Cycle (%):

- Idle (warm): ~65-85% (vanes mostly closed for quicker spool)

- Cruising: Varies widely based on load, speed, and desired boost.

- WOT: ~20-30% (vanes more open for maximum flow)

Impact on Timing: Optimal VGT operation ensures the engine is breathing efficiently. Incorrect VGT positioning can lead to inadequate cylinder filling or excessive backpressure, forcing the PCM to adjust injection timing sub-optimally.

- Engine Oil Temperature (EOT) & Engine Coolant Temperature (ECT) (°F):

- Operating Range: 190-230°F. EOT should generally be within 10-15°F of ECT.

Impact on Timing: The PCM uses temperature data to adjust fuel trims and injection timing, especially during warm-up and to manage engine efficiency. Excessive delta between EOT and ECT can indicate oil cooler issues, impacting overall engine health and indirect timing.

Data Table: Key 6.0 Powerstroke Timing-Related Parameters and Diagnostic Values

Below is a quick reference for common diagnostic values. Remember, these are typical ranges and can vary. Always consult a factory service manual for precise specifications.

| Component/Parameter | Typical Idle Range (Warm Engine) | Typical WOT Range | Impact on Timing/Performance |

|---|---|---|---|

| ICP Pressure (psi) | 500-750 | 3,000-4,000+ | Directly controls injector actuation. Low pressure = no fire/misfire. |

| IPR Duty Cycle (%) | 20-30% | 60-85% | PCM's command for ICP. High duty cycle at idle indicates leaks or HPOP issues. |

| Fuel Pulse Width (ms) | 1.5-2.5 | 3.0-5.0+ | Duration of fuel injection. Incorrect duration affects power and efficiency. |

| VGT Duty Cycle (%) | 65-85% | 20-30% | Controls turbocharger boost. Affects engine breathing and overall efficiency. |

| EOT/ECT Delta (°F) | +/- 15°F | +/- 15°F | Indicates oil cooler health. High delta impacts oil integrity and engine longevity. |

Common Timing-Related Issues in the 6.0 Powerstroke

Given the complexity of the 6.0 Powerstroke's timing system, several common failure points can disrupt its precise operation:

- Sticking IPR Valve: One of the most common culprits. A contaminated or failing IPR can stick open or closed, leading to low or no ICP pressure. Symptoms include hard starting (especially when hot), rough idle, stalling, or a complete no-start.

- Failing HPOP or Leaks in High-Pressure Oil System: The HPOP itself can fail, or leaks can develop in the standpipes, dummy plugs, or branch tube. This results in insufficient oil pressure to actuate the injectors, causing extended crank times, no-start conditions, or reduced power.

- Faulty ICP Sensor: If the ICP sensor sends inaccurate readings, the PCM will try to compensate by adjusting the IPR valve incorrectly, leading to erratic engine behavior, misfires, or stalling. Sometimes, oil can seep into the sensor's connector, causing problems.

- Cam/Crank Sensor Failures: These critical sensors provide the foundational data for the PCM to time injections. A failure in either can lead to a no-start, rough running, or the engine dying unexpectedly while driving. They can be intermittent.

- Injector Failures: While not strictly "timing," a failed or worn injector (stuck open, stuck closed, or poor spray pattern) significantly impacts combustion timing for that cylinder. This leads to misfires, white smoke, or excessive fuel dilution in the oil.

- FICM (Fuel Injection Control Module) Issues: The FICM is responsible for boosting voltage to the injectors, ensuring they fire quickly and efficiently. Low FICM voltage (below 48V) can severely impact injector performance and, by extension, fuel injection timing, causing hard starts, rough running, and power loss.

Diagnosing Timing Problems: Tools and Techniques

Accurate diagnosis is paramount when troubleshooting 6.0 Powerstroke timing specifications. A shotgun approach of replacing parts without proper diagnosis can be costly and frustrating. Here’s how skilled technicians approach it:

1. Diagnostic Scan Tool (Ford IDS, FORScan, AutoEnginuity)

This is your most important weapon. A capable scan tool allows you to:

- Read DTCs (Diagnostic Trouble Codes): While codes don't always tell the whole story, they provide a starting point.

- Monitor Live Data: View all the parameters mentioned above (ICP, IPR, FPW, VGT, CMP, CKP, EOT, ECT, FICM voltage, etc.) in real-time. Look for values outside the normal operating ranges, or values that are erratic.

- Perform Bi-directional Controls: Command the IPR to a specific duty cycle, test VGT actuator function, or perform injector "buzz tests" to listen for injector solenoid operation.

- Crank/No-Start Diagnostics: Monitor ICP pressure and IPR duty cycle during cranking to determine if the engine is building sufficient high-pressure oil.

2. Visual Inspection

Don't underestimate the power of a thorough visual inspection:

- Check for oil leaks, especially around the ICP sensor or HPOP cover.

- Inspect wiring harnesses and connectors for damage, chafing, or corrosion.

- Look for signs of fuel leaks or air intrusion in the fuel system.

- Check oil and coolant levels and condition.

3. Pressure Gauges and Multimeter

- High-Pressure Oil Gauge: While the ICP sensor provides a digital reading, sometimes a mechanical gauge can offer an independent verification of high-pressure oil (HPO) system integrity.

