Upgrading 6.0 Powerstroke Engine Components for Performance: Boost Power and Efficiency

Featured image for this comprehensive guide about Upgrading 6.0 Powerstroke engine components for performance

Image source: images.hgmsites.net

The Ford 6.0 Powerstroke diesel engine, produced from 2003 to 2007, is a true legend – albeit one with a complex reputation. While renowned for its impressive power output and torque in stock form, it also gained notoriety for several common failure points. However, for the discerning enthusiast or workhorse owner, the 6.0 Powerstroke isn’t just a motor; it’s a platform with immense potential waiting to be unlocked. With the right performance upgrade strategy, this engine can be transformed into an incredibly reliable and high-performing powerhouse.

Are you looking to squeeze more horsepower out of your F-Series truck or Excursion? Do you want better throttle response, improved towing capabilities, or simply a more durable and efficient engine? Upgrading specific 6.0 Powerstroke engine components is the key. This comprehensive guide will walk you through the most impactful modifications, from fuel system enhancements to turbocharger upgrades and critical “bulletproofing” measures, all designed to not only boost power and efficiency but also significantly enhance the longevity and reliability of your beloved diesel.

Forget the whispers of unreliability; with smart, targeted modifications, your 6.0 Powerstroke can rival – and often surpass – the performance and dependability of newer diesel engines. Let’s dive into the world of 6.0 Powerstroke performance upgrades and discover how to build the ultimate diesel machine.

Quick Answers to Common Questions

Where should I start when upgrading 6.0 Powerstroke engine components for performance?

Begin with a solid foundation by ensuring your truck’s maintenance is up-to-date. Then, focus on reliability upgrades like head studs before diving into power-adding components.

What are the most impactful upgrades for a 6.0 Powerstroke to boost power and efficiency?

A custom tune, an upgraded turbocharger, and improved fuel system components typically offer the biggest gains in power and torque, directly boosting your engine’s output significantly.

Will upgrading 6.0 Powerstroke engine components for performance reduce my engine’s lifespan?

Not necessarily, if done correctly and responsibly. Proper tuning, quality parts, and regular maintenance can ensure enhanced performance without compromising reliability.

Do I need an aftermarket tuner or custom tuning for these performance upgrades?

Absolutely! Custom tuning is crucial for optimizing your engine’s parameters to match your new components, ensuring maximum performance, efficiency, and reliability.

Can I improve fuel efficiency when upgrading 6.0 Powerstroke engine components for performance?

Yes, often! Many performance upgrades, especially custom tunes and efficient injectors, can actually improve your fuel economy by optimizing combustion and power delivery.

📋 Table of Contents

- Unleashing Power: Fuel System and Injector Upgrades

- Breathing Life into Your 6.0: Turbochargers, Intakes, and Exhaust

- Mastering Control: Custom Tuning and Engine Monitoring

- Fortifying the Foundation: Critical Reliability & Cooling System Enhancements

- Optimizing the High-Pressure Oil System (HPOP) & Internal Upgrades

- Estimated Performance Gains by Upgrade Stage

- Conclusion: Unlock Your 6.0 Powerstroke’s True Potential

Unleashing Power: Fuel System and Injector Upgrades

The foundation of any serious 6.0 Powerstroke performance upgrade begins with its ability to deliver fuel. More fuel, precisely delivered, means more power. The stock fuel system has its limitations, especially when pushing beyond factory power levels. Upgrading these components is crucial for both performance and reliability.

Learn more about Upgrading 6.0 Powerstroke engine components for performance – Upgrading 6.0 Powerstroke Engine Components for Performance: Boost Power and Efficiency

Image source: motortrend.com

Performance Fuel Injectors

The heart of your fuel delivery system, the injectors, are often the first bottleneck when seeking more power. Stock injectors are designed for stock power. When you add a tune or a larger turbo, they simply can’t keep up. Upgrading to larger, aftermarket performance fuel injectors is a common and highly effective way to increase horsepower and torque.

