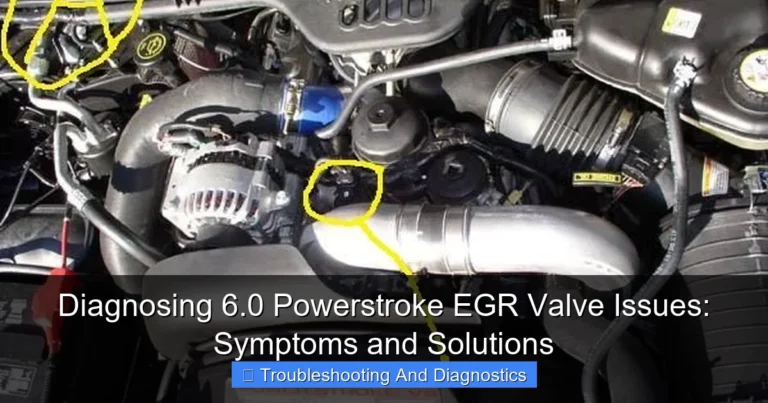

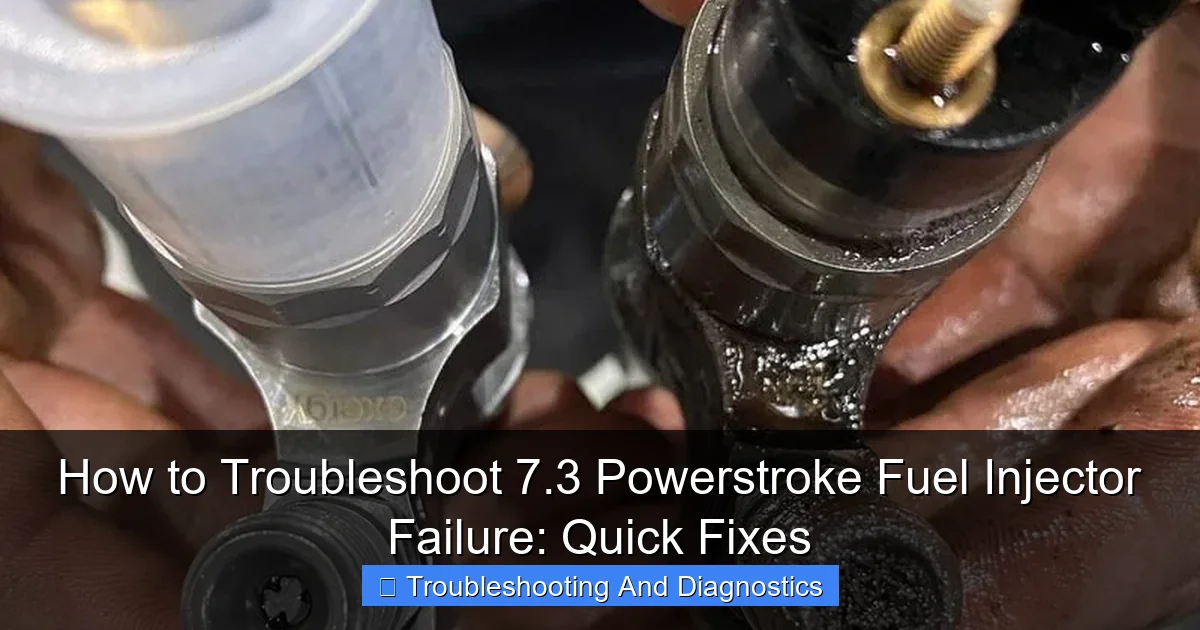

How to Troubleshoot 7.3 Powerstroke Fuel Injector Failure: Quick Fixes

Featured image for this comprehensive guide about How to troubleshoot 7.3 Powerstroke fuel injector failure

Image source: cdn.carcomplaints.com

The 7.3 Powerstroke is a legend. Known for its robust reliability, incredible torque, and a distinctive diesel rumble, it has earned a special place in the hearts of truck enthusiasts and hard-working individuals alike. For many, it’s not just a truck; it’s a family heirloom, a trusted workhorse, or a weekend adventure rig. But even the most legendary engines have their Achilles’ heel, and for the mighty 7.3L, one of the more common and frustrating issues drivers encounter is fuel injector failure.

