1995 7.3 Powerstroke Fuel Leak Issues

Featured image for this comprehensive guide about 1995 7.3 powerstroke engine fuel leak

Image source: i.ytimg.com

Ah, the legendary 1995 7.3 Powerstroke. For many truck enthusiasts, it’s not just an engine; it’s a way of life, a testament to American engineering, and a powerhouse that continues to haul, tow, and conquer even decades after its birth. Known for its robust design and impressive longevity, this direct-injected beast earned its stripes as a true workhorse. However, even legends have their Achilles’ heels, and for the venerable 1995 7.3 Powerstroke engine, one common adversary that often rears its head is the dreaded fuel leak.

There’s nothing quite like the unmistakable scent of diesel fuel, especially when it’s emanating from where it shouldn’t be. A 7.3 Powerstroke fuel leak isn’t just an inconvenience; it can be a serious issue, leading to decreased performance, potential fire hazards, environmental concerns, and a significant dent in your wallet if left unaddressed. Whether you’re a seasoned DIY mechanic or just starting to notice the tell-tale signs, understanding the common causes, symptoms, and solutions for a 1995 7.3 Powerstroke fuel leak is crucial for keeping your classic rig running strong.

In this comprehensive guide, we’ll dive deep into the world of 1995 7.3 Powerstroke fuel leak issues. We’ll explore why these engines are prone to leaks, pinpoint the most common culprits, walk you through the diagnostic process, and arm you with actionable tips for both repair and prevention. So, grab your wrenches, put on your safety glasses, and let’s get to the bottom of that persistent diesel drip.

Quick Answers to Common Questions

Where does the 1995 7.3 Powerstroke engine fuel leak typically originate?

Often, you’ll find fuel leaks around the fuel bowl, fuel lines (especially the return lines), or the fuel filter housing, as these are common weak points that degrade over time.

How serious is a 1995 7.3 Powerstroke engine fuel leak?

A fuel leak can be quite serious, posing a fire hazard and potentially leaving you stranded, so it’s always wise to address any 1995 7.3 Powerstroke engine fuel leak promptly for safety.

What are common signs I have a 1995 7.3 Powerstroke engine fuel leak?

Besides the obvious strong smell of diesel fuel, you might notice drips or puddles under your truck, decreased fuel economy, or even experience a rough idle or hard starting.

Can I fix a 1995 7.3 Powerstroke engine fuel leak myself?

Many common fuel leaks on a 1995 7.3 Powerstroke engine, especially those involving o-rings, rubber lines, or the fuel bowl, are DIY-friendly for someone with basic mechanical skills and the right tools.

What should I do immediately if I suspect a 1995 7.3 Powerstroke engine fuel leak?

For safety, park your truck in a well-ventilated area away from any ignition sources, and then visually inspect the engine bay and undercarriage to locate the source of the 1995 7.3 Powerstroke engine fuel leak before driving further.

📋 Table of Contents

- Why Your 1995 7.3 Powerstroke Might Be Leaking Fuel

- Common Sources of 1995 7.3 Powerstroke Fuel Leaks

- Symptoms of a 7.3 Powerstroke Fuel Leak

- Diagnosing Your 1995 7.3 Powerstroke Fuel Leak

- Fixing the Fuel Leak: DIY vs. Professional Repair

- Prevention and Maintenance Tips for Your 7.3 Powerstroke

- Conclusion: Keeping Your 1995 7.3 Powerstroke Leak-Free

Why Your 1995 7.3 Powerstroke Might Be Leaking Fuel

The 1995 7.3 Powerstroke, while incredibly durable, is now a vintage engine. Time, heat, vibrations, and continuous exposure to fuel and oil take their toll on even the most robust components. Understanding these underlying factors is the first step in diagnosing and addressing a fuel leak.

Learn more about 1995 7.3 powerstroke engine fuel leak – 1995 7.3 Powerstroke Fuel Leak Issues

Image source: exatin.info

Age and Material Degradation

- Rubber Hoses and O-Rings: Over decades, rubber and synthetic polymer components naturally degrade. They can become brittle, crack, swell, or lose their elasticity due to constant exposure to heat, cold, engine vibrations, and the chemicals within diesel fuel itself. This is perhaps the most common reason for a 1995 7.3 Powerstroke fuel leak.

- Metal Fatigue: While less common for the fuel system specifically, constant vibration can lead to hairline cracks in metal lines or housings over extreme periods.

