6.0 Powerstroke Injector Flow Rate Specifications

Featured image for this comprehensive guide about 6.0 Powerstroke injectors flow rate

6.0 Powerstroke Injector Flow Rate Specifications

For any enthusiast or owner of a Ford 6.0 Powerstroke diesel engine, understanding the intricate workings of its fuel system is paramount. At the heart of this system are the injectors, precision components responsible for delivering fuel to the combustion chamber. Their performance, particularly their 6.0 Powerstroke injectors flow rate, dictates everything from horsepower and torque to fuel efficiency and engine longevity. Whether you’re chasing more power, diagnosing a rough idle, or simply striving to maintain peak performance, a deep dive into injector specifications is essential.

The 6.0 Powerstroke is legendary for its raw power and, at times, its complexity. The injectors in these engines are not simple mechanical devices; they are sophisticated, oil-fired components that rely on a delicate balance of high-pressure oil and precise electrical signals. This intricate design means that even slight deviations in Powerstroke injector flow can lead to significant operational issues or untapped potential. This comprehensive guide will explore the fundamental aspects of 6.0 Powerstroke injectors flow rate, from stock specifications to common problems and the exciting world of aftermarket upgrades.

Join us as we demystify the numbers, explain the technology, and provide actionable insights to help you get the most out of your 6.0 Powerstroke. Understanding these specifications isn't just for mechanics; it's for any owner who wants to be informed, empowered, and truly in control of their diesel machine.

Quick Answers to Common Questions

What is the stock 6.0 Powerstroke injectors flow rate?

The factory 6.0 Powerstroke injectors typically have a flow rate around 135-140cc (cubic centimeters). This is the standard for stock performance and emissions compliance.

Why would someone want to change their 6.0 Powerstroke injectors flow rate?

Upgrading your 6.0 Powerstroke injectors flow rate is usually done to increase horsepower and torque, especially when paired with other performance modifications like a larger turbo or custom tuning. More fuel means more power!

How do different 6.0 Powerstroke injectors flow rate options impact performance?

Higher 6.0 Powerstroke injectors flow rates deliver more fuel into the combustion chamber, directly translating to more potential power. However, it's crucial to match the flow rate to your engine's needs and tuning to avoid issues.

Do higher 6.0 Powerstroke injectors flow rates hurt fuel economy?

Not necessarily! While they can deliver more fuel, a properly tuned engine with a larger flow rate can sometimes maintain decent fuel economy under normal driving, though aggressive driving will certainly consume more. It really depends on your tune and driving style.

What should I consider before upgrading my 6.0 Powerstroke injectors flow rate?

Before changing your 6.0 Powerstroke injectors flow rate, you absolutely need to consider custom tuning, your turbocharger size, and your overall power goals. Incorrectly matched injectors can lead to poor performance or even engine damage.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Fuel Injection System

- Stock 6.0 Powerstroke Injector Flow Rate Specifications

- The Impact of Injector Flow Rate on Performance

- Common Issues Affecting 6.0 Powerstroke Injector Flow and Performance

- Upgrading Your 6.0 Powerstroke Injectors: Options and Considerations

- Conclusion

Understanding the 6.0 Powerstroke Fuel Injection System

Before we delve into specific flow rates, it's crucial to grasp how the 6.0 Powerstroke's fuel injection system operates. Unlike many conventional diesel engines, the 6.0 Powerstroke utilizes a High-Pressure Oil (HEUI) system, which is key to understanding its injector characteristics and performance.

The HEUI System Explained

HEUI stands for Hydraulically-actuated, Electronically-controlled Unit Injector. This system employs high-pressure engine oil, rather than a mechanical cam, to actuate the fuel injectors. Here’s a simplified breakdown:

