6.0 Powerstroke Fuel Leak Diesel Tech Ron Solutions

Featured image for this comprehensive guide about 6.0 powerstroke fuel leak on engine diesel tech ron

Image source: cdn.shopify.com

The roar of a 6.0 Powerstroke is music to many diesel enthusiasts’ ears, signifying raw power and reliability. However, this symphony can quickly turn into a discordant note when you discover that tell-tale sign of trouble: a fuel leak. A 6.0 Powerstroke fuel leak on engine is not just an inconvenience; it’s a serious issue that can impact performance, fuel economy, and even lead to dangerous situations. For many owners, the first thought might be, “Where do I even begin?”

Whether you’re a seasoned diesel mechanic or a proud owner facing this problem for the first time, understanding the intricacies of your 6.0 Powerstroke’s fuel system is paramount. The infamous 6.0 has a reputation for some complex issues, and fuel leaks are certainly among them. But fear not! With the right knowledge and a methodical approach, you can diagnose and resolve these issues effectively. And who better to draw wisdom from than an expert like Diesel Tech Ron, whose practical insights have guided countless mechanics and DIYers through the labyrinth of diesel engine repairs?

This comprehensive guide dives deep into the world of 6.0 Powerstroke fuel leak on engine diesel tech ron solutions. We’ll explore the common culprits, provide actionable diagnostic steps, and outline the necessary repairs, all while keeping the practical, no-nonsense approach often championed by experts in the field. By the end, you’ll be equipped with the knowledge to tackle that pesky fuel leak, restore your engine’s integrity, and keep your Powerstroke running strong for years to come.

Quick Answers to Common Questions

What’s a common sign of a 6.0 Powerstroke fuel leak on the engine?

You’ll often notice a strong diesel smell inside or around your truck, or you might see wet spots on top of the engine near the injectors or fuel lines. Diesel Tech Ron frequently highlights these as primary indicators.

Is a 6.0 Powerstroke fuel leak on the engine a serious problem?

Absolutely, it’s not just messy! A significant 6.0 Powerstroke fuel leak can lead to reduced fuel economy, potential engine damage, and even fire hazards if left unaddressed, so prompt attention is crucial.

Where do 6.0 Powerstroke fuel leaks typically occur on the engine?

Common culprits for a 6.0 Powerstroke fuel leak include cracked fuel lines, worn injector return o-rings, or issues with the STC fitting and standpipes under the HPOP cover. Diesel Tech Ron often pinpoints these areas.

Can I still drive my truck with a 6.0 Powerstroke fuel leak on the engine?

While your truck might still run, it’s strongly advised not to drive it with a known 6.0 Powerstroke fuel leak. It poses a significant fire risk and can cause further damage to your engine or its components.

What should I do first if I suspect a 6.0 Powerstroke fuel leak on my engine?

Your first step should be to safely park the truck and visually inspect the top of the engine with a flashlight for any visible fuel puddles or active drips. Then, consider consulting resources like Diesel Tech Ron for diagnostic guidance before attempting repairs.

📋 Table of Contents

- Understanding the 6.0 Powerstroke Fuel System: A Brief Overview

- Common Culprits: Where 6.0 Powerstroke Fuel Leaks Occur

- Diagnosing a 6.0 Powerstroke Fuel Leak: Diesel Tech Ron’s Approach

- Actionable Solutions: Fixing Your 6.0 Powerstroke Fuel Leak

- Preventative Measures and Long-Term Maintenance for Your 6.0 Powerstroke

- Conclusion

Understanding the 6.0 Powerstroke Fuel System: A Brief Overview

Before we can pinpoint a 6.0 Powerstroke fuel leak, it’s crucial to understand how the fuel system operates. The 6.0 Powerstroke utilizes a sophisticated common rail injection system, which is a significant departure from earlier diesel engines. This system is designed for precise fuel delivery and optimal combustion, but its complexity can also introduce unique challenges when it comes to leaks.

