2004 Powerstroke Fuel in Engine Problem

Featured image for this comprehensive guide about 2004 powerstroke fuel in engine

Image source: i.ytimg.com

The rumble of a 6.0L Powerstroke engine is music to many diesel enthusiasts’ ears – a testament to raw power and unwavering utility. However, for owners of the 2004 model year, this symphony can sometimes be interrupted by a concerning and potentially catastrophic issue: fuel in engine oil. It’s a problem that can steal sleep, lighten wallets, and significantly shorten the life of your beloved truck if not addressed promptly and correctly. If you’re experiencing a strange smell from your oil, a change in engine performance, or worse, an alarmingly high oil level, you’re not alone, and you’ve come to the right place.

The dreaded discovery of 2004 Powerstroke fuel in engine oil signifies a critical breach within the intricate workings of your diesel powerhouse. This isn’t just an inconvenience; it’s a direct threat to your engine’s lubrication system, leading to rapid wear, decreased performance, and ultimately, severe engine damage. Understanding the root causes, recognizing the symptoms, and knowing the right diagnostic and repair steps are paramount for any 6.0L owner.

In this comprehensive guide, we’ll dive deep into the world of 6.0 Powerstroke fuel dilution, exploring the common culprits behind this issue, how to accurately diagnose it, and the most effective strategies for repair and prevention. Our goal is to equip you with the knowledge and actionable insights needed to tackle this problem head-on, ensuring your 2004 Powerstroke continues to deliver the power and reliability you expect. Let’s get started on protecting your investment.

Quick Answers to Common Questions

What exactly does “2004 Powerstroke fuel in engine” mean?

It typically means diesel fuel is mixing with your engine’s oil, often due to an internal leak. This dilutes the oil, severely reducing its lubrication ability and causing serious wear.

How serious is having “2004 Powerstroke fuel in engine”?

Very serious! Fuel in your oil can quickly lead to extensive engine damage, including worn bearings, camshaft issues, and even complete engine failure if not addressed promptly.

What are the common signs of “2004 Powerstroke fuel in engine”?

You might notice your oil level rising on the dipstick, a strong diesel smell from the oil, decreased oil pressure, or the oil appearing much thinner than usual. Some owners also report engine knocking or rough running.

What usually causes “2004 Powerstroke fuel in engine”?

The most common culprits for a 2004 Powerstroke fuel in engine problem are failed injector O-rings or a cracked injector body, which allow fuel to seep into the crankcase. Sometimes, a high-pressure oil pump (HPOP) seal can also be a factor.

What should I do immediately if I suspect “2004 Powerstroke fuel in engine”?

Stop driving your truck as soon as it’s safe and get it to a qualified diesel mechanic for diagnosis right away. Continuing to drive will only worsen potential damage and significantly increase your repair costs.

📋 Table of Contents

- Understanding the 6.0L Powerstroke Fuel System and Its Vulnerabilities

- Identifying the Symptoms: Is Fuel in Your Oil?

