6.0 Powerstroke Crankcase Ventilation System Specifications

Featured image for this comprehensive guide about 6.0 Powerstroke crankcase ventilation system specs

6.0 Powerstroke Crankcase Ventilation System Specifications

Category: Technical Specifications

The 6.0 Powerstroke engine, a marvel of diesel engineering from Ford, often evokes strong opinions among truck enthusiasts. Known for its immense power and torque, it also gained a reputation for specific vulnerabilities. One critical, yet often overlooked, aspect of this engine’s health and longevity is its crankcase ventilation system. Far from a simple hose, this system is a complex network designed to manage the internal gases of your engine, directly impacting performance, emissions, and the lifespan of critical components like your turbocharger.

Understanding the intricacies of the 6.0 Powerstroke crankcase ventilation system specs is not just for mechanics; it’s essential for any owner looking to maintain their truck’s peak performance and avoid costly repairs. Whether you’re dealing with excessive oil consumption, puzzling oil leaks, or simply aiming for preventative maintenance, a deep dive into how this system works, what its specifications are, and common failure points will empower you to make informed decisions. Let’s pull back the curtain and explore the vital role this system plays in your diesel powerhouse.

Quick Answers to Common Questions

What’s the main job of the 6.0 Powerstroke crankcase ventilation system?

It’s crucial for removing blow-by gases and pressure from the engine’s crankcase, preventing oil contamination and seal leaks. Essentially, it helps the engine breathe properly and keeps things clean according to its original design specs.

Why should I care about my 6.0 Powerstroke crankcase ventilation system’s performance?

A properly functioning system prevents sludge buildup, oil leaks, and premature engine wear, directly impacting your engine’s longevity and performance. Keeping an eye on these 6.0 Powerstroke crankcase ventilation system specs ensures your engine stays healthy.

Are there common issues with the 6.0 Powerstroke crankcase ventilation system specs that I should know about?

Yes, one common issue is the build-up of oil and soot, which can clog the system or lead to oil leaks, often affecting the longevity of components like the turbo. Many owners look into modifications to improve its efficiency and address these specific 6.0 Powerstroke crankcase ventilation system specs.

What’s the “CCV Mod” people talk about regarding the 6.0 Powerstroke crankcase ventilation system?

The “CCV Mod” typically involves rerouting the crankcase ventilation gases to vent to the atmosphere instead of back into the turbocharger inlet. This can prevent oil and soot from coating your turbo and intercooler, directly addressing common issues with the original 6.0 Powerstroke crankcase ventilation system specs.

How often should I inspect or maintain my 6.0 Powerstroke crankcase ventilation system?

It’s a good idea to inspect the hoses and connections for leaks or cracks during your regular oil changes, or at least every 15,000 miles. Keeping these 6.0 Powerstroke crankcase ventilation system specs in check is key to preventing bigger problems down the road.

📋 Table of Contents

- Understanding the Core: What is Crankcase Ventilation?

- The Anatomy of the 6.0 Powerstroke CCV System: Components and Their Roles

- Key Specifications and Performance Metrics

- Common Issues and Failure Points of the 6.0 Powerstroke CCV System

- Maintenance, Upgrades, and Actionable Tips for Optimal Performance

- Conclusion

Understanding the Core: What is Crankcase Ventilation?

At the heart of every internal combustion engine, including your robust 6.0 Powerstroke, is the phenomenon known as “blow-by.” This refers to the small amount of combustion gases and fuel vapors that inevitably escape past the piston rings and into the crankcase during engine operation. While a normal occurrence, if left unmanaged, these gases can create significant problems. Uncontrolled blow-by leads to pressure buildup within the crankcase, which can force oil past seals and gaskets, causing leaks. More critically, these gases contain corrosive elements and unburnt fuel that can contaminate the engine oil, accelerating wear on internal components.

This is precisely where the crankcase ventilation system steps in. Historically, older engines used simple “breather” tubes that vented these gases directly into the atmosphere – an environmentally unfriendly approach. Modern engines, especially those designed for high performance and stringent emissions standards like the 6.0 Powerstroke, employ a Closed Crankcase Ventilation (CCV) system. The 6.0 Powerstroke CCV system is designed to capture these blow-by gases, separate oil mist from them, and then re-introduce the ‘cleaned’ gases back into the engine’s intake system to be re-burned. This not only prevents harmful emissions but also contributes to engine cleanliness and efficiency. It’s a testament to the sophisticated engineering within your Powerstroke, ensuring your engine breathes correctly while minimizing its environmental footprint.

