How to Troubleshoot 6.0 Powerstroke Hard Starting Issues: Common Causes

Featured image for this comprehensive guide about How to troubleshoot 6.0 Powerstroke hard starting issues

Image source: cdn11.bigcommerce.com

How to Troubleshoot 6.0 Powerstroke Hard Starting Issues: Common Causes

There are few things more frustrating for a truck owner than turning the key and hearing nothing but a prolonged, struggling crank or, worse, no response at all. If you own a 6.0 Powerstroke, you’re likely familiar with its reputation for being a powerful workhorse, but also one that can present unique challenges, especially when it comes to starting. A 6.0 Powerstroke hard starting issue isn’t just an inconvenience; it can be a sign of a deeper problem affecting your truck’s performance and reliability.

The 6.0L Powerstroke diesel engine, manufactured by Ford between 2003 and 2007, is a complex machine with an intricate network of systems – fuel, electrical, oil, and emissions – all working in harmony. When one of these components falters, it can quickly lead to a Powerstroke hard start fix scenario. Diagnosing the root cause can feel like finding a needle in a haystack, but with a systematic approach and a little knowledge, many of these problems can be identified and resolved. This comprehensive guide is designed to empower you with the knowledge to tackle common 6.0 Powerstroke hard starting issues, helping you get your beloved truck back on the road.

We’ll delve into the most frequent culprits behind a 6.0 Powerstroke no start or hard start condition, providing actionable troubleshooting steps and insights into how each system impacts your engine’s ability to fire up. By the end of this post, you’ll have a much clearer understanding of where to begin your diagnosis and what to look for when your 6.0 Powerstroke won’t start without a fight.

Quick Answers to Common Questions

What’s the absolute first thing I should check when my 6.0 Powerstroke has hard starting issues?

Always start with your batteries and charging system. Weak batteries can prevent the starter from cranking fast enough and the FICM from getting adequate voltage to properly fire the injectors.

How often are 6.0 Powerstroke hard starting issues caused by the FICM?

The FICM (Fuel Injection Control Module) is a frequent culprit; a faulty FICM often can’t provide enough voltage to fire the injectors, leading to hard starts, especially when cold. Checking its voltage is a critical early step.

Do 6.0 Powerstroke hard starting issues get worse in cold weather?

Absolutely! Cold temperatures can exacerbate hard starting by making your engine oil thicker, reducing battery efficiency, and placing a heavier load on your glow plug system, which is crucial for cold starts.

Could a fuel problem be causing my 6.0 Powerstroke hard starting issues?

Definitely. Insufficient fuel pressure or a clogged fuel filter can starve your injectors, preventing proper combustion and resulting in frustratingly difficult starting.

Are 6.0 Powerstroke hard starting issues always a sign of something major or expensive?

Not necessarily! While they can point to serious problems, sometimes the fix is as simple as cleaning battery terminals, replacing a worn starter, or upgrading your fuel filters.

📋 Table of Contents

- Fuel System Diagnostics: Is Your 6.0 Powerstroke Getting Fuel?

- Injector and FICM Woes: The Heart of the Injection System

- Electrical & Battery: Powering Up Your Powerstroke

- High-Pressure Oil System: The 6.0’s Achilles’ Heel

- Sensor Failures & EGR System Concerns

- Common 6.0 Powerstroke Hard Start Scenarios: Quick Reference

- Conclusion: Conquering Your 6.0 Powerstroke Starting Woes

Fuel System Diagnostics: Is Your 6.0 Powerstroke Getting Fuel?

The first step in addressing 6.0 Powerstroke hard starting issues often begins with the most fundamental requirement for any internal combustion engine: fuel. A lack of proper fuel delivery or pressure can quickly lead to your truck cranking endlessly without catching.

Learn more about How to troubleshoot 6.0 Powerstroke hard starting issues – How to Troubleshoot 6.0 Powerstroke Hard Starting Issues: Common Causes

Image source: cdn11.bigcommerce.com

Checking Fuel Pressure and Flow

For a 6.0 Powerstroke, adequate fuel pressure is critical. The optimal range for fuel pressure at the secondary filter housing should be between 50-60 PSI. Anything significantly below this can cause injectors to struggle, leading to a hard starting issue.