Design Characteristics and Wear Points

- High-Pressure Oil Pump (HPOP) System: The 7.3 Powerstroke is an HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, meaning it uses high-pressure oil to fire the injectors. However, fuel is also present in close proximity to the HPOP reservoir and associated lines, especially if there’s a crossover connection or a failure in the fuel system components that run near it. A high-pressure oil leak can sometimes be mistaken for a fuel leak or exacerbate a fuel system leak due to the similar appearance of fluids.

- Fuel Bowl Location: The fuel bowl, a critical component for filtering and heating fuel, is located on top of the engine. Its elevated position means any leak from the bowl or its associated lines will drip directly onto the engine, making it a prominent source of visible leaks.

- Injector O-Rings: The injectors themselves have O-rings that seal them against the cylinder head and the fuel rails. These O-rings are under constant thermal stress and high-pressure fuel exposure, making them a common failure point for an internal or external 7.3 Powerstroke fuel leak.

Previous Repairs and Improper Installation

Sometimes, a fuel leak isn’t due to natural wear but rather an oversight during a previous repair. Incorrectly torqued fittings, damaged O-rings during installation, or using sub-par aftermarket parts can all contribute to developing a new 1995 Powerstroke fuel leak.

| Common Leak Point | Primary Symptom | Typical Solution/Repair | Estimated Repair Cost (Parts & Labor) |

|---|---|---|---|

| Fuel Bowl O-rings/Gaskets | Fuel smell in engine bay, wetness around fuel filter housing, potential hard starting. | Replace fuel bowl O-ring kit, including fuel heater O-ring. | $50 – $200 |

| Fuel Line Connections (e.g., steel braided lines) | Visible fuel drip, strong fuel odor, wet spots under the vehicle. | Replace leaky fuel lines, tighten fittings, or use new crush washers/seals. | $100 – $350 |

| Injector Return Line O-rings/Washers | Fuel pooling in the cylinder head valley, strong fuel odor, reduced fuel economy. | Replace fuel return line O-rings/washers and associated banjo bolt seals. | $200 – $600 |

| Fuel Pressure Regulator (FPR) Diaphragm | Fuel odor, wetness around the fuel bowl/FPR housing, poor fuel pressure symptoms. | Replace FPR diaphragm or entire FPR assembly. | $150 – $400 |