| Component Upgrade | Description / Type | Estimated Performance Gain (HP / TQ) | Key Benefit / Consideration |

|---|---|---|---|

| Custom Tuning / Programmer | ECU re-calibration for fuel, timing, and boost parameters | +50-150 HP / +100-300 TQ | Most cost-effective, improves driveability & fuel economy (mild tunes) |

| Larger Injectors | High-flow fuel injectors (e.g., 155/30, 175/75) | +80-200 HP (requires tuning & adequate turbo) | Delivers more fuel for higher power, often needed with upgraded turbos |

| Upgraded Turbocharger | Larger compressor/turbine wheels (e.g., KC Turbo, Barder) | +70-180 HP (requires tuning & injector support) | Increased airflow for higher power, lower EGTs, improved spool/driveability |

| ARP Head Studs | Replaces factory torque-to-yield head bolts with stronger studs | Indirect (enables higher power reliably) | Crucial for reliability with increased boost/power, prevents head gasket failure |

| Aftermarket Lift Pump | Integrated fuel pump & filtration system (e.g., FASS, AirDog) | +10-20 HP (indirect, maintains fuel pressure) | Ensures consistent fuel pressure, better filtration, extends injector life |

- How they work: Larger injectors allow more fuel to be delivered into the combustion chamber per injection cycle. This translates directly to more power, assuming your other components (like your turbo and tune) can handle the extra fuel.

- Benefits: Significant horsepower and torque gains (often 50-200+ HP depending on size and other mods), improved throttle response.

- Considerations: Must be paired with appropriate custom tuning. Larger injectors can also increase Exhaust Gas Temperatures (EGTs), requiring monitoring. Common sizes range from 155cc to 205cc or larger, with various nozzle options.

High-Volume Fuel Pumps and Regulators

Even with larger injectors, if your fuel pump can’t supply enough fuel at the right pressure, you won’t realize their full potential. The factory fuel pump is adequate for stock applications but can struggle under higher demands, leading to fuel pressure drops and potential injector damage.

- Upgraded Fuel Pumps: Aftermarket pumps, often referred to as “lift pumps,” provide consistent, higher volume fuel delivery to the injectors. Brands like FASS and AirDog are popular choices, which also incorporate filtration.

- Regulated Return Fuel System: The stock 6.0 Powerstroke fuel system is a “deadhead” design, meaning fuel flows to the injectors and dead-ends there. A regulated return system circulates fuel past all injectors and returns excess to the tank, ensuring more consistent fuel pressure at each injector and reducing heat buildup in the fuel lines. This is a highly recommended reliability and performance upgrade.

Fuel System Filtration and Air Separation (FASS/AirDog)

Beyond simply moving fuel, ensuring its cleanliness and aeration-free state is paramount for injector longevity and optimal performance. Air in the fuel can cause cavitation, damaging injectors over time. Poor filtration allows contaminants to pass through, grinding away at precision injector components.

- FASS (Fuel Air Separation System) and AirDog: These integrated systems combine a high-volume lift pump with advanced filtration and a built-in air/vapor separation system.

- Benefits: Extended injector life, improved fuel economy (due to aerated fuel being less efficient), consistent fuel pressure, and often noticeable performance gains by providing cleaner, denser fuel.

- Actionable Tip: Even if you’re not planning massive power, a FASS or AirDog system is an excellent 6.0 Powerstroke reliability upgrade that protects your expensive injectors.

