How to Troubleshoot 7.3 Powerstroke Injector Issues: Diagnose and Repair

Featured image for this comprehensive guide about How to troubleshoot 7.3 Powerstroke injector issues

Image source: cimg5.ibsrv.net

How to Troubleshoot 7.3 Powerstroke Injector Issues: Diagnose and Repair

The 7.3L Powerstroke engine is legendary. Known for its incredible durability and pulling power, it’s a workhorse that has earned its reputation among truck enthusiasts and working professionals alike. Produced from 1994.5 to 2003, millions of these engines are still on the road today, reliably serving their owners. However, even the most robust engines aren’t immune to wear and tear, and for the 7.3L, one of the most common and often perplexing challenges revolves around its injectors. When your beloved Powerstroke starts acting up – with rough idles, a sudden loss of power, or that tell-tale smoke from the exhaust – it’s often a sign that you’re facing 7.3 Powerstroke injector issues.

Navigating the world of diesel engine diagnostics can feel daunting, especially when it comes to the complex High-Pressure Oil Pump (HPOP) driven injector system that powers the 7.3L. These aren’t simple electronic components; they’re electromechanical marvels that rely on a finely tuned balance of high-pressure oil and fuel to deliver that iconic Powerstroke performance. Understanding how to accurately diagnose 7.3 Powerstroke injectors is crucial, not just for saving money on unnecessary repairs, but for keeping your truck running strong for years to come. This comprehensive guide will equip you with the knowledge and actionable steps needed to identify, understand, and ultimately resolve common 7.3 Powerstroke injector problems, turning frustration into triumph.

Whether you’re a seasoned diesel mechanic or a dedicated DIYer, this post will walk you through everything from recognizing initial symptoms to performing advanced diagnostic tests. We’ll demystify the intricacies of the 7.3L’s fuel injection system and provide a clear roadmap to effectively troubleshoot 7.3 Powerstroke injectors. Let’s dive in and get your Powerstroke purring again!

Quick Answers to Common Questions

What are the common signs of 7.3 Powerstroke injector issues?

Rough idle, excessive smoke (especially white or black), noticeable loss of power, and poor fuel economy are classic indicators. You might also hear a distinct miss or knock from the engine.

Can I keep driving my truck if I suspect 7.3 Powerstroke injector issues?

While your truck might still run, it’s generally not recommended to drive with suspected 7.3 Powerstroke injector issues. Continuing to drive can potentially lead to more serious engine damage or reduced performance.

What’s the very first thing I should check when troubleshooting 7.3 Powerstroke injector issues?

Start with the basics: ensure your fuel filter is clean and your oil level is full. The 7.3’s HEUI system relies on engine oil pressure, so low oil can mimic severe 7.3 Powerstroke injector issues.

Is it always the injectors, or could something else cause similar symptoms?

Not always! Issues like a failing Injector Pressure Regulator (IPR) valve, Injector Control Pressure (ICP) sensor, or even air in the fuel system can present symptoms very similar to 7.3 Powerstroke injector issues. A good diagnostic process is key.

How difficult is it for a DIYer to diagnose and fix 7.3 Powerstroke injector issues?

Many diagnostic steps, like a buzz test or cylinder contribution test, are quite manageable for a DIYer with a good scanner. While replacing the injectors themselves is a bigger job, many owners successfully tackle 7.3 Powerstroke injector issues with patience and the right tools.

📋 Table of Contents

- Understanding Your 7.3L Powerstroke Injector System: The HEUI Advantage

- Common Symptoms of 7.3 Powerstroke Injector Problems

- Initial Diagnostic Steps: The Low-Tech Approach

- Advanced Diagnostics: Using Scan Tools and Specialized Tests

- Addressing the Root Cause: Repair and Prevention

- Conclusion: Empowering Your 7.3L Powerstroke’s Longevity

Understanding Your 7.3L Powerstroke Injector System: The HEUI Advantage

Before you can effectively troubleshoot 7.3 Powerstroke injectors, it’s essential to understand how they operate. The 7.3L Powerstroke utilizes a unique hydraulically actuated electronically controlled unit injector (HEUI) system. Unlike common rail systems, the HEUI injectors rely on high-pressure engine oil, rather than solely fuel pressure, to atomize and inject fuel into the cylinders. This innovative design, introduced by International Navistar, was cutting-edge for its time and contributed significantly to the engine’s power and efficiency.

