6.0 Powerstroke Camshaft Specifications: What You Should Know

Featured image for this comprehensive guide about 6.0 Powerstroke camshaft specs

The Ford 6.0 Powerstroke diesel engine, while legendary for its potential, is also infamous for its factory limitations. Owners often find themselves on a quest for enhanced performance, improved reliability, and a more responsive driving experience. At the heart of this quest, and indeed at the very core of how your engine breathes and performs, lies the camshaft. Understanding 6.0 Powerstroke camshaft specs isn’t just for mechanics; it’s crucial for any owner looking to truly unlock their truck’s potential.

Far from being a simple, unchangeable component, the camshaft dictates the precise timing and duration of your engine’s valve events. This means it controls exactly when and for how long air enters and exhaust gases leave the cylinders. Altering these parameters can dramatically shift your engine’s power band, improve turbo spool, and even influence fuel efficiency. Whether you’re chasing more horsepower for the track, better torque for towing, or simply want to optimize an EGR delete, diving deep into 6.0 Powerstroke camshaft specifications is an essential step.

In this comprehensive guide, we’ll strip away the technical jargon and provide you with everything you need to know about 6.0 Powerstroke camshaft specs. We’ll explore the factory design, discuss the limitations that lead many to consider an upgrade, break down the critical terminology, and guide you through the exciting world of aftermarket performance camshafts. Get ready to understand the heartbeat of your diesel engine like never before, equipping you with the knowledge to make informed decisions for your truck’s future.

Quick Answers to Common Questions

Why would I even consider changing my 6.0 Powerstroke camshaft specs?

Upgrading your 6.0 Powerstroke camshaft specs can significantly improve power, torque, and engine efficiency, especially if you’re looking for more performance or better towing capabilities. It’s a key modification for unlocking your engine’s full potential.

What are the main benefits of an aftermarket 6.0 Powerstroke camshaft?

You can expect gains in horsepower and and torque, a broader powerband, and sometimes even improved fuel economy or a smoother idle. The right 6.0 Powerstroke camshaft specs can truly transform your truck’s responsiveness.

Are there different kinds of 6.0 Powerstroke camshaft specs for different uses?

Absolutely! You’ll find camshafts optimized for specific applications, like heavy towing, street performance, or even racing. Choosing the right 6.0 Powerstroke camshaft specs depends entirely on how you use your truck.

Do I need other modifications to go along with new 6.0 Powerstroke camshaft specs?

Often, yes. To fully capitalize on your new 6.0 Powerstroke camshaft specs, complementary upgrades like custom tuning, upgraded valve springs, and possibly improved injectors or turbo are highly recommended. These help ensure optimal performance and reliability.

Will changing my 6.0 Powerstroke camshaft specs make my truck sound different?

Yes, a performance 6.0 Powerstroke camshaft can definitely change your engine’s sound, often giving it a more aggressive or noticeable idle “lope.” This is a common characteristic of more performance-oriented 6.0 Powerstroke camshaft specs.

📋 Table of Contents

- Understanding the Heartbeat: What is a Camshaft?

- Decoding the Stock 6.0 Powerstroke Camshaft Specs

- When and Why to Upgrade Your 6.0 Powerstroke Camshaft

- Navigating 6.0 Powerstroke Camshaft Upgrades: What to Look For

- Installation, Tuning, and Maintenance Tips for Your New 6.0 Powerstroke Camshaft

- Conclusion

Understanding the Heartbeat: What is a Camshaft?

Before we dive into the specific numbers and design philosophies behind the 6.0 Powerstroke camshaft specs, it’s vital to grasp what a camshaft is and why it’s so fundamental to your engine’s operation. Often referred to as the “brain” or “heartbeat” of the engine, the camshaft orchestrates the rhythmic dance of intake and exhaust valves, controlling the engine’s breathing cycle.

The Basics of Camshaft Function

In simple terms, the camshaft is a rotating shaft with precisely shaped lobes (cams) that push against lifters, which in turn move pushrods, rocker arms, and finally open the engine’s intake and exhaust valves. As the crankshaft turns, synchronized with the camshaft via a timing chain or gears, the camshaft rotates, ensuring that the valves open and close at precisely the right moment for each cylinder’s combustion cycle. This timing is critical for drawing in fresh air, compressing it with fuel, extracting power, and expelling spent exhaust gases.