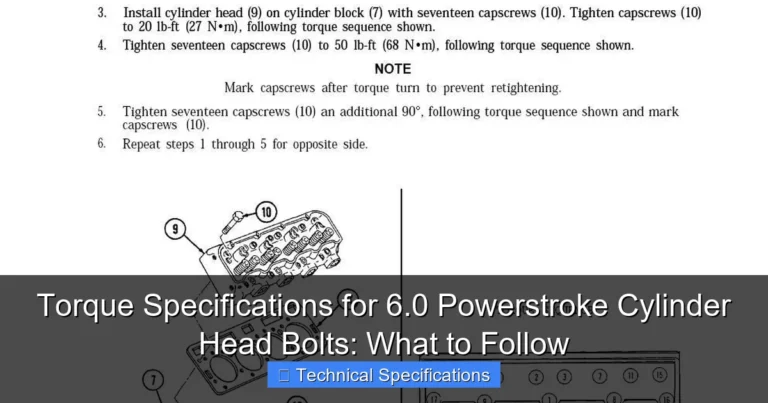

| Specification Item | Details / Value | Notes / Impact |

|---|---|---|

| System Type | Open Crankcase Ventilation (OCV) | Vents blow-by gasses directly to atmosphere (stock design) |

| Ventilation Point | Passenger Side Valve Cover | “Doghouse” or breather box houses the oil separator/mesh |

| New Engine Blow-by (Typical) | ~1.5 – 2.5 CFM (Cubic Feet per Minute) | Excessive blow-by indicates engine wear (e.g., piston rings) |

| Maintenance/Inspection | Periodically inspect for oil residue, leaks, or blockages | No factory “filter change” interval; aftermarket solutions are common |

| Common Failure Indication | Excessive oil in turbo intake, oil leaks, oil film on engine | Can lead to reduced turbo life, increased oil consumption, emissions issues |

The Anatomy of the 6.0 Powerstroke CCV System: Components and Their Roles

The 6.0 Powerstroke crankcase ventilation system is more than just a single component; it’s an integrated network designed to efficiently manage blow-by gases. To truly grasp the 6.0 Powerstroke crankcase ventilation system specs, you need to understand each part and its specific function.

The Oil Separator (or “Doghouse” / CCV Filter Housing)

Perhaps the most critical component in the 6.0 Powerstroke CCV system is the oil separator, often affectionately (or sometimes derisively) referred to as the “doghouse” due to its distinctive shape and location on top of the passenger-side valve cover. Its primary role is to separate oil mist from the blow-by gases before they are returned to the engine’s intake. Inside, it utilizes a combination of baffling, chambers, and a filter media (some designs use coalescing filters, others rely more on centrifugal force) to cause oil droplets to condense and fall out of the gas stream. This collected oil then drains back into the valve cover and engine’s oil pan. A well-functioning oil separator is paramount to preventing oil accumulation in your turbocharger and intercooler, which can lead to reduced efficiency, smoke, and premature component wear.

Inlet and Outlet Hoses

Connecting the various parts of the 6.0 Powerstroke CCV system are a series of robust hoses. These hoses carry the blow-by gases from the valve cover to the oil separator and then the ‘cleaned’ gases from the separator back to the turbocharger inlet. The main vent hose is critical, typically featuring a durable, oil and heat-resistant construction. These hoses must withstand constant exposure to oil vapors and engine heat cycles without collapsing, cracking, or developing leaks. Their routing is precise, ensuring proper flow and preventing kinking, which could restrict ventilation.

Turbocharger Inlet (Pre-Turbo)

Once the blow-by gases have passed through the oil separator and are largely free of oil mist, they are routed back into the engine’s air intake system, specifically into the turbocharger inlet. Re-introducing these gases pre-turbo ensures they are fully combusted in the engine cylinders, contributing to reduced emissions. However, this also means that if the oil separator is not performing optimally, any residual oil mist will be drawn directly into the turbo, potentially coating the compressor wheel, intercooler, and intake manifold. This can lead to sludge buildup, reduced airflow, and ultimately, turbocharger issues, underscoring the importance of proper 6.0 Powerstroke crankcase ventilation system function.

Internal Engine Passages

While not external components, the internal passages within the 6.0 Powerstroke engine block and valve covers are integral to the CCV system. These passages provide the pathways for blow-by gases to exit the crankcase and cylinder heads, eventually making their way to the external components like the oil separator. Any blockages or restrictions within these internal passages, though rare, can impede proper ventilation and lead to pressure buildup, even if external components are functioning correctly.