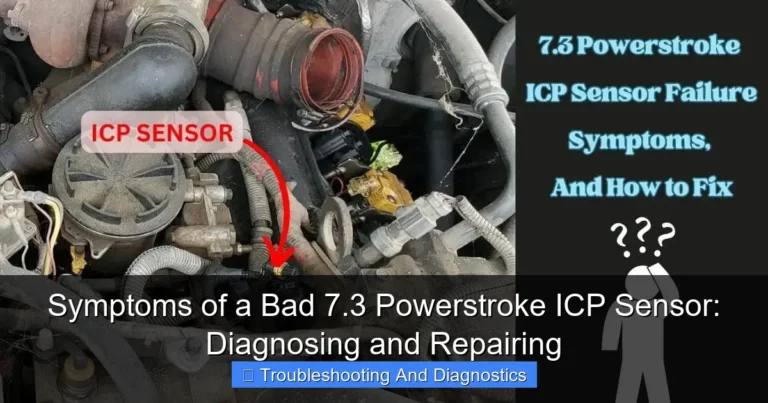

Learn more about How to troubleshoot 7.3 Powerstroke injector issues – How to Troubleshoot 7.3 Powerstroke Injector Issues: Diagnose and Repair

Image source: autotrends.org

Key Components of the HEUI System:

- High-Pressure Oil Pump (HPOP): This gear-driven pump is the heart of the HEUI system. It pressurizes engine oil to extremely high levels (up to 3,000 PSI or more) to drive the injectors.

- Injector Pressure Regulator (IPR) Valve: The IPR valve controls the amount of oil pressure sent to the injectors, directly influencing injection timing and fuel delivery. It’s crucial for engine performance.

- Injector Control Pressure (ICP) Sensor: This sensor monitors the oil pressure in the high-pressure oil galleries (oil rails) that feed the injectors. The PCM uses this feedback to adjust the IPR valve.

- Oil Rails: These internal passages within the cylinder heads distribute high-pressure oil to each injector.

- Fuel Injectors: Each injector is a complex electromechanical device. High-pressure oil enters the injector, pushing a intensifier piston which then pressurizes the fuel within the injector body, forcing it out through the nozzle. A solenoid on top of the injector controls the opening and closing of an internal poppet valve, allowing oil to actuate the intensifier piston.

- Under Valve Cover Harness (UVCH): This harness carries the electrical signals from the Injector Drive Module (IDM) to the solenoids on top of each injector, enabling them to fire.

- Injector Drive Module (IDM): The IDM is a separate module that takes signals from the Powertrain Control Module (PCM) and boosts the voltage (up to 110-120V) to rapidly open and close the injector solenoids.

- Fuel Pump and Fuel Pressure Regulator (FPR): While oil actuates the injectors, a separate electric fuel pump supplies fuel at a lower, consistent pressure (around 45-70 PSI) to the injectors. The FPR maintains this pressure.

Understanding this intricate interplay of oil and fuel is fundamental to accurately pinpointing the source of 7.3 Powerstroke injector problems. A fault in any one of these components can mimic a bad injector, making thorough diagnostics essential.

| Symptom | Primary Diagnostic Step / Common Cause | Expected Findings / Solution |

|---|---|---|

| Hard Start (Cold or Hot) / No Start | Monitor ICP (Injection Control Pressure) & IPR (Injector Pressure Regulator) duty cycle during crank. Check engine oil level & quality. | ICP < 500 PSI (min for start) suggests HPOP, IPR valve, or ICP sensor issues. IPR duty cycle > 65% during crank indicates an ICP system leak (e.g., injector O-rings, standpipes, dummy plugs). Low/aerated oil affects HPOP. |