A failing fuel injector can turn your dependable diesel into a sputtering, sluggish mess, causing everything from a rough idle to a complete loss of power. The good news? Many 7.3 Powerstroke injector problems can be accurately diagnosed and, in some cases, even resolved with a bit of knowledge and the right tools. This comprehensive guide will walk you through the essential steps to troubleshoot 7.3 Powerstroke fuel injector failure, offering actionable tips and quick fixes to get your beloved truck roaring back to life. Let’s dive in and unravel the mysteries of your 7.3L’s fuel system!

Quick Answers to Common Questions

What are the first signs of 7.3 Powerstroke fuel injector failure?

Keep an eye out for rough idling, excessive white or blue smoke from the exhaust, misfires, or a noticeable drop in power and fuel economy. These are often the earliest indicators that your 7.3 Powerstroke fuel injector might be failing.

Is there a quick, easy way to test for 7.3 Powerstroke fuel injector failure at home?

Yes, you can often perform a “buzz test” using an inexpensive OBD-II scanner, which cycles each injector and listens for an audible click. This is a great initial step to pinpoint potential 7.3 Powerstroke fuel injector failure.

What’s a common reason these injectors go bad in a 7.3 Powerstroke?

Often, it comes down to fuel quality issues like contamination, or simply high mileage and wear and tear on the injector components. Addressing the root cause is key to preventing recurring 7.3 Powerstroke fuel injector failure.

What’s the very first thing I should check if I suspect 7.3 Powerstroke fuel injector failure?

Start by checking your oil level and quality, as the 7.3 Powerstroke uses oil to actuate the injectors. Low or dirty oil can mimic 7.3 Powerstroke fuel injector failure, so ensure it’s topped up and clean first.

Can I still drive my truck if I suspect 7.3 Powerstroke fuel injector failure?

It’s best to address 7.3 Powerstroke fuel injector failure promptly to prevent further engine damage or potential breakdowns. While you might be able to limp it home, prolonged driving isn’t recommended and could cause more serious problems.

📋 Table of Contents

- Understanding 7.3 Powerstroke Fuel Injectors: The Heart of Your Diesel

- Recognizing the Symptoms: Is It Truly a 7.3 Injector Problem?

- Essential Tools and Safety Precautions for 7.3 Injector Troubleshooting

- Step-by-Step Troubleshooting Guide for 7.3 Powerstroke Fuel Injectors

- Common 7.3 Injector Failure Scenarios and Quick Fixes

- Common 7.3 Powerstroke Injector DTCs and Potential Causes

- When to Seek Professional Help (and Preventative Maintenance)

- Conclusion

Understanding 7.3 Powerstroke Fuel Injectors: The Heart of Your Diesel

Before we can fix a problem, we need to understand what we’re dealing with. The 7.3 Powerstroke engine utilizes a unique system known as the Hydraulic Electronic Unit Injector (HEUI) system. Unlike many conventional diesel engines that use a mechanical pump to pressurize fuel, the HEUI system employs high-pressure engine oil to actuate the fuel injectors. This design allows for precise control over fuel delivery, contributing to the 7.3L’s impressive power and efficiency.

