6.0 Powerstroke Fuel System Specifications: A Detailed Overview

Featured image for this comprehensive guide about 6.0 Powerstroke fuel system specifications

Image source: ww2.justanswer.com

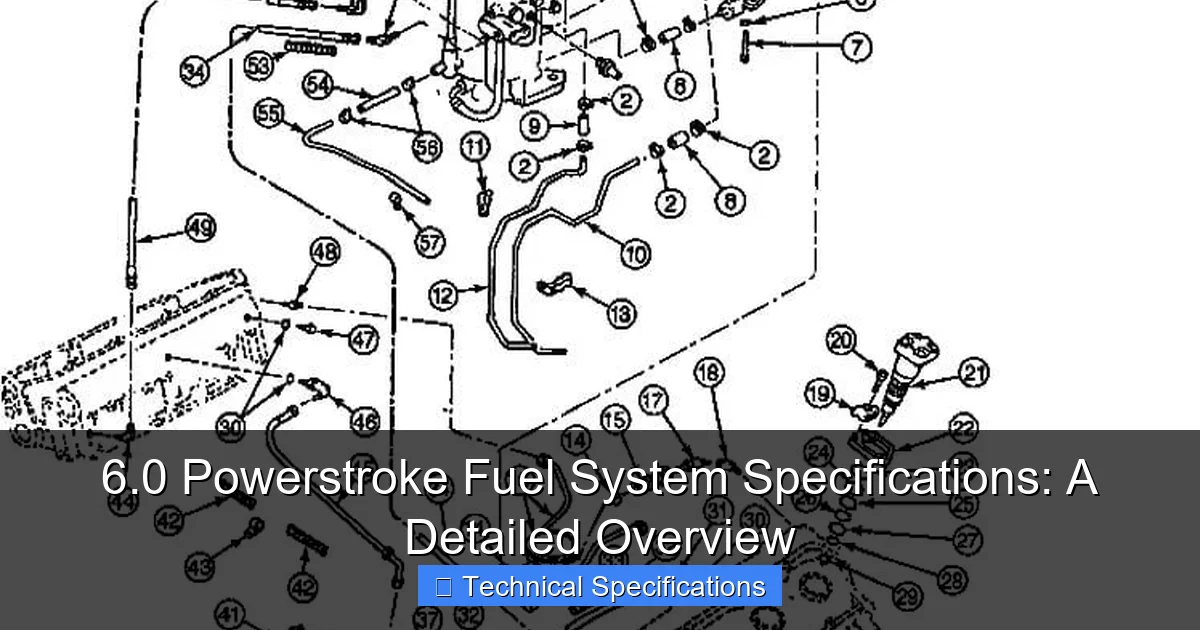

The Ford 6.0 Powerstroke diesel engine, produced from 2003 to 2007, is a powerhouse known for its immense torque and towing capabilities. Despite its robust performance, it also carries a reputation for certain complexities, especially concerning its fuel system. For any owner, enthusiast, or technician working with this legendary engine, a deep understanding of the 6.0 Powerstroke fuel system specifications is not just helpful—it’s absolutely critical for maintaining performance and preventing costly failures.

The fuel system on the 6.0 Powerstroke is a sophisticated network designed to deliver precisely measured fuel at high pressures to the injectors, which are themselves hydraulically actuated by high-pressure oil. This intricate dance between fuel, oil, and electronics means that even minor deviations from factory specifications can lead to significant issues, ranging from reduced power and poor fuel economy to catastrophic engine damage. Ignoring the health of your fuel system is akin to ignoring the heart of your diesel workhorse.

In this comprehensive guide, we’ll peel back the layers of the 6.0 Powerstroke fuel delivery system. We’ll explore its fundamental architecture, delve into the critical specifications of its key components, discuss common problems and how to troubleshoot them, and provide actionable tips for maintenance and performance upgrades. Our goal is to equip you with the knowledge needed to ensure your 6.0 Powerstroke runs reliably and efficiently for years to come.

Quick Answers to Common Questions

What’s the recommended fuel pressure for a 6.0 Powerstroke?

Optimal fuel pressure for your 6.0 Powerstroke fuel system is crucial; you’re looking for about 45-60 psi at idle, under load, and at wide open throttle to ensure proper injector function. If it drops too low, you risk injector damage and poor performance.

How many fuel filters does the 6.0 Powerstroke have, and where are they located?