| Rough Idling / Misfire / Stuttering | Perform Cylinder Contribution Test (CCT) & Buzz Test. Inspect Under Valve Cover Harness (UVCH) for oil/burn marks. | CCT identifies weak/dead cylinders. Buzz Test checks injector solenoid circuits. Oil in UVCH connector or burned pins indicate failing harness/gaskets; replace UVCH. Poor injector wiring can cause intermittent misfires. |

| Excessive Smoke (White/Black/Blue) | Note smoke color/smell. Check fuel pressure (45-70 PSI). Perform glow plug system test. | White smoke (cold): Unburnt fuel, often glow plugs or poor injector atomization. Black smoke: Over-fueling (bad injector), restricted air intake, or exhaust. Blue smoke: Burning oil, potentially worn injector O-rings or internal engine issue. Ensure stable fuel pressure. |

| Loss of Power / Poor Acceleration / Lag | Check fuel pressure, boost pressure, Exhaust Back Pressure (EBP) sensor readings. Perform a power balance test. | Low fuel pressure (<45 PSI) starves injectors. Low boost indicates turbo/CAC issues. High EBP (>ambient at idle) points to restricted exhaust. Weak/worn injectors won’t deliver adequate fuel for power. |

| Fuel in Oil (Oil Dilution) / Diesel Smell in Oil | Send oil sample for analysis. Inspect injector body and lower O-rings upon removal. | Confirmed fuel dilution (e.g., >2% fuel in oil) points to failing injector lower O-rings, injector body cracks, or a compromised fuel supply system. Address quickly to prevent engine damage. |

Common Symptoms of 7.3 Powerstroke Injector Problems

Your 7.3L Powerstroke has a distinct way of telling you when its injectors are struggling. Recognizing these tell-tale signs is the first and most critical step in successful troubleshooting. If you experience any of the following, it’s time to investigate bad 7.3 Powerstroke injector symptoms:

Learn more about How to troubleshoot 7.3 Powerstroke injector issues – How to Troubleshoot 7.3 Powerstroke Injector Issues: Diagnose and Repair

Image source: cdn11.bigcommerce.com

1. Rough Idle and Misfires:

- Description: The engine runs unevenly, shudders, or vibrates excessively, especially at idle. You might feel a distinct “miss” or stumble.

- Why it happens: A faulty injector might not be delivering the correct amount of fuel, or it could be sticking open or closed, leading to incomplete combustion in one or more cylinders. This is a classic sign of a 7.3 Powerstroke misfire.

2. Hard Starting, Especially When Cold:

- Description: The engine cranks for an extended period before firing up, or it might not start at all. This is often more pronounced in colder temperatures.

- Why it happens: Worn injector O-rings or internal leaks can bleed off high-pressure oil or fuel, preventing sufficient pressure from building up quickly enough to actuate the injectors. Air intrusion can also contribute to this, especially if O-rings are compromised. This is a common indicator of a 7.3 Powerstroke hard start issue.

3. Excessive Smoke from the Exhaust:

- Description:

- White/Blue Smoke: Often indicates unburnt fuel. A sticking injector can be over-fueling a cylinder, or an O-ring issue might allow oil into the combustion chamber.

- Black Smoke: While some black smoke under heavy acceleration is normal for a diesel, excessive black smoke can point to over-fueling, clogged injectors, or poor atomization.

- Why it happens: Improper fuel delivery or atomization due to a failing injector means fuel isn’t burning completely, leading to visible exhaust smoke.

4. Loss of Power and Poor Acceleration:

- Description: Your truck feels sluggish, struggles to accelerate, or lacks its usual “oomph.”

- Why it happens: When one or more injectors aren’t firing correctly, the engine can’t produce its full power output, resulting in noticeable performance degradation.

5. Decreased Fuel Economy:

- Description: You’re filling up more frequently than usual, and your miles per gallon have taken a hit.

- Why it happens: Leaky, clogged, or poorly functioning injectors can lead to inefficient fuel burning, causing the engine to consume more fuel to achieve the same output.

6. Engine Noise (Knocking or Tapping):

- Description: You might hear a distinct knocking or tapping sound emanating from the engine, sometimes described as a “hammering” noise.

- Why it happens: This can be caused by an injector firing at the wrong time (pre-ignition or post-ignition) or due to extreme pressure imbalances in the combustion chamber.