Learn more about How to troubleshoot 7.3 Powerstroke fuel injector failure – How to Troubleshoot 7.3 Powerstroke Fuel Injector Failure: Quick Fixes

Image source: norcaldieselperformance.com

How 7.3 Injectors Work (HEUI System)

In a nutshell, here’s how the HEUI system operates:

| Common Symptom | Probable Injector-Related Cause | Key Diagnostic Step / Tool |

|---|---|---|

| Rough Idle / Misfire (especially cold start) | Worn injector O-rings, weak solenoid, cracked poppet valve, low compression in affected cylinder. | Perform Buzz Test (solenoid continuity), Cylinder Contribution Test (scan tool) to isolate cylinder. |

| Excessive White/Blue Smoke | Leaking injector nozzle (unburnt fuel, white smoke), worn injector allowing fuel into oil (blue smoke). | Check coolant level/color, perform oil analysis for fuel dilution, visual inspection of injector tips (if accessible). |

| Hard Start / No Start (especially hot) | Worn injector O-rings bleeding off High-Pressure Oil Pump (HPOP) pressure (common after 150k miles). | Monitor HPOP pressure (KOEO & cranking; typically needs >500 PSI to fire), Air Test the HPOP system. |

| Loss of Power / Poor Fuel Economy | Clogged nozzle, weak injector spring, injector not firing consistently or fully. | Check fuel pressure (should be ~60-70 PSI), perform “Cut-Out” Test (individually disable injectors via scan tool). |

| Intermittent Misfire / Stalling | Under Valve Cover Harness (UVCH) connection failure to injectors, loose/burnt connector pins (a very common 7.3L failure point). | Visually inspect UVCH connectors and harness for melting/fraying; perform Buzz Test for solenoid continuity issues. |

- A High-Pressure Oil Pump (HPOP) pressurizes engine oil, sending it to the injectors.

- The Injector Control Pressure (ICP) sensor monitors this oil pressure, while the Injector Pressure Regulator (IPR) valve controls it.

- When the engine’s Powertrain Control Module (PCM) commands an injector to fire, it sends an electrical signal to a solenoid on the injector.

- This solenoid opens an internal valve, allowing high-pressure oil to enter the injector.

- The high-pressure oil then pushes on an intensifier piston, which in turn pressurizes the fuel within the injector to incredibly high levels (up to 21,000 psi!).

- Finally, this highly pressurized fuel is injected into the combustion chamber as a fine mist.

This intricate dance between oil and fuel means that issues with either system can lead to symptoms often mistaken solely for fuel injector failure. Understanding this relationship is key to accurate diagnosis.

Common Causes of 7.3 Fuel Injector Failure

Several factors can contribute to 7.3 Powerstroke injector problems. Identifying the root cause is crucial for a lasting repair.

- Wear and Tear: Over time, the internal components of the injectors simply wear out, especially after hundreds of thousands of miles.

- Poor Fuel Quality: Contaminated fuel or water in the fuel can wreak havoc on injector nozzles and internal seals, leading to clogs or corrosion.

- Oil Contamination/Degradation: Since engine oil actuates the injectors, dirty, low-quality, or incorrect viscosity oil can damage the injector’s internal components and restrict its operation.

- Electrical Issues: The injector solenoids are electronically controlled. Faulty wiring, chafed connectors (especially the Under Valve Cover (UVC) harness), or a failing solenoid itself can prevent an injector from firing.

- High-Pressure Oil System Problems: Issues with the HPOP, IPR valve, or ICP sensor can directly impact injector operation, often mimicking injector failure.

- Stiction: This is a common term for injectors “sticking” due to deposits or wear, often exacerbated by poor oil quality.

Recognizing the Symptoms: Is It Truly a 7.3 Injector Problem?

Your 7.3 Powerstroke is usually pretty vocal when something’s amiss. Pay close attention to its behavior, as specific symptoms can point directly to fuel injector failure. However, it’s vital to remember that some of these signs can overlap with other engine issues, so thorough diagnosis is always necessary.

Learn more about How to troubleshoot 7.3 Powerstroke fuel injector failure – How to Troubleshoot 7.3 Powerstroke Fuel Injector Failure: Quick Fixes

Image source: blog.duramaxtuner.com

Common Signs of Failing Injectors

- Rough Idle: One of the most common indicators. If your truck idles like it has a severe case of the shivers, especially when cold, a failing injector is a prime suspect.