- The Root Causes of 2004 Powerstroke Fuel in Engine Problems

- Diagnosing the Problem: Pinpointing the Leak

- Solutions and Prevention: Fixing and Protecting Your 6.0L

- Costs, Time, and What to Expect

- Conclusion: Empowering Your 2004 Powerstroke for the Long Haul

Understanding the 6.0L Powerstroke Fuel System and Its Vulnerabilities

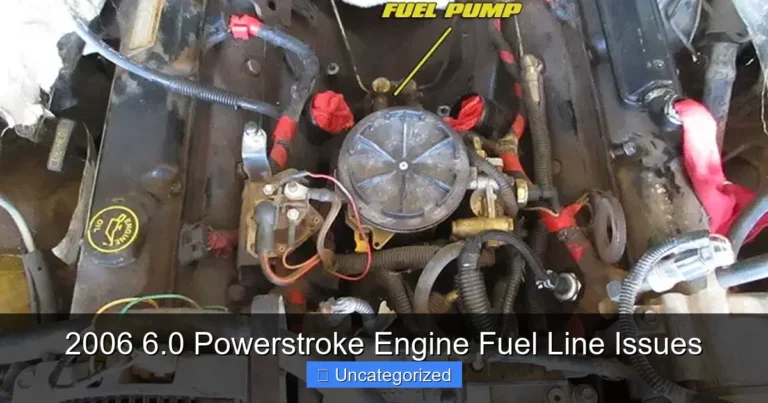

To truly grasp why you might find fuel in engine oil in your 2004 Powerstroke, it’s essential to understand the basics of its fuel and lubrication systems. The 6.0L Powerstroke, a direct-injection diesel engine, relies on a complex network to deliver fuel precisely when and where it’s needed. This system involves a low-pressure fuel pump, high-pressure fuel injectors, and a sophisticated control module, all working in harmony.

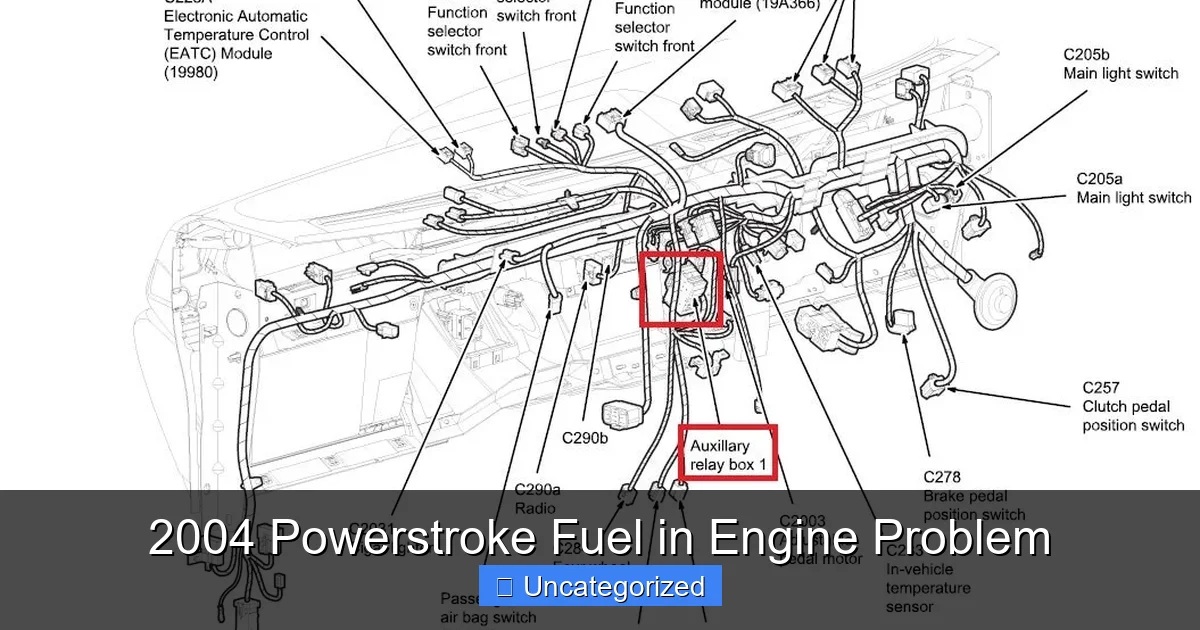

Learn more about 2004 powerstroke fuel in engine – 2004 Powerstroke Fuel in Engine Problem

Image source: powerstroke.org

How the Fuel System Works (Brief Overview)

Fuel delivery in your 6.0L Powerstroke begins with the electric fuel pump, typically located on the frame rail, which pulls diesel from the tank and sends it forward to the engine. Before reaching the injectors, the fuel passes through a series of filters – a crucial step in maintaining fuel purity. Once filtered, the fuel enters the high-pressure common rail system, which then supplies individual fuel injectors. These injectors are not just simple spray nozzles; they are precision instruments that use high-pressure engine oil, delivered by the High-Pressure Oil Pump (HPOP), to atomize and inject fuel directly into the combustion chambers at incredibly high pressures, sometimes exceeding 20,000 PSI.

