Symptoms of a Bad Crankshaft Position Sensor

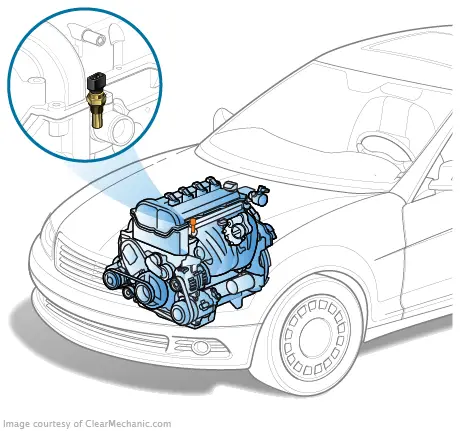

The crankshaft position sensor is an essential component of a vehicle’s ignition system. It monitors the position and rotational speed of the crankshaft, which plays a crucial role in the engine’s combustion process. When a crankshaft position sensor malfunctions, it can lead to a variety of performance issues and potential safety concerns. Understanding the symptoms of a bad crankshaft position sensor can help you identify and address issues before they escalate.

Common Signs of a Failing Crankshaft Position Sensor

Recognizing the symptoms of a faulty crankshaft position sensor can save you time, money, and stress. Here are some common signs that may indicate a problem with this vital component:

| Symptom | Description |

|---|---|

| 1. Engine Stalling | One of the primary signs of a bad crankshaft position sensor is engine stalling. If the sensor is not functioning properly, it may send incorrect signals to the vehicle’s computer, resulting in irregular spark timing and fuel injection. This can cause the engine to stall unexpectedly, especially at low speeds or while idling. |

| 2. Rough Idling | A failing crankshaft position sensor can disrupt the engine’s idle speed control. You may notice that the engine idles roughly or inconsistently, with fluctuations in RPM (revolutions per minute). This can lead to overall poor engine performance and potential drivability issues. |

| 3. Difficulty Starting the Engine | When the crankshaft position sensor is malfunctioning, it can impact the engine’s ability to start smoothly. You may experience prolonged cranking, hesitation, or even complete failure to start the engine. This symptom is particularly noticeable when the engine is warm. |

| 4. Misfiring Engine | A bad crankshaft position sensor may cause the engine to misfire, leading to rough and uneven acceleration. This can result in decreased performance, reduced fuel efficiency, and increased emissions. Additionally, you may detect vibrations or jerking sensations while driving. |

| 5. Check Engine Light | Many modern vehicles are equipped with an onboard diagnostics system that can detect irregularities in the engine, including issues related to the crankshaft position sensor. If the sensor is generating abnormal data, it is likely to trigger the check engine light on the dashboard. Scanning the vehicle’s computer for trouble codes can provide valuable insights into the source of the problem. |

Impact of Ignoring Crankshaft Position Sensor Issues

Ignoring the symptoms of a bad crankshaft position sensor can have serious consequences for your vehicle’s performance and reliability. In addition to the immediate impact on engine operation, a malfunctioning sensor can lead to long-term damage to other components, such as the catalytic converter, oxygen sensors, and even the engine itself. Furthermore, continued driving with a faulty sensor can pose safety risks, as unpredictable engine behavior may compromise your ability to control the vehicle.

Addressing Crankshaft Position Sensor Problems

If you suspect that your vehicle’s crankshaft position sensor is failing, it is essential to address the issue promptly. Here are the steps you can take to diagnose and resolve problems related to this critical component:

- Diagnostic Testing: A professional diagnostic scan tool can be used to retrieve trouble codes from the vehicle’s computer. This can help identify specific issues related to the crankshaft position sensor and other related systems.

- Visual Inspection: Check the sensor for any visible signs of damage, corrosion, or disconnection. Ensure that the wiring and connectors associated with the sensor are in good condition.

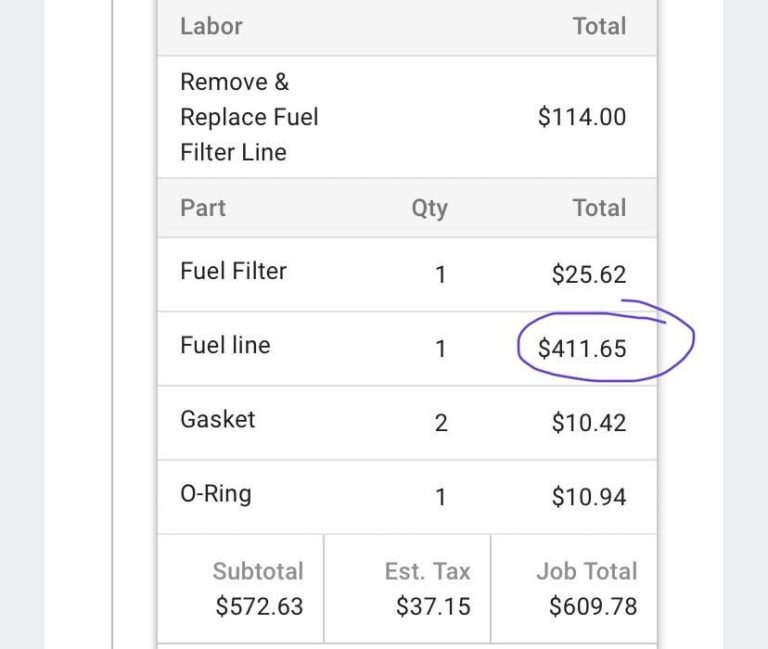

- Professional Repair: If you are not comfortable with automotive diagnostics and repairs, it is advisable to consult a qualified mechanic. They can accurately assess the condition of the crankshaft position sensor and perform any necessary replacements or repairs.

- Quality Replacement: When replacing the crankshaft position sensor, opt for a high-quality OEM (original equipment manufacturer) or aftermarket part from a reputable supplier. This ensures compatibility and reliable performance.

- Regular Maintenance: Incorporating regular inspections and maintenance checks into your vehicle care routine can help prevent and detect potential issues with the crankshaft position sensor before they escalate into more severe problems.

Credit: www.1aauto.com

Frequently Asked Questions Of Symptoms Of A Bad Crankshaft Position Sensor

What Are The Common Symptoms Of A Bad Crankshaft Position Sensor?

The common symptoms of a bad crankshaft position sensor include engine stalling, rough idling, and difficulty starting.

How Does A Bad Crankshaft Position Sensor Affect The Engine Performance?

A bad crankshaft position sensor can lead to misfiring, poor fuel efficiency, and loss of power while driving.

What Can Happen If A Faulty Crankshaft Position Sensor Goes Unrepaired?

If left unaddressed, a faulty crankshaft position sensor can cause irreversible damage to the engine and lead to costly repairs.

How Crucial Is The Role Of A Crankshaft Position Sensor In Vehicle Operation?

The crankshaft position sensor is essential for engine timing and fuel injection, making it vital for overall vehicle performance.

Conclusion

Recognizing the symptoms of a bad crankshaft position sensor is crucial for maintaining the optimal performance and reliability of your vehicle. By addressing issues related to this essential component in a timely manner, you can minimize the risk of potential damage and safety concerns. Whether you are experiencing engine stalling, rough idling, difficulty starting the engine, misfires, or a persistent check engine light, it is important to take proactive steps to diagnose and resolve problems with the crankshaft position sensor.

Remember that seeking professional assistance when dealing with complex automotive systems can ensure accurate diagnosis and effective repairs, ultimately promoting the long-term health of your vehicle.