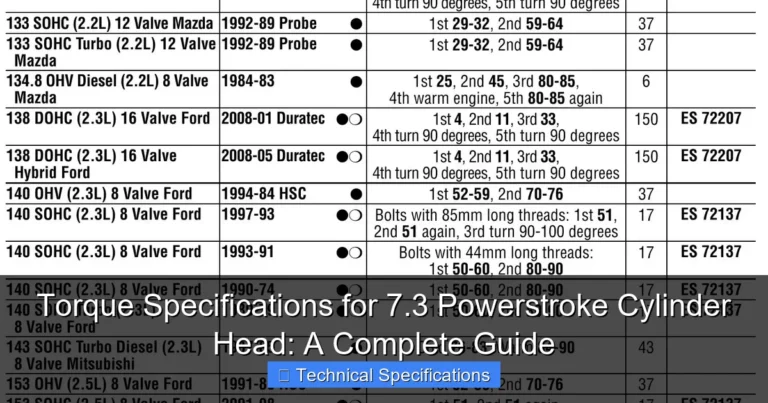

| Injector Type / Application | Nominal Flow Rate (cc/min) | Estimated Horsepower Support (HP) |

|---|---|---|

| 2003-2004 Stock Injector (AD Code) | ~135 | Up to 350 |

| 2005-2007 Stock Injector (AP Code) | ~148 | Up to 375 |

| Aftermarket "Stage 1" (e.g., 155/30) | 155 | 375 - 425 |

| Aftermarket "Stage 2" (e.g., 175/75) | 175 | 450 - 500 |

| Aftermarket "Stage 3" (e.g., 205/100) | 205 | 500 - 550+ |

- High-Pressure Oil Pump (HPOP): This pump takes engine oil and pressurizes it, typically between 500 and 3,600 PSI.

- High-Pressure Oil Rails: The pressurized oil travels through these rails to each injector.

- Fuel Injection Control Module (FICM): This electronic module receives signals from the engine’s computer (PCM) and sends a high-voltage (48-volt) pulse to the solenoid on each injector.

- Injector Actuation: When the FICM signals an injector, an internal poppet valve opens, allowing high-pressure oil to enter the injector. This oil then pushes a intensifier piston, which in turn pressurizes the fuel within the injector to extremely high levels (up to 26,000 PSI or more) and forces it through the nozzle into the combustion chamber.

This complex dance of oil and electricity means that not only the fuel delivery but also the oil pressure and electrical signals must be precisely coordinated for optimal 6.0 Powerstroke injectors flow rate and engine performance.

The Importance of Precise Fuel Delivery

Why is precise fuel delivery, governed by the 6.0 Powerstroke injectors flow rate, so vital? It's the cornerstone of efficient and powerful combustion:

- Power and Torque: More fuel, delivered correctly, translates directly to more power. However, "more" isn't always "better" without proper atomization and timing.

- Fuel Economy: Properly atomized fuel burned efficiently maximizes the energy extracted from each drop, leading to better MPG.

- Emissions: A clean, complete burn reduces harmful emissions, making your truck environmentally friendlier and helping it pass inspections.

- Engine Longevity: Incorrect or inconsistent fuel delivery can lead to hot spots, excessive carbon buildup, and increased wear on critical engine components, potentially shortening engine life.

- Smooth Operation: Consistent fuel delivery across all cylinders ensures a smooth idle and vibration-free operation.

Any deviation in the specified diesel injector flow can manifest as rough idling, loss of power, excessive smoke, or even engine damage. Therefore, understanding and maintaining the proper flow rates is paramount.

Stock 6.0 Powerstroke Injector Flow Rate Specifications

When your 6.0 Powerstroke rolled off the factory line, it was equipped with injectors designed to meet specific performance, emissions, and fuel economy targets. These stock injectors had particular flow rates that varied slightly across different production years and engine revisions.

OEM Injector Codes and Ratings

Ford used different injectors throughout the 6.0 Powerstroke's production run (2003-2007 for Super Duty trucks, 2003-2010 for E-series vans). The primary distinction lies in the early 2003 models versus later models, although there were minor revisions even within those periods. The flow rate of an injector is typically measured in cubic centimeters (cc) per 1,000 strokes (the volume of fuel delivered over a specific number of injection events) and influenced by nozzle size and design.

- Early 2003 (FICM strategy 03M05/03M06): These injectors typically had a nominal flow rate of around 135cc. They were generally characterized by an 8-hole nozzle design.

- Late 2003 - 2007 (FICM strategy 03M07/04M01/05M01 and later): The later injectors generally offered a slightly increased flow, around 155cc. These also featured an 8-hole nozzle, but with subtle differences in internal components and perhaps spray pattern for improved atomization and emissions compliance.