Key Specifications and Performance Metrics

Understanding the quantifiable aspects of the 6.0 Powerstroke crankcase ventilation system specs provides a baseline for diagnosing issues and ensuring optimal engine health. While some exact “specs” are more operational expectations than hard-coded numbers on a part, they are crucial for system evaluation.

Blow-by Volume Expectations

The amount of blow-by gas produced by an engine is a key indicator of its internal health, particularly the condition of the piston rings and cylinder walls. For a healthy 6.0 Powerstroke engine, particularly one that’s relatively new or well-maintained, expect a relatively low volume of blow-by. As the engine accumulates mileage and wear, this volume will naturally increase. Excessive blow-by indicates significant internal wear, potentially necessitating major engine work.

- New/Healthy Engine (Warm Idle): Approximately 2-3 cubic feet per minute (CFM) or 50-80 liters per minute (L/min).

- Acceptable/Moderate Wear (Warm Idle): Up to 5-6 CFM (140-170 L/min) is often considered a diagnostic threshold before serious concerns arise.

- Excessive Blow-by: Anything significantly above 6 CFM, especially accompanied by visible smoke from the oil fill cap or dipstick tube, indicates substantial engine wear.

Monitoring blow-by can be done with specialized tools or, for a rough estimation, the simple “oil cap test” (placing the oil fill cap upside down on the fill tube while the engine is running to see if it dances excessively or blows off).

Oil Separator Efficiency

While there isn’t a universally published “percentage efficiency” spec for the 6.0 Powerstroke oil separator, its effectiveness is critical. A properly functioning separator should remove the vast majority of oil mist from the blow-by gases. An inefficient separator will allow oil to pass into the turbocharger inlet, leading to visible oil residue in the turbo compressor housing, intercooler boots, and potentially blue smoke from the exhaust under load. Its efficiency relies on:

- Cleanliness: A clogged or saturated filter media will reduce separation effectiveness.

- Integrity: Cracks or damage to the housing can bypass the separation process.

Operating Temperature Range

The CCV system is designed to function across the engine’s normal operating temperature range. However, extremely cold temperatures can lead to increased condensation within the system, potentially causing ice buildup in hoses or the separator. Conversely, sustained high temperatures can accelerate the breakdown of hose materials and oil volatility, contributing to sludge. The system’s design accounts for typical diesel engine operating temperatures, which generally run hotter than gasoline engines.

Hose Diameters and Materials

The hoses used in the 6.0 Powerstroke CCV system are specified for their diameter, ensuring adequate flow of gases, and material composition, to withstand the harsh environment.

- Main Vent Line Diameter: Typically around 1 inch (25mm) internal diameter for the primary hose connecting the separator to the turbo inlet. Smaller lines may be used for drain-back or pressure equalization.

- Material: Hoses are typically made from oil and heat-resistant rubber or silicone compounds, designed to prevent deterioration from oil vapors and high engine bay temperatures.

Incorrect hose diameters or materials can lead to restrictions, collapse, or premature failure, compromising the entire system.

Here’s a summary of key operational parameters:

| Component/Metric | Specification/Value (Approximate) | Notes |

|---|---|---|

| New Engine Blow-by (Warm Idle) | 2-3 CFM (50-80 L/min) | At normal operating temperature, good piston ring seal. |

| Acceptable Blow-by (Worn Engine) | Up to 5-6 CFM (140-170 L/min) | Diagnostic threshold; consult professional if consistently higher. |

| Main CCV Hose ID | ~1 inch (25mm) | Crucial for proper gas flow; variations exist. |

| Oil Separator Service Interval | Inspect at every oil change, replace as needed. | No fixed interval; depends on engine health and driving conditions. |

| Operating Pressure (Crankcase) | Slight vacuum to slightly positive pressure (near atmospheric) | Significant positive pressure indicates restriction or excessive blow-by. |

Common Issues and Failure Points of the 6.0 Powerstroke CCV System

Despite its critical role, the 6.0 Powerstroke crankcase ventilation system is unfortunately a common source of problems for owners. Understanding these failure points is essential for proactive maintenance and accurate diagnostics, directly relating to the importance of knowing your 6.0 Powerstroke crankcase ventilation system specs.

Clogging of the Oil Separator/Filter

This is arguably the most prevalent issue. Over time, especially in engines with higher blow-by or those using lower quality oils, the internal filter media or baffles within the oil separator can become saturated and clogged with oil sludge, carbon, and other contaminants.

- Symptoms:

- Excessive oil consumption.

- Oil accumulation in the turbocharger inlet, intercooler pipes, and charge air cooler.