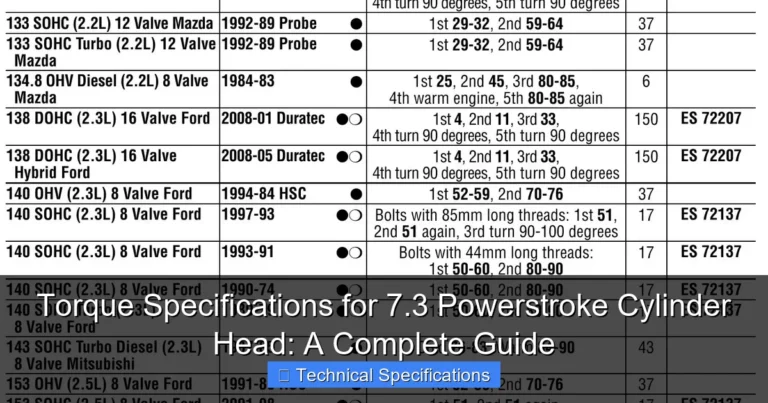

| Camshaft Type / Grind | Intake/Exhaust Lift (in.) | Intake/Exhaust Duration (@.050°) | Lobe Separation Angle (LSA) |

|---|---|---|---|

| Stock OEM Replacement | ~0.420 / 0.420 | ~190° / 190° | ~104° |

| Mild Performance / Towing | ~0.435 / 0.435 | ~195° / 198° | ~105° |

| Aggressive Street / Performance | ~0.445 / 0.445 | ~200° / 204° | ~106° |

| Race / High RPM | ~0.455 / 0.455 | ~208° / 212° | ~108° |

Every decision made in the design of a camshaft – from the height of its lobes to their shape and separation – directly impacts how efficiently your engine can breathe. This, in turn, dictates its power output, torque characteristics, fuel economy, and even idle quality. When we talk about 6.0 Powerstroke camshaft specs, we’re talking about the blueprints that define these crucial valve events.

Key Camshaft Terminology Explained

To truly understand 6.0 Powerstroke cam specs, you need to be familiar with a few core terms. These are the numbers and concepts that differentiate one camshaft from another and dictate its performance characteristics:

- Lift: This refers to how far the valve opens from its fully closed position. Measured in inches (e.g., .550″ lift), higher lift generally allows more air to flow into or out of the cylinder, potentially increasing power at higher RPMs. However, excessive lift requires stronger valve springs and can lead to valve-to-piston contact if not carefully matched to other engine components.

- Duration: Duration measures how long, in degrees of crankshaft rotation, the valve remains open. A longer duration means the valve is open for a longer period, allowing more air to enter or exit. Shorter duration typically favors low-end torque and better idle, while longer duration generally shifts the power band to higher RPMs, improving top-end horsepower.

- Lobe Separation Angle (LSA): Expressed in degrees (e.g., 108° LSA), this is the angle in crankshaft degrees between the centerline of the intake lobe and the centerline of the exhaust lobe. A tighter (lower) LSA increases valve overlap (the period when both intake and exhaust valves are open), which can improve turbo spool and top-end power but may lead to a choppier idle and increased emissions. A wider (higher) LSA reduces overlap, improving idle quality, drivability, and often fuel economy, but potentially sacrificing some peak power and turbo responsiveness.

- Overlap: This is the period, measured in crankshaft degrees, when both the intake and exhaust valves are open simultaneously at the end of the exhaust stroke and the beginning of the intake stroke. Overlap helps scavenge exhaust gases and draw in the fresh air charge. The amount of overlap is directly influenced by duration and LSA.

- Intake Centerline (ICL) & Exhaust Centerline (ECL): These are the points of maximum lift for the intake and exhaust lobes, respectively, relative to Top Dead Center (TDC) of the piston. These, along with LSA, help define when the valve events occur.

Grasping these terms is your first step towards making informed decisions about modifying your 6.0 Powerstroke’s camshaft. They are the language through which engine builders communicate performance characteristics.