Your 6.0 Powerstroke fuel system has two fuel filters: one primary filter located in the frame rail near the tank, and a secondary filter located under the hood on top of the engine. Both are vital for keeping your injectors clean.

What’s a common upgrade for the 6.0 Powerstroke fuel system?

Many owners upgrade their 6.0 Powerstroke fuel system with a regulated return system or an aftermarket lift pump like FASS or AirDog. These modifications help maintain consistent fuel pressure and flow, especially beneficial for modified trucks.

Does the 6.0 Powerstroke use a High-Pressure Oil Pump (HPOP) to deliver fuel?

This is a common point of confusion! The 6.0 Powerstroke fuel system uses a low-pressure electric fuel pump to deliver fuel to the injectors; the HPOP is exclusively for pressurizing oil to actuate the fuel injectors.

What are some signs of a failing 6.0 Powerstroke fuel system component?

You might notice symptoms like hard starts, poor acceleration, reduced fuel economy, or a “bucking” feeling if there’s an issue with your 6.0 Powerstroke fuel system. Checking fuel pressure is often the first diagnostic step.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Fuel System Architecture

- Key Fuel System Components: A Deep Dive into Specifications

- Critical Fuel Pressure Specifications and Why They Matter

- Common 6.0 Powerstroke Fuel System Issues and Troubleshooting

- Maintenance Best Practices for Your 6.0 Powerstroke Fuel System

- Upgrading Your 6.0 Powerstroke Fuel System: Performance & Reliability

- Conclusion

Understanding the 6.0 Powerstroke Fuel System Architecture

The 6.0 Powerstroke fuel system operates on a two-stage principle: a low-pressure fuel delivery system and a high-pressure oil system that actuates the injectors. It’s a “dead-head” design, meaning fuel is pressurized to the injectors, but there’s no continuous return line to the tank from the engine’s fuel rails for excess fuel, only a small vent. This design choice, while simplifying some aspects, also presents unique challenges.

Learn more about 6.0 Powerstroke fuel system specifications – 6.0 Powerstroke Fuel System Specifications: A Detailed Overview

Image source: 3.bp.blogspot.com

Fuel journey begins in the tank, where a pick-up screen ensures large contaminants don’t enter the lines. From there, the electric 6.0 Powerstroke fuel pump (often referred to as the lift pump) draws fuel and pushes it through a primary fuel filter, typically located on the frame rail. This filter removes larger particles, protecting the pump and subsequent components. The fuel then travels to the engine bay, entering a secondary fuel filter housing mounted on top of the engine. After passing through this much finer filter, the fuel enters the fuel rails, supplying the injectors.

| Component/Specification | Value/Range | Notes |

|---|---|---|

| Fuel Pump Type | Electric Rotary Vane Pump | Frame-mounted, supplies fuel to the secondary filter housing |

| Fuel Operating Pressure | 45-70 PSI | Measured at the secondary filter housing (engine side) |

| Fuel Injector Type | HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) | Actuated by high-pressure engine oil, not fuel pressure |

| High-Pressure Oil Pump (HPOP) Max Pressure | ~3600-4000 PSI | Required to actuate injectors, varies with engine load |

| Secondary Fuel Filter Micron Rating | 2-5 Micron | Engine-mounted, critical for injector longevity |

| Fuel Tank Capacity (Standard) | 29-38 Gallons (approx.) | Varies by truck configuration (e.g., cab/bed size) |

The innovative aspect of the 6.0 Powerstroke fuel injector system is its reliance on high-pressure oil. The High-Pressure Oil Pump (HPOP), driven by the engine, pressurizes engine oil to extreme levels. This high-pressure oil is then routed to the injectors via standpipes and dummy plugs. When the Engine Control Module (ECM) commands an injector to fire, the Fuel Injection Control Module (FICM) sends a high-voltage signal to the injector. This signal opens a poppet valve, allowing high-pressure oil to enter the injector, which in turn forces the fuel out into the combustion chamber. This unique HEUI (Hydraulically Actuated Electronic Unit Injector) system demands precise synchronization and healthy components from both the fuel and oil sides.