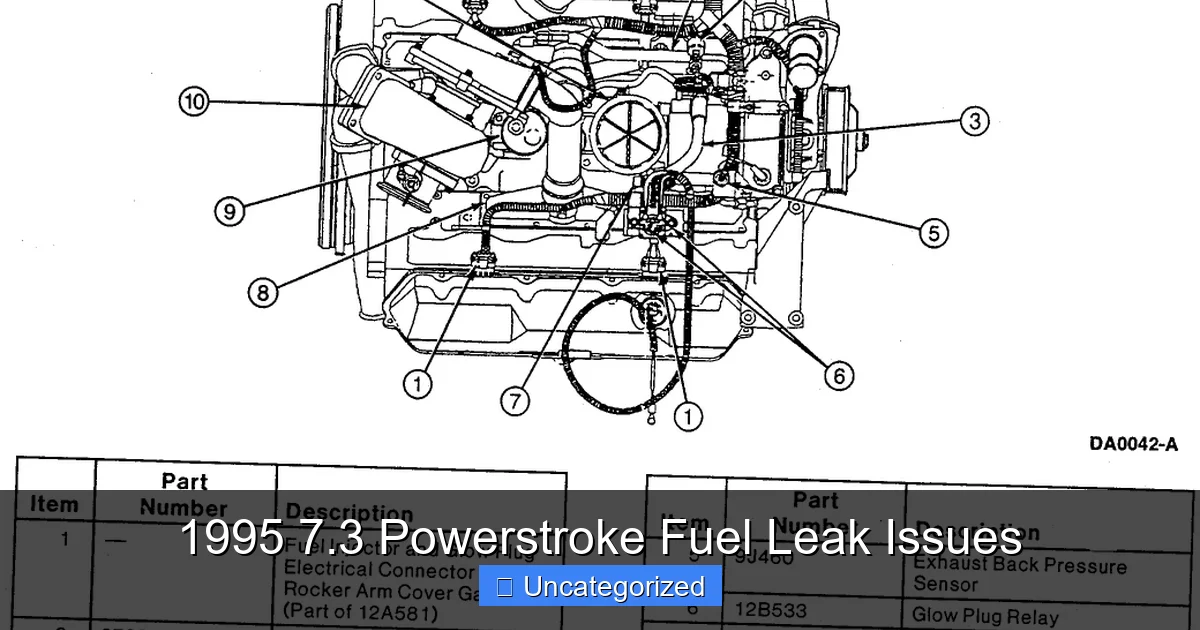

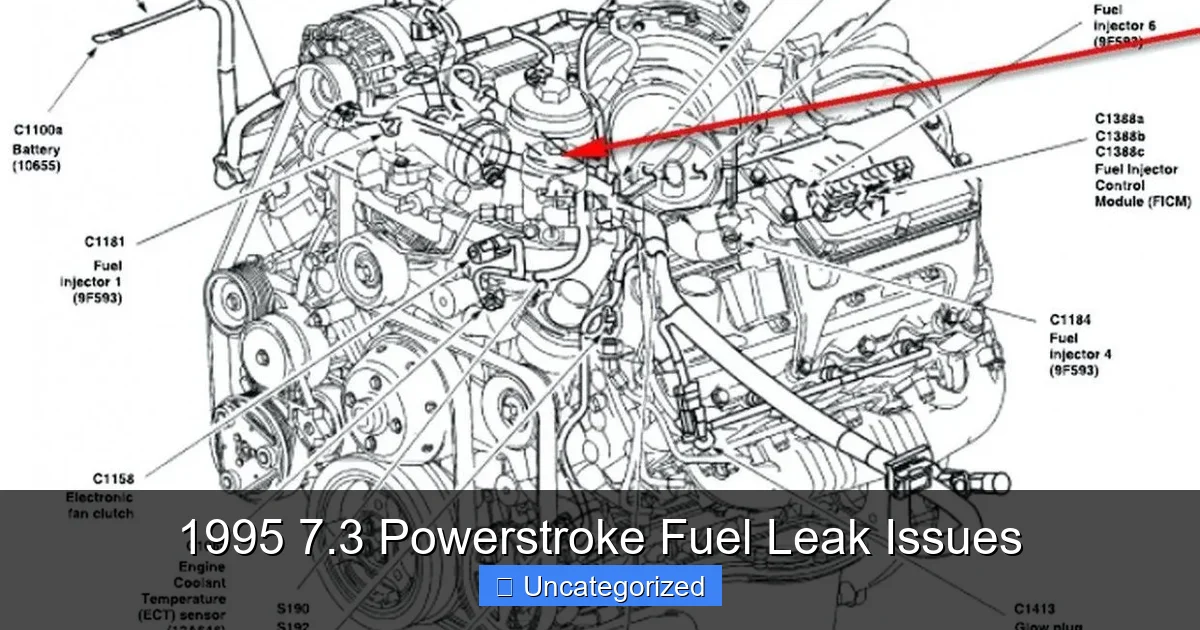

Common Sources of 1995 7.3 Powerstroke Fuel Leaks

When you’re trying to track down a fuel leak on your 1995 7.3 Powerstroke, knowing where to look first can save you a lot of time and frustration. Here are the most frequent culprits:

Learn more about 1995 7.3 powerstroke engine fuel leak – 1995 7.3 Powerstroke Fuel Leak Issues

Image source: i.pinimg.com

The Fuel Filter Housing (or Fuel Bowl)

This is arguably the most common source of a 7.3 Powerstroke fuel leak. The fuel bowl sits prominently on top of the engine and contains several potential leak points:

- Drain Valve: The plastic drain valve at the bottom of the fuel bowl is notorious for cracking or failing, leading to a steady drip. The O-rings on the drain valve can also wear out.

- Heater Element: The electrical heater element, designed to warm the fuel in cold weather, can develop leaks around its sealing O-ring or where it threads into the bowl.

- Fuel Lines and Fittings: The metal and rubber lines connecting to and from the fuel bowl often have banjo bolts or quick-disconnect fittings. The copper washers on banjo bolts or the O-rings in quick-disconnects can fail.

- Gasket/Seals: The main gasket that seals the top of the fuel bowl to the base can deteriorate, especially if it’s been opened and re-sealed multiple times.

Injector O-Rings and Glow Plug Harness

While often associated with internal oil leaks leading to “coke bottle” oil in the fuel, injector O-rings can also lead to external fuel leaks, especially if the upper O-rings fail. The glow plug harnesses run alongside the injectors inside the valve covers. The connection points and the harness grommets that pass through the valve cover can develop leaks where fuel and oil could potentially escape.