Decoding the Stock 6.0 Powerstroke Camshaft Specs

The factory 6.0 Powerstroke camshaft was designed with a specific set of parameters in mind, balancing performance, emissions compliance, and mass-market drivability. Understanding these original 6.0 Powerstroke camshaft specs is crucial for appreciating why many owners opt for an upgrade.

Factory Design Philosophy

Ford and Navistar engineered the original 6.0 Powerstroke camshaft to provide a broad, usable torque curve suitable for a wide range of applications, from daily driving to heavy towing. The design prioritized:

- Emissions Compliance: Meeting stringent EPA regulations was a primary concern, which often necessitates compromises in raw performance.

- Drivability: A smooth idle and predictable throttle response were essential for consumer satisfaction across diverse driving conditions.

- Longevity: The stock cam was built to last, assuming reasonable maintenance and typical operating conditions.

- Fuel Economy: While not the absolute top priority, efficient combustion contributed to acceptable fuel mileage for a heavy-duty truck.

- Integration with the EGR System: The camshaft timing plays a significant role in managing exhaust gas recirculation, which was a core part of the 6.0 Powerstroke’s emissions strategy.

These priorities led to a relatively mild camshaft profile compared to what’s achievable with aftermarket performance designs. The emphasis was on a user-friendly engine that performed adequately in most scenarios, rather than maximizing horsepower or torque at extreme ends of the RPM spectrum.

The Specifics: Stock 6.0 Powerstroke Camshaft Specifications

Pinpointing exact, universally agreed-upon factory 6.0 Powerstroke camshaft specs can sometimes be challenging due to proprietary data and slight variations over production years. However, based on reverse engineering, reputable aftermarket research, and common understanding within the diesel community, we can characterize the stock cam’s properties:

| Specification | Approximate Value / Characteristic |

|---|---|

| Intake Lift | ~0.330″ – 0.350″ (at the cam lobe; actual valve lift is higher due to rocker arm ratio, often around 0.530″ – 0.560″ gross valve lift) |

| Exhaust Lift | ~0.330″ – 0.350″ (at the cam lobe; actual valve lift is higher due to rocker arm ratio, often around 0.530″ – 0.560″ gross valve lift) |

| Intake Duration (@.050″) | ~190° – 200° (relatively short) |

| Exhaust Duration (@.050″) | ~190° – 200° (relatively short) |

| Lobe Separation Angle (LSA) | ~109° – 112° (moderate to wide, reducing overlap) |

| Overlap | Relatively low, contributing to smoother idle and emissions control. |

*Note: These are approximate values for comparison. Always consult specific manufacturer data for exact aftermarket 6.0 Powerstroke camshaft specs. The “gross valve lift” refers to the lift after accounting for the rocker arm ratio, which typically amplifies the cam lobe lift.

What these numbers tell us is that the stock cam is designed for efficiency and a broad, manageable power delivery, rather than aggressive peak performance. The relatively short duration and moderate LSA result in a smooth idle and good low-end torque, but they also limit the engine’s ability to “breathe” optimally at higher RPMs or when significantly increasing fueling or boost.

Limitations of the Stock Camshaft

While adequate for most stock applications, the factory 6.0 Powerstroke camshaft presents several limitations for owners seeking enhanced performance or addressing common issues:

- Limited Airflow: The relatively short duration and moderate lift restrict the engine’s ability to ingest and expel large volumes of air, especially at higher boost pressures or with larger injectors. This can become a bottleneck for maximizing horsepower.

- Suboptimal for Performance Upgrades: When you add larger injectors, a bigger turbo, or custom tuning, the stock cam can’t fully capitalize on these modifications. It essentially chokes the engine’s potential.

- EGR System Interaction: The stock cam’s overlap and timing were designed to work with the factory EGR system. For trucks with an EGR delete, the stock cam can sometimes lead to less efficient scavenging and potential “reversion” issues where exhaust gases are pulled back into the intake manifold.

- Turbo Lag: While not solely a cam issue, the stock cam’s characteristics don’t do much to mitigate turbo lag. Performance cams, particularly those with tighter LSAs, can significantly improve turbo spool-up.

- Wear Potential: Like any engine component, the stock camshaft can experience wear, particularly in high-mileage or poorly maintained engines. Upgrading during a rebuild can address this proactively.

These limitations are why a 6.0 Powerstroke camshaft upgrade is often considered a fundamental step in any serious performance build or reliability enhancement strategy for this platform.