| Symptom / Observation | Likely Source (6.0L Powerstroke) | Typical Impact / Risk | Recommended Action |

|---|---|---|---|

| Strong diesel smell in engine oil | Failed injector O-rings or internal injector fuel leaks | Oil viscosity reduction (e.g., 15W-40 effectively thinner), reduced lubrication | Immediate oil change, comprehensive diagnostic test (e.g., injector contribution/leak-down) |

| Engine oil level rising on dipstick | Significant, ongoing fuel intrusion from multiple injector failures | Severely compromised lubrication, potential for catastrophic bearing or turbocharger failure | Stop driving immediately, do not restart engine, diagnose and repair fuel system |

| Oil analysis report showing >2% fuel dilution | Cumulative effect of minor injector leaks, high-pressure oil (HPO) system cross-contamination | Accelerated engine wear, decreased oil change interval effectiveness, reduced engine lifespan | Shorten oil change intervals, investigate fuel pressure and injector health |

| Hard starting (especially cold), rough idle, misfires | Fuel system issues contributing to injector stiction, possibly exacerbated by fuel-diluted oil | Reduced engine performance, increased exhaust emissions, eventual injector failure | Use reputable fuel/oil additives (e.g., Archoil AR9100), plan for injector replacement if persistent |

| Excessive black smoke from exhaust during acceleration | Inefficient fuel combustion due to compromised injectors, potentially related to fuel dilution reducing atomization | Reduced power, poor fuel economy, DPF issues (if present on modified engine), increased emissions | Inspect air filter, turbocharger, and injector health; check for proper fuel pressure |

Common Vulnerabilities of the 6.0L Leading to Fuel in Oil

While innovative for its time, the 6.0L Powerstroke, particularly early models like the 2004, had certain design elements that proved to be points of vulnerability. When it comes to fuel in engine oil, the primary culprits almost always revolve around the fuel injectors themselves or the components directly related to their sealing and function. The very design of the HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, where fuel and oil are in close proximity within the injector, creates potential pathways for cross-contamination if seals fail or components crack.

- Close Proximity of Fuel and Oil: Inside each injector, high-pressure engine oil actuates a plunger that pressurizes and injects fuel. If internal seals or the injector body itself fail, fuel can leak into the oil gallery, and vice versa.

- Heat and Pressure Stress: The extreme temperatures and pressures inherent in a diesel engine’s operation put immense stress on injector components and seals over time, leading to degradation.

- Fuel Contamination: Poor fuel quality, including water or particulate contamination, can accelerate wear on injector components, leading to internal leaks.

- Oil Degradation: Infrequent oil changes or using incorrect oil viscosity can compromise the lubricating and sealing properties of the engine oil, indirectly affecting injector health.

Identifying the Symptoms: Is Fuel in Your Oil?

Catching 2004 Powerstroke fuel in engine oil early is crucial for mitigating damage. The symptoms can range from subtle to unmistakable, but vigilance is key. Don’t wait for your engine to start knocking before you investigate. Here’s what to look for:

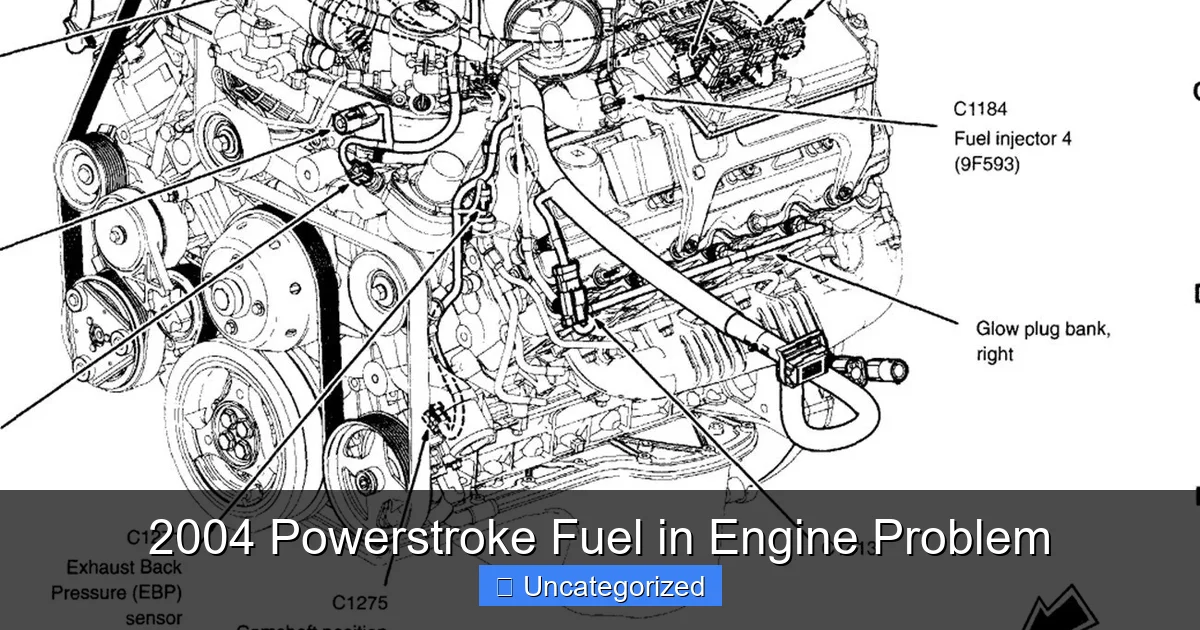

Learn more about 2004 powerstroke fuel in engine – 2004 Powerstroke Fuel in Engine Problem

Image source: fordfiringorder.com

Visual Cues and Odors

This is often the first and most obvious indicator. When you check your oil, pay close attention to more than just the level.

- Elevated Oil Level: The most straightforward sign. If your dipstick shows the oil level consistently rising above the “full” mark, especially between oil changes, it’s a strong indication of fuel dilution. Fuel is being added to your oil reservoir.

- Strong Diesel Smell from the Oil: A distinct and pungent diesel odor emanating from the oil on your dipstick or from the oil fill cap is a tell-tale sign. Engine oil should smell like, well, engine oil – not fuel.

- Thinner Oil Viscosity: Fuel is much less viscous than engine oil. If you rub a drop of oil between your fingers and it feels noticeably thinner or less “slippery” than fresh oil, it’s likely diluted.

- Dark, Milky Appearance: While diesel oil darkens quickly, if it takes on an unusually dark, almost black, and sometimes milky appearance (especially if water is also present due to other issues), it warrants further investigation.

Engine Performance Changes

Beyond visual checks, your truck’s performance can also betray the presence of fuel in engine oil.

- Decreased Engine Performance: Fuel-diluted oil provides less effective lubrication, leading to increased friction and wear. This can manifest as reduced power, sluggish acceleration, or a general feeling of the engine not running as smoothly.

- Rough Idling or Misfires: Severely diluted oil can impact injector operation, leading to inconsistent fuel delivery, which can cause rough idling, intermittent misfires, or a noticeable “lope” in the engine’s sound.

- Increased Exhaust Smoke: If fuel is leaking into the combustion chamber uncontrollably due to injector issues (which can also lead to fuel in oil), you might see excessive black or white smoke from the exhaust.

- Check Engine Light (CEL): While not specific to fuel dilution, the CEL might illuminate due to associated engine performance issues or sensor readings being out of range as a result of the underlying problem.

Oil Analysis: The Definitive Test

For a definitive diagnosis, especially if symptoms are subtle or you want to confirm your suspicions, an oil analysis is invaluable. Services like Blackstone Labs or other industrial oil analysis companies can precisely measure the percentage of fuel in your oil, along with other contaminants and wear metals. This small investment can save you thousands in potential engine repairs.