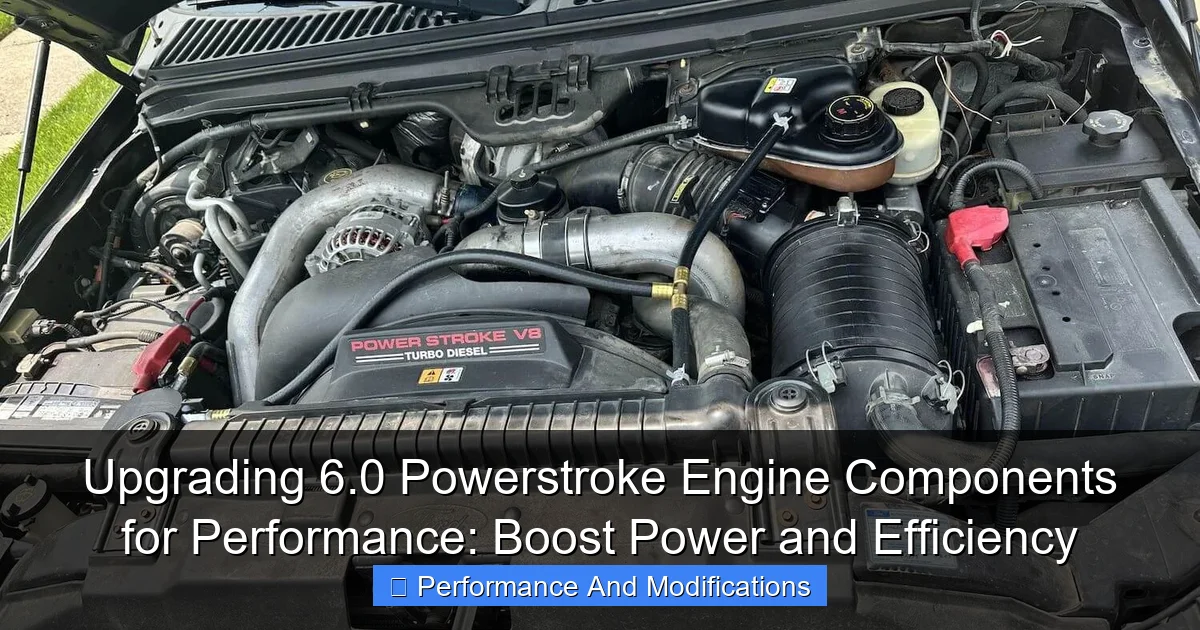

Breathing Life into Your 6.0: Turbochargers, Intakes, and Exhaust

For a diesel engine, airflow is just as critical as fuel. Efficiently moving air in and out of the engine directly impacts power, throttle response, and EGTs. Optimizing these systems is a cornerstone of any serious 6.0 Powerstroke performance build.

Learn more about Upgrading 6.0 Powerstroke engine components for performance – Upgrading 6.0 Powerstroke Engine Components for Performance: Boost Power and Efficiency

Image source: motorbiscuit.com

Performance Turbocharger Upgrades

The variable geometry turbocharger (VGT) on the 6.0 Powerstroke is innovative but can be a source of problems (sticking vanes) and a limiting factor for higher power. Upgrading your turbo is one of the most exciting and impactful modifications for raw power gains.

- Aftermarket VGT Turbos: Many companies offer improved VGT turbos that spool faster, flow more air, and are more durable than stock. These maintain the VGT benefits (quick spool, exhaust braking) while increasing overall output.

- Fixed Geometry (Non-VGT) Turbos: For extreme power, some enthusiasts opt for larger, fixed geometry turbos. These often require external wastegates and sacrifice some low-end spool for massive top-end power.

- Benefits: Dramatically increased horsepower and torque, reduced EGTs (with proper tuning and sizing), improved throttle response, and a more aggressive exhaust note.

- Considerations: Sizing is critical; too large and you’ll have excessive turbo lag; too small and you’ll run out of breath at higher RPMs. Professional installation and custom tuning are a must.

Cold Air Intake (CAI) Systems

Letting your engine breathe easier starts at the intake. A restrictive stock air box can choke your engine, especially when you start adding other performance parts. A Cold Air Intake (CAI) system is often one of the first and simplest 6.0 Powerstroke mods.

- How they work: CAIs typically feature a larger, less restrictive air filter (often cone-shaped), a wider intake tube, and a design that isolates the filter from engine bay heat, drawing in cooler, denser air.

- Benefits: Modest horsepower and torque gains (5-20 HP), improved throttle response, enhanced engine sound, and potentially better fuel economy. Cooler air is denser, meaning more oxygen for combustion.

- Actionable Tip: Look for a CAI with a quality filter that offers excellent filtration efficiency to protect your turbo and engine from contaminants.

Upgraded Intercoolers

The air compressed by your turbocharger gets hot. Hot air is less dense and carries less oxygen, reducing power. An intercooler cools this compressed air before it enters the engine.

- Larger, More Efficient Intercoolers: Aftermarket intercoolers typically have larger cores and more efficient fin designs, allowing them to dissipate heat more effectively.

- Benefits: Cooler intake air, resulting in a denser air charge, which translates to more power and reduced EGTs, especially when towing or under heavy load. This is a vital component for high-horsepower builds.

High-Flow Exhaust Systems

Just as important as getting air in is getting exhaust gases out efficiently. A restrictive stock exhaust system creates back pressure, which hinders turbo spool, increases EGTs, and reduces overall engine efficiency.