Learn more about 6.0 powerstroke fuel leak on engine diesel tech ron – 6.0 Powerstroke Fuel Leak Diesel Tech Ron Solutions

Image source: i.ytimg.com

How the 6.0 Powerstroke Delivers Fuel

The journey of fuel in your 6.0 Powerstroke begins at the fuel tank, where it’s drawn by a low-pressure fuel pump. This pump pushes fuel through a series of filters – typically one on the frame and another on top of the engine – to ensure it’s clean and free of contaminants. From there, the fuel enters the fuel rails, which distribute it to each of the eight injectors. These injectors, unlike older mechanical designs, are electronically controlled and actuated by high-pressure oil (HEUI – Hydraulically Actuated Electronically Controlled Unit Injector). The Fuel Injection Control Module (FICM) plays a critical role in providing the necessary voltage to fire the injectors.

| Common Leak Source | Typical Symptoms / Indicators | Est. Repair Time (Labor Hrs) | Est. Parts Cost ($USD) |

|---|---|---|---|

| Fuel Injector O-rings / Body | Fuel smell, rough idle, misfire, fuel in oil (dilution), visible leak in valley. | 4 – 16 hrs (per bank, depending on complexity) | $50 – $200 (o-rings) to $300 – $600+ (per injector) |

| Fuel Filter Housing (Upper) | Visible fuel puddle on top of engine, strong fuel smell, potential air intrusion. | 0.5 – 1.5 hrs | $10 – $50 (seal kit) to $100 – $250 (new housing) |

| Fuel Pressure Regulator (FPR) Gasket | Visible fuel leak at rear of engine block/firewall, strong fuel smell. | 2 – 4 hrs | $20 – $60 (gasket kit) |

| Fuel Supply/Return Lines & Fittings | Visible dripping fuel, strong fuel smell, specific location varies. | 1 – 5 hrs (depending on line access) | $50 – $300 (per line/fitting) |

The fuel system on the 6.0 Powerstroke operates under various pressures. The low-pressure side typically maintains about 45-60 PSI, essential for supplying the injectors. Any deviation from these pressures can indicate a restriction or, more commonly for our topic, a leak. Because the injectors rely on both fuel and high-pressure oil to operate, a leak in either system can manifest with similar symptoms or even lead to cross-contamination, making diagnosis a bit tricky. Understanding this dual-fluid operation is key to diagnosing any 6.0 Powerstroke fuel leak on engine effectively.

Common Culprits: Where 6.0 Powerstroke Fuel Leaks Occur

When searching for a 6.0 Powerstroke fuel leak, there are several hotspots that experienced technicians, including the likes of Diesel Tech Ron, often check first. These components are known failure points due to heat cycling, vibration, material degradation, or simply design weaknesses. Identifying these common leak points can significantly narrow down your diagnostic process and save valuable time and effort.

Learn more about 6.0 powerstroke fuel leak on engine diesel tech ron – 6.0 Powerstroke Fuel Leak Diesel Tech Ron Solutions

Image source: i.ytimg.com

Injector O-Rings and Fuel Supply Lines

One of the most common sources of a 6.0 Powerstroke fuel leak on engine stems from the fuel injector O-rings. Over time, these seals can harden, crack, or become compromised, leading to fuel leaking into the cylinder head or externally. Symptoms might include a diesel smell, visible fuel, or even misfires if the leak is severe enough to affect injector operation. Similarly, the fuel supply lines that connect to each injector can develop cracks or loose fittings, especially where they are exposed to heat and vibration.

Standpipes and Dummy Plugs

While primarily associated with high-pressure oil system leaks, the standpipes and dummy plugs within the cylinder heads can also be a source of confusion, sometimes mimicking a fuel leak. If the seals on these components fail, high-pressure oil can leak, and in some cases, it can appear as though fuel is leaking due to its location and how it mixes with other fluids. It’s crucial to differentiate between an oil leak and a 6.0 Powerstroke fuel leak, as the repair procedures are vastly different.

High-Pressure Oil Pump (HPOP) Cover and Fuel Rails

The HPOP cover, located at the back of the engine, is sealed with gaskets that can degrade, potentially leading to oil leaks. While not a direct fuel leak point, issues here can sometimes lead to confusion. More directly related, the fuel rails themselves, which distribute fuel to the injectors, can develop cracks or have loose connections, causing a legitimate fuel leak on 6.0 Powerstroke. The banjo bolts and sealing washers used to connect fuel lines to the rails are particularly susceptible to developing leaks over time.

Fuel Filter Housing & Fuel Pressure Regulator (FPR)

The primary fuel filter housing, typically located on top of the engine, is another notorious spot for leaks. The cap’s O-ring, the housing itself (especially if plastic), or the lines leading to and from it can all fail. The Fuel Pressure Regulator (FPR), often integrated into or near the filter housing, can also be a source. If its internal diaphragm or external seals fail, you might observe a steady drip or spray of fuel from this area. This is a relatively easier 6.0 Powerstroke fuel leak to spot and often resolve.