- Engine Misfires: You might feel a noticeable stumble or jerk, particularly under acceleration. This happens when an injector isn’t delivering fuel correctly to one or more cylinders. You might even get a Check Engine Light (CEL) with a P030x code (e.g., P0301 for cylinder 1 misfire).

- Excessive Smoke from the Exhaust:

- White Smoke: Often seen during cold starts and can indicate unburnt fuel passing through the exhaust, a sign of poor injector atomization or a failed injector.

- Black Smoke: Can indicate too much fuel (rich condition) or incomplete combustion, potentially from a leaky or stuck-open injector.

- Blue Smoke: Typically points to burning oil, which could be related to worn injector O-rings allowing oil into the combustion chamber.

- Loss of Power and Poor Acceleration: If your truck feels sluggish and struggles to get up to speed or climb hills, it could be due to one or more injectors not delivering enough fuel.

- Decreased Fuel Economy: A failing injector can either leak fuel (wasting it) or cause the engine to compensate by injecting more fuel, leading to a noticeable drop in MPG.

- Hard Starts (Especially When Hot): This can be a sign of low oil pressure to the injectors, or internal injector wear causing pressure loss.

- Engine Knocking or Clicking Sound: A distinct mechanical knock, often described as a “hammering” sound, can indicate a severely failed injector or issues with the high-pressure oil system. Sometimes, a “ticking” can be a sign of a bad UVC harness or loose injector solenoid.

- Cylinder Contribution Balance Test Failure: A diagnostic test that shows certain cylinders contributing less power than others.

If you’re experiencing any combination of these symptoms, it’s time to roll up your sleeves and begin the troubleshooting process to confirm if you have a 7.3 Powerstroke fuel injector failure.

Essential Tools and Safety Precautions for 7.3 Injector Troubleshooting

Before you start poking around your engine, gather the right tools and prioritize safety. Working on a diesel engine involves high pressures and electrical currents, so caution is paramount.

Must-Have Tools

- OBD-II Scanner/Diagnostic Tool: Essential for reading Diagnostic Trouble Codes (DTCs), performing buzz tests, and monitoring live data (like ICP, IPR, engine oil temperature). A high-quality scanner like Forscan, AutoEnginuity, or a Snap-On diagnostic tool is highly recommended for accurate 7.3 Powerstroke diagnostics.

- Multimeter: For checking electrical continuity, resistance, and voltage in wiring and injector solenoids.

- Fuel Pressure Gauge: To verify adequate fuel supply pressure to the injectors.

- Engine Oil Pressure Gauge: To check the general health of your lubrication system (though the ICP sensor is more directly relevant to HEUI).

- Test Light or Noid Light: To check for power at the injector harness connectors.

- Basic Hand Tools: Sockets, wrenches, screwdrivers, pliers.

- Torque Wrench: Critical for reassembly, especially when dealing with valve covers and injector hold-downs.

- Safety Glasses and Gloves: Always protect your eyes and hands.

- Shop Rags and Parts Cleaner: For keeping things tidy and clean.

- Flashlight/Work Light: To illuminate dark engine bays.

Safety First!

- Disconnect the Battery: Always disconnect both negative battery terminals before working on electrical components or removing valve covers to prevent accidental shorts or engine cranking.

- Allow Engine to Cool: Engine components, especially exhaust manifolds and turbo, can be extremely hot. Give your truck plenty of time to cool down.

- Beware of High-Pressure Systems: The fuel and oil systems operate under very high pressure. Exercise extreme caution when dealing with fuel lines or the HPOP system. Fuel and oil can be forced out at high velocity, causing injury.

- Wear Personal Protective Equipment (PPE): Safety glasses are non-negotiable. Gloves protect your hands from grease and sharp edges.

- Work in a Well-Ventilated Area: Fumes from fuel, oil, and cleaners can be harmful.

- Jack Stands: If you need to lift the truck, always use proper jack stands. Never rely solely on a jack.