- Performance Exhaust Systems: These typically feature larger diameter piping (e.g., 4 or 5-inch), mandrel bends for smoother flow, and less restrictive mufflers (or muffler deletes).

- Benefits: Reduced back pressure, quicker turbo spool, lower EGTs, slight horsepower and torque gains, and the iconic “diesel rumble.”

- Considerations: Be aware of local emissions regulations regarding DPF (Diesel Particulate Filter) or catalytic converter removal, though the 6.0 Powerstroke generally predates DPF requirements.

Mastering Control: Custom Tuning and Engine Monitoring

Even the best hardware upgrades are useless without the right software. Custom engine tuning is the brain that brings all your upgraded 6.0 Powerstroke engine components together, while proper monitoring ensures everything is running safely and optimally.

Custom ECU Tuning (Flasher/Programmers)

This is arguably the single most impactful performance upgrade for any modern diesel engine. The Engine Control Unit (ECU) dictates fuel delivery, injection timing, turbo boost, and many other critical parameters.

- How it works: A performance tuner or programmer modifies the software “map” within your ECU. This is customized to take advantage of your specific hardware upgrades (injectors, turbo, exhaust, etc.).

- Benefits: Massive gains in horsepower and torque (often 50-150+ HP on a stock truck, much more with supporting mods), improved throttle response, better shift points for the transmission, and potentially improved fuel economy when driven conservatively.

- Custom Tuning vs. Off-the-Shelf: While some tuners offer pre-loaded “box” tunes, a truly custom tune written specifically for your truck and its modifications by a reputable tuner is always the superior choice for optimal performance, reliability, and safety.

- Actionable Tip: Never run a truck with significant hardware upgrades (like larger injectors or turbos) without a corresponding custom tune. Doing so can cause severe engine damage.

Essential Monitoring Gauges

When you start modifying your 6.0 Powerstroke for performance, monitoring your engine’s vitals becomes non-negotiable. Running “blind” is a recipe for disaster. These gauges provide critical feedback to prevent catastrophic failures.

- Key Gauges to Install:

- EGT (Exhaust Gas Temperature) Gauge: Crucial for preventing meltdown. High EGTs can severely damage your turbo, pistons, and valves.

- Fuel Pressure Gauge: Ensures your fuel pump and regulator are maintaining adequate pressure to protect your injectors.

- Boost Gauge: Monitors turbocharger output and helps diagnose potential issues.

- Oil Temperature/Pressure Gauges: Especially important given the 6.0’s oil cooler issues. Monitoring oil temps helps prevent overheating.

- Coolant Temperature Gauge: To keep an eye on your engine’s overall thermal health.

- Methods of Monitoring: Dedicated pillar-mounted gauges, OBD-II scan tools like an SCT Livewire or Edge Insight CTS3, or smartphone apps paired with Bluetooth adapters can display these parameters.

Fortifying the Foundation: Critical Reliability & Cooling System Enhancements

The 6.0 Powerstroke has a few well-known weak points that must be addressed, especially when increasing power. These “bulletproofing” modifications are not just about performance; they’re about ensuring your investment lasts.

Head Studs: The Ultimate Insurance Policy

This is arguably the most talked-about and essential 6.0 Powerstroke reliability upgrade. The factory Torque-To-Yield (TTY) head bolts are notorious for stretching and allowing the cylinder heads to lift under increased cylinder pressure, leading to blown head gaskets.

- How they work: Head studs (e.g., from ARP) replace the factory head bolts. Studs clamp the cylinder heads to the block with much greater and more consistent force, resisting head lift even under high boost and cylinder pressures.

- Benefits: Prevents blown head gaskets, significantly improves engine reliability, especially crucial for any tuned or high-horsepower application.

- Actionable Tip: If you’re doing any significant work that requires removing the cylinder heads, installing head studs is a no-brainer. It’s cheap insurance against a very expensive problem.

EGR System Upgrades (Delete or Cooler)

The Exhaust Gas Recirculation (EGR) system on the 6.0 Powerstroke is a common failure point, leading to coolant leaks and contamination, and can contribute to oil cooler failure.

- EGR Delete Kit: This completely removes the EGR valve and cooler, preventing future failures and eliminating the potential for exhaust gases and soot to clog the intake. Requires custom tuning to avoid check engine lights.