If your 7.3L Powerstroke exhibits any of these bad 7.3 Powerstroke injector symptoms, it’s a clear signal that it’s time to move on to diagnostic steps to confirm the source of the trouble.

Initial Diagnostic Steps: The Low-Tech Approach

Before you even think about plugging in an expensive scan tool, there are several foundational checks you can perform that often reveal the root cause of 7.3 Powerstroke injector issues. These low-tech steps can save you time and money by ruling out simpler problems.

1. Check Engine Oil Level and Quality:

- Action: The HEUI system relies entirely on engine oil. Check your dipstick. Is the oil level full? Is the oil clean, or is it excessively dirty and diluted with fuel?

- Insight: Low oil pressure or dirty, contaminated oil can severely impact HPOP performance and injector actuation. A high oil level could indicate fuel dilution, often caused by leaking injector O-rings. Ensure you’re using the correct viscosity oil for your climate, as specified by Ford/International.

2. Inspect Fuel Filters:

- Action: When was your last fuel filter change? Clogged fuel filters restrict fuel flow, leading to fuel starvation and symptoms that mimic bad injectors.

- Insight: A clean fuel system is paramount. Change your primary and secondary fuel filters regularly (every 10,000-15,000 miles, or more frequently if you suspect poor fuel quality). A simple replacement can often resolve rough running or power loss.

3. Visual Inspection for Leaks and Loose Connections:

- Action: With the engine off and cool, meticulously inspect the engine bay. Look for oil leaks around the HPOP, ICP sensor, and especially under the valve covers (though this requires removal). Check fuel lines for leaks.

- Insight: Leaks in the high-pressure oil system (e.g., a cracked HPOP line or a faulty ICP sensor) can cause insufficient oil pressure, leading to injector issues. Fuel leaks can reduce fuel pressure to the injectors.

4. Listen for the “7.3 Powerstroke Injector Buzz”:

- Action: With the engine off, turn the key to the “on” position (without starting). You should hear a distinct “buzzing” sound coming from the engine bay. This is the IDM cycling power to the injectors as part of a system self-check.

- Insight: If you don’t hear the buzz, or it’s weak/intermittent, it could indicate a problem with the IDM, the UVCH, or the injectors themselves. This is a basic form of the “Buzz Test” discussed in the advanced section.

5. Check Battery and Charging System:

- Action: A weak battery or failing alternator can impact the performance of the IDM, leading to insufficient voltage to fire the injectors correctly. Have your batteries tested and check your alternator’s output.

- Insight: Diesel engines require robust electrical systems. Ensure your batteries are fully charged and in good condition, and that the alternator is charging properly.

These initial checks address common, often overlooked culprits. If your symptoms persist after performing these basic diagnostics, it’s time to delve deeper with advanced tools and tests to precisely diagnose 7.3 Powerstroke injectors.

Advanced Diagnostics: Using Scan Tools and Specialized Tests

When the basic checks don’t pinpoint the problem, it’s time to bring in the big guns: a quality scan tool and specialized diagnostic tests. These tools allow you to communicate with the PCM and IDM, revealing hidden fault codes and live data that are critical for accurately identifying 7.3 Powerstroke injector problems.

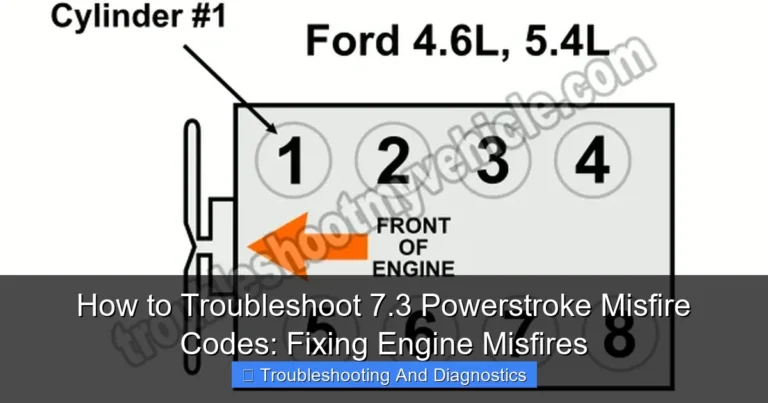

1. The Cylinder Contribution Test (CCT):

- Purpose: This test identifies which specific cylinders are contributing less power than others, indicating a potential misfire or weak injector.