Key Fuel System Components: A Deep Dive into Specifications

To truly understand the 6.0 Powerstroke fuel system specifications, let’s break down the critical components and their roles:

Learn more about 6.0 Powerstroke fuel system specifications – 6.0 Powerstroke Fuel System Specifications: A Detailed Overview

Image source: avatars.miarroba.st

The 6.0 Powerstroke Fuel Pump (Lift Pump)

The heart of the low-pressure system, the electric 6.0 Powerstroke fuel pump is typically frame-mounted near the fuel tank. Its primary role is to draw fuel from the tank and deliver it under pressure to the engine. The OEM specification for the 6.0 Powerstroke fuel pressure from the lift pump is generally in the range of 45-70 PSI (pounds per square inch) at the secondary filter housing. While this range is acceptable, most experts agree that maintaining fuel pressure above 50 PSI, ideally closer to 60-65 PSI, particularly under load, is crucial for optimal performance and injector longevity. Pressures dropping below 45 PSI, especially under heavy acceleration or towing, can lead to severe issues.

Fuel Filters: Your First Line of Defense

The 6.0 Powerstroke employs a two-stage filtration system, a testament to the importance of clean fuel for its sensitive injectors:

- Primary Fuel Filter: Located on the frame rail, this filter typically has a micron rating of around 10-20 microns. Its job is to capture larger debris before it reaches the electric fuel pump and the secondary filter.

- Secondary Fuel Filter: Situated on top of the engine, this is the final filtration stage before fuel reaches the injectors. It’s a much finer filter, usually rated at 2-5 microns. This extreme precision is vital for protecting the delicate internal components of the HEUI injectors. Clogged filters are a common culprit for low fuel pressure and engine performance issues.

6.0 Powerstroke Fuel Injectors (HEUI)

The Siemens/International G2.9 6.0 Powerstroke fuel injectors are highly sophisticated components. They don’t just inject fuel; they use pressurized engine oil to do so. These injectors are capable of extremely precise fuel delivery, with multiple injection events per combustion cycle (pilot, main, post-injection) to optimize combustion, reduce noise, and improve emissions. While there isn’t a simple “PSI” spec for the injector itself in terms of how much fuel it delivers (as that’s controlled by injection duration and oil pressure), their operational integrity relies entirely on consistent fuel supply and proper high-pressure oil actuation.

Fuel Injection Control Module (FICM)

The FICM is unique to the HEUI system and is a vital electronic brain. It takes the engine’s 12V battery voltage and steps it up to a critical 48 Volts, which is then used to energize the solenoids within each injector. This high voltage is necessary for rapid and precise injector actuation. The OEM specification for FICM output voltage is a steady 48 Volts. Any drop below 47.5V, especially below 45V, can lead to a host of problems, including hard starts, rough idle, lack of power, and even “no start” conditions. Many consider a healthy FICM to be one of the pillars of a reliable 6.0 Powerstroke.

Fuel Pressure Regulator (FPR)

While the 6.0 Powerstroke doesn’t have a traditional return-style fuel pressure regulator on the engine (like many common rail diesels), it does utilize a fuel pressure regulator within the fuel pump assembly to maintain base pressure. Additionally, a fuel pressure sensor monitors the pressure at the secondary filter housing, sending data to the ECM. Ensuring this sensor is accurate is crucial for diagnosing any pressure-related issues.

Critical Fuel Pressure Specifications and Why They Matter

Monitoring and maintaining proper fuel pressure is perhaps the single most critical aspect of the 6.0 Powerstroke fuel system. Deviations from specifications can quickly lead to expensive repairs, particularly to the injectors.

Low-Pressure Fuel System Specifications Explained

As mentioned, the target 6.0 Powerstroke fuel pressure at the secondary filter housing should ideally be between 50-65 PSI. While the factory spec allows for as low as 45 PSI, continuous operation at the lower end of this spectrum, especially under load, can be detrimental. Here’s why:

- Injector Lubrication: Fuel isn’t just for combustion; it also provides crucial lubrication for the internal moving parts of the injectors. Insufficient pressure can lead to “fuel starvation,” causing metal-on-metal wear and premature failure (often manifesting as stiction).

- Injector Cooling: Fuel also helps to cool the injectors. Low pressure and flow mean less cooling, which can exacerbate wear, especially in an engine known for generating significant heat.

- FICM Stress: When fuel pressure is low, the FICM and injectors have to work harder to achieve the desired injection event, putting undue strain on these expensive components.