- Upgraded EGR Cooler: If you need to retain the EGR system for emissions compliance or simply prefer to, aftermarket EGR coolers are available that are significantly more robust than the factory unit.

- Benefits: Improved reliability, cleaner intake tract, lower EGTs, and often a slight increase in throttle response.

- Considerations: EGR delete kits are illegal for street use in many areas due to emissions regulations. Always check local laws.

Upgraded Oil Coolers

Another major weakness of the 6.0 Powerstroke is its oil cooler, which is prone to clogging from casting sand and coolant contamination, leading to elevated engine oil temperatures and potential damage to the High-Pressure Oil Pump (HPOP) and injectors.

- Aftermarket Oil Coolers: Many companies offer redesigned or external oil coolers that are more robust and less prone to clogging.

- How to check: Monitor the delta (difference) between your Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT). If the EOT is consistently more than 15 degrees F higher than ECT (at cruising speed once fully warmed up), your oil cooler is likely failing.

- Benefits: Extended engine life, protection for expensive components, and maintaining optimal operating temperatures.

- Actionable Tip: Pair an oil cooler replacement/upgrade with a coolant flush and, ideally, a coolant filtration system to prevent future clogging.

High-Performance Radiators and Cooling System Maintenance

Beyond the oil cooler, ensuring your entire cooling system is up to the task is vital, especially with increased power and potential for higher heat output.

- Aftermarket Radiators: Larger, more efficient radiators can offer superior heat rejection, which is particularly beneficial for heavy towing or sustained high-performance driving.

- Coolant Filtration System: These systems filter contaminants out of your coolant, preventing them from clogging your oil cooler and other vital components. A highly recommended preventative measure.

- Coolant Type: Ensure you’re using the correct extended-life coolant (EC-1 rated) and maintain it properly.

Optimizing the High-Pressure Oil System (HPOP) & Internal Upgrades

The 6.0 Powerstroke is an HEUI (Hydraulically Actuated Electronically Controlled Unit Injector) system, meaning high-pressure oil is used to fire the fuel injectors. A robust High-Pressure Oil Pump (HPOP) and associated components are essential for consistent fuel delivery and overall engine health, especially when running larger injectors.

High-Pressure Oil Pump (HPOP) Enhancements

The factory HPOP can be a point of failure, particularly the STC (Snap-To-Connect) fitting. While later models received an updated STC fitting, it’s still a good idea to inspect or upgrade.

- Aftermarket HPOP: For very large injectors or extreme horsepower, an upgraded, higher-volume HPOP might be necessary to maintain sufficient oil pressure to fire the injectors effectively.

- STC Fitting Upgrade: A common and highly recommended reliability mod for early 6.0s (and good insurance for all years) is to replace the factory STC fitting with a more robust, one-piece unit. This prevents the HPOP from losing oil pressure due to a failed fitting.

- Benefits: Consistent oil pressure to the injectors, improved injector operation, and enhanced overall reliability of the HEUI system.

Standpipes and Dummy Plugs

Within the oil rails that deliver high-pressure oil to the injectors, the standpipes and dummy plugs are also known failure points, leading to leaks and loss of oil pressure. These are often replaced as part of a comprehensive 6.0 Powerstroke bulletproofing strategy.

- Upgraded Standpipes and Dummy Plugs: Aftermarket versions are designed to be more robust and seal better, preventing costly high-pressure oil leaks within the valve covers.

- Actionable Tip: If you’re replacing injectors or doing any work in the valve train, it’s highly advisable to upgrade these components as preventative maintenance.

Pushrods and Valve Springs (For Extreme Builds)

While most enthusiasts won’t need to delve into internal engine modifications for significant power gains, for those pushing the limits, valve train upgrades become necessary.

- Heavy-Duty Pushrods: Stock pushrods can flex under extremely high cylinder pressures and RPMs, leading to valve train instability. Stronger pushrods maintain valve control.

- Upgraded Valve Springs: Stiffer valve springs are essential when increasing RPM limits or using larger cams, preventing valve float at higher engine speeds.

- Considerations: These are generally for competition or very high-horsepower builds and usually involve pulling the engine for installation.