Actionable Tip: If you suspect 6.0 Powerstroke fuel dilution, take an oil sample immediately. It’s a relatively inexpensive test that provides irrefutable evidence and helps prioritize repairs.

The Root Causes of 2004 Powerstroke Fuel in Engine Problems

When it comes to fuel in engine oil on a 2004 Powerstroke, the vast majority of cases point directly to issues within or around the fuel injectors. The 6.0L’s HEUI system, while efficient, has its Achilles’ heel when components degrade. Let’s break down the primary culprits.

Failed Fuel Injectors: The Primary Path

Each of the eight injectors in your 6.0L Powerstroke is a complex, precision-engineered component. They are the most common gateway for fuel to enter your engine oil. Here’s how:

- Leaking O-Rings: Each fuel injector is sealed by several O-rings – some to separate the fuel side from the oil side, and others to seal the injector within the cylinder head. Over time, these rubber O-rings can harden, crack, or degrade due to extreme heat, pressure, and chemical exposure. A failure in the lower O-rings, which seal the injector to the combustion chamber, or the internal O-rings that separate fuel and oil within the injector body, can allow fuel to seep past and enter the engine’s oil galleries.

- Cracked Injector Bodies: While less common than O-ring failure, an injector body can develop hairline cracks due to extreme stress, manufacturing defects, or prolonged exposure to contaminated fuel or poor lubrication. These cracks provide a direct pathway for fuel to escape into the oil system.

- Internal Leaks and Stiction-Related Wear: Stiction, a common issue in 6.0L injectors (where internal components stick due to oil degradation or contamination), can lead to excessive wear on internal injector parts. This wear can create internal passages or compromise seals, allowing fuel to bypass its intended path and mix with the actuating oil, eventually making its way into the crankcase. Poor fuel quality and infrequent fuel filter changes exacerbate these issues.

Fuel Pressure Regulator (FPR) and Fuel Supply (Indirect Impact)

While the Fuel Pressure Regulator (FPR) and issues with the overall fuel supply system don’t directly cause fuel in engine oil, they can indirectly contribute to injector failure and, subsequently, fuel dilution. An improperly functioning FPR can lead to either excessively high or low fuel pressure. Both scenarios are detrimental to injector health:

- High Fuel Pressure: Can overstress injector components and seals, accelerating wear and increasing the likelihood of leaks.

- Low Fuel Pressure: Can starve injectors, leading to cavitation, overheating, and premature wear, especially in conjunction with the high-pressure oil acting on them. This creates a cascade effect that ultimately compromises the injector’s integrity.

Ensuring your fuel system maintains optimal pressure and cleanliness is a critical preventative measure against future injector-related fuel dilution problems. The “Blue Spring Mod” (covered in a later section) is a popular upgrade precisely because it addresses this aspect of fuel system health.

Diagnosing the Problem: Pinpointing the Leak

Once you suspect fuel in engine oil, accurate diagnosis is paramount. Jumping to conclusions and replacing parts without proper testing can be costly and won’t solve the underlying problem. Here’s a structured approach to pinpointing the leak.

DIY Checks You Can Perform

- Regular Dipstick Checks: Make this a habit. Look for rising oil levels and smell for diesel fuel.

- Visual Inspection: With the engine off and cool, carefully inspect around the injectors, valve covers, and fuel lines for any obvious signs of fuel leaks or weeping. While internal leaks are the most common cause of fuel in oil, external leaks can also indicate a broader fuel system problem.

- Bubble Test (Visual Fuel Pressure Test): If you have access to a fuel pressure gauge, connect it. With the engine running, observe the fuel pressure. If it’s fluctuating wildly or consistently low, it could point to a fuel supply issue that’s stressing the injectors. While not directly identifying fuel *in oil*, it’s part of a holistic diagnosis.

Professional Diagnostic Tools and Tests

For precise identification of the faulty injector or source of the leak, professional diagnostic equipment is often required.