FICM and Fuel Cooler Leaks

While less common, leaks can also occur around the Fuel Injection Control Module (FICM) if its housing or associated fuel lines are compromised. Additionally, some 6.0 Powerstrokes feature a fuel cooler, often located near the transmission, which can develop leaks over time due to corrosion or damage. Although external to the engine, a leak here can contribute to significant fuel loss and should not be overlooked when tracking down a 6.0 Powerstroke fuel leak on engine diesel tech ron would advise.

Diagnosing a 6.0 Powerstroke Fuel Leak: Diesel Tech Ron’s Approach

Diagnosing a 6.0 Powerstroke fuel leak on engine requires a systematic approach, often emphasizing safety first. As Diesel Tech Ron would stress, guesswork leads to frustration and potentially costly mistakes. A methodical process helps isolate the source of the leak efficiently.

Visual Inspection: The First Line of Defense

The initial step in diagnosing any fuel leak is a thorough visual inspection. Start by looking for obvious signs: puddles of diesel under the truck, a strong diesel smell (especially after driving), or visible stains on engine components. Use a bright flashlight and mirrors to inspect hard-to-reach areas. Pay close attention to:

- The top of the engine around the fuel filter housing and injector area.

- Along the fuel lines running to and from the engine.

- Around the High-Pressure Oil Pump (HPOP) cover, as oil leaks can sometimes mimic fuel.

- The fuel cooler, if equipped, and its connections.

Even a small amount of residue can indicate a leak that becomes more pronounced under pressure. Look for areas where dirt and grime appear washed away, leaving a clean streak, or where a gummy, fuel-soaked mess has accumulated.

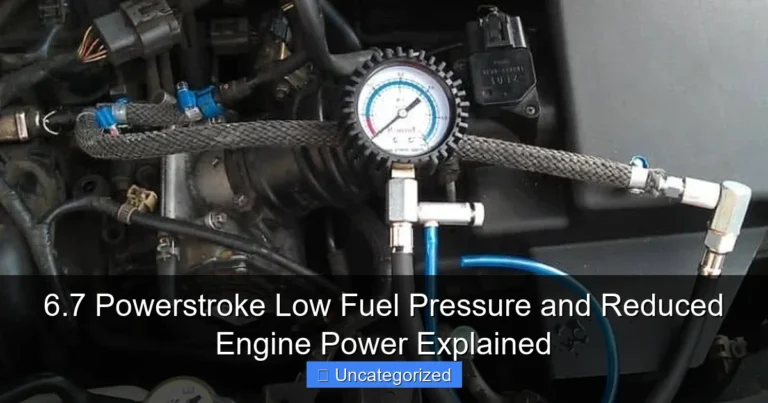

Pressure Testing the Fuel System

A crucial diagnostic step for a 6.0 Powerstroke fuel leak is to perform a fuel pressure test. This involves connecting a fuel pressure gauge to the dedicated test port on the fuel filter housing. With the engine running (or even just cranking in some cases), you should observe specific pressure readings:

- **Idle:** 45-60 PSI

- **WOT (Wide Open Throttle):** Should not drop below 40-45 PSI

If your fuel pressure is consistently low, it could indicate a weak fuel pump, a clogged filter, or, pertinent to our discussion, a significant leak. A “dead-head” pressure test (blocking the return line briefly) can help differentiate between a weak pump and a major leak. Many of Diesel Tech Ron’s videos highlight the importance of proper fuel pressure, emphasizing that low pressure often stems from a bypass valve leak or a fuel return leak rather than just a weak pump.

“Wiggle Test” and Engine On Checks

Once you’ve narrowed down the general area, a “wiggle test” can be incredibly effective. With the engine running and fuel pressure present, carefully (and safely!) wiggle fuel lines, connectors, and components. Sometimes, a leak will only become apparent when the engine vibrates or when a component is slightly moved. Listen for hissing sounds, and watch for any sudden drips or sprays of fuel. For a more precise visual, a borescope or an inspection camera can be invaluable for peering into tight spots, helping to locate that elusive 6.0 Powerstroke fuel leak on engine that’s hidden from plain sight.

Listening and Smelling for Clues

Your senses are powerful diagnostic tools. A distinct smell of raw diesel fuel is an obvious indicator. Listen for any unusual sounds – a hiss could point to a high-pressure leak, while a gurgle might indicate air in the system due to a suction side leak. Sometimes, the sound of fuel dripping onto a hot exhaust manifold can also be a tell-tale sign, accompanied by a wisp of smoke or steam.