Step-by-Step Troubleshooting Guide for 7.3 Powerstroke Fuel Injectors

Now, let’s get down to business. Follow these steps systematically to diagnose 7.3 Powerstroke injector problems and pinpoint the source of your engine’s woes.

Step 1: Initial Visual Inspection

Start with the basics. Many problems can be spotted without sophisticated tools.

- Check Fluid Levels: Ensure engine oil and fuel levels are correct. Low oil can directly impact the HEUI system.

- Inspect Wiring and Connectors: Look for any obvious signs of damaged, chafed, or loose wiring, especially around the valve covers where the UVC harness (Under Valve Cover harness) connects. Check for corrosion on terminals.

- Examine Fuel Lines: Look for leaks, kinks, or damaged fuel lines that could restrict fuel flow or allow air into the system.

- Listen for Obvious Noises: While the engine is running, listen for any unusual knocking, ticking, or clicking sounds that might indicate a specific cylinder’s injector issue.

Step 2: OBD-II Scan for Diagnostic Trouble Codes (DTCs)

Connect your OBD-II scanner and read for any stored or pending codes. This is often the quickest way to narrow down the problem.

- Common Injector-Related Codes:

- P030x: Misfire detected in cylinder ‘x’ (e.g., P0301 for cylinder 1).

- P1316: Injector Circuit Malfunction/IDM Codes Detected. This is a very common code for 7.3L injectors.

- P02xx: Injector Circuit High/Low (e.g., P0201 for Injector Circuit/Open Cylinder 1).

- P1211 / P1212: ICP (Injector Control Pressure) related codes – indicating issues with the high-pressure oil system.

- P1283 / P1284: IPR (Injector Pressure Regulator) related codes.

- Interpret Codes: Don’t just clear codes and hope for the best. Research what each code means for your 7.3L engine. A single code can often point you in the right direction.

Step 3: Performing a Buzz Test (Injector Solenoid Test)

Most advanced OBD-II scanners can perform an “Injector Buzz Test.” This test cycles each injector solenoid, allowing you to hear if it’s working properly.

- How to Do It: With the engine off and key on, initiate the buzz test through your scanner.

- What to Listen For: You should hear a distinct, uniform “buzz” or “click” from each injector solenoid as it’s activated. A missing buzz, a weak buzz, or an unusual sound from a specific cylinder’s injector indicates a problem with that injector’s solenoid or its electrical circuit.

- Significance: A successful buzz test primarily confirms the electrical integrity of the injector solenoid and its wiring. It doesn’t guarantee the mechanical health of the injector.

Step 4: Cylinder Contribution Test

Many diagnostic scanners can also perform a “Cylinder Contribution Test” (or “Cylinder Balance Test”).

- How it Works: The PCM temporarily disables each injector one by one and measures the drop in engine RPM. A cylinder that shows a minimal drop in RPM when its injector is disabled indicates that it wasn’t contributing much power in the first place, suggesting an issue with that cylinder’s injector or compression.

- Interpretation: This test helps isolate specific weak or non-contributing cylinders, pointing directly to potential 7.3 Powerstroke fuel injector failure in those cylinders.

Step 5: High-Pressure Oil Pump (HPOP) and Injector Control Pressure (ICP) Checks

Remember, the HEUI system relies on high-pressure oil. Problems here can mimic 7.3 injector problems.

- Monitor ICP Sensor Readings: Use your scanner to monitor ICP (Injector Control Pressure) during cranking and while the engine is running.

- During Cranking: You need at least 500 PSI for the engine to start. If it’s low, it could be the HPOP, IPR valve, or a leak in the high-pressure oil system.

- At Idle: Should be around 500-800 PSI.

- Under Load: Can climb to 3,000 PSI or more.

- Check IPR Valve Operation: The IPR (Injector Pressure Regulator) valve controls ICP. A faulty IPR can cause low or erratic ICP. Your scanner can often show IPR duty cycle. If ICP is low but the IPR duty cycle is high, the IPR might be stuck open or there’s a significant leak in the HPOP system.