- Performance Degradation: You’ll experience symptoms like reduced power, sluggish acceleration, poor throttle response, and potentially codes like P0087 (Fuel Rail/System Pressure – Too Low).

For these reasons, installing a permanent, accurate fuel pressure gauge in your cab is one of the most highly recommended modifications for any 6.0 Powerstroke owner. It allows real-time monitoring, enabling you to catch pressure drops before they cause serious damage.

High-Pressure Oil System Interaction

While not strictly a “fuel” specification, the high-pressure oil system is inseparable from fuel injection on the 6.0 Powerstroke. The HPOP generates pressures between 500 PSI at idle to over 3,600 PSI under heavy load. This oil pressure is what *actuates* the injectors. If there are leaks in the high-pressure oil system (e.g., standpipes, dummy plugs, HPOP fittings), the injectors won’t fire correctly, even if fuel pressure is perfect. It’s a symbiotic relationship where both fuel and oil pressures must be within their respective specifications for the engine to run correctly.

Key Operating Specifications Summary Table

Here’s a quick reference for critical 6.0 Powerstroke fuel system specifications and related parameters:

| Component/Parameter | OEM Specification | Ideal Operating Range | Notes |

|---|---|---|---|

| Lift Pump Fuel Pressure | 45-70 PSI (at secondary filter) | 50-65 PSI | Measure under load; minimum 45 PSI. Below 45 PSI is problematic. |

| Secondary Fuel Filter Micron Rating | 2-5 Micron | N/A | Crucial for injector protection. |

| FICM Output Voltage | 48 Volts | 47.5-48.5 Volts (engine running) | Check KOEO (Key On Engine Off) and KOER (Key On Engine Running). Below 45V causes issues. |

| HPOP Pressure (ICP) | 500-3600+ PSI | ~500 PSI (idle), ~3600+ PSI (WOT) | Measured by IPR (Injection Pressure Regulator) & ICP (Injection Control Pressure) sensor. Essential for injector actuation. |

Common 6.0 Powerstroke Fuel System Issues and Troubleshooting

Despite its capabilities, the 6.0 Powerstroke fuel system is known for a few common failure points. Knowing what to look for and how to diagnose can save you time and money.

1. Low Fuel Pressure

- Symptoms: Hard starts (especially hot), extended crank times, loss of power, reduced fuel economy, rough idle, bucking, surging, DTC P0087.

- Causes: Failing electric 6.0 Powerstroke fuel pump, severely clogged fuel filters (primary or secondary), restricted fuel lines, failing fuel pressure regulator, or a significant leak in the fuel system.

- Troubleshooting: The first and most crucial step is to measure fuel pressure directly at the secondary filter housing using a mechanical gauge. Observe pressure at idle, during acceleration, and under heavy load. If it consistently drops below 45-50 PSI, investigate the pump, filters, and lines.

2. Fuel Injector Issues (Stiction & Failure)

The 6.0 Powerstroke fuel injectors are prone to “stiction” (a portmanteau of static and friction) and outright failure.

- Symptoms: Rough idle, misfires, excessive white/blue smoke, loss of power, poor cold starting, engine knocking.

- Causes: Low fuel pressure (leading to inadequate lubrication and cooling), poor quality fuel, extended oil change intervals (contaminating the high-pressure oil actuating the injectors), worn internal injector components.

- Troubleshooting: A full scan tool with diagnostic capabilities is essential. Perform an injector “buzz test” to check electrical continuity, and a “contribution test” to identify weak or failed injectors. Also, check FICM voltage and fuel pressure as these directly impact injector health.

3. FICM Failure

A common and often frustrating issue, FICM failures directly impact injector operation.

- Symptoms: No start (cranks but won’t fire), hard starting (especially cold), extended crank, rough idle, bucking, stalling, reduced power, misfires, white smoke.

- Causes: Heat cycling, vibration, voltage spikes (e.g., from weak batteries or a failing alternator), and general wear over time.

- Troubleshooting: Measure FICM voltage. This can be done with a multimeter at specific pins on the FICM connector or via a scan tool that reads FICM voltage PIDs (Parameter IDs). If voltage consistently drops below 47.5V (especially under load or during cranking), the FICM likely needs repair or replacement.

4. Clogged Fuel Filters

- Symptoms: Similar to low fuel pressure, as clogged filters are a primary cause: reduced power, sluggishness, hard starts, and potentially a whining noise from the fuel pump.