Fuel Lines and Hoses

From the fuel tank to the engine, your 1995 7.3 Powerstroke relies on a network of fuel lines. These include:

- Rubber Sections: Many older diesel trucks still have original rubber fuel lines, which are highly susceptible to dry rot, cracking, and chafing over time. Check all rubber sections, especially near the frame, fuel tank, and engine bay.

- Metal Lines: While more durable, metal lines can corrode, especially in areas exposed to road salt or moisture. They can also crack due to excessive vibration if not properly secured.

- Fuel Pressure Regulator (FPR): Located near the fuel bowl, the FPR has its own O-rings and seals that can fail, causing a leak.

The Lift Pump

The mechanical lift pump on the 1995 7.3 Powerstroke (mounted on the engine block) is responsible for drawing fuel from the tank and sending it to the fuel bowl. Over time, the diaphragm inside can fail, or the seals around the mounting flange can degrade, leading to an external fuel leak. A common sign is fuel dripping down the side of the engine block near the pump.

Fuel Tank and Sending Unit

Don’t overlook the obvious! While less common to manifest as an “engine” leak, issues with the fuel tank itself or the sending unit can cause substantial fuel loss. Rust on the tank, a faulty gasket around the sending unit, or cracked plastic lines at the top of the tank are all possibilities, usually resulting in a leak further back on the truck.

Symptoms of a 7.3 Powerstroke Fuel Leak

Catching a 1995 7.3 Powerstroke fuel leak early can prevent more significant problems down the line. Keep an eye (and nose) out for these tell-tale signs:

The Obvious Signs

- Smell of Diesel: This is often the first and most noticeable symptom. If you smell diesel fuel, especially after driving or when the engine is running, it’s a strong indicator of a leak. The smell can be particularly strong inside the cab if the leak is under the hood.

- Visible Fuel Puddles or Stains: Check under your truck when parked. Small puddles or dark stains on the ground are a dead giveaway. Also, look for wet spots or streaks of fuel on the engine, frame, or transmission bell housing.

- Fuel Consumption Increase: If you’re filling up more often than usual without a change in driving habits, a hidden 7.3 Powerstroke fuel leak could be the culprit.

Performance-Related Symptoms

- Hard Starts or Long Cranks: If fuel pressure is bleeding off due to a leak, especially overnight, it can take longer for the fuel system to prime, leading to extended cranking times before the engine fires.

- Rough Idle or Misfires: An inconsistent fuel supply to the injectors due to a leak can cause the engine to run roughly, especially at idle, or even misfire.

- Reduced Power or Hesitation: While less common for external leaks unless they are very severe, a significant drop in fuel pressure could manifest as a noticeable decrease in power or hesitation under acceleration.

- Engine Stalling: In extreme cases of a severe 1995 7.3 Powerstroke fuel leak, the engine might stall due to a complete loss of fuel pressure or supply.

Diagnosing Your 1995 7.3 Powerstroke Fuel Leak

Pinpointing the exact source of a fuel leak can sometimes feel like a detective mission, but with a systematic approach, you can usually find the culprit. Always ensure the engine is cool, the area is well-ventilated, and you have appropriate safety gear.

Visual Inspection: The First Step

- Clean the Area: Before you start, thoroughly clean the suspected leaky area of the engine. Use a degreaser and rinse well. A clean surface makes it much easier to spot fresh fuel.

- Inspect the Top of the Engine:

- Focus on the fuel bowl: Check the drain valve, heater element, and all fuel lines connected to it. Look for wetness or dried fuel residue.

- Inspect injector caps and valve covers: While injector O-rings often leak internally, external fuel near the valve cover gaskets can indicate a problem.

- Inspect Below the Engine: Use a flashlight to look at the engine block, transmission bell housing, and frame rails. Pay close attention to the area around the lift pump.

- Trace Fuel Lines: Follow the fuel lines from the tank forward, looking for chafing, cracks, or wet spots on both rubber and metal sections.

- Start the Engine: With a clean engine, start it up and let it idle. Carefully watch for any new drips or sprays of fuel. A small mirror and a flashlight can help you see hard-to-reach areas. Rev the engine slightly to increase fuel pressure and potentially reveal leaks that are only active under load.