When and Why to Upgrade Your 6.0 Powerstroke Camshaft

Deciding to upgrade your 6.0 Powerstroke camshaft is a significant step that can dramatically alter your engine’s performance characteristics. It’s not a decision to be taken lightly, but for many owners, it represents a crucial modification in their quest for a more powerful, reliable, and responsive truck.

Common Reasons for a Camshaft Upgrade

Owners typically consider a 6.0 Powerstroke camshaft upgrade for several key reasons:

- Increased Horsepower and Torque: This is arguably the most common motivation. A performance camshaft can unlock significant gains across the RPM range, providing more grunt for towing or exhilarating acceleration for street performance. By optimizing valve timing, lift, and duration, the engine can breathe more efficiently, leading to more power.

- Improved Turbo Spool: Many performance camshafts are designed with LSA and overlap characteristics that promote faster turbocharger spool-up. This reduces turbo lag, making the truck feel more responsive and powerful, especially from a standstill or during gear changes.

- Better EGR Management (Especially with Deletes): For trucks with an EGR delete, an aftermarket cam can be tailored to minimize exhaust gas reversion into the intake manifold, leading to cleaner intake temperatures and more consistent combustion. Some cams are specifically designed to optimize performance after an EGR delete.

- Addressing Wear or Failure: If your original 6.0 Powerstroke cam shows signs of wear (e.g., pitted lobes, excessive runout) or if your engine is undergoing a complete rebuild, upgrading the camshaft is a logical and cost-effective decision to enhance performance while the engine is already apart.

- Complementing Other Modifications: A camshaft upgrade is rarely a standalone modification. It truly shines when paired with other performance parts like larger fuel injectors, a bigger turbocharger, and custom engine tuning. It acts as the “bottleneck breaker” that allows these other components to perform to their full potential.

Ultimately, a cam upgrade is about optimizing the engine’s breathing to match the demands of its owner and any other modifications present.

Types of Performance Camshafts for the 6.0 Powerstroke

The aftermarket offers a variety of 6.0 Powerstroke camshaft specs tailored for different performance goals. Here are the main categories you’ll encounter:

- Towing/Torque Cams: These cams typically feature slightly increased lift and duration compared to stock, often with a tighter LSA than stock. The goal is to improve low-to-mid range torque, reduce turbo lag, and provide a broader, more usable powerband for heavy hauling. They maintain excellent street manners and a relatively smooth idle.

- Street Performance Cams: A step up from towing cams, these offer more aggressive lift and duration figures, often with an LSA that balances turbo spool with a strong mid-range and top-end power. They are designed for trucks that see regular street duty but also crave significant power improvements for spirited driving or occasional track use. Idle quality might be slightly more aggressive than stock but still perfectly acceptable.

- Race/High-HP Cams: These are the most aggressive profiles, featuring maximum lift and duration, often with tighter LSAs to maximize valve overlap for peak horsepower at higher RPMs. They are typically reserved for dedicated competition vehicles or extreme high-performance street builds. Expect a noticeable lopey idle, and potentially some sacrifice in low-end drivability or fuel economy. These cams almost always require extensive supporting modifications.

The “best” cam is entirely dependent on your individual needs and how you use your truck. There’s no one-size-fits-all solution when it comes to specific 6.0 Powerstroke camshaft specs.

The Synergy of Modifications

It cannot be stressed enough: a camshaft does not work in isolation. Its true potential is realized when it’s part of a cohesive modification strategy. Consider the camshaft as a conductor, orchestrating the performance of the entire engine orchestra:

- Injectors: Larger injectors dump more fuel. A performance cam helps ensure enough air is present to burn that fuel efficiently, translating it into power.

- Turbocharger: An upgraded turbo pushes more air. A cam with optimized duration and lift allows the engine to ingest and expel that increased airflow effectively. Cams can also significantly influence how quickly a larger turbo spools up.

- Head Studs: Any significant power increase on a 6.0 Powerstroke necessitates head studs to prevent head gasket failure. This is almost a prerequisite for a cam upgrade.

- Tuning: This is absolutely critical. A custom tune specifically calibrated for your new 6.0 Powerstroke camshaft specs, along with all other modifications, is essential. Without it, the engine won’t run correctly, and you won’t realize any of the potential gains.