- Injector Buzz Test: Using a diagnostic scan tool (like Ford’s IDS or capable aftermarket tools), a “buzz test” can be performed. This electronically cycles each injector, listening for consistent “buzzing” sounds. An injector that doesn’t buzz or sounds weak could be failing electronically, which can be linked to mechanical failures causing leaks.

- Cylinder Contribution Test: Also performed with a scan tool, this test monitors the power output from each cylinder. A weak or failing injector (leaking fuel or not delivering enough fuel) will cause a cylinder to “contribute” less power, identifying it as a potential culprit.

- Compression and Leak-Down Tests: These tests assess the sealing integrity of your engine’s combustion chambers. While primarily for internal engine wear, abnormal results can sometimes point to severe injector sealing issues where fuel is leaking into the cylinder and then past piston rings into the oil.

- Relative Compression Test: A quicker, non-invasive version of the compression test often available on advanced scan tools.

- Oil Analysis (Revisited): As mentioned, this is your gold standard. Not only will it confirm fuel dilution, but it can also reveal wear metals (like iron, copper, lead) that indicate which engine components are suffering from lack of lubrication due to diluted oil. This data helps prioritize repairs and assess the extent of engine damage.

A Step-by-Step Diagnostic Approach

- Confirm Fuel Dilution: Start with an oil analysis to definitively prove fuel is in your oil and quantify the amount.

- Check Fuel Pressure: Ensure the low-pressure fuel system is delivering adequate and consistent pressure (around 50-60 psi at idle). Low pressure can cause injector wear.

- Run Injector Buzz Test & Contribution Test: Use a scan tool to identify any electronically or mechanically weak injectors.

- Visual Inspection of Injector Cups/Seals: If comfortable, carefully remove valve covers (engine cold) and inspect around the injectors for any signs of fuel residue or weeping. This might require further disassembly in extreme cases.

- Consider Professional Assistance: If DIY diagnostics don’t yield a clear answer, or if the problem requires specialized tools, consult a qualified diesel mechanic who specializes in 6.0L Powerstrokes.

Solutions and Prevention: Fixing and Protecting Your 6.0L

Addressing 2004 Powerstroke fuel in engine issues is critical, but so is preventing their recurrence. Here’s a look at both repair strategies and preventative measures.

Repairing Injector Issues

Once a faulty injector (or set of injectors) is identified as the source of 6.0 Powerstroke fuel dilution, the primary solution is replacement or, in some cases, professional rebuilding.

- Injector Replacement: This is the most common and often most reliable fix. It’s recommended to replace all injectors on a bank (e.g., driver’s side or passenger’s side) or even all eight, especially if the truck has high mileage and multiple injectors show signs of wear. High-quality remanufactured or new injectors from reputable sources are essential.

- O-Ring Replacement (Less Common for Fuel-in-Oil): While O-rings can be replaced, internal leaks or cracked bodies require full injector replacement. O-ring kits are more often used when the injector is removed for other work, or if an *external* oil or fuel leak is identified at the injector base. For fuel *in oil*, it’s often a more complex internal failure or lower O-ring failure.

- Stiction Additives: For early stages of stiction (where injectors are sticking but not yet leaking fuel into oil), specialized oil additives like Archoil AR9100 or Hot Shot’s Secret Stiction Eliminator can sometimes help free up sticky internal injector components. However, once fuel is definitely in the oil, this is not a fix for the leak itself but might improve overall injector health.

Addressing Fuel System Weaknesses

Beyond fixing the leaking injector, consider upgrades to improve the overall health of your 6.0L’s fuel system and prevent future issues.

- “Blue Spring Mod”: This popular upgrade replaces the stock fuel pressure regulator spring with a stronger “blue spring” from Ford. It raises and stabilizes the fuel pressure, ensuring injectors receive adequate and consistent fuel supply, which can extend their lifespan. This is a relatively inexpensive and highly recommended modification for all 6.0L Powerstrokes.