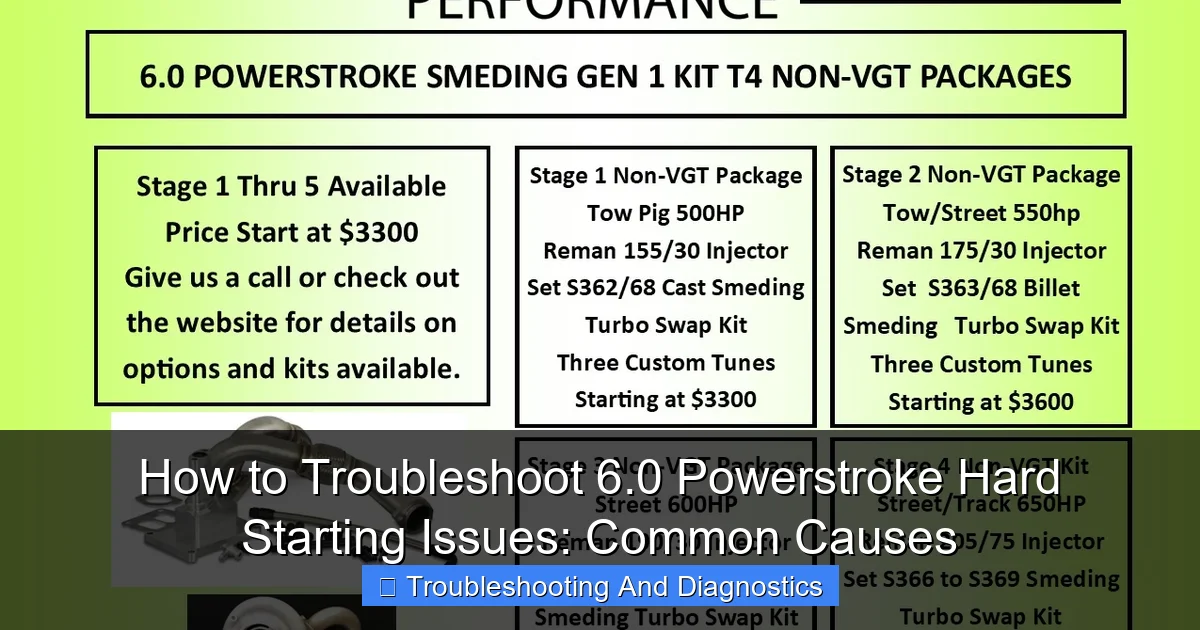

| Symptom / Area | Common Cause(s) | Diagnostic Steps / Typical Readings |

|---|---|---|

| Cranks, No Start (or Long Crank) | Low High-Pressure Oil (HPOP) System Pressure (ICP/IPR) | Monitor ICP pressure during cranking (target >500 psi). Check IPR duty cycle (should be <85% before start). Check for HPOP system leaks (standpipes/dummy plugs, STC fitting). |

| Slow Crank / No Crank | Weak Batteries / Faulty Starter Motor | Test individual battery voltage (should be >12.4V static, >10V cranking). Inspect battery terminals for corrosion. Test starter motor operation. |

| Hard Start in Cold Weather (OK when warm) | Glow Plug System Failure | Scan for GPCM (Glow Plug Control Module) codes (P0670-P0678). Test resistance of individual glow plugs (0.5-2.0 Ohms). Verify GPCM activation. |

| Cranks, No Start (or Cranks/Starts/Dies) | Low Fuel Pressure / Fuel Aeration | Monitor fuel pressure at filter housing (target 45-70 psi at idle). Replace fuel filters (every 10k-15k miles). Perform clear hose test for air in fuel. |

| Cranks, No Start (No Injector Buzz) | FICM (Fuel Injection Control Module) Voltage Drop | Monitor FICM MPower voltage during cranking and running (target 48.0V, acceptable >45V). Check for FICM related DTCs. |

- Symptoms of Low Fuel Pressure: Extended cranking, rough idle after starting, lack of power, and potential for misfires. In severe cases, a complete 6.0 Powerstroke no start.

- How to Test: You’ll need a fuel pressure gauge that can connect to the port on top of your secondary fuel filter housing (on the engine). With the key on (engine off) or while cranking, observe the pressure.

- Common Culprits:

- Weak Fuel Pump: Over time, the electric fuel pump (located on the frame rail) can weaken or fail entirely.

- Clogged Fuel Filters: The 6.0 Powerstroke has two fuel filters – one on the frame rail and a secondary one on top of the engine. Clogged filters restrict fuel flow. Ford recommends replacing them every 15,000 miles or annually.