- Causes: Contaminated fuel, extended service intervals, using low-quality filters.

- Troubleshooting: Always address filters first when diagnosing fuel pressure issues. If pressure improves significantly after replacement, you’ve found your culprit.

Maintenance Best Practices for Your 6.0 Powerstroke Fuel System

Preventative maintenance is your best defense against costly 6.0 Powerstroke fuel system issues. Adhering to these practices will significantly improve your engine’s reliability and longevity.

1. Regular Fuel Filter Replacement

This is arguably the most critical and often overlooked maintenance item. The 6.0 Powerstroke fuel filters are non-negotiable for protection.

- Frequency: Replace both the primary (frame-mounted) and secondary (engine-mounted) fuel filters every 10,000 to 15,000 miles or annually, whichever comes first. If you use poor quality fuel or operate in dusty conditions, consider more frequent changes.

- Quality Matters: Always use OEM Ford/Motorcraft filters or high-quality aftermarket equivalents. Cheap filters may not meet the micron ratings or can have poor sealing, compromising filtration and potentially damaging your injectors.

2. Monitor Fuel Pressure Consistently

As highlighted, low fuel pressure is a silent killer for 6.0 injectors.

- Install a Gauge: Invest in a reliable, permanent fuel pressure gauge in your cab. This allows you to monitor pressure in real-time, providing immediate feedback on the health of your 6.0 Powerstroke fuel delivery system.

- Regular Checks: Get into the habit of observing your fuel pressure under various conditions – at idle, during cruising, and especially under heavy acceleration or towing. Any sustained drop below 50 PSI warrants immediate investigation.

3. Use Quality Fuel and Fuel Additives

The type of fuel you put in your tank directly impacts your fuel system’s health.

- Reputable Stations: Purchase diesel fuel from high-volume, reputable stations to minimize the risk of contaminated fuel.

- Cetane Boosters: A good cetane booster can improve combustion efficiency and reduce diesel knock.

- Lubricity Additives: Modern Ultra-Low Sulfur Diesel (ULSD) has less lubricity than older diesel fuels. A quality lubricity additive is highly recommended to protect your 6.0 Powerstroke fuel pump and injectors from premature wear.

- Anti-Gelling Agents: In cold climates, use an anti-gelling additive to prevent fuel from gelling, which can clog filters and lines.

4. Periodically Check FICM Voltage

Don’t wait for symptoms to appear.

- Regular Scans: If you have a scan tool capable of reading FICM voltage, check it during your routine maintenance. Perform tests both with the key on/engine off (KOEO) and with the engine running (KOER). This helps catch potential FICM degradation early.

5. Address Issues Promptly

Ignoring symptoms like hard starting, rough idle, or power loss will only lead to more severe and costly repairs down the line. Diagnostic time and proactive repairs are always cheaper than reactive, catastrophic fixes.

Upgrading Your 6.0 Powerstroke Fuel System: Performance & Reliability

For those looking to enhance reliability, extend component life, or unlock more power from their 6.0 Powerstroke, several aftermarket upgrades for the fuel system are highly popular and effective.

1. Aftermarket Fuel Pumps (FASS, AirDog, etc.)

One of the most common and beneficial upgrades is replacing the OEM lift pump with a higher-performance aftermarket fuel pump system.

- Benefits: These systems often provide higher and more consistent fuel pressure (e.g., a steady 60-70 PSI), improved filtration (sometimes with water separation), and air removal (de-aeration). Consistent pressure significantly extends injector life, and clean, air-free fuel improves combustion efficiency and reduces wear. Many aftermarket pumps are also quieter and easier to service.

- Recommendation: A FASS or AirDog system is a popular choice for both stock and modified trucks.

2. Regulated Return Fuel System

The factory “dead-head” fuel system can lead to uneven fuel pressure across the rails, especially at higher fuel demands. A regulated return system addresses this.

- How it Works: It adds a fuel return line from the engine’s fuel rails back to the tank, along with a dedicated fuel pressure regulator on the engine. This creates a constant flow of fuel through the engine, ensuring that all injectors receive fresh, consistent fuel pressure.

- Benefits: Improved injector life, smoother idle, better throttle response, and more consistent power delivery, particularly beneficial for trucks with performance tuning or larger injectors.

3. Performance Fuel Injectors

If you’re chasing significant horsepower gains, upgrading your 6.0 Powerstroke fuel injectors is a common path.