- Regulated Return Fuel System: For a more comprehensive solution, a regulated return fuel system upgrade routes excess fuel from the cylinder heads back to the tank, rather than returning it from the fuel filter housing. This ensures consistent fuel pressure and flow to all injectors, eliminating common fuel aeration and pressure drop issues in the cylinder heads, further promoting injector longevity.

- High-Quality Fuel Filters: Regularly replace both the chassis-mounted and engine-mounted fuel filters with OEM or high-quality aftermarket filters. Contaminated fuel is a major contributor to injector wear.

Preventative Maintenance Strategies

Prevention is always better than cure. Regular and meticulous maintenance is your best defense against diesel engine oil contamination.

- Frequent Oil Changes: Adhere strictly to or even shorten Ford’s recommended oil change intervals (typically 5,000 to 7,500 miles, or 6 months, whichever comes first), especially if you tow or idle frequently. Use high-quality synthetic or semi-synthetic diesel-specific engine oil (e.g., Ford/Motorcraft or a reputable brand meeting CJ-4 or CK-4 specifications).

- Quality Fuel: Use reputable fuel stations and, if possible, consider adding a high-quality diesel fuel additive that helps with lubrication, cetane boost, and water dispersion.

- Monitor Fuel Pressure: Install an aftermarket fuel pressure gauge in the cabin. This allows you to constantly monitor your fuel pressure and quickly identify if it drops below the optimal range (around 50-60 PSI, never below 45 PSI under load).

- Regular Oil Analysis: Periodically sending an oil sample for analysis is a proactive measure. It can detect minor fuel dilution or increased wear metals before they become major problems, giving you time to address them.

Costs, Time, and What to Expect

Discovering 2004 Powerstroke fuel in engine oil is undoubtedly stressful. Understanding the potential costs, the time involved, and the long-term outlook can help you prepare for the necessary repairs.

Estimated Repair Costs

The cost of repairing 6.0 Powerstroke fuel dilution varies significantly based on whether you perform the work yourself, the number of injectors needing replacement, and labor rates in your area. This is a general estimate:

| Component/Service | Parts Cost (Estimate) | Labor Hours (Estimate) | Total Cost (Estimate) |

|---|---|---|---|

| Single New Injector | $300 – $450 | 2-4 hours | $500 – $900 |

| Single Remanufactured Injector | $200 – $350 | 2-4 hours | $400 – $800 |

| Set of 4 New Injectors (Bank) | $1200 – $1800 | 6-10 hours | $1800 – $2800+ |

| Set of 8 New Injectors | $2400 – $3600 | 10-16 hours | $3400 – $5200+ |

| Set of 8 Remanufactured Injectors | $1600 – $2800 | 10-16 hours | $2600 – $4400+ |

| Oil Change (post-repair) | $80 – $150 | 0.5-1 hour | $80 – $250 |

| Fuel Filter Change | $50 – $100 | 0.5-1 hour | $50 – $150 |

| Oil Analysis (Diagnostic) | $30 – $50 | N/A | $30 – $50 |

*Note: Labor rates typically range from $100-$150 per hour. These are estimates and can vary widely based on part quality, shop rates, and additional issues discovered during repair. Always get a detailed quote.

The Importance of Timely Repair

Delaying repairs for 2004 Powerstroke fuel in engine issues is akin to playing Russian roulette with your engine. Fuel in the oil drastically reduces the oil’s lubricating properties, leading to accelerated wear on critical engine components, including:

- Camshaft and lifters

- Bearings (rod, main, turbocharger)

- Piston rings and cylinder walls

- High-Pressure Oil Pump (HPOP) and its components

Prolonged dilution will lead to catastrophic engine failure, requiring a complete engine rebuild or replacement, which can easily cost upwards of $8,000 to $15,000. The cost of replacing a few injectors pales in comparison to a new engine.