- Leaking Fuel Lines/O-rings: Small leaks can allow air into the system or reduce pressure.

Air in the Fuel System

Air in the fuel system is another common cause of 6.0 Powerstroke hard starting issues. Unlike gasoline engines, diesel engines are highly intolerant of air in the fuel lines.

- Symptoms: Long cranking, sputtering, engine starting but running very rough and then possibly dying, particularly after a fuel filter change or if the tank ran very low.

- Causes: Often occurs after replacing fuel filters if the system isn’t properly primed, or if there’s a leak allowing air ingress. Running out of fuel is a guaranteed way to introduce air.

- Bleeding Procedure: The 6.0 Powerstroke has a self-priming fuel system. After replacing filters or if air is suspected, simply cycle the key to the “on” position (without starting) for about 30 seconds, then turn it off. Repeat this 3-4 times. This allows the fuel pump to push fuel through the system and purge air.

Injector and FICM Woes: The Heart of the Injection System

Beyond simply getting fuel to the engine, the 6.0 Powerstroke relies heavily on its injectors and the module that controls them. Problems here are notorious for causing 6.0 Powerstroke hard starting issues.

Learn more about How to troubleshoot 6.0 Powerstroke hard starting issues – How to Troubleshoot 6.0 Powerstroke Hard Starting Issues: Common Causes

Image source: cdn11.bigcommerce.com

Fuel Injection Control Module (FICM) Health

The FICM (Fuel Injection Control Module) is a vital component that steps up the truck’s 12V power to a robust 48V to fire the injectors. Without this crucial voltage, your injectors won’t spray fuel, leading directly to a 6.0 Powerstroke no start condition.

- Crucial Role: The FICM essentially acts as the brain for the injectors, dictating when and how they open.

- Symptoms of a Failing FICM:

- Extended cranking times, especially when cold.

- Complete no-start condition.

- Rough idle, misfires, or “chugging” engine.

- Reduced power and poor fuel economy.

- How to Test FICM Voltage: This is a relatively simple test requiring a multimeter. You can check the FICM output voltage at specific pins on the module’s harness connector (usually pins 1 and 2 or 3 and 4 on the main harness plug). While cranking, the voltage should ideally hold at a steady 48-48.5 volts. Anything below 45 volts indicates a failing FICM. Many owners report issues even at 46-47 volts.

- Common Causes of Failure: Heat and vibration under the hood are the primary culprits. Aftermarket tuners can also stress the FICM.

Injector Problems (Stiction & Failure)

The 6.0 Powerstroke utilizes a HEUI (Hydraulically actuated, Electronically controlled, Unit Injector) system, meaning high-pressure oil is used to actuate the fuel injectors. Problems with the injectors themselves are a frequent cause of 6.0 Powerstroke hard starting issues.

- Symptoms:

- Long Crank (Hot or Cold): Injectors not firing correctly lead to extended cranking.

- White/Blue Smoke: Unburnt fuel (white) or burning oil (blue) can indicate injector issues.

- Rough Idle/Misfires: Uneven fuel delivery.

- Knocking Sounds: Can indicate faulty injector operation.

- “Stiction”: This term refers to the internal components of the injector sticking, usually due to carbon buildup or old oil. It’s a very common 6.0 Powerstroke hard starting issue, especially after the truck has been sitting or when the engine is warm (hot stiction).

- Diagnostic Steps:

- Contribution Test: A scan tool can perform a cylinder contribution test to identify underperforming injectors.

- Listen with a Stethoscope: Carefully listening to each injector can sometimes reveal differences in operation.

- Oil Analysis: Can sometimes reveal issues, though less direct for starting problems.

- Solutions:

- Additives: High-quality diesel fuel additives designed to clean injectors and prevent stiction can often resolve mild cases. Hot Shot’s Secret Stiction Eliminator is a popular choice for this specific problem.

- Replacement: Severely failed injectors will require replacement. This is an expensive repair, so thorough diagnosis is key.

Electrical & Battery: Powering Up Your Powerstroke

A diesel engine, especially the 6.0 Powerstroke, demands immense electrical power to crank over and ignite. Often, a seemingly complex 6.0 Powerstroke hard starting issue boils down to simple electrical problems.

Battery and Charging System Checks

The 6.0 Powerstroke has two batteries for a reason – it needs substantial cranking power. Weak batteries are a leading cause of 6.0 Powerstroke no start or very hard starting issues.