Thinking of your build as a system, where each component enhances the others, is key to a successful and satisfying upgrade.

Navigating 6.0 Powerstroke Camshaft Upgrades: What to Look For

Once you’ve decided to upgrade, the next challenge is selecting the right camshaft. With a variety of aftermarket options boasting different 6.0 Powerstroke camshaft specs, it’s easy to feel overwhelmed. Knowing what to prioritize based on your driving style and existing modifications is paramount.

Key Specifications in Aftermarket Cams

When comparing aftermarket 6.0 Powerstroke camshaft specs, pay close attention to the following numbers:

- Lift: Aftermarket cams for the 6.0 Powerstroke typically feature higher lift than stock. While more lift means more airflow, there’s a limit. Excessive lift can lead to valve spring bind (where the spring compresses fully before the valve is fully open), coil bind (spring coils touching each other), or even valve-to-piston contact. Most performance cams will require upgraded valve springs to handle the increased lift and spring pressure, preventing valve float at higher RPMs.

- Duration: Performance cams generally have longer duration numbers. Longer duration helps extend the power band into higher RPMs, ideal for peak horsepower. However, too much duration can negatively impact low-end torque, worsen idle quality, and potentially increase emissions. Look for duration numbers that align with your desired power band.

- Lobe Separation Angle (LSA): This is a critical spec for the 6.0 Powerstroke.

- Tighter LSA (e.g., 104-108°): Increases valve overlap. This helps promote faster turbo spool by improving exhaust gas scavenging. It can create a more aggressive idle and is often favored in performance builds, especially with EGR deletes, but might be more sensitive to tuning.

- Wider LSA (e.g., 110-114°): Decreases valve overlap. Leads to a smoother idle, better emissions control, and can sometimes be more forgiving with less aggressive tuning. It might slightly reduce turbo responsiveness compared to a tighter LSA.

Many successful 6.0 Powerstroke performance cams utilize a tighter LSA than stock to maximize the effectiveness of EGR delete kits and improve turbo response.

- Material and Manufacturing: A quality camshaft will be made from durable, hardened steel and precisely ground. Reputable manufacturers invest in R&D and quality control. Don’t skimp on this component; a cheap cam can lead to premature wear or even catastrophic engine failure.

Choosing the Right Cam for Your Application

Your driving habits and truck’s purpose should be the primary guides in selecting your 6.0 Powerstroke camshaft specs:

- Daily Driver/Towing: Focus on cams designed for “towing” or “street” applications. These will have moderate increases in lift and duration, often with an LSA that promotes quick turbo spool and a broad torque curve, while maintaining a smooth, quiet idle and good drivability. Look for cams that advertise improved low-end and mid-range power.

- Street/Weekend Warrior: If you’re looking for a significant bump in power for spirited driving and occasional heavy use, but still need excellent street manners, a slightly more aggressive “street performance” cam will be appropriate. These will provide a noticeable increase in horsepower and torque throughout the RPM range, with perhaps a slightly more aggressive idle.

- Competition/High-Performance: For trucks dedicated to drag racing, sled pulling, or extreme horsepower builds, a “race” or “extreme performance” cam with the most aggressive 6.0 Powerstroke camshaft specs is the choice. Be prepared for a very lopey idle, potentially reduced low-end torque, and the absolute necessity of extensive supporting modifications and custom tuning to make it work effectively.

Always read reviews, consult with experienced diesel performance shops, and don’t hesitate to contact camshaft manufacturers directly to discuss your specific build goals.

Essential Supporting Modifications

Upgrading your 6.0 Powerstroke camshaft is rarely a standalone modification. To ensure reliability and extract maximum performance, several supporting modifications are often critical:

- Valve Springs: This is arguably the most crucial supporting modification. Higher lift and more aggressive ramps on aftermarket cams necessitate stiffer valve springs to prevent valve float at higher RPMs. If your valves float, they don’t follow the cam lobe properly, leading to a loss of power and potential engine damage. Many performance camshaft kits include upgraded valve springs, or they are highly recommended as a separate purchase.