Actionable Solutions: Fixing Your 6.0 Powerstroke Fuel Leak

Once you’ve identified the source of your 6.0 Powerstroke fuel leak, the next step is repair. The complexity and cost of the repair will depend heavily on the location and severity of the leak. Some repairs are straightforward DIY projects, while others require specialized tools and expertise. Always remember to prioritize safety when working with fuel.

DIY vs. Professional Repair

Deciding whether to tackle the repair yourself or seek professional help often comes down to your mechanical aptitude, available tools, and the nature of the leak. Simple leaks, such as a weeping fuel filter cap O-ring or a loose fuel line fitting, are generally within the scope of an average DIYer. However, issues involving injector removal, internal engine components, or extensive fuel rail work might be best left to a certified diesel mechanic. A serious 6.0 Powerstroke fuel leak on engine can quickly escalate if not handled correctly, potentially leading to further damage or safety hazards. Diesel Tech Ron often provides insights into what a home mechanic can realistically achieve.

Repairing Specific Leak Points

- Injector O-rings: This is a common and labor-intensive repair. It involves removing the valve covers, disconnecting fuel and oil lines, and carefully extracting the injectors. New O-rings must be properly seated, and the injectors reinstalled with precision. This is a task that often benefits from specialized tools for injector removal and installation.

- Standpipes and Dummy Plugs: If identified as the source (often an oil leak mistaken for fuel), these require valve cover removal and replacement with updated parts. While not a direct fuel leak, understanding its distinction is crucial.

- Fuel Filter Housing: Leaks here are usually from a damaged O-ring on the cap or a cracked housing. Replacement of the O-ring or the entire housing is relatively simple, requiring basic hand tools. Ensure to use quality OEM or reputable aftermarket parts.

- Fuel Line Repairs: Leaking fuel lines might require replacing individual sections, banjo bolts, or entire line assemblies. Always use appropriate fuel-rated hosing and clamps, and ensure all connections are torqued to specification to prevent future leaks.

- Fuel Pressure Regulator (FPR): If the FPR is leaking externally, it often means the entire unit needs replacement. This is usually a straightforward bolt-on replacement once access is gained.

Essential Tools and Parts

For most 6.0 Powerstroke fuel leak on engine diesel tech ron type repairs, you’ll need a standard set of mechanic’s tools, including wrenches, sockets, screwdrivers, and a torque wrench. Depending on the specific leak, specialized tools might be required, such as injector pullers, fuel line disconnect tools, and fuel pressure test kits. Always opt for high-quality OEM or reputable aftermarket replacement parts. Cheaper alternatives might save money upfront but can lead to recurring issues down the road.

Common 6.0 Powerstroke Fuel Leak Points & Repair Difficulty

| Leak Point | Typical Symptoms | Repair Difficulty (1-5, 5=Hardest) | Estimated Parts Cost |

|---|---|---|---|

| Injector O-Rings | Fuel smell, visible fuel in valley, rough idle, misfire | 4 | $150 – $400 (O-rings for all 8) |

| Fuel Filter Cap O-Ring | Visible leak from filter cap, diesel smell | 1 | $10 – $30 |

| Fuel Lines / Banjo Bolts | Visible leak from line connections, diesel smell | 2-3 | $50 – $200 (per line/fitting) |

| Fuel Pressure Regulator (FPR) | Visible leak from FPR, low fuel pressure, diesel smell | 2 | $100 – $250 |

| Standpipes / Dummy Plugs (if fuel related) | Often mistaken for oil leak, similar to injector O-rings | 4 | $100 – $300 |

| HPOP Cover Gasket (less common fuel leak) | Oil leak primarily, can mix with fuel if present | 4 | $50 – $150 |

Preventative Measures and Long-Term Maintenance for Your 6.0 Powerstroke

Preventing a 6.0 Powerstroke fuel leak on engine is always better than repairing one. Proactive maintenance and regular inspections can significantly extend the life of your fuel system components and help you avoid costly breakdowns. Many of Diesel Tech Ron‘s lessons emphasize the importance of routine checks and quality parts.

Regular Fuel System Checks

Make it a habit to perform regular visual inspections of your engine bay and undercarriage for any signs of fuel leaks. A quick check after each oil change or every few thousand miles can catch small leaks before they become major problems. Pay particular attention to the areas mentioned in the “Common Culprits” section. Don’t just look, but also smell for any lingering diesel odor. Check the integrity of all fuel lines and connections – ensure they are tight and free from cracks or chafing. The condition of rubber hoses is particularly important, as they can degrade over time due to heat and exposure to fuel.