- Fuel Pressure Gauge: Confirm adequate fuel supply pressure (typically 45-70 psi at the secondary fuel filter housing). Low fuel pressure can mimic HPO issues.

- Multimeter: Test wiring for continuity, resistance, and voltage drops, especially to the FICM and IPR valve.

4. Relative Compression Test

While not directly a "timing" test, low compression in one or more cylinders can drastically affect how the engine runs and how the PCM tries to compensate with fuel injection timing. This can be done with a specialized diagnostic tool.

Maintaining Optimal Timing: Proactive Steps and Best Practices

Preventative maintenance is the cornerstone of keeping your 6.0 Powerstroke's complex timing system in top shape. Proactive steps can save you from costly repairs down the road.

- Regular Oil Changes with Quality Oil: The HPO system runs on engine oil. Contaminated, degraded, or incorrect viscosity oil can lead to premature wear of the HPOP, IPR valve, and injectors. Use only CJ-4 or CK-4 rated 15W-40 or 5W-40 synthetic diesel engine oil. Adhere to Ford's recommended intervals (typically 5,000-7,500 miles, or sooner for heavy-duty use).

- Maintain Clean Fuel Filters: Clogged fuel filters restrict fuel flow to the injectors, causing low fuel pressure and potentially impacting injection timing and duration. Replace both primary and secondary fuel filters every 10,000-15,000 miles, or as recommended by Ford.

- Monitor FICM Voltage: Periodically check your FICM voltage, especially if you experience cold-start issues or rough running. Maintain it above 48V. There are aftermarket monitors available that plug into the OBD-II port.

- Address Oil Cooler Issues Promptly: A failing oil cooler not only causes EOT/ECT delta but also contaminates the engine oil with coolant, accelerating wear on HPOP, IPR, and injectors. Preventative maintenance on the oil cooler (flushing or replacement with an upgraded unit) is highly recommended.

- Use OEM or High-Quality Aftermarket Parts: When replacing critical components like the IPR valve, ICP sensor, HPOP, or injectors, invest in reputable parts. Sub-standard components often fail prematurely, leading to repeated issues and headaches.

- Regular Diagnostic Monitoring: Even without a check engine light, occasionally hooking up a scan tool and reviewing live data can provide early warnings of component degradation. Learning your truck's "normal" operating parameters can help you spot deviations quickly.

Conclusion

Mastering the 6.0 Powerstroke timing specifications is less about memorizing static numbers and more about understanding a dynamic, interconnected system. From the high-pressure oil that actuates the injectors to the precise signals from the camshaft and crankshaft sensors, every component plays a vital role in the engine's intricate dance of combustion. By understanding these components, knowing their normal operating ranges, and recognizing the symptoms of common failures, you can effectively diagnose and address issues before they escalate.

The 6.0 Powerstroke, when given the care and attention it deserves, is a robust and powerful engine. Embracing proactive maintenance, utilizing the right diagnostic tools, and relying on quality parts are your best defenses against timing-related woes. Keep your Powerstroke's heartbeat perfectly synchronized, and it will reward you with years of reliable performance, powering you through every mile with unwavering strength and efficiency. Understanding 6.0 Powerstroke timing isn't just about repairs; it's about unlocking the full potential of your truck.

🎥 Related Video: How to correct engine valve clearances?😳😲 #shorts

📺 Mechanic Repair Team

How to correct engine valve clearances? valve clearance,engine,how to adjust valve clearance,how to set valve lash,valve …

Frequently Asked Questions

What are the general 6.0 Powerstroke timing specifications?

Unlike older engines with static timing, the 6.0 Powerstroke’s timing refers to the precise relative phasing between the crankshaft and camshaft. This correlation ensures the valves open and close, and the injectors fire at the exact optimal moment for efficient combustion and peak performance.

Why is accurate 6.0 Powerstroke timing so crucial for engine performance?

Precise timing is vital because it directly impacts fuel injection events and valve actuation, which in turn dictate combustion efficiency, power output, and fuel economy. Even slight discrepancies in 6.0 Powerstroke timing can lead to significant performance degradation, increased emissions, and potential engine damage.

What are the signs of incorrect 6.0 Powerstroke timing?

Symptoms of incorrect timing can include reduced engine power, poor fuel economy, rough idle, hard starting, or increased exhaust smoke. You might also encounter diagnostic trouble codes (DTCs) related to cam/crank correlation, indicating that the engine’s internal synchronization is off.

How is the 6.0 Powerstroke timing set or confirmed?

Physical timing is set during engine assembly by aligning specific marks on the camshaft and crankshaft gears, often requiring specialized alignment tools. Electronically, the Powertrain Control Module (PCM) monitors the Crankshaft Position (CKP) and Camshaft Position (CMP) sensors to confirm correct correlation during operation.

What are common 6.0 Powerstroke timing-related problems to watch out for?

Common issues include wear or stretch in the timing chain, damage to the timing gears, or failures of the crankshaft or camshaft position sensors. These component degradations can disrupt the precise synchronization of the engine, leading to various performance problems.

Are there special tools required for checking or adjusting 6.0 Powerstroke timing specs?

Yes, for diagnosing and verifying 6.0 Powerstroke timing, a diagnostic scan tool capable of reading live data for cam/crank correlation PIDs is essential. For physical adjustments or component replacement during engine repair, specialized alignment tools are required to ensure precise camshaft and crankshaft positioning.