- Blue or white smoke from the exhaust (especially under load).

- Increased crankcase pressure, potentially leading to oil leaks from seals and gaskets (e.g., rear main seal, front cover seal).

- Puking oil from the oil fill cap or dipstick tube.

- Causes: High blow-by (due to engine wear), infrequent oil changes, poor quality oil, extended idling.

Cracked or Deteriorated Hoses

The hoses connecting the various parts of the CCV system are constantly exposed to engine heat, oil vapors, and vibration. Over time, this can lead to material degradation.

- Symptoms:

- Visible cracks, splits, or softness in the hoses.

- Oil leaks around the hose connections.

- Unmetered air entering the intake (if a hose post-separator is cracked), potentially affecting engine performance.

- Vacuum leaks (if a hose before the separator is cracked), leading to oil smell in the cabin.

- Difficulty in maintaining stable engine idle.

- Causes: Age, heat cycling, chemical exposure (oil, fuel vapors), physical abrasion.

Excessive Blow-by from Worn Engine

While the CCV system is designed to manage blow-by, it has limits. If the engine itself is significantly worn (e.g., worn piston rings, cylinder walls), the volume of blow-by gas can overwhelm the system.

- Symptoms:

- High oil consumption that cannot be attributed to leaks or a clogged separator.

- Persistent blue smoke from the exhaust.

- Noticeable pressure pushing out of the oil fill cap or dipstick tube, even with a clean CCV system.

- Reduced engine power and fuel economy.

- Causes: High mileage, poor maintenance, engine overheating, contaminated fuel/oil, internal engine component failure.

Oil Leaks from the CCV System

Beyond internal engine leaks, the CCV system itself can be a source of external oil leaks.

- Symptoms:

- Oil residue on the valve cover, around the oil separator housing, or along the CCV hoses.

- Drips of oil on the ground below the engine.

- Causes: Clogged separator leading to pressure buildup, cracked housing, deteriorated O-rings or gaskets, loose hose clamps, cracked hoses.

Addressing these common issues quickly is key to preventing secondary problems, such as turbocharger failure or excessive oil consumption, which can be far more expensive to repair than a simple CCV component replacement.

Maintenance, Upgrades, and Actionable Tips for Optimal Performance

Maintaining the 6.0 Powerstroke crankcase ventilation system is paramount for the longevity and performance of your engine. By understanding the 6.0 Powerstroke crankcase ventilation system specs and common issues, you can implement effective strategies to keep your diesel running strong.

Regular Inspection and Cleaning

Preventative maintenance is your best defense against CCV system failures.

- Inspect Hoses: At every oil change or service interval, visually inspect all CCV hoses for cracks, softness, swelling, or signs of oil seepage. Pay close attention to bends and connection points. Replace any compromised hoses immediately.

- Check Separator Housing: Look for oil leaks around the “doghouse” housing. Ensure it’s securely seated and the mounting bolts/clips are tight.

- Blow-by Test: Periodically perform a simple blow-by test by removing the oil fill cap and placing it upside down on the fill tube. A slight dance is normal, but if it consistently blows off or is accompanied by heavy smoke, it’s an indication of excessive blow-by or a clogged CCV system.

- Clean Components (Where Applicable): While some oil separators are sealed, others may allow for internal cleaning or filter replacement. Consult your service manual or a reputable mechanic for specific guidance. Often, simply replacing the entire oil separator assembly is the most straightforward and effective solution for a clogged unit.

When to Replace Components

There’s no fixed replacement schedule for the entire 6.0 Powerstroke CCV system, but components should be replaced as needed based on inspection and symptoms.

- Oil Separator: If you’re experiencing excessive oil in the turbo, increased crankcase pressure, or visible oil leaks from the separator itself, it’s time for a replacement. Many owners opt to replace this unit proactively if they suspect it’s aging or if they’re doing other major engine work.

- Hoses: Replace any hoses that show signs of cracking, swelling, or hardening. Always use high-quality, oil-resistant hoses designed for diesel applications.

- Gaskets/O-rings: If you disassemble any part of the CCV system, always replace the associated gaskets and O-rings to prevent leaks.

The “CCV Delete” / “Reroute” Modification

Many 6.0 Powerstroke owners consider a “CCV delete” or “reroute” modification. This modification involves diverting the blow-by gases from the oil separator and turbo inlet to vent directly to the atmosphere (usually through a catch can) or to a designated “sump” tank.

- Pros:

- Keeps the turbocharger, intercooler, and intake manifold much cleaner, reducing sludge buildup.