- How it works: The PCM momentarily cuts fuel to individual cylinders and monitors changes in crankshaft speed. A cylinder that shows little to no change when its fuel is cut suggests it wasn’t contributing much power in the first place, pointing to an issue with that cylinder’s injector or compression.

- Tool: Requires a capable scan tool (e.g., AE (AutoEnginuity), Ford IDS, ForScan with an ELM327 adapter).

- Insight: The CCT is invaluable for pinpointing specific 7.3 Powerstroke misfire culprits. It will often indicate a “low contribution” fault for a particular cylinder.

2. The Injector Buzz Test (Advanced):

- Purpose: This test checks the electrical integrity of the IDM, UVCH, and injector solenoids.

- How it works: The scan tool commands the IDM to rapidly cycle each injector solenoid, producing a distinct “buzzing” or “clicking” sound from each injector.

- Tool: Requires a capable scan tool.

- Insight: If an injector doesn’t buzz, it could indicate:

- A faulty solenoid within the injector.

- An open circuit in the UVCH or external harness.

- A problem with the IDM for that specific injector driver circuit.

3. Injector Kill Test:

- Purpose: Similar to the CCT but often performed manually or with simpler scan tools, this test allows you to disable individual injectors one by one.

- How it works: With the engine running, you can either use a scan tool to electronically “kill” an injector or, in older models, unplug its electrical connector (though this is less recommended due to potential harness damage). If disabling an injector makes no difference to the engine’s idle quality, that injector was likely dead or weak to begin with.

- Insight: Helps confirm which cylinder is causing the rough idle 7.3 Powerstroke.

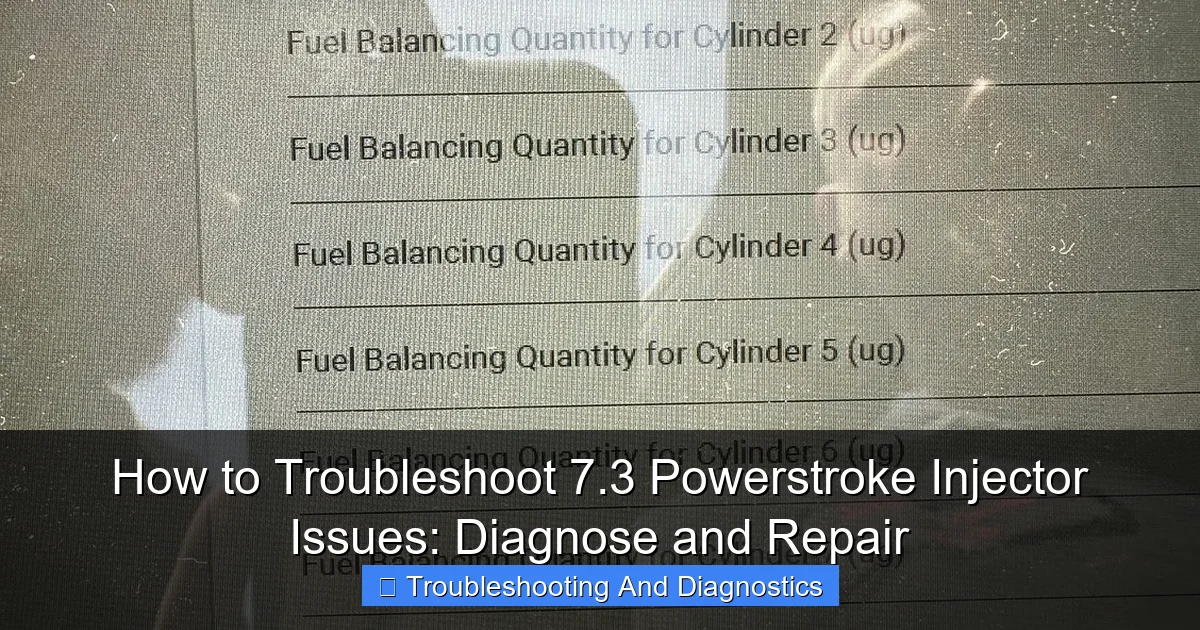

4. Monitoring ICP and IPR Values (Live Data):

- Purpose: To assess the health of the high-pressure oil system, which directly affects injector performance.