Advanced Diagnostic Techniques

- Fuel System Pressure Test: If you suspect a leak but can’t see it, a fuel pressure gauge can be a valuable tool. Connect it to the Schrader valve on the fuel bowl. A drop in pressure, especially after the engine is shut off, indicates a leak somewhere in the system.

- Dye Test: For elusive leaks, a UV dye kit can be invaluable. Add UV-reactive dye to your diesel fuel, run the engine for a while, and then use a UV light (blacklight) to scan for glowing leaks. This method is highly effective for finding even tiny drips.

- Air Pressure Test (for specific components): After draining fuel from a component like the fuel bowl, you can sometimes pressurize it with a small amount of air and use soapy water to look for bubbles, indicating a leak.

Fixing the Fuel Leak: DIY vs. Professional Repair

Once you’ve identified the source of your 1995 7.3 Powerstroke fuel leak, the next step is to fix it. The complexity of the repair often dictates whether it’s a job for your garage or a professional mechanic.

Common DIY-Friendly Repairs

Many 7.3 Powerstroke fuel leak issues are straightforward for the average wrench-turner:

- Fuel Bowl Drain Valve/Heater O-Rings: This is a very common fix. Kits are readily available, and replacing the valve or the O-rings usually involves draining the fuel bowl and unscrewing the component. Be careful not to overtighten plastic parts.

- Rubber Fuel Lines: If you find a cracked or chafed rubber fuel line, it’s usually a simple matter of cutting out the bad section and replacing it with new, SAE J30R9 rated diesel fuel hose and appropriate hose clamps. Ensure the new hose is the correct diameter.

- Lift Pump Replacement: Replacing the mechanical lift pump on the engine block is a relatively simple bolt-on job. You’ll need to drain some fuel, unbolt the old pump, clean the mounting surface, install a new gasket (often included with the pump), and bolt on the new unit. Remember to prime the fuel system afterward.

- Fuel Pressure Regulator O-Rings: Kits are available for rebuilding the FPR. This involves carefully disassembling the regulator, replacing the O-rings, and reassembling it.

More Complex or Time-Consuming Repairs

Some leaks require more specialized tools, experience, or time:

- Injector O-Rings: While possible for advanced DIYers, replacing injector O-rings requires removing the valve covers, disconnecting the glow plug harnesses, removing the oil deflector, and carefully pulling the injectors. This is a more involved process and often done in conjunction with other maintenance like glow plug replacement or valve cover gasket replacement. It’s easy to damage the O-rings during installation if not done precisely.

- Metal Fuel Line Repair/Replacement: If a metal line is corroded or cracked, repair can involve flaring tools, bending new lines, or sourcing specific pre-bent replacements, which can be challenging.

- Internal Fuel Tank Issues: Repairs within the fuel tank (e.g., sending unit gasket, pickup tube issues) require dropping the fuel tank, which can be a heavy and cumbersome job, often requiring specialized jack stands or a transmission jack.

When to Call a Professional

If you’re unsure about the diagnosis, lack the necessary tools, or are uncomfortable with the complexity of a particular repair, don’t hesitate to consult a qualified diesel mechanic. A misdiagnosed or poorly executed repair can lead to more significant issues and potentially dangerous situations. Professionals have specialized diagnostic equipment and experience with common 1995 7.3 Powerstroke fuel leak issues.

Estimated Repair Cost Breakdown

Costs can vary widely based on parts quality (OEM vs. aftermarket), labor rates, and geographical location. The following table provides rough estimates for common 7.3 Powerstroke fuel leak repairs:

| Leak Source | Typical Parts Cost (USD) | Estimated Labor Hours | DIY Difficulty |

|---|---|---|---|

| Fuel Bowl Drain Valve/O-rings | $15 – $50 | 0.5 – 1.0 | Low |

| Fuel Bowl Heater Element | $30 – $70 | 0.5 – 1.0 | Low |

| Rubber Fuel Lines (short section) | $10 – $30 | 0.5 – 1.5 | Low |

| Lift Pump | $70 – $150 | 1.0 – 2.0 | Medium |

| Fuel Pressure Regulator O-rings | $20 – $40 | 1.0 – 2.0 | Medium |

| Injector O-rings (all 8) | $50 – $150 | 4.0 – 8.0 | High |

| Fuel Tank Sending Unit Gasket | $20 – $60 | 2.0 – 4.0 (tank drop) | High |

Note: These are rough estimates. Always get a quote from your local parts supplier and mechanic.