- Importance of Strong Batteries: The starter motor, FICM, and glow plugs all draw significant power. If the voltage drops too low during cranking, the FICM might not get enough power to fire the injectors, even if it’s otherwise healthy.

- Symptoms: Slow cranking, clicking sounds (if the starter can’t engage), dim dashboard lights, or a complete no-crank situation.

- Testing Battery Voltage:

- Static Test: With the engine off, each battery should read at least 12.6 volts. Anything below 12.4V is considered discharged.

- Load Test: The most accurate test is a load test, which can be done at most auto parts stores for free.

- Cranking Voltage: While cranking, the combined battery voltage should not drop below 10-10.5 volts.

- Checking Alternator Output: Once the engine is running, the alternator should be charging both batteries. You should see around 13.5-14.5 volts across each battery terminal.

- Corrosion and Loose Terminals: Always inspect battery terminals and cables for corrosion, tightness, and damage. A poor connection can mimic a dead battery.

Glow Plug System Inspection

Glow plugs are essential for cold starting a diesel engine, especially in colder climates. They preheat the combustion chambers to aid ignition.

- Role: Provide heat to help ignite fuel on cold starts.

- Symptoms of Bad Glow Plugs/GPCM:

- Extreme hard starting issue in cold weather.

- Excessive white smoke immediately after starting (unburnt fuel).

- Engine may eventually start but run very rough until it warms up.

- Testing Glow Plugs:

- Resistance Check: With the glow plug harness disconnected, measure the resistance of each glow plug. A good glow plug will show very low resistance (typically less than 1 ohm). An open circuit or very high resistance indicates a bad glow plug.

- Parasitic Draw Test: Can sometimes indicate a faulty glow plug control module (GPCM) staying on too long.

- Glow Plug Control Module (GPCM): This module controls the glow plugs. A faulty GPCM can prevent any or all glow plugs from functioning, leading to cold start difficulties. Often, a scan tool will show a DTC (Diagnostic Trouble Code) for a failing GPCM or specific glow plugs.

Starter Motor and Solenoid

While less common than battery issues, a failing starter motor or solenoid can also lead to a 6.0 Powerstroke no start scenario.

- Symptoms: A single click when turning the key, slow cranking (even with good batteries), or no sound at all.

- Basic Checks: Ensure all connections to the starter are clean and tight. You can also try tapping the starter gently with a hammer (if accessible) while someone tries to start the truck; sometimes this can temporarily free a sticky solenoid.

High-Pressure Oil System: The 6.0’s Achilles’ Heel

The 6.0 Powerstroke’s reliance on high-pressure oil for injector actuation makes its high-pressure oil system (HPOP system) a frequent source of hard starting issues.

High-Pressure Oil Pump (HPOP) Failure

The HPOP is arguably one of the most critical components for the 6.0 Powerstroke’s operation. It pressurizes engine oil to the extreme levels needed to fire the injectors.

- Function: Takes engine oil and pressurizes it (often above 3,000 PSI) for the HEUI injectors.

- Symptoms: The most common symptom of HPOP failure is a no start or extremely long crank, particularly when the engine is warm. When the oil thins out at operating temperature, a weak HPOP struggles even more to build sufficient pressure.

- Diagnosis: A scan tool capable of monitoring live data is essential here. You need to observe the ICP (Injection Control Pressure) during cranking. The engine requires a minimum of 500 PSI ICP to start. If it’s not reaching this value, the HPOP system is suspect.

- Common Failure Points:

- The HPOP itself: Internal wear can reduce its pumping efficiency.

- STC (Standpipe and Dummy Plug) Fitting: This Snap-To-Connect fitting on the HPOP discharge tube is a notorious weak point, prone to leaking and causing a loss of pressure.

- Branch Tube and Standpipes: Leaks within these components (under the valve covers) can also cause pressure loss.

IPR Valve & ICP Sensor

These two components work in tandem with the HPOP to manage and monitor oil pressure.

- IPR (Injection Pressure Regulator) Valve:

- Function: Controls the oil pressure delivered by the HPOP to the injectors. It’s an electro-hydraulic valve that dictates how much oil is bypassed back to the crankcase, thereby regulating the pressure.

- Symptoms of Failure: Erratic idle, stalling, no start (especially hot), or hard starting issue. A stuck open IPR will prevent pressure from building; a stuck closed IPR will cause excessive pressure.