- How it works: Using a scan tool, monitor the ICP (Injector Control Pressure) sensor readings and the IPR (Injector Pressure Regulator) valve duty cycle (%).

- Normal Ranges (approximate):

- ICP at Idle: 500-800 PSI

- ICP at WOT (Wide Open Throttle): 2,000-3,000+ PSI

- IPR Duty Cycle at Idle: 8-15%

- IPR Duty Cycle at WOT: 35-65%

- Insight:

- Low ICP, High IPR Duty Cycle (at idle or under load): Indicates a leak in the high-pressure oil system (e.g., HPOP, ICP sensor itself, standpipes, oil rail plugs, or injector O-rings bleeding off pressure). The IPR is trying to build pressure but can’t.

- ICP reading stuck at 0 or 2500+ PSI: Likely a faulty ICP sensor or its wiring.

- Fluctuating ICP: Could indicate HPOP issues or intermittent leaks.

5. Fuel Pressure Test:

- Purpose: To ensure adequate fuel supply to the injectors.

- How it works: Install a fuel pressure gauge on the fuel filter housing or another suitable test port.

- Normal Range: 45-70 PSI at idle.

- Insight: If fuel pressure is consistently below 45 PSI, you could have a failing fuel pump, a clogged fuel filter, a faulty fuel pressure regulator, or air intrusion. While not an injector issue directly, low fuel pressure *will* cause injector-like symptoms.

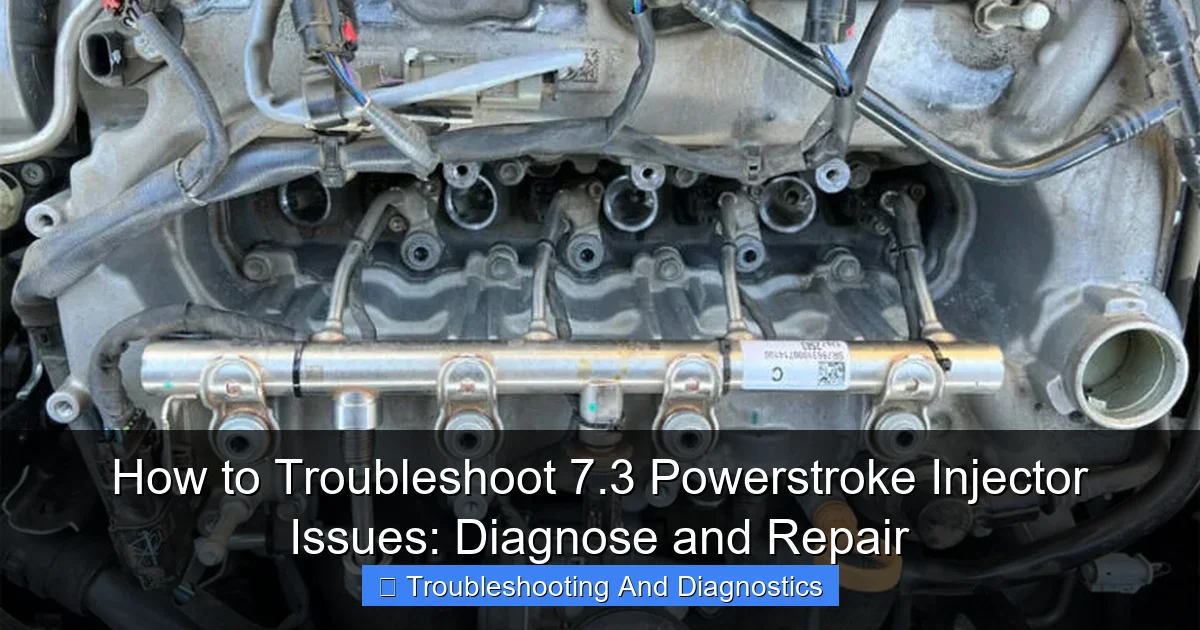

6. Under Valve Cover Harness (UVCH) Inspection and Ohming Injectors:

- Purpose: The UVCH is a common failure point due to heat and vibration, leading to intermittent injector operation.