It's important to note that these are nominal "stock" flow rates. The actual flow can vary slightly from injector to injector, which is why Ford introduced Injector Quantity Adjustment (IQA) codes, discussed below. When discussing stock 6.0 injectors, these are the primary ratings you'll encounter.

How Flow Rate is Measured and Managed

Injector flow rates aren't just arbitrary numbers; they are precisely measured and managed by the engine's control systems:

- Injector Quantity Adjustment (IQA) Codes: Each OEM injector comes with a unique IQA code (a string of letters and numbers). This code represents the actual flow characteristics of that specific injector and is programmed into the PCM and FICM when the injector is installed. This allows the engine computer to make tiny adjustments to the injector's firing pulse width to ensure consistent fuel delivery across all cylinders, compensating for minor manufacturing variations in Powerstroke injector flow.

- Testing Methods: Injector flow testing is performed on specialized benches. These machines measure the volume of fuel delivered over a set number of injection events at various pressures and pulse widths. They also analyze the spray pattern to ensure proper atomization.

Data Table: Common Stock 6.0 Powerstroke Injector Specifications

Here's a quick reference for the nominal specifications of OEM 6.0 Powerstroke injectors:

| Year/Engine Revision | Injector Type/Part Number Range (OEM) | Nominal Flow Rate (cc) | Nozzle Holes | Typical Application Notes |

|---|---|---|---|---|

| Early 2003 | 3C3Z-9E527-AA (and similar) | ~135cc | 8-hole | Found in trucks manufactured before 09/2003 |

| Late 2003 - 2007 | 3C3Z-9E527-AB (and similar) | ~155cc | 8-hole | Found in trucks manufactured after 09/2003 (most common) |

Note: These are nominal values. Actual flow can vary slightly, and part numbers can cross-reference to several suppliers. Always verify compatibility with your specific vehicle's build date.

The Impact of Injector Flow Rate on Performance

The 6.0 Powerstroke injectors flow rate is not just a technical detail; it's a fundamental determinant of your engine's capabilities. Whether you're towing heavy loads, accelerating on the highway, or simply cruising, the injectors are constantly working to match fuel delivery to demand.

Fueling Your Horsepower Dreams

The most direct impact of injector flow rate is on the engine's power output. Simply put, more fuel means more potential energy for combustion. However, it's not a linear relationship, and simply installing larger injectors without proper tuning can be detrimental. When performance enthusiasts talk about increasing horsepower in a 6.0 Powerstroke, increasing the diesel injector flow is often one of the first modifications considered. Uprated injectors allow the engine to burn more fuel per combustion cycle, leading to significantly higher horsepower and torque figures, especially when combined with a larger turbocharger and appropriate tuning.

Beyond Horsepower: Efficiency and Emissions

While horsepower gains are exciting, the correct 6.0 Powerstroke injectors flow rate also plays a crucial role in efficiency and emissions:

- Optimal Atomization: Properly sized and functioning injectors ensure fuel is atomized into a fine mist, which mixes more effectively with air for a cleaner, more complete burn. Poor atomization can lead to wasted fuel and increased soot.

- Reduced Smoke: Insufficient injector flow for the amount of air being ingested (or improper timing) can lead to incomplete combustion, resulting in black smoke. Conversely, too much fuel without adequate air or proper atomization will also create smoke. The goal is a clean burn.

- Exhaust Gas Temperatures (EGTs): Injector flow directly impacts EGTs. Larger injectors, especially with aggressive tuning, can significantly raise EGTs, which can be dangerous for turbochargers and other exhaust components. Proper tuning ensures EGTs remain within safe limits.

Achieving a balance between impressive power and reliable, efficient operation is the ultimate goal, and it heavily relies on optimizing injector flow rates for your specific setup.

Tuning Considerations for Injector Upgrades

Perhaps the most critical aspect of modifying 6.0 Powerstroke injectors flow rate is custom tuning. Installing larger injectors without custom programming is a recipe for disaster:

- Engine Control Module (ECM) Calibration: The stock ECM is calibrated for the original injector size. Installing larger injectors will confuse the ECM, leading to over-fueling, excessive smoke, high EGTs, potential engine damage, and poor performance.