Long-Term Outlook for Your 6.0L

Despite its reputation, a properly maintained and “bulletproofed” 6.0L Powerstroke can be an incredibly reliable and powerful truck. Addressing fuel in engine oil problems proactively, coupled with other common 6.0L upgrades and diligent maintenance, can give your truck a new lease on life. Many 6.0L owners successfully mitigate these issues and enjoy hundreds of thousands of trouble-free miles. Your 2004 Powerstroke, with the right care, still has plenty of life left in it.

The key is to use quality parts, perform the work correctly (or have a trusted professional do it), and commit to a rigorous maintenance schedule. This includes not just oil and fuel filter changes, but also monitoring fluid levels and engine performance closely. Your vigilance will be rewarded with a powerful and dependable truck.

Conclusion: Empowering Your 2004 Powerstroke for the Long Haul

The discovery of 2004 Powerstroke fuel in engine oil is a significant concern for any owner. However, it’s not a death sentence for your truck. By understanding the common culprits, primarily failed fuel injectors and their associated seals, and by being vigilant about symptoms like rising oil levels or a distinct diesel smell, you’re already on the path to resolving the issue.

Accurate diagnosis, whether through meticulous DIY checks, professional diagnostic tools, or the invaluable insight of an oil analysis, is the critical first step. Once the source of the 6.0 Powerstroke fuel dilution is identified, prompt and effective repairs – typically involving injector replacement – are essential to prevent irreversible engine damage. Beyond the fix, implementing preventative measures like the “Blue Spring Mod,” using high-quality filters, and adhering to strict maintenance schedules will bolster your truck’s longevity and reliability.

Your 2004 Powerstroke is a robust machine, and with informed action, it can continue to serve you faithfully for years to come. Don’t let the fear of complex repairs deter you. Take a proactive approach, seek expert advice when needed, and invest in the proper care your diesel workhorse deserves. By doing so, you’ll not only resolve the immediate problem but also ensure your Powerstroke remains a powerful and dependable partner on the road ahead.

Frequently Asked Questions

What are the common signs of the “2004 Powerstroke fuel in engine” problem?

Symptoms typically include an elevated oil level on the dipstick, a strong diesel smell emanating from the engine oil, and potentially a noticeable thinning of the oil’s consistency. You might also experience reduced fuel economy or a rougher running engine.

What are the primary causes of fuel getting into the engine oil on a 2004 Powerstroke?

The most frequent cause is failed or deteriorated fuel injector O-rings, which allow high-pressure fuel to leak past the injector body directly into the engine’s oil passages. Less commonly, a cracked fuel injector body or an issue with the high-pressure oil pump (HPOP) system (though fuel in the HPOP is usually oil, not fuel) could contribute to the problem.

Is it safe to drive my 2004 Powerstroke if I suspect fuel in the engine oil?

No, it is highly unadvised to continue driving with fuel diluted engine oil. Fuel significantly compromises the lubricating properties of the oil, leading to accelerated wear on critical engine components such as bearings, camshafts, and turbocharger. This can quickly result in severe and very costly engine damage.

How is the “2004 Powerstroke fuel in engine” problem typically diagnosed by a mechanic?

A mechanic will usually begin by checking the oil level and smelling the oil for diesel presence. Further diagnosis often involves an oil analysis to confirm fuel dilution percentage and performing a cylinder contribution test or an air test on the fuel system to pinpoint the failing injector or seal.

What are the potential repairs for a 2004 Powerstroke experiencing fuel in the engine oil?

The most common repair involves replacing the faulty fuel injector O-rings or the entire problematic fuel injector(s) if the body is cracked. After any repair, a thorough engine oil and filter change is crucial to remove the contaminated oil and prevent further damage from fuel dilution.

Can I prevent fuel dilution in my 2004 Powerstroke’s engine oil?

While complete prevention of injector O-ring failure isn’t guaranteed, regular oil changes with the correct specification oil and using high-quality diesel fuel can help maintain injector health. Promptly addressing any subtle changes in engine performance, smoke, or fuel economy can also help catch issues before severe fuel dilution occurs.