- How it works: This requires removing the valve covers. Once exposed, visually inspect the UVCH for burnt, melted, or loose connectors. You can also use a multimeter to “ohm out” each injector solenoid through the UVCH connection. A reading between 3.0-5.0 ohms is typical. Readings outside this range (open circuit or short) indicate a faulty solenoid or UVCH.

- Insight: UVCH issues are a very frequent cause of 7.3 Powerstroke injector issues and misfires. Often, simply replacing the UVCH can resolve the problem without needing new injectors. Pay close attention to the 9-pin connector that passes through the head.

Addressing the Root Cause: Repair and Prevention

Once you’ve accurately diagnosed the problem, the next step is to execute the repair. Depending on your diagnosis, the solution for repair 7.3 Powerstroke injectors can range from simple fixes to comprehensive replacements.

Common Repair Scenarios:

- UVCH Replacement: If the Buzz Test or Ohming reveals a faulty UVCH, this is a relatively straightforward repair once the valve covers are off. It’s often recommended to replace both sides if one is failing due to age.

- Injector O-Ring Replacement: Leaking O-rings are a common cause of hard starting and high-pressure oil bleed-off. This involves removing the injectors, replacing the three O-rings on each, and potentially replacing the copper washer at the tip. Be meticulous with cleanliness!

- Injector Replacement: If a specific injector is truly faulty (failed solenoid, internal mechanical wear, clogged nozzle), replacement is necessary. This is a significant job, requiring specialized tools and a high degree of cleanliness. Always replace with quality remanufactured or new injectors.

- HPOP Replacement: If diagnostics point to a failing HPOP (e.g., inability to build sufficient ICP despite good IPR duty cycle), it will need to be replaced. Ensure the reservoir is full of clean oil before startup.

- ICP Sensor / IPR Valve Replacement: These are critical for controlling and sensing oil pressure. If either is faulty, replacing it can resolve pressure-related issues.

- IDM Replacement: While less common than UVCH or injector failures, a failed IDM can cause widespread injector issues. Diagnostics like the Buzz Test help confirm this.

- Fuel System Components: If low fuel pressure is the culprit, replacing the fuel pump, fuel filter, or fuel pressure regulator will be necessary.

Preventative Maintenance to Extend Injector Life:

Prevention is always better than cure. Following good maintenance practices can significantly extend the life of your 7.3 Powerstroke injectors and associated components:

- Regular Oil Changes: The HEUI system runs on your engine oil. Use high-quality synthetic or semi-synthetic oil of the correct viscosity and change it religiously (every 5,000-7,500 miles). Dirty or low oil directly impacts HPOP and injector health.

- Consistent Fuel Filter Replacement: Change your primary and secondary fuel filters every 10,000-15,000 miles, or more often if you use questionable fuel sources. Clogged filters starve the injectors.

- Use Quality Fuel: Opt for reputable fuel stations. Consider using a quality diesel fuel additive, especially one with lubricity enhancers and cetane boosters, to protect injectors and improve combustion.

- Monitor for Leaks: Regularly check for oil and fuel leaks around the engine. Address them promptly before they cause major issues.

- Keep Electrical Connections Clean: Periodically check and clean electrical connections, especially those related to the IDM, UVCH, and sensors, to prevent corrosion and ensure good contact.