Estimated Performance Gains by Upgrade Stage

While specific gains vary significantly based on component choices, tuning, and the truck’s overall condition, this table provides a general idea of what to expect from different levels of 6.0 Powerstroke performance upgrades:

| Upgrade Stage | Key Modifications | Estimated HP Gain (Over Stock) | Estimated Torque Gain (Over Stock) | Reliability Impact |

|---|---|---|---|---|

| Stage 1: Mild Performance | Cold Air Intake, High-Flow Exhaust, Custom ECU Tune | +50 to +100 HP | +100 to +180 lb-ft | Moderate (Increased stress on stock components) |

| Stage 2: Street Performance / Towing | Stage 1 + Larger Injectors (155-175cc), Upgraded Turbo, FASS/AirDog Fuel System, Head Studs, Upgraded Oil Cooler | +100 to +200 HP | +200 to +400 lb-ft | High (Significant reliability enhancements) |

| Stage 3: High Performance / Competition | Stage 2 + Larger Injectors (190-225+cc), High-Flow HPOP, Upgraded Intercooler, Regulated Return, Full “Bulletproofing” (EGR Delete, etc.), Drivetrain Upgrades | +200 to +350+ HP | +400 to +700+ lb-ft | Very High (Engine built for extreme demands) |

Conclusion: Unlock Your 6.0 Powerstroke’s True Potential

The 6.0 Powerstroke is a magnificent engine with a checkered past, but its future, with the right modifications, can be incredibly bright. By strategically upgrading key 6.0 Powerstroke engine components, you can not only resolve its notorious reliability issues but also transform it into a formidable performer that delivers impressive power, improved efficiency, and rock-solid dependability.

Whether your goal is to conquer the toughest towing jobs, dominate the drag strip, or simply enjoy a more responsive and trustworthy daily driver, the path to a high-performing 6.0 Powerstroke is clear. Prioritize “bulletproofing” measures like head studs, an upgraded oil cooler, and a robust fuel system first. Then, layer on performance enhancements such as custom tuning, a high-flow turbo, and larger injectors. Always remember that a balanced approach, where each modification complements the others, is key to achieving optimal results.

Investing in your 6.0 Powerstroke performance upgrade is more than just buying parts; it’s about building a truck that stands the test of time and delivers a driving experience unlike any other. Embrace the potential, make informed choices, and get ready to experience the true power and efficiency your 6.0 Powerstroke was always meant to have!

🎥 Related Video: How To Double Your Powerstrokes Horsepower With Only 3 Mods

📺 Powerstroke Central

I just opened my own automotive shop in Bryan, Texas if you would like to bring your truck by for work! The details are below …

Frequently Asked Questions

What are the most crucial first steps when upgrading 6.0 Powerstroke engine components for performance?

Start by addressing known reliability issues and ensuring your engine is in solid condition. Key initial upgrades often include an EGR delete kit, a new oil cooler, and installing head studs with updated gaskets to create a robust foundation for increased power.

Which 6.0 Powerstroke engine components offer the biggest performance boost for the money?

A high-quality custom tuning module or “tuner” is often the most impactful initial performance upgrade, as it optimizes fuel delivery, timing, and other engine parameters. Coupled with an upgraded air intake system, these modifications can significantly improve horsepower and torque output.

Will upgrading 6.0 Powerstroke engine components for performance negatively impact my engine’s reliability?

When done correctly with quality parts and proper tuning, performance upgrades can actually enhance reliability by addressing factory weaknesses. For instance, an EGR delete and head studs proactively prevent common failure points, allowing the engine to handle increased power more robustly.

What kind of turbocharger upgrades are available for the 6.0 Powerstroke, and what are their benefits?

Options range from upgraded stock replacement turbos with improved internals to larger, aftermarket single or even compound turbo systems. These upgrades reduce lag, increase airflow, and dramatically boost horsepower and torque throughout the RPM range, especially at higher power levels.

Do I need to upgrade my fuel system when upgrading 6.0 Powerstroke engine components for performance?

For significant power gains, particularly beyond 500 horsepower, an upgraded fuel system is often necessary to sustain the increased demand. This typically involves larger injectors and a higher-capacity fuel pump to ensure adequate fuel delivery and prevent fuel starvation under heavy load.

What is a realistic budget for upgrading 6.0 Powerstroke engine components for performance?

The cost varies widely based on desired power levels and the extent of modifications. A basic “bulletproof” package with tuning might range from $2,000-$4,000, while comprehensive upgrades including a new turbo, injectors, and fuel system can easily exceed $10,000-$15,000 or more.