- Pushrods: While often overlooked, upgraded pushrods are a wise investment, especially with stiffer valve springs. Stronger, thicker-wall pushrods prevent flex and ensure accurate valve train control, particularly in high-RPM or high-boost applications.

- Lifters: New lifters are often recommended or included with a new camshaft, especially if your engine has significant mileage. Worn lifters can cause noise and premature wear on a new camshaft.

- Custom Tuning: This is not optional. A camshaft change fundamentally alters the engine’s breathing. Your engine control unit (ECU) needs to be recalibrated with custom tuning to account for the new 6.0 Powerstroke camshaft specs, adjusting fuel delivery, injection timing, turbo VGT control, and other parameters to optimize performance and ensure safe operation.

- Head Studs: If you’re upgrading your cam for more power, you’re likely increasing cylinder pressures. Head studs are almost universally recommended for any 6.0 Powerstroke making significant power to prevent head gasket failure.

- Fueling and Turbo Upgrades: As mentioned before, a cam upgrade synergizes with larger injectors and upgraded turbochargers. Ensure your fuel system (fuel pump, filters) can support increased fuel demand.

Factor these additional costs into your budget when planning a 6.0 Powerstroke camshaft upgrade. Skipping essential supporting modifications can lead to poor performance, unreliability, and costly engine damage.

Installation, Tuning, and Maintenance Tips for Your New 6.0 Powerstroke Camshaft

So, you’ve chosen your performance camshaft, understood the new 6.0 Powerstroke camshaft specs, and gathered all your supporting modifications. What’s next? The installation process, followed by critical tuning and ongoing maintenance, are the final steps to fully realizing the benefits of your upgrade.

The Installation Process (Overview)

A camshaft replacement on a 6.0 Powerstroke is not a trivial task. It requires significant disassembly of the engine front, including removal of the high-pressure oil pump (HPOP), front cover, harmonic balancer, and various other components. While possible for an advanced DIY mechanic, professional installation by a reputable diesel performance shop is highly recommended due to the complexity and the need for specialized tools and knowledge. Misaligning timing or improper assembly can lead to catastrophic engine damage.

Key steps typically include:

- Draining fluids and disconnecting batteries.

- Removing necessary accessories and engine components to access the front cover.

- Removing the front cover and timing gear.

- Carefully extracting the old camshaft.

- Installing the new camshaft, ensuring proper lubrication.

- Replacing lifters, pushrods, and valve springs (if upgrading these components).

- Reassembling the engine, paying meticulous attention to torque specs, O-rings, and gaskets.

- Refilling fluids and performing initial checks.

This is a labor-intensive process, often taking a full day or more, even for experienced technicians. Budget for labor costs if you’re not performing the installation yourself.

The Critical Role of Custom Tuning

We’ve touched on it before, but it bears repeating: custom tuning is absolutely essential after a 6.0 Powerstroke camshaft upgrade. You cannot simply drop in a new cam and expect your truck to run optimally, or even safely, on a generic or “canned” tune. Here’s why:

- Optimizing for New Cam Specs: The factory ECU is calibrated for the stock 6.0 Powerstroke camshaft specs. A new cam fundamentally changes how the engine breathes. A custom tuner adjusts fuel delivery, injection timing, turbocharger variable geometry turbo (VGT) control, idle characteristics, and other critical parameters to match the new cam profile.

- Preventing Issues: Without proper tuning, you could experience poor idle, erratic power delivery, excessive smoke, higher exhaust gas temperatures (EGTs), or even engine damage. The engine’s computer needs to “understand” the new valve timing events.

- Maximizing Performance: A good custom tune will unlock the full potential of your cam and other modifications. It ensures that all components are working in harmony, delivering maximum safe power and optimal drivability.

Work with a tuner who specializes in the 6.0 Powerstroke and has experience tuning for aftermarket camshafts. Be prepared for data logging and revisions to dial in the perfect tune for your specific setup.

Post-Installation Care and Maintenance

Once your new cam is installed and the truck is running, a few considerations will help ensure its longevity and performance:

- Break-in Procedures: Some camshaft manufacturers recommend specific break-in procedures for new cams and lifters, especially for flat-tappet designs (less common in 6.0s but good to confirm). Follow these instructions diligently to properly mate components and prevent premature wear.