- How to Test: A scan tool can monitor IPR duty cycle and commanded vs. actual ICP. The IPR valve can also be removed and inspected for debris or damage. A common trick is to listen for a faint humming noise from the IPR with the key on; absence of this might indicate an electrical fault.

- ICP (Injection Control Pressure) Sensor:

- Function: Measures the actual oil pressure in the high-pressure oil system and sends this data to the PCM (Powertrain Control Module).

- Symptoms of Failure: No start, hard start, engine surging, or rough running. A common failure is internal oil leakage, visible as oil pooling in the ICP sensor connector.

- Test: If the sensor is leaking or reading erratically, sometimes simply unplugging it will allow the PCM to revert to a default pressure, potentially allowing the engine to start (though it will run in limp mode). A scan tool will display the ICP reading; if it’s erratic or reads zero while cranking, the sensor is suspect.

Oil Levels and Quality

Given the HEUI system’s reliance on engine oil, ensuring proper oil levels and using the correct type of oil is paramount.

- Essential for HEUI: Low oil levels can lead to cavitation in the HPOP and insufficient pressure for the injectors.

- Check Oil Level: Always ensure your engine oil is at the full mark.

- Proper Oil Type: Use only diesel-specific engine oil (CJ-4 or CK-4 rated) with the correct viscosity (e.g., 15W-40 or 5W-40 in colder climates). Incorrect oil can cause stiction and HPOP issues.

Sensor Failures & EGR System Concerns

While not always the first suspect, certain sensor failures and issues with the Exhaust Gas Recirculation (EGR) system can also contribute significantly to 6.0 Powerstroke hard starting issues.

Crankshaft & Camshaft Position Sensors (CKP/CMP)

These sensors are vital for the engine’s computer (PCM) to know the exact position and speed of the crankshaft and camshaft, which is critical for precise fuel injection timing and ignition.

- Crucial for Timing: Without accurate signals from these sensors, the PCM can’t properly time the fuel injection or the FICM’s firing of the injectors.

- Symptoms of Failure: A complete no start condition, random engine stalling while driving, or a very long crank with no successful ignition.

- Diagnostics: Failures of the CKP or CMP sensors almost always generate a specific DTC (Diagnostic Trouble Code). A scan tool can also monitor their signals. They are relatively inexpensive parts, but diagnosis is key to avoid unnecessary replacement.

EGR Valve and Cooler Issues

The EGR system’s primary role is to reduce emissions, but a fault within it can certainly impact starting.

- EGR Valve:

- Symptoms affecting starting: If the EGR valve gets stuck open, it can essentially create a large vacuum leak or allow exhaust gas into the intake during cranking. This can lead to a significant loss of compression in the cylinders, making it extremely difficult for the engine to build enough pressure to start. You might experience extended cranking, rough starting, or a 6.0 Powerstroke no start.

- Visual Inspection: Check for excessive soot or carbon buildup around the valve.

- Scan Tool: Can command the EGR valve open/closed and monitor its position.

- EGR Cooler:

- Symptoms affecting starting: An internal leak in the EGR cooler can allow coolant to enter the intake manifold or cylinders. If a significant amount of coolant pools in a cylinder, it can lead to “hydro-lock” – a condition where the engine cannot crank over because liquid (coolant) is incompressible. This results in an immediate no start or a very slow, struggling crank that abruptly stops.

- Warning Signs: White smoke from the exhaust (burning coolant), unexplained coolant loss, coolant in the oil, or bubbling in the degas bottle.

- Diagnosis: A pressure test of the cooling system can sometimes reveal an EGR cooler leak. Inspection of the intake manifold might show signs of coolant.

Common 6.0 Powerstroke Hard Start Scenarios: Quick Reference

Here’s a quick summary of common 6.0 Powerstroke hard starting issues, their symptoms, and typical solutions:

| Issue | Common Symptoms | Typical Fix / Diagnostic Step |

|---|---|---|

| Low FICM Voltage | Long crank, no start (especially cold), rough idle, misfires. | Test FICM output (should be 48V). Replace/repair FICM if below 45V. |

| Weak HPOP System (including STC, standpipes) | Long crank, no start (especially hot). | Monitor ICP during cranking (needs >500 PSI). Diagnose/replace HPOP, STC fitting, standpipes. |