- FICM Programming: While the FICM primarily controls the voltage to the injectors, its strategy must be compatible with the ECM's fuel delivery commands, especially with modified injectors.

- Optimizing Fueling and Timing: Custom tuning allows a skilled tuner to adjust fuel pulse width, injection timing, and fuel pressure to precisely match the characteristics of your new injectors, optimizing them for your turbocharger, HPOP, and other modifications. This ensures peak performance, efficiency, and reliability.

Always budget for professional custom tuning when upgrading your 6.0 Powerstroke injectors.

Common Issues Affecting 6.0 Powerstroke Injector Flow and Performance

Even the most meticulously designed injectors can fall victim to wear, contamination, and the unique stresses of diesel operation. The 6.0 Powerstroke's HEUI system, while robust, has its own set of vulnerabilities that can impact injector flow rates and overall engine health.

The Culprits: What Goes Wrong?

Several common problems can degrade the performance of your 6.0 Powerstroke injectors:

- Stiction: This is a common issue unique to HEUI injectors. It refers to the internal moving parts of the injector (specifically the spool valve) sticking due to carbon, varnish, or wear, particularly when the engine oil is cold or degraded. This causes delayed or inconsistent injection, leading to rough idle, misfires, and hard starts, directly impacting the effective 6.0 Powerstroke injectors flow rate.

- Nozzle Wear/Clogging: Over time, the tiny holes in the injector nozzle can wear or become clogged by fuel contaminants. This distorts the spray pattern, leading to poor atomization, incomplete combustion, increased smoke, and reduced power.

- Contaminated Fuel: Water or debris in the fuel system is an injector killer. It can cause corrosion, pitting, and scoring of internal injector components, severely compromising their ability to deliver fuel precisely.

- O-Ring Failure: Each injector has several O-rings that seal against the high-pressure oil rails and the cylinder head. If these O-rings degrade or fail, high-pressure oil can leak, leading to a loss of oil pressure, insufficient injector actuation, and poor performance (often referred to as a "low ICP" or "no start hot" condition).

- FICM Issues: While not directly an injector issue, a failing FICM (Fuel Injection Control Module) can cause low voltage to the injectors. This results in weak or inconsistent injector firing, leading to many of the same symptoms as failing injectors themselves.

- Injector Solenoid Failure: The electrical solenoid on top of the injector can fail, preventing the injector from firing at all.

Symptoms of Failing Injectors

Recognizing the signs of failing injectors early can save you significant time and money:

- Rough Idle: One of the most common symptoms, particularly if one or more cylinders are not firing consistently.

- Misfires/Loss of Power: The engine feels sluggish, struggles under load, or misfires, indicating inconsistent fuel delivery.

- Excessive Smoke: White, blue, or black smoke from the exhaust can all be indicators of injector problems, depending on the nature of the failure (e.g., unburnt fuel, oil contamination).

- Hard Starting (Especially When Hot or Cold): Stiction often causes hard starts when the engine is cold. Leaking O-rings or poor oil pressure can cause hot start issues.

- Poor Fuel Economy: Inconsistent or incorrect 6.0 Powerstroke injectors flow rate can lead to wasted fuel.

- Increased Engine Noise: A noticeable "clatter" or "knock" that wasn't there before.

- Check Engine Light: The PCM may log fault codes related to injector circuit performance or cylinder contribution.

Diagnosing Injector Problems

Pinpointing injector issues often requires a systematic approach:

- Cylinder Contribution Test: This diagnostic test, performed with a suitable scan tool, measures the contribution of each cylinder to the engine's overall power output, helping identify weak or failing injectors.

- FICM Voltage Test: Verify the FICM is delivering a consistent 48 volts to the injectors. Any deviation can indicate a FICM issue, not necessarily bad injectors.

- Oil Analysis: Sending a sample of your engine oil for analysis can reveal fuel dilution (often from leaking injector seals) or excessive wear metals.

- Fuel Pressure Test: Ensure adequate fuel supply pressure to the injectors. Low fuel pressure can mimic injector issues.