- Can make diagnosing blow-by issues easier as you’ll see oil accumulation in the catch can.

- Potentially improves turbo longevity by reducing contamination.

- Cons:

- Legality and Emissions: Venting blow-by to the atmosphere is illegal in many regions due to environmental regulations and will cause your vehicle to fail emissions inspections.

- Odor: Vented blow-by gases can produce an unpleasant odor, especially when idling.

- Mess: A catch can requires regular emptying, and if not properly designed, can create an oily mess.

- Cold Weather Issues: In extremely cold climates, condensation in the vented line can freeze, causing blockages and leading to crankcase pressure buildup.

Consideration: Before performing a CCV delete, research local laws, understand the environmental impact, and consider a properly designed catch-can system to manage the collected oil.

Monitoring Blow-by

Regularly monitoring your engine’s blow-by is one of the most proactive steps you can take. While the oil cap test is a rough guide, a professional blow-by test using a specialized manometer or flow meter can give you precise readings against factory 6.0 Powerstroke crankcase ventilation system specs. This allows you to catch engine wear early and address it before it leads to more severe problems.

Importance of Quality Oil

Using the correct specification and high-quality engine oil is crucial. Quality oil resists thermal breakdown and sludge formation better than conventional oils, which helps keep your CCV system cleaner and more efficient. Refer to your owner’s manual for recommended oil types and change intervals specific to your 6.0 Powerstroke.

Conclusion

The 6.0 Powerstroke crankcase ventilation system is a vital, yet often misunderstood, component of your truck’s engine. Far from a simple afterthought, its design and proper function directly impact your engine’s internal cleanliness, emissions compliance, and overall longevity. Understanding the 6.0 Powerstroke crankcase ventilation system specs, from blow-by expectations to component roles, empowers you as an owner to identify potential issues early and implement effective maintenance strategies.

Whether you opt for meticulous stock system maintenance or consider modifications like a CCV reroute, the goal remains the same: to efficiently manage engine blow-by and protect your turbocharger and intake system from oil contamination. By prioritizing the health of your CCV system, performing regular inspections, and addressing issues promptly, you’ll contribute significantly to the enduring power and reliability that the 6.0 Powerstroke is capable of delivering. Don’t let a small system lead to big problems – keep your Powerstroke breathing clean and running strong!

🎥 Related Video: How To Find Bolt Torque Specifications

📺 The Clay Way

I get tons of questions about torque specs I don’t think people quite understand that it’s not the manufacturer that makes up the …

Frequently Asked Questions

What is the primary purpose of the crankcase ventilation system on a 6.0 Powerstroke engine?

The primary purpose of the 6.0 Powerstroke crankcase ventilation system is to remove harmful “blow-by” gases from the engine’s crankcase. These gases, which are a byproduct of combustion, can cause pressure buildup and contaminate engine oil if not properly vented.

How does the 6.0 Powerstroke’s crankcase ventilation system typically operate?

The 6.0 Powerstroke utilizes an open crankcase ventilation (OCV) system that routes blow-by gases from the “doghouse” cover on top of the engine back into the turbocharger inlet. Before re-entering the intake, an internal oil separator removes most of the oil vapor to reduce intake contamination.

What are the main components of the 6.0 Powerstroke crankcase ventilation system?

The key components include the crankcase vent filter or “doghouse” assembly, which incorporates an oil separator, and the hoses that route the gasses. This system is designed to manage internal crankcase pressure and minimize oil vapor discharge back into the engine’s intake.

What are the common symptoms of a malfunctioning 6.0 Powerstroke crankcase ventilation system?

A malfunctioning 6.0 Powerstroke crankcase ventilation system can lead to various issues, including increased oil consumption, oil leaks from seals, and a buildup of sludge in the intake. You might also notice a strong oil smell or increased pressure when removing the oil fill cap.

Are there any recommended modifications or upgrades for the 6.0 Powerstroke crankcase ventilation system?

Many 6.0 Powerstroke owners opt for a “CCV Mod” which involves rerouting the crankcase ventilation system to vent to the atmosphere or a catch can. This modification aims to prevent oil vapors from re-entering the turbo and intercooler, reducing carbon buildup and “coking.”

Why is proper maintenance of the 6.0 Powerstroke crankcase ventilation system important for engine longevity?

Proper maintenance of the 6.0 Powerstroke crankcase ventilation system is crucial because it ensures harmful blow-by gases and oil vapors are efficiently removed from the engine. This prevents pressure buildup, reduces oil contamination, and ultimately helps prolong the life of engine seals and internal components.