- Look for External Oil Leaks: Especially around the HPOP and its lines.

Step 6: Fuel System Integrity Checks

Even with perfect oil pressure, if fuel isn’t getting to the injectors correctly, you’ll have problems.

- Fuel Pressure Test: Connect a fuel pressure gauge to the Schrader valve on the fuel filter housing. You should see 45-70 PSI at idle. Low fuel pressure can starve the injectors, causing misfires and power loss.

- Check Fuel Filter: A clogged fuel filter can restrict fuel flow, leading to low pressure. Replace it if it’s old or dirty.

- Check for Air in Fuel: Air bubbles in the fuel lines can cause rough running and hard starts. You can sometimes see this by observing fuel return lines, or by simply cycling the key a few times to purge air after a filter change.

Step 7: Electrical Circuit Diagnostics (Multimeter Use)

If the buzz test indicated an issue, it’s time to test the wiring and injector solenoids more directly. This often requires removing the valve covers.

- Inspect Under Valve Cover (UVC) Harness: This is a notorious failure point. Once the valve covers are off, carefully inspect the UVC harness for chafing, burnt connectors, or loose connections that lead to the injectors.

- Quick Fix: Sometimes simply reseating a loose UVC connector can temporarily resolve a misfire.

- Test Injector Solenoid Resistance: With the UVC harness disconnected from the injector, use a multimeter to check the resistance of each injector’s solenoid.

- Expected Resistance: A healthy 7.3 Powerstroke injector solenoid should have a resistance of approximately 2.8 to 4.0 ohms.

- Interpretation: Readings significantly outside this range (e.g., infinite resistance for an open circuit, or very low resistance for a short) indicate a failed solenoid, meaning the injector needs replacement.

- Check for Power to Injectors: Use a test light or noid light connected to the injector harness connector (with the UVC harness unplugged from the injector but plugged into the main harness) while cranking. You should see a flash for each injector, indicating the PCM is sending a signal.

Common 7.3 Injector Failure Scenarios and Quick Fixes

While a full injector replacement is sometimes inevitable, some 7.3 Powerstroke injector problems have simpler solutions.

Loose or Damaged UVC Harness

- Scenario: Misfires, rough idle, P1316, P030x codes. Often intermittent.

- Diagnosis: Visual inspection under the valve cover reveals chafed wires, burnt connectors, or simply a loose plug. A buzz test might show one or more injectors failing.

- Quick Fix: For a loose connection, simply reseating the UVC harness connector firmly can sometimes restore function. For damaged wires or burnt connectors, the UVC harness needs to be replaced. This is a common and relatively inexpensive repair compared to full injector replacement.

Failed Injector O-Rings

- Scenario: White smoke (especially at startup), oil in the fuel, hard starts (especially hot), fuel in the oil, rough idle.

- Diagnosis: A tell-tale sign is seeing engine oil in the fuel bowl (after removing the fuel filter). Hard starts when hot are also characteristic, as hot oil is thinner and leaks more easily past worn O-rings, leading to a loss of ICP pressure during cranking.

- Quick Fix: Unfortunately, this isn’t a “quick fix” in the traditional sense, as it requires removing the valve cover and pulling the problematic injector(s). However, replacing injector O-rings is significantly less expensive than replacing the entire injector body if the injector itself is otherwise healthy.

Sticking/Contaminated Injector Nozzle (Stiction)

- Scenario: Rough idle, sluggish performance, misfires, especially after cold starts.

- Diagnosis: Often confirmed after other electrical and pressure checks come back normal. Can sometimes be indicated by cylinder contribution test results.

- Quick Fix (Temporary/Preventative): High-quality diesel fuel additives designed to clean injectors (like Archoil AR9100 or Hot Shot’s Secret Stiction Eliminator) can sometimes free up sticking components and restore proper spray patterns. This is more of a preventative measure or a first-attempt solution for mild cases of stiction. For severe cases, the injector may require professional cleaning or replacement.