- Oil Quality and Change Intervals: Continue to use high-quality diesel-rated engine oil and adhere to recommended (or even shortened) oil change intervals. Clean, fresh oil is crucial for the health of your camshaft and valve train. Some might consider using an oil with higher zinc content during break-in, but always consult your cam manufacturer for recommendations.

- Listening for Abnormal Noises: Pay attention to any new or unusual noises coming from the engine. Ticking, tapping, or knocking could indicate an issue with the valvetrain that needs immediate attention.

- Monitor Gauges: Keep an eye on your engine’s vitals, especially EGTs and coolant temperatures, particularly after a performance upgrade. Proper gauges are essential for monitoring your modified truck’s health.

With proper installation, meticulous tuning, and diligent maintenance, your new 6.0 Powerstroke camshaft will provide years of enhanced performance and enjoyment.

Conclusion

The 6.0 Powerstroke is an engine with immense potential, and at the core of unlocking that potential lies a deep understanding of its camshaft specs. From the factory’s design compromises to the exhilarating world of aftermarket performance, the camshaft dictates your engine’s breathing, directly influencing its power, torque, turbo response, and overall character.

We’ve journeyed through the intricacies of camshaft terminology, examined the limitations of the stock 6.0 Powerstroke camshaft specs, and explored the compelling reasons for an upgrade. Whether your goal is to enhance towing capability, boost street performance, or create a competition-ready beast, selecting the right camshaft—and understanding its accompanying lift, duration, and LSA figures—is a critical decision. Remember that a camshaft upgrade is rarely a standalone modification; it thrives as part of a synergistic system including upgraded valve springs, pushrods, and, most importantly, custom tuning.

By carefully considering your driving needs, researching available options, and consulting with experienced professionals, you can confidently choose the optimal 6.0 Powerstroke camshaft specs for your truck. This fundamental upgrade has the power to transform your driving experience, delivering a level of performance and responsiveness that will make you fall in love with your 6.0 Powerstroke all over again. Invest wisely, tune meticulously, and unleash the true potential of your diesel legend!

🎥 Related Video: How To Choose The Right Cam

📺 POWERNATION

Pat Topolinski from Engine Power goes over one of the most discussed topics when it comes to engines: cam selection.

Frequently Asked Questions

What are the stock 6.0 Powerstroke camshaft specifications?

The factory 6.0 Powerstroke camshaft is engineered for broad, reliable performance, balancing power, efficiency, and emissions compliance. It features specific lift, duration, and lobe separation angle (LSA) values designed for everyday driving and consistent output across the RPM range.

Why should I consider upgrading my 6.0 Powerstroke camshaft?

Upgrading your 6.0 Powerstroke camshaft can significantly enhance engine performance, improving horsepower, torque, and turbo spool-up. Aftermarket camshafts are often designed to optimize for specific applications like towing, street performance, or drag racing, offering better airflow and cylinder filling.

What types of aftermarket 6.0 Powerstroke camshafts are available?

Aftermarket 6.0 Powerstroke camshafts are typically categorized by their intended use, such as “Street,” “Towing,” “Performance,” or “Race” grinds. These different designs vary in lift, duration, and LSA to provide specific power characteristics, like increased low-end torque for towing or higher RPM power for performance applications.

What factors should I consider when choosing a 6.0 Powerstroke camshaft?

When selecting a 6.0 Powerstroke camshaft, consider your primary application (towing, daily driving, performance), your existing turbocharger, and injector size. The camshaft needs to be matched to these components to ensure optimal engine efficiency and power delivery, preventing issues like excessive exhaust gas temperatures or poor idle quality.

Do I need other parts when installing a new 6.0 Powerstroke camshaft?

Yes, installing an aftermarket 6.0 Powerstroke camshaft often requires upgrading other valvetrain components for proper operation and durability. It is highly recommended to replace the lifters, and depending on the cam’s lift and spring pressure, upgraded valve springs and pushrods might also be necessary to prevent component failure.

How much performance can I expect from an upgraded 6.0 Powerstroke camshaft?

The performance gains from an upgraded 6.0 Powerstroke camshaft vary significantly based on the specific grind and supporting modifications. Many owners report noticeable improvements in throttle response, quicker turbo spool, and increases in both horsepower and torque, especially when paired with a custom tune and larger injectors.