Quality Fuel Filters and Fuel Treatment

The 6.0 Powerstroke is notoriously sensitive to fuel quality. Using high-quality fuel filters and replacing them at or before the manufacturer-recommended intervals (typically every 10,000 to 15,000 miles) is paramount. Clogged filters can put undue stress on the fuel pump and cause erratic fuel pressure, which can indirectly contribute to leaks. Additionally, incorporating a high-quality diesel fuel additive that provides lubricity and cleans the fuel system can help protect injectors and seals, prolonging their life and preventing a future 6.0 Powerstroke fuel leak on engine.

Addressing Related Issues Promptly

The interconnectedness of the 6.0 Powerstroke’s systems means that an issue in one area can cascade into another. For instance, a persistent high-pressure oil leak could lead to conditions that stress fuel system components. Likewise, a failing FICM might not directly cause a fuel leak, but its impact on injector performance could lead to premature wear. Addressing any engine performance issues, even if seemingly minor, can prevent more significant problems like a persistent fuel leak on 6.0 Powerstroke down the line. Staying on top of routine maintenance, such as oil changes with correct oil, coolant system health, and ensuring proper battery voltage for the FICM, all contribute to overall engine longevity and reduce the likelihood of fuel system failures.

Conclusion

A 6.0 Powerstroke fuel leak on engine is undoubtedly a concerning issue for any owner, but it’s far from a death sentence for your truck. By understanding the intricate fuel system, knowing the common leak points, and employing systematic diagnostic methods – much like those advocated by experts such as Diesel Tech Ron – you can effectively identify and resolve these problems. Whether you choose to tackle the repair yourself or enlist the help of a professional, armed with the knowledge from this guide, you’ll be able to make informed decisions.

Remember, preventative maintenance is your best defense. Regular inspections, timely filter changes, and using quality fuel additives will go a long way in ensuring your 6.0 Powerstroke continues to perform reliably for years to come. Don’t let a lingering diesel smell or a visible drip turn into a major headache. Take action, address the leak promptly, and get back to enjoying the power and performance your Powerstroke was designed to deliver. A well-maintained 6.0 is a strong and dependable truck, ready for any challenge the road throws its way.

Frequently Asked Questions

What are the most common causes of a 6.0 Powerstroke fuel leak?

The most frequent culprits for a 6.0 Powerstroke fuel leak include degraded injector O-rings, cracked or worn fuel lines, and issues with the fuel pressure regulator. These components can fail due to age, heat, and vibration, leading to a noticeable diesel smell or visible leaks.

How can I tell if my 6.0 Powerstroke has a fuel leak?

Key indicators of a 6.0 Powerstroke fuel leak often include a strong diesel odor inside or around the engine bay, visible puddles or wet spots under the truck, or a noticeable drop in fuel economy. You might also experience engine performance issues like rough idling or hard starting if the leak is significant.

Where do 6.0 Powerstroke fuel leaks typically occur, and how can Diesel Tech Ron’s advice help me find it?

Common locations for a 6.0 Powerstroke fuel leak are often around the fuel lines running over the valve covers, the fuel filter housing, and the fuel pressure regulator. Diesel Tech Ron’s solutions typically detail systematic inspection methods and visual cues to help pinpoint the exact source of the leak efficiently.

Is a 6.0 Powerstroke fuel leak a serious problem, and what are the risks?

Yes, a 6.0 Powerstroke fuel leak is a serious issue that requires immediate attention. It poses a significant fire hazard, can lead to costly damage to other engine components if left unaddressed, and results in substantial fuel waste, impacting your wallet and the environment.

Can I fix a 6.0 Powerstroke fuel leak myself, or should I seek professional help?

While some minor 6.0 Powerstroke fuel leaks might be manageable for experienced DIYers with the right tools and mechanical knowledge, many require specialized diagnostic equipment and expertise. Consulting resources from Diesel Tech Ron can provide valuable guidance, but professional assistance often ensures a thorough and lasting repair, especially for complex issues.

What are typical repair costs for a 6.0 Powerstroke fuel leak, and what kind of solutions does Diesel Tech Ron offer?

Repair costs for a 6.0 Powerstroke fuel leak can vary widely, from a few hundred dollars for simple O-ring replacements to over a thousand for more complex component failures like injector housing repairs or fuel line replacements. Diesel Tech Ron offers comprehensive solution guides, troubleshooting tips, and step-by-step repair instructions to help identify and fix various types of fuel leaks efficiently.