| Low Fuel Pressure | Long crank, sputtering, lack of power. | Test fuel pressure at filter housing (needs 50-60 PSI). Replace fuel pump, filters. |

| Injector Stiction / Failure | Long crank (hot or cold), white/blue smoke, rough idle, knocking. | Use stiction additive. Perform contribution test. Replace injectors if severely failed. |

| Weak Batteries / Charging System | Slow crank, no crank, dim lights, clicking. | Test battery voltage (each >12.6V), load test. Check alternator output. Clean terminals. |

| Faulty IPR Valve | No start (especially hot), stalling, erratic idle. | Monitor IPR duty cycle and ICP. Inspect/replace IPR. |

| Faulty ICP Sensor | No start, hard start, engine surging, oil in connector. | Monitor ICP reading. Unplug sensor to see if engine starts (limp mode). Replace. |

| Bad Glow Plugs / GPCM | Very hard cold start, excessive white smoke on startup. | Test glow plug resistance. Check for GPCM DTCs. Replace. |

Conclusion: Conquering Your 6.0 Powerstroke Starting Woes

Troubleshooting 6.0 Powerstroke hard starting issues can feel like a daunting task, given the engine’s complexity and its various interconnected systems. However, by approaching the problem systematically – starting with the simplest checks and progressing to more complex diagnostics – you can significantly narrow down the potential causes. Remember that a reliable Powerstroke hard start fix often requires patience, attention to detail, and sometimes, a good quality scan tool.

Whether it’s a critical component like the FICM or HPOP, or a more common issue like weak batteries or clogged fuel filters, understanding the underlying mechanisms of your 6.0 Powerstroke will empower you to tackle these problems head-on. Don’t let a 6.0 Powerstroke no start or hard starting issue leave you stranded. Equip yourself with this knowledge, perform your checks diligently, and you’ll be well on your way to restoring your truck’s reliable performance.

If, after following these comprehensive steps, your 6.0 Powerstroke won’t start, or if you encounter issues beyond your comfort level, don’t hesitate to consult a qualified diesel mechanic specializing in Powerstroke engines. Professional diagnostics can save you time, money, and further frustration, ensuring your truck receives the expert care it needs to keep running strong for years to come.

🎥 Related Video: makes it EVEN HARDER, Powerstroke 6.0 Hard Start b #diesel #repair #palmsprings #truck

📺 Small Hands Garage

Frequently Asked Questions

My 6.0 Powerstroke is hard to start, where should I begin troubleshooting?

Start by checking your batteries and charging system, as low voltage is a common culprit for hard starting issues. Then, move on to fuel system basics like verifying adequate fuel pressure and inspecting the condition of your fuel filters.

Could a fuel system problem cause my 6.0 Powerstroke hard starting issues?

Absolutely. Low fuel pressure due to a failing fuel pump, clogged fuel filters, or a faulty fuel pressure regulator (FPR) can severely impact starting. Ensure your filters are clean and check the fuel pressure at the secondary filter housing.

What role do glow plugs play in 6.0 Powerstroke hard starting, especially in cold weather?

Glow plugs are critical for initial combustion, especially in cold conditions, by preheating the cylinders. A failing Glow Plug Control Module (GPCM) or dead glow plugs can lead to significant 6.0 Powerstroke hard starting or no-start conditions when the engine is cold.

How does the FICM relate to 6.0 Powerstroke hard starting?

The Fuel Injection Control Module (FICM) is essential for providing the high voltage needed to fire the fuel injectors. If your FICM voltage drops below 48 volts, it can cause various hard starting, misfiring, or no-start problems. Testing FICM voltage is a crucial step in diagnosis.

What common high-pressure oil system issues can cause my 6.0 Powerstroke to have hard starting problems?

The 6.0 Powerstroke relies heavily on its High-Pressure Oil Pump (HPOP) and related components. Common issues like a leaking STC fitting, faulty IPR valve, or failing standpipes/dummy plugs can cause a loss of high-pressure oil, preventing the injectors from firing and leading to hard starting.

Besides the common issues, what other components might cause 6.0 Powerstroke hard starting?

Don’t overlook sensors like the Camshaft Position Sensor (CMP) or Crankshaft Position Sensor (CKP, also known as CKPS), which are vital for engine timing. A problematic Injection Pressure Regulator (IPR) valve or a worn High-Pressure Oil Pump (HPOP) can also be underlying causes of persistent hard starting problems.