- High-Pressure Oil System Diagnostics: Check ICP (Injection Control Pressure) and IPR (Injector Pressure Regulator) readings to ensure the HPOP is supplying sufficient pressure.

Given the complexity, professional diagnosis is highly recommended for persistent injector problems. Addressing these issues promptly is crucial for maintaining optimal 6.0 Powerstroke injectors flow rate and preventing further engine damage.

Upgrading Your 6.0 Powerstroke Injectors: Options and Considerations

For many 6.0 Powerstroke owners, the stock injector flow rates are just the starting point. Upgrading injectors is a popular path to significantly boost horsepower and torque, but it requires careful planning and consideration of your overall build.

Why Upgrade Your 6.0 Powerstroke Injectors?

The motivations for upgrading are typically:

- Increased Horsepower and Torque: The primary reason for larger injectors. More fuel, combined with more air, equals more power.

- Improved Towing Performance: Greater power output makes towing heavy loads much easier and less strenuous on the engine.

- Future Power Goals: If you plan other modifications like a larger turbocharger, upgraded injectors are often a prerequisite.

- Replacing Failed Stock Injectors: If your stock injectors fail, it can be a cost-effective decision to upgrade to a slightly larger size if you have future power aspirations.

Understanding Aftermarket Flow Rates

Aftermarket 6.0 Powerstroke injectors flow rate designations are a bit different from stock. They typically include two numbers:

- Cubic Centimeters (cc): This denotes the overall volume of fuel the injector can flow per 1,000 strokes. Common aftermarket sizes range from 175cc, 190cc, 205cc, 225cc, 250cc, and even larger.

- Nozzle Percentage (%): This indicates how much larger the nozzle orifices are compared to the stock nozzle. For example, "30%" means the nozzle has 30% more flow area than stock. This affects atomization and spray pattern. Common percentages include 30%, 75%, 100%, and even 200%.

So, an injector described as "175cc/30%" would flow 175cc of fuel and have nozzles that are 30% larger than stock. The combination of increased volume and larger nozzle holes allows for the significant power gains seen with upgraded 6.0 injectors.

Common aftermarket categories include:

- Stock-Appearing/Performance Stock: Often around 175cc, these are good for mild power bumps (e.g., 50-75 HP over stock) and typically use stock-sized nozzles for excellent atomization.

- Mild Performance: Injectors in the 190-205cc range with 30-75% over nozzles. These are popular for daily drivers and towing, offering significant power gains (e.g., 75-150 HP) while still being relatively streetable.

- Aggressive Performance/Race: 225cc and above with 100%+ nozzles are for serious power applications, often requiring substantial turbo, HPOP, and fuel system upgrades.

Matching Injectors to Your Setup

Choosing the right 6.0 Powerstroke injectors flow rate is crucial and depends heavily on your other modifications:

- Turbocharger Size: Larger injectors require more air. A stock turbo (especially early 03 models) will struggle to keep up with anything much larger than 175cc injectors without severe exhaust gas temperatures (EGTs) and smoke. Upgraded turbochargers are often necessary.

- High-Pressure Oil Pump (HPOP) Capacity: The HPOP must be able to supply enough high-pressure oil to actuate the larger injectors. For very large injectors (e.g., 205cc and above), a "gen 2" HPOP or a dual HPOP system might be required to maintain sufficient ICP.

- Fuel Supply System (Lift Pump): The factory lift pump (in-tank module) might be sufficient for mildly upgraded injectors, but for anything significant, an upgraded FASS or AirDog fuel system is highly recommended to ensure consistent low-pressure fuel delivery.

- Transmission Limitations: The 5R110W automatic transmission is robust but has its limits. Very high horsepower builds may require transmission upgrades to handle the increased torque.

Always consider your entire power package to ensure compatibility and prevent component failure. Don't just pick the biggest injectors; choose the ones that match your goals and supporting modifications.

Installation and Maintenance Tips for Optimal Injector Performance

Whether you're installing new stock or aftermarket injectors, proper procedure is vital:

- Cleanliness is Key: Any dirt or debris introduced during installation can immediately damage new injectors. Work in a clean environment and ensure all fuel lines and oil passages are spotless.