Prevention and Maintenance Tips for Your 7.3 Powerstroke

While you can’t stop the march of time, proactive maintenance can significantly reduce your chances of experiencing a 1995 7.3 Powerstroke fuel leak.

Regular Inspections

- Under the Hood Checks: Make it a habit to visually inspect your engine bay every few weeks or during oil changes. Look for any wet spots, unusual residue, or smells. Pay particular attention to the fuel bowl, fuel lines, and connections.

- Under the Truck Checks: Periodically look under your truck for drips or stains on the ground or on the frame.

Timely Component Replacement

- Replace Old Rubber Hoses: If your truck still has original rubber fuel lines, consider proactively replacing them. Even if they’re not actively leaking, they’re likely brittle and a failure is imminent.

- Fuel Filter Maintenance: Regularly change your fuel filter according to your owner’s manual. When doing so, carefully inspect the fuel bowl drain valve and heater element for any signs of wear or cracking. Consider replacing the O-rings on these components as a preventative measure during filter changes.

- Use Quality Parts: When replacing fuel system components, opt for OEM or high-quality aftermarket parts. Cheap parts often mean cheap materials and seals, leading to premature failure and another 7.3 Powerstroke fuel leak down the road.

Proper Fluid Management

- Keep Your Fuel System Clean: Use good quality diesel fuel and consider using a reputable fuel additive, especially during colder months, to help keep the fuel system clean and lubricated.

- Address Oil Leaks Promptly: While not directly a fuel leak, oil leaks can degrade rubber and plastic components in the engine bay, potentially leading to future fuel system failures.

Conclusion: Keeping Your 1995 7.3 Powerstroke Leak-Free

The 1995 7.3 Powerstroke is a magnificent engine, a testament to durability and power that continues to impress decades later. However, like any aging component, its fuel system can become susceptible to leaks due to material degradation and constant stress. By understanding the common sources of a 7.3 Powerstroke fuel leak, recognizing the symptoms, and adopting a proactive approach to diagnosis and maintenance, you can keep your beloved truck running strong and leak-free for many more miles.

Whether it’s a simple O-ring replacement or a more involved injector O-ring job, addressing a 1995 Powerstroke fuel leak promptly is crucial. It not only prevents further damage and costly repairs but also ensures the safety and reliability of your vehicle. So, keep those eyes peeled, that nose alert for diesel fumes, and give your 1995 7.3 Powerstroke engine the attention it deserves. Happy trucking!

Frequently Asked Questions

What are the common signs of a fuel leak on a 1995 7.3 Powerstroke engine?

Look for a strong diesel smell, visible puddles or wet spots under the truck (especially on the engine or transmission bell housing), and potentially reduced fuel economy. You might also notice a loss of power or rough idling if air is being introduced into the fuel system.

Where are the most common places for a 1995 7.3 Powerstroke to develop a fuel leak?

The most frequent culprits are the fuel lines themselves, particularly the return lines, and the O-rings on the fuel bowl heater, injector return lines (pigtail O-rings), or the fuel filter housing. The fuel pump or its connections can also be a source of a fuel leak.

Is a fuel leak on my 1995 7.3 Powerstroke dangerous, and can I still drive with it?

Yes, a fuel leak is dangerous as diesel is flammable and can pose a fire hazard, especially near hot engine components. It’s highly recommended to address any fuel leak immediately; continued driving could exacerbate the problem or create a hazardous situation.

How do I diagnose and fix a 1995 7.3 Powerstroke fuel leak myself?

Start by visually inspecting all fuel lines, the fuel bowl, and injector areas with the engine running, using a flashlight. For common leaks like O-rings or fuel lines, kits are available for replacement, often requiring basic hand tools and a good service manual.

What specific parts or kits are usually needed to repair a 1995 7.3 Powerstroke fuel leak?

Depending on the leak location, you might need a fuel bowl O-ring kit, injector return line O-rings (sometimes called “pigtail” O-rings), new fuel line sections, or an entirely new fuel filter housing assembly. Always identify the exact source of the fuel leak before purchasing parts.

What can I do to prevent future fuel leak issues on my 1995 7.3 Powerstroke?

Regular inspection of fuel lines and connections during routine maintenance is key. Proactively replacing old, brittle fuel lines and O-rings, especially when doing other engine work, can significantly reduce the risk of developing a fuel leak.