Failed Injector Solenoid

- Scenario: Hard misfire on one cylinder, dead cylinder, no buzz during buzz test, specific P02xx code.

- Diagnosis: Failed buzz test, open circuit or incorrect resistance reading on multimeter test of the solenoid.

- Quick Fix: The solenoid is an integral part of the injector. If it fails, the entire injector typically needs to be replaced. While not a “quick fix,” confirming it’s the solenoid through testing avoids unnecessary replacement of other components.

IPR Valve Issues Mimicking Injector Problems

- Scenario: Hard starts (especially hot), intermittent power loss, stalling, P1211/P1212 codes. These symptoms can be very similar to a widespread 7.3 Powerstroke fuel injector failure.

- Diagnosis: Low ICP readings during cranking and running, despite a healthy HPOP, with a high IPR duty cycle. Visually inspecting the IPR valve for debris on its screen can also be helpful.

- Quick Fix: The IPR valve is relatively accessible. Replacing a faulty IPR valve can often resolve these symptoms, saving you from mistakenly replacing all your injectors.

Common 7.3 Powerstroke Injector DTCs and Potential Causes

Understanding these codes can quickly guide your troubleshooting efforts.

| DTC (Diagnostic Trouble Code) | Description | Potential Injector-Related Cause(s) |

|---|---|---|

| P030x (e.g., P0301) | Cylinder ‘x’ Misfire Detected | Failed injector solenoid, clogged nozzle, worn O-rings, bad UVC harness connection for that cylinder. |

| P020x (e.g., P0201) | Injector Circuit/Open Cylinder ‘x’ | Open circuit in injector solenoid, damaged wiring (UVC harness), faulty PCM driver. |

| P1316 | Injector Circuit Malfunction/IDM Codes Detected | Indicates the Injector Driver Module (IDM) has detected a fault. Often points to injector electrical issues (solenoid, UVC harness). |

| P1211 | ICP Actual Pressure Not Equal to Desired | Low ICP due to HPOP issues, IPR valve failure, ICP sensor, or internal oil leaks (e.g., worn injector O-rings). |

| P1212 | ICP Too Low During Cranking | Insufficient ICP to fire injectors. Can be HPOP, IPR valve, ICP sensor, or significant high-pressure oil leaks (e.g., injector O-rings). |

| P1283 / P1284 | IPR Circuit Fault | Problem with the Injector Pressure Regulator (IPR) valve itself or its electrical circuit. Directly affects ICP control. |

When to Seek Professional Help (and Preventative Maintenance)

While this guide provides extensive information to troubleshoot 7.3 Powerstroke fuel injector failure, there are times when it’s best to call in the experts.

Knowing Your Limits

If you’ve gone through these steps and are still stumped, or if the repairs require specialized tools (like an injector removal tool for stuck injectors) or more advanced diagnostic equipment (like an oscilloscope for electrical signal analysis), it’s wise to consult a qualified diesel mechanic. A professional will have the experience and equipment to accurately diagnose complex issues and perform repairs without causing further damage.

Attempting repairs beyond your skill level can lead to more costly problems, especially with sensitive components like the HEUI injectors and high-pressure oil system. Don’t risk it if you’re uncomfortable.

Preventative Maintenance to Extend Injector Life

An ounce of prevention is worth a pound of cure, especially with your valuable 7.3 Powerstroke. Following a strict maintenance schedule can significantly extend the life of your injectors and prevent many common failures.

- Regular Oil Changes: Use only the manufacturer-recommended engine oil (typically 15W-40 CI-4 or CJ-4 rated diesel oil). High-quality, clean oil is crucial for the HEUI system. Adhere to the recommended oil change intervals, typically 3,000-5,000 miles. Consider a bypass oil filter system for even better oil cleanliness.