- Considerations: Larger injectors deliver more fuel per injection cycle. However, they require custom tuning to correctly manage fuel delivery and often necessitate other supporting modifications like an upgraded turbocharger, HPOP, and fuel pump to provide adequate fuel and oil. This is a performance-focused upgrade, not just a reliability one.

4. FICM Upgrades

Beyond simply repairing a failing FICM, there are options to enhance them.

- Performance FICMs: Some companies offer “tuned” FICMs that can deliver slightly higher voltage or more optimized injection strategies, potentially leading to small power gains and improved throttle response.

- Reliability Mods: Common FICM repairs often involve upgrading internal components (e.g., circuit boards, transistors) to be more robust and resistant to heat and vibration, extending the life of the module.

Remember, any major modification should be done with careful research and consideration of how it integrates with other engine components and your overall goals for the truck.

Conclusion

The 6.0 Powerstroke fuel system is a marvel of diesel engineering, but its sophisticated design demands attention to detail. Understanding the critical 6.0 Powerstroke fuel system specifications – from the ideal operating pressure of your lift pump and the micron ratings of your filters to the vital 48 Volts supplied by your FICM – is not just academic; it’s essential for the health and longevity of your engine.

By diligently following recommended maintenance schedules, especially for fuel filter replacement, and by proactively monitoring key parameters like fuel pressure and FICM voltage, you can mitigate many of the common issues associated with this platform. And for those seeking enhanced performance and even greater reliability, strategic upgrades to the fuel delivery system offer proven benefits.

Ultimately, a well-maintained and properly understood 6.0 Powerstroke fuel system is the cornerstone of a powerful, dependable, and enjoyable driving experience. Don’t let neglect turn a minor spec deviation into a major headache; empower yourself with knowledge and keep your Powerstroke roaring down the road for years to come.

🎥 Related Video: How to test for Failed Injectors on 6.0 #powerstrokediesel #ford

📺 It’s Maynard

Frequently Asked Questions

What are the key components of the 6.0 Powerstroke fuel system specifications?

The 6.0 Powerstroke fuel system is comprised of several essential components including an in-tank lift pump, a dual-stage fuel filter system (one frame-mounted, one on the engine), the fuel rails, and eight Hydraulic Electronic Unit Injectors (HEUI). These parts work together to deliver and pressurize fuel for efficient combustion and operation.

What is the recommended fuel pressure specification for the 6.0 Powerstroke fuel system?

The factory specification for the 6.0 Powerstroke fuel system requires a minimum of 45-50 PSI at idle, with 55-60 PSI being ideal. Maintaining proper fuel pressure is critical for injector longevity and preventing premature failure, as low pressure can starve the injectors of adequate lubrication and cooling.

How often should fuel filters be replaced on the 6.0 Powerstroke?

Ford recommends replacing both the frame-mounted primary fuel filter and the engine-mounted secondary fuel filter every 15,000 miles or 12 months, whichever comes first. Regular filter changes are vital for protecting the sensitive HEUI injectors from contaminants and ensuring optimal fuel delivery, directly impacting the fuel system’s lifespan.

Can you explain the fuel injector specifications for the 6.0 Powerstroke?

The 6.0 Powerstroke utilizes HEUI (Hydraulic Electronic Unit Injector) injectors, which are unique in that they use high-pressure engine oil to atomize and inject fuel directly into the cylinders. These injectors operate at very high pressures, often exceeding 3,600 PSI of injection pressure, controlled by the FICM (Fuel Injection Control Module) and PCM.

Is the 6.0 Powerstroke fuel system a return-style or returnless system?

The 6.0 Powerstroke fuel system is a “dead head” or returnless system from the factory. Fuel is delivered from the tank to the fuel rails, and excess fuel is regulated at the fuel pressure regulator (FPR) on the engine, with no direct return line from the rails back to the tank. This design can sometimes lead to issues with heat buildup and inconsistent fuel flow.

What are common upgrades to optimize the 6.0 Powerstroke fuel system?

Popular upgrades for the 6.0 Powerstroke fuel system include installing an aftermarket regulated return system to ensure consistent fuel pressure at the rails and cooler fuel. Many owners also opt for upgraded lift pumps, such as AirDog or FASS systems, which provide better filtration and higher flow rates to support modified engines and prolong injector life beyond factory specifications.