Troubleshooting Quick Reference Guide:

Here’s a quick reference for common symptoms and potential primary causes:

| Symptom | Most Likely Primary Cause(s) | Diagnostic Test(s) |

|---|---|---|

| Rough Idle / Misfire | Bad injector, UVCH, IDM, low compression | CCT, Buzz Test, Injector Kill Test, Ohming Injectors |

| Hard Start (Cold/Hot) | Injector O-rings, HPOP, IPR valve, low fuel pressure, ICP sensor | Monitor ICP/IPR (live data), Fuel Pressure Test |

| Excessive Smoke (White/Blue) | Leaky injector, injector O-rings, oil dilution | CCT, Monitor ICP/IPR, Visual inspection (oil level/quality) |

| Loss of Power / Poor Acceleration | Multiple weak injectors, HPOP, IPR valve, low fuel pressure | CCT, Monitor ICP/IPR, Fuel Pressure Test |

| No Injector Buzz | UVCH, IDM, PCM fault | Buzz Test (basic & advanced), Ohming UVCH/Injectors |

| Low ICP / High IPR % | HPOP, IPR valve, high-pressure oil leaks (injector O-rings, standpipes, oil rail plugs) | Monitor ICP/IPR (live data) |

Conclusion: Empowering Your 7.3L Powerstroke’s Longevity

The 7.3L Powerstroke is a phenomenal engine, and understanding how to troubleshoot 7.3 Powerstroke injector issues is key to keeping yours running strong for hundreds of thousands of miles. While injector problems can seem complex, by systematically following the diagnostic steps outlined in this guide – from initial low-tech checks to advanced scan tool analysis – you can accurately pinpoint the source of the trouble.

Remember, patience and a methodical approach are your best tools when facing any 7.3 Powerstroke injector problems. Don’t jump to conclusions or replace parts haphazardly. Invest in a good scan tool if you plan on doing your own diagnostics, as the live data and specialized tests are invaluable. Whether you end up replacing a worn UVCH, refreshing some O-rings, or investing in new injectors, the satisfaction of getting your 7.3L Powerstroke back to peak performance is immeasurable. With diligent maintenance and a solid understanding of its HEUI system, your legendary Powerstroke will continue to be a reliable workhorse for years to come.

🎥 Related Video: 7.3 P1316 Diagnosis – Troubleshooting and Repair of Injector/Glow Plug Harness

📺 Jason Frat

What to look for and how to solve P1316 code.

Frequently Asked Questions

What are the common symptoms of failing 7.3 Powerstroke injectors?

Rough idle, excessive smoke (white, blue, or black), loss of power, poor fuel economy, and misfires are common indicators of failing 7.3 Powerstroke injectors. You might also notice a distinct “lope” in the idle or a strong, unburnt diesel smell from the exhaust.

How can I accurately diagnose a faulty 7.3 Powerstroke injector?

The most effective diagnostic methods include performing a “buzz test” and a Cylinder Contribution Test (CCT) using a compatible diagnostic scanner. An ohm test on the injector’s solenoid and a “bubble test” on the fuel return can also help pinpoint specific issues with the 7.3 Powerstroke injector.

What typically causes 7.3 Powerstroke injector failures?

The most common causes of 7.3 Powerstroke injector failures are contaminated fuel, low oil pressure/volume (as High-Pressure Oil Pump, or HPOP, drives the injectors), and general wear and tear from high mileage. Electrical issues within the Injector Driver Module (IDM) or the injector’s internal coil can also lead to problems.

Is replacing 7.3 Powerstroke injectors a DIY job, or should I take it to a mechanic?

While replacing 7.3 Powerstroke injectors is a challenging DIY job that requires specialized tools and a good understanding of the engine, it is possible for experienced mechanics. However, if you’re not comfortable working with complex engine components and fuel systems, it’s often best to consult a qualified Powerstroke specialist to ensure proper installation.

What specialized tools are needed for troubleshooting and replacing 7.3 Powerstroke injectors?

For troubleshooting, a diagnostic scanner capable of performing buzz tests and CCTs is essential. For replacement of 7.3 Powerstroke injectors, you’ll need an injector puller, special sockets for the valve cover and glow plug connectors, torque wrenches, and potentially an oil rail plug removal tool.

How can I maintain my 7.3 Powerstroke to prevent future injector problems?

Regular fuel filter replacement, using high-quality diesel fuel, and ensuring your engine oil is always at the correct level and changed frequently are crucial for preventing 7.3 Powerstroke injector issues. Consider using a reputable fuel additive to help keep injectors clean and lubricated, and address any HPOP or fuel pressure issues promptly.