- Fuel Filter Replacement: Change your fuel filter at least every 15,000 miles, or more frequently if you use questionable fuel sources. A clean fuel filter is your first line of defense against contaminants reaching the injectors.

- Use Quality Fuel: Always fill up at reputable stations to avoid contaminated or low-quality diesel fuel. Water in fuel is a major enemy of injectors.

- Fuel Additives: Regularly use a high-quality diesel fuel additive. Look for products that offer lubricity enhancement, cetane boosting, and stiction elimination properties. These can help keep your injectors clean, lubricated, and operating smoothly.

- Monitor Fuel System: Periodically check your fuel bowl for contaminants or water. Drain the water separator regularly.

- Listen to Your Truck: Pay attention to any changes in engine sound, performance, or exhaust smoke. Early detection can prevent minor issues from becoming major 7.3 Powerstroke fuel injector failure.

Conclusion

The 7.3 Powerstroke is an incredible engine, built to last. While fuel injector failure is a common concern for these workhorses, it’s far from a death sentence. By understanding how your HEUI system works, recognizing the symptoms, and systematically following the troubleshooting steps outlined in this guide, you can confidently diagnose 7.3 Powerstroke injector problems and even perform many of the necessary repairs yourself. Whether it’s a simple UVC harness issue or a more complex injector solenoid failure, proper diagnosis is your best friend.

Remember, diligent preventative maintenance is the cornerstone of a long and healthy life for your 7.3L’s fuel system. Treat your truck right with quality fluids and regular upkeep, and it will continue to serve you faithfully for hundreds of thousands of miles to come. So, grab your tools, embrace the challenge, and keep that legendary 7.3 Powerstroke roaring down the road!

🎥 Related Video: How to positively check for a dead 7.3 Ford PowerStroke fuel injector. 1995-2003

📺 Ron Williams

IF THIS VIDEO HELPED YOU OR SOMEONE ELSE, CLICK HERE TO DONATE SO I CAN CONTINUE TO SHARE VIDEOS.

Frequently Asked Questions

What are the common symptoms of a failing 7.3 Powerstroke fuel injector?

A failing 7.3 Powerstroke fuel injector often causes rough idling, misfires, a loss of power, and excessive black or white smoke from the exhaust. You might also notice a decrease in fuel efficiency and a distinctive “lope” or knocking sound from the engine.

How can I quickly diagnose if my 7.3 Powerstroke fuel injector is the problem?

Start by checking your engine oil level and condition, as the 7.3 Powerstroke’s injectors are hydraulically actuated. A simple cylinder contribution test using a diagnostic scanner can pinpoint which cylinder is misfiring, providing a quick way to narrow down the issue.

What common issues can mimic 7.3 Powerstroke fuel injector failure?

Several problems can mimic a bad injector, including a faulty Injector Pressure Regulator (IPR) valve, a High-Pressure Oil Pump (HPOP) issue, or even a Camshaft Position Sensor (CPS) failure. Low engine oil levels or a clogged fuel filter can also present similar symptoms, so check these first.

Are there any simple “quick fixes” or initial checks I can perform at home for a 7.3 Powerstroke?

Absolutely. Ensure your engine oil is full and clean, as low or dirty oil significantly impacts injector operation. Check for any loose electrical connections on the injectors or the Injection Control Pressure (ICP) sensor, as these can often cause intermittent issues.

What basic tools do I need for initial 7.3 Powerstroke fuel injector troubleshooting?

For initial troubleshooting, an OBD-II scanner capable of reading live data and performing a cylinder contribution test is invaluable. A multimeter can help test electrical connections, and a stethoscope is useful for listening to individual injector sounds to pinpoint problems.

When should I consider calling a professional for my 7.3 Powerstroke fuel injector issues?

If basic checks and quick fixes don’t resolve the symptoms, or if the problem worsens, it’s time to consult a professional. Issues related to the High-Pressure Oil Pump (HPOP), Injector Control Pressure (ICP) sensor, or actual injector replacement require specialized tools and expertise to ensure proper repair.