- New O-Rings and Copper Washers: Always use new O-rings and copper crush washers when installing injectors. These are crucial for proper sealing and heat transfer.

- Proper Torque: Follow torque specifications meticulously for injector hold-downs and fuel lines.

- Fuel System Maintenance: Regular fuel filter changes (every 10,000-15,000 miles, or more often with questionable fuel) are non-negotiable. Consider using a quality fuel additive to lubricate and clean the fuel system, helping maintain optimal injector performance.

- Engine Oil Quality and Changes: Since the 6.0 Powerstroke injectors are oil-fired, the quality and cleanliness of your engine oil are paramount. Use recommended CJ-4 or CK-4 spec synthetic or semi-synthetic oil and adhere to strict oil change intervals (typically 5,000 miles, or sooner if severely used). This is your best defense against stiction.

- Proper Break-in: If installing new injectors, follow the manufacturer's break-in procedure, which often involves specific driving cycles to help seat new components.

Diligent maintenance is your best friend in prolonging the life and performance of your 6.0 Powerstroke injectors, regardless of their flow rate.

Conclusion

The 6.0 Powerstroke injectors flow rate stands as a critical metric for understanding, diagnosing, and enhancing your diesel engine's performance. From the subtle nuances of OEM specifications to the exhilarating potential of aftermarket upgrades, every aspect of fuel delivery plays a pivotal role in the power, efficiency, and reliability of your truck.

We've journeyed through the intricate HEUI system, explored the stock Powerstroke injector flow rates that laid the foundation, and examined the profound impact these specifications have on horsepower, efficiency, and emissions. Moreover, we've shone a light on the common pitfalls that can plague these complex components and discussed the strategic considerations for those looking to unleash more power through upgraded 6.0 Powerstroke injectors.

Ultimately, whether you choose to maintain stock reliability or embark on a quest for higher horsepower, knowledge is your most powerful tool. Understand your engine's needs, pay attention to the symptoms it presents, invest in quality components, and, critically, ensure proper maintenance and professional tuning. By doing so, you'll not only preserve the life of your 6.0 Powerstroke injectors but also ensure that your legendary diesel continues to deliver the performance and dependability you expect for many miles to come. Drive smart, maintain diligently, and enjoy the power.

🎥 Related Video: Diesel Injector Torch Test!

📺 Virtual Motivation

Frequently Asked Questions

What is the standard or stock 6.0 Powerstroke injector flow rate?

The factory 6.0 Powerstroke injectors typically have a flow rate of around 155cc (cubic centimeters per 1000 strokes). This flow rate is designed to meet the engine’s original power and emissions specifications when new.

Why is understanding the 6.0 Powerstroke injector flow rate important for engine performance?

The flow rate directly impacts how much fuel is delivered into the combustion chamber during each injection event. An optimal flow rate ensures proper fuel atomization and complete combustion, which is crucial for horsepower, torque, and fuel efficiency.

How is the flow rate of 6.0 Powerstroke injectors measured or expressed?

Injector flow rate is typically measured in cubic centimeters (cc) per 1000 strokes or sometimes in pounds per hour (lb/hr). This specification indicates the volume of fuel an injector can deliver under specific pressure and pulse width conditions.

What are the common upgrade options for increasing 6.0 Powerstroke injector flow rate?

Many owners upgrade to higher flow rate injectors, such as 175cc, 190cc, 205cc, or even larger sizes, to support increased horsepower goals. These larger injectors usually require custom tuning to ensure proper fuel delivery and engine operation.

How does wear or failure in 6.0 Powerstroke injectors affect their flow rate?

Worn or failing 6.0 Powerstroke injectors can have inconsistent, reduced, or even excessive flow rates compared to their specifications. This can lead to symptoms like poor fuel economy, rough idle, loss of power, excessive smoke, and elevated exhaust gas temperatures.

How does the flow rate of 6.0 Powerstroke injectors relate to potential horsepower output?

Generally, a higher injector flow rate allows for more fuel to be delivered into the engine, which directly correlates with the engine’s ability to produce more horsepower. However, maximizing performance also requires matching fuel delivery with appropriate turbocharging, air